Professional Documents

Culture Documents

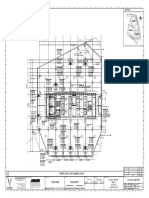

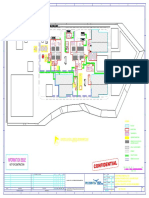

HITW-DH001 White Tank Plan

Uploaded by

Arsalan Ullah KhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HITW-DH001 White Tank Plan

Uploaded by

Arsalan Ullah KhanCopyright:

Available Formats

DETAILING: CD A

CD B

CD D

DETTAGLI: CD F CD G CD H CD J CD K CD L CD M CD N CD P CD Q CD R CD S

DETAILING:

DETAILLIERUNG:

DRYTECH DETAILS 4450

CD C

4265 6355 4800 4800

CD E

6475 5130 2895 2085 5770 2230

N 740459.263

E 722213.065

N 740456.343

55806

E 722157.335

D 17

it

/Ex

try

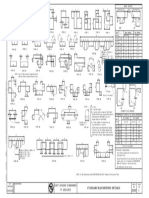

Detail 1 Building Above

En

8000

C 12

A) Concrete Bed

B) DRYset Crack Inducer Unit CIU

C) Added constructive stirrup

Added constructive stirrup reinforcement

30

20

inside C 11 Fire Rated Ventilation

Ductwork and Grille to

D4

M&E Specifications Basement level car park

D protected corridor ventilation

1000 (minimum 0.5m2) via fire-resistant

B ELEC D1 1 MECH D1 2 ductwork - TBC W/ PMEP

10

C 1.2 m² 1.2 m²

29

I Stage D 16

A I Stage C 10 BD1.B2.002

IDR020A FD60S

BD1.B2.001

BC.B2. IDR020A FD60S BD1.B2. BD1.B2.003

EDR031A FD60S EDR031A FD60S IDR030A FD30S

Ventilation Lobby

D6 4.7 m² Fire Rated Ventilation

3990

Ventilation Lobby

Ductwork and Grille to

13.7 m² Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD

bottom/ outside M&E Specifications

BC.B2.001 01 02 03 04 05 06 07 08 09 10 11

D3

IDR020A FD60S

ELEC C1 1

90

1.3 m²

51

BC.B2.002

IDR030A FD30S

D 15

Lift Core C1

3.5 m² BD1.B2.004

C9 17.6 m² IDR030A FD30S

Detail 2 Lobby

9.2 m²

from 25 cm

BC.B2.003

d2 d1

IDR030A FD30S

D12

Car Parking

2

GFPBD1-24-ZZ-4001

Lobby

14.9 m²

D2

6000

8390

A) Wall GFPBC-24-ZZ-4001 1701.4 m²

Staircore C 1

B) DRYset Injection Channel 19.8 m²

D 14

C) Cold Joint

A D) Concrete Bed

00

10

BC.B1.002 BD1.B1.002 WHITE TANK REQUIREMENTS FOR BASEMENT SLABS AND WALLS

5 IDR030A FD30S IDR030A FD30S

21

outside

Use appropriate dewatering/pumping systems to prevent casting of any concrete elements

10

BC.B1.001

II Stage IDR030A FD30S Lobby

9 m²

in the presence of water.PVC or cement spacers, minimum height 40 mm, must be placed

inside Fire Rated Ventilation on a level, smooth layer of lean blinding concrete.

1:12

Ductwork and Grille to D 13

B

M&E Specifications

For basement slabs, the supports of the upper mesh should be placed on a level, smooth

C Comms Room BD1.B1.001

Mo

12 Bicycle 12.4 m² IDR030A FD30S

layer of lean blinding concrete.

from 25 cm

vem Spaces Ventilation Lobby Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD

en Ventilation Lobby

I Stage D

C8

t Jo

int

9.6 m² 12 13 16

14 15 17 18 19 20

4.4 m² Any extraneous elements must not be incorporated into the elements of the White Tank

BC.B1.

Fire Rated Ventilation

system.

S

EDR031A FD60S 1000

The minimum thickness of foundations and walls when using the White Tank system can

CE

Ductwork and Grille to

BD1.B1. BD1.B1. M&E Specifications

bottom/ outside

PA

90

EDR020A FD60S EDR031A FD60S

7615

not be less than 250 mm.

29

ES

Movement Joint

1000

10 bikes 2

3

The DRYset Crack Inducing Units, both for horizontal elements and walls, must be

BIK

Building Above 4

5

adequately supported by reinforcing stirrups, as shown in the typical details.

174

22 Bicycle 6

Mo

Spaces 7 vem

Detail 3 Block CD Block

e CD Block CD Block CD Block CD Block CD Block CD

Do not use metal strips or similar as formwork spacers. Do not use elements such as

70

22nt J

8

21 23 24 25 26 27

oin

23

1:6

t

from 25 cm

"Stabox" or similar for the starter bars in the walls.

16 Bicycle +17.679 m 4729

d2 d1 Spaces

Movement Joint

D 12 Any change in the positioning of any DRYset Crack Inducing Unit with respect to the

Move

m ent Jo

int

positions indicated on the Drytech project must be authorized by Drytech staff.

For concrete cast in contact with earth or sheet-piles, a layer of Delta type mebrane or

1:12

D>35 cm

Movement Joint

II Stage D 16 Bicycle

MECH C2 2

2 m²

Spaces BC.B1.003

IDR013

non-woven fabric (400 g/m) must be provided by the Main Contractor prior to casting.

B

C

BC.B1.

IDR020A FD60S

Before casting of the walls, in order to prevent the leak of fine soil particles, the supports for

the formworks located on horizontal slab elements should be sealed using polyurethane

8130

5891

foam or similar approved.

outside inside

I Stage 10 Bicycle

Spaces 0

12 Bicycle

Spaces

Car Parking

1701.4 m²

Block CD

29 Do not carry out any concrete placement for White tank elements if the ambient air

00

8 Bicycle

temperature is below -2°C or above +35°C.

50

B) DRYset Injection Channel

C) Cold Joint Spaces

A) Wall

A D) Floor slab The addition of water to any concrete mix is prohibited without authorization by Drytech

staff.

8 Bicycle BC.B1.004

Spaces IDR013

Block CD

28 D 11

The maximum allowable drop height for placement of fresh concrete should be 2.5m to

prevent the separation of its components

8 Bicycle

Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD

Place the concrete with the aid of at least two vibrators of suitable diameter.

Spaces

38 37 36 35 34 33 32 31 30

Block CD Place the concrete with a concrete pump, avoiding direct fall or lifting at height with the aid

48

of the bucket

Detail 4 Any gravel nests or similar that prevent effective seal of the Drytech White Tank system

7260

inside

must be highlighted and will require additional remedial measures before sign-off of the

Block CD

6000 49

White Tank system.

d1

≥ 25 cm

C B

The casting of any portion of the basement slab shall be executed without interruption, in

0

49

II Stage I Stage A Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD

13

39 40 41 42 43 44 45 46 47

strips with a maximum width of 2.5 m.

d2

Block CD

50

D 10

The casting of any walls/vertical elements shall be executed without interruptions, in

outside

A) Wall

B) DRYset Injection Channel

horizontal lifts with a maximum height of 0.5 m.

C) Cold Joint (Comax type B reinforcement steel / double-edged - two profiles-) Curing of all concrete walls/vertical elements shall be executed as per guidance provided in

3565

C6 the following Table.

Block CD Curing of walls casting shall be executed as per following Table

51

BD2.B1.001 MECH D2

IDR020A FD60S 1 m²

1

Step detail - see drawing DH002 Temperature < 5°C ≥ 5°C, < 25°C ≥ 25°C

D9 Thickness wall

DN < 45 cm s 72 h s 48 h s 72 h

5745

Detail 5 ≥ 45 cm s 96 h s 72 h s 96 h

s = formworks complete removal with release of the blocks 24 hours after the casting of the concrete

2830

Plantroom

Louvred

Ventilation Panel

Louvred Steel Curing of concrete basement slabs/horizontal elements shall be carried out as per

1000

Double Doors 1000

BC.B1. NFR

Louvred D8

guidance provided in the following table.

d1

C5

from 25 cm

Ventilation Panel

B A 2150 Temperature < 5°C ≥ 5°C , < 15°C ≥ 15°C , < 25°C ≥ 25°C

1720

C II Stage I Stage BD2.B1.

EDR025A FD60SCorridor BD2.B1. Gen. Room Thickness foundation

d2

22.8 m² EDR025A FD60S 32.0 m²

D7 < 45 cm M 36 h M 24 h T 24 h or A T 36 h or A

Mechanical Ventilation Fan

7.9 m²

Fire Rated Ventilation

≥ 45 cm, < 95 cm M 60 h M 48 h T 36 h or A T 48 h

BD2.B1.

BD2.B1. Ductwork and Grille to ≥ 95 cm, < 145 cm M 84 h M 72 h T 48 h T 72 h

450

EDR005 FD60S

4800

EDR031A FD60S 4

Refer to M&E drawings M&E Specifications ≥ 145 cm M 108 h M 96 h T 72 h T 96 h

A) Concrete Bed Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD Block CD 3

and details 65 64 63 62 61 60 59 58 57 56 55 54 53 52 Ventilation Lobby 2

NB: T= non-woven fabric (weight 200 g/mq), to be kept constantly and uniformly wet

B) DRYset Injection Channel

4035

bottom/ outside 4.6 m² 1

C) Cold Joint (Comax type B reinforcement steel for joint/ double-edged - two profiles-) M= thermal pad (typePolimaxitalia-PolymantPlus thick 10 mm or Trocelien-C30Trosil 10 mm thick or similar)

2400

A= spraying of anti-evaporation product (type MapecureCa or SikaAntisol or similar) to be applied when the concrete is still fresh

Exhaust Shaft

2.8 m² during the livelling of the casting surface

Cleaners Store

1280

4.7 m²

D6

Backfilling can take place only after Drytech Technical staff has ensured that all formwork

BD2.B1.008

BD2.B1.003 ELEC D2IDR020A

2 FD60S

holes have been sealed and closed.

IDR030A FD30S +17.425 m 1.1 m²

Detail 6 Anything covering the raft foundation or perimeter walls (such as screed, grout, ventilated

2880

2

Building Above GFPBD2-24-ZZ-4002

Lobby

9.4 m² BD2.B1.

from 25 cm

Staircore D2 2

14.4 m²

EDR025A FD60S

under floor type 'igloo', plaster, coating or in general elements which cover the structures

Lift

containing profiles for injection) can only be carried out after completion of the Drytech

D4

d2 d1

3.2 m² D5

from 25 cm

from 25 cm

injecting work; after the final element has been cast, it is recommended that the contractor

D III Stage III Stage D

A) Wall

B allows at least four weeks before injecting and as a minimum, as long as possible. Profiles

BD2.B1.

B) DRYset Injection Channel

C) Cold Joint

EDR025A FD60S must be injected before turning off the water pumping systems; if Drytech injection is not

Water Tank Room

A

D) Concrete Bed

A

84.1 m² carried out as recommended and additional cost is incurred, Drytech will be entitled to claim

Sprinkler Pump Room

C4 60.3 m² for the additional costs associated with injection resin overconsumption.

outside outside

OPERATION: Drytech shall be informed by phone at least 3 days before installation of the DRYSet Crack

8550

II Stage

inside II Stage

INTERVENTO:

INTERVENTION:

PLANINHALT: NOTES: REFER TO MEP DRAWINGS AND

Inducing Elements and 7 days before injection of any Drytech system elements.

SCHEDULES FOR PLANT REQUIREMENTS,

C

INCLUDING SUMPS, PLINTHS AND D2 OPERATION:

INTERVENTO:

All horizontal and vertical surfaces exposed to

from 25 cm

from 25 cm

D I Stage BUILDER'S WORK OPES.

INTERVENTION:

PLANINHALT: HITW-DH001

D1

bottom/ outside

ground require radon protection. D4

Basement

1no Radon sump required per core (3no. sumps Flue Shaft

0.5 m²

White Tank

Typical pipe penetration in total). Locate centrally within yellow hatched Sprinkler Tank 1

31.4 m²

Sprinkler Tank 2

33.2 m²

D3 CLIENT:

COMMITTENTE:

zone and duct to outside of building envelope. PRINCIPAL:

Townmore

6950

WICHTIGSTE:

Radon sumps to be located with 200mm layer of Drytech white tank systems

T2 permeable hardcore (to conform with I.S. EN

A) Concrete Bed D3

B) DRYset injection sleeve

C) Sewer penetration

Drytech Ireland

1875

D D) Injection hoses Unit D5, M7 Business Park,

II Stage E) Cable ties

F) Wall

78

30

13242:2002 + A1:2007 and meet specification as D2

Newhall, Naas

Co. Kildare

Telephone: +353 45 83 11 60

E

N 740380.116

E 722151.066

outlined in Annex E of accompanying guidance N 740383.574

E 722217.031

Waterproofing System Engineering

E-Mail: ger.shortt@drytech.ie

A

I Stage

B document to this standard, S.R. 21:2014 + 4450 4265 6355 4800 4800 6475 5130 2895 2085 5770 2230

www.drytech.ch

C

A1:2016. CD F CD G CD H CD J CD K CD L CD M CD N CD P CD Q CD R CD S

Scale:

Scala:

Date:

Data:

Rev No.:

Tav.:

Drawn:

Disegnato:

Simona Verified:

Verificato:

Echelle: Date: Table: Etabli: Eu Lieu: P. Keller

Massstab: Datum: 04.04.2023 Pnummer: 1 Herbaj

Gezeichnet: Aufgetreten:

Date Modification

Rev.:

File: HITW White Tank.dwg This plan is property of Drytech. All rights are reserved

You might also like

- 1880P3-28 - Unit H (TRANSITION)Document1 page1880P3-28 - Unit H (TRANSITION)Ryan BacalaNo ratings yet

- PL1 209Document1 pagePL1 209Lorenz Carlo Robedillo GonzalesNo ratings yet

- Plano Estructural: Cimentacion Losa de EntrepisoDocument1 pagePlano Estructural: Cimentacion Losa de EntrepisoSantos Lopez JorgeNo ratings yet

- E-EB-126-rev1 (Deck Plate) - ModelDocument1 pageE-EB-126-rev1 (Deck Plate) - ModelJoy FernandezNo ratings yet

- Balcont DetailsDocument1 pageBalcont DetailsBharani MadamanchiNo ratings yet

- All Falls Down - Alan WalkerDocument2 pagesAll Falls Down - Alan Walkerpiotr hryciukNo ratings yet

- CUATRO PUNTOS CARDINALES - CARNAVALITO-PianoDocument1 pageCUATRO PUNTOS CARDINALES - CARNAVALITO-PianoAlbin.NelsonNo ratings yet

- Hino NacionalDocument4 pagesHino Nacionaladrian hannemannNo ratings yet

- Typical Section (X-X) : MP1 MP2 MP3 MP4 Mp8 Future MP3 Mp7 Future Mp6 Future Mp5 FutureDocument1 pageTypical Section (X-X) : MP1 MP2 MP3 MP4 Mp8 Future MP3 Mp7 Future Mp6 Future Mp5 FuturesartajNo ratings yet

- ΣΗΚΩ ΧΟΡΕΨΕDocument1 pageΣΗΚΩ ΧΟΡΕΨΕgiannisNo ratings yet

- Fdot Design Standards: 21300 1 Standard Bar Bending DetailsDocument1 pageFdot Design Standards: 21300 1 Standard Bar Bending DetailstonydisojaNo ratings yet

- Circle of Life: (Tema Do Filme: "O Rei Leão)Document1 pageCircle of Life: (Tema Do Filme: "O Rei Leão)betoladarioNo ratings yet

- E-EB-126-rev1 (Deck Plate) - Model.1Document1 pageE-EB-126-rev1 (Deck Plate) - Model.1Joy FernandezNo ratings yet

- American Audio v4000 Audio Pa 2002 SCHDocument1 pageAmerican Audio v4000 Audio Pa 2002 SCHFrancisco Sanabria Najera100% (1)

- American Audio V4000 SchematicDocument1 pageAmerican Audio V4000 Schematicdavid julio diazNo ratings yet

- Ilfs-Nagpur Metro-cn-1011-Details of Steel I Girder at Platform Level-17m SpanDocument1 pageIlfs-Nagpur Metro-cn-1011-Details of Steel I Girder at Platform Level-17m SpanrohitNo ratings yet

- Opening Credits: Star Trek:PicardDocument2 pagesOpening Credits: Star Trek:PicardugurillaNo ratings yet

- Opening Credits PDFDocument2 pagesOpening Credits PDFugurillaNo ratings yet

- Farewell To A FriendDocument3 pagesFarewell To A FriendPaulNo ratings yet

- Power Supply CEM842A Orion TV29LB929Document2 pagesPower Supply CEM842A Orion TV29LB929Traian Miclau100% (3)

- When You Say Nothing at All: G D Csus2 D G D Csus2 DDocument6 pagesWhen You Say Nothing at All: G D Csus2 D G D Csus2 DFelix WinarsoNo ratings yet

- AUD600 Power Supply Rev 3.0.1 SimulationDocument1 pageAUD600 Power Supply Rev 3.0.1 SimulationGianmarco ScarabelloNo ratings yet

- 7500 PlansDocument149 pages7500 PlansGabrielito PachacamaNo ratings yet

- Tapcon 240: Title Project: SheetDocument6 pagesTapcon 240: Title Project: SheetHarold PuinNo ratings yet

- Hexacopter DesignDocument1 pageHexacopter DesignRidzky Zulfikar Widyo BaskoroNo ratings yet

- U/S D/S: Sectional ElevationDocument2 pagesU/S D/S: Sectional ElevationRajender Reddy ParneNo ratings yet

- Hajanga Lead SheetDocument9 pagesHajanga Lead SheetAxelBlom100% (1)

- Bag's Groove: Milt Jackson - Ed. 1952 120Document1 pageBag's Groove: Milt Jackson - Ed. 1952 120Francesco GiordanoNo ratings yet

- P&id For Bed& Fly Ah SystemDocument3 pagesP&id For Bed& Fly Ah Systemraaj bharathNo ratings yet

- Information Issue: ConfidentialDocument1 pageInformation Issue: Confidentialthongchai_007No ratings yet

- As Found Floor Plan Proposed Floor Plan: LegendDocument1 pageAs Found Floor Plan Proposed Floor Plan: LegendVincent FilomenaNo ratings yet

- M457 A BP 3.001 Section M457 3.001 SectionDocument1 pageM457 A BP 3.001 Section M457 3.001 SectionAbdul Halim EmbongNo ratings yet

- 0 Fecd 7 D 4Document1 page0 Fecd 7 D 4rw6zqgn94yNo ratings yet

- Trust and Obey - 02-Piano ScoreDocument6 pagesTrust and Obey - 02-Piano ScoreFREDERICKIENo ratings yet

- Asurion Clark - Scheme 12 - Floorplan & RCP - 09feb2023Document8 pagesAsurion Clark - Scheme 12 - Floorplan & RCP - 09feb2023JohnNo ratings yet

- Schematic - Design Mock Up - Main PCB Copy - 20200327153258Document1 pageSchematic - Design Mock Up - Main PCB Copy - 20200327153258Yoshua M FANo ratings yet

- #REF! #REF! Time Extensions: 378 328 - Due To Cutting Permit 888 123 - Due To Bad Weather #REF! 59 - Due To Bad Weather (For Approval) #REF! #REF!Document1 page#REF! #REF! Time Extensions: 378 328 - Due To Cutting Permit 888 123 - Due To Bad Weather #REF! 59 - Due To Bad Weather (For Approval) #REF! #REF!Melrose LaforgaNo ratings yet

- Entrance Level (0.00) Building Outdoor Equipotential Bus (S) Termination Conductor With The Loop Earth Electrode ConductorDocument1 pageEntrance Level (0.00) Building Outdoor Equipotential Bus (S) Termination Conductor With The Loop Earth Electrode ConductorsartajNo ratings yet

- Strip PAD: Fabrication AI02571 AI01651 AI01046 AI02525 OF AI02252 Finish AI02719Document1 pageStrip PAD: Fabrication AI02571 AI01651 AI01046 AI02525 OF AI02252 Finish AI02719Isaías AguilarNo ratings yet

- Cantina BandDocument1 pageCantina BandHERNAN ALONSO SANCHEZ RAMOSNo ratings yet

- Chordify - Chinna Kuyil Padum Pattu Tamil Song Practice For Female SingerDocument2 pagesChordify - Chinna Kuyil Padum Pattu Tamil Song Practice For Female Singerravi_annasNo ratings yet

- 220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Document200 pages220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Văn Ngọc NguyễnNo ratings yet

- Cotton Tail - BassDocument3 pagesCotton Tail - BassJosecarlos GonzalezNo ratings yet

- A105 - Service Block DetailsDocument1 pageA105 - Service Block DetailsØwięs MØhãmmedNo ratings yet

- For Discussion: SpectrumDocument1 pageFor Discussion: Spectrumshubhamoffice007No ratings yet

- 6505 MHDocument10 pages6505 MHJulio Güissa57% (7)

- Pioneer DDJ-RX rrv4642 DJ ControllerDocument22 pagesPioneer DDJ-RX rrv4642 DJ Controllerpablobcasino1No ratings yet

- Galuppi - Sonata-Re MinoreDocument4 pagesGaluppi - Sonata-Re MinoreAngelo MerlettiNo ratings yet

- Ar-02 2nd Floor PlanDocument1 pageAr-02 2nd Floor PlanSharlene MadridNo ratings yet

- OTVC Sony KV2184MT OTVC Sony KV2184MT: (Strona 1/2) (Strona 1/2)Document2 pagesOTVC Sony KV2184MT OTVC Sony KV2184MT: (Strona 1/2) (Strona 1/2)Benkő ZsoltNo ratings yet

- Almost Bo-Tenor - Sax - 1Document2 pagesAlmost Bo-Tenor - Sax - 1uriupsNo ratings yet

- Residencia: CondosDocument1 pageResidencia: CondosCARLOS CABNo ratings yet

- Schedule of Lap Length For ReinforcementDocument1 pageSchedule of Lap Length For Reinforcementchiranjeevimd2991 MDNo ratings yet

- National Highway Authority of India: Vax Consultants Pvt. LTDDocument2 pagesNational Highway Authority of India: Vax Consultants Pvt. LTDSelvan KstNo ratings yet

- DA/2 Area: Chain Link Fence (H 2.0m)Document1 pageDA/2 Area: Chain Link Fence (H 2.0m)heri_prasetyadiNo ratings yet

- Quiero Conocer A Jesús BBDocument3 pagesQuiero Conocer A Jesús BBjosebrazon1816No ratings yet

- SHD Str-010-Titik Koordinat Tiang Pancang Gedung A3 (R1)Document4 pagesSHD Str-010-Titik Koordinat Tiang Pancang Gedung A3 (R1)EmilNo ratings yet

- DHQC Cecb MB Ti Ar DW ML 02 80541Document1 pageDHQC Cecb MB Ti Ar DW ML 02 80541Kumudu PereraNo ratings yet

- 02a-4 D-Can Xlrteh4300g033850Document1 page02a-4 D-Can Xlrteh4300g033850Daniel PricopNo ratings yet

- Battery-Size-Calculator (UPS) - Copy2Document3 pagesBattery-Size-Calculator (UPS) - Copy2Arsalan Ullah KhanNo ratings yet

- Rigid PVC Conduit & FittingsDocument20 pagesRigid PVC Conduit & FittingsArsalan Ullah KhanNo ratings yet

- Brochure Indirect Storage TanksDocument4 pagesBrochure Indirect Storage TanksArsalan Ullah KhanNo ratings yet

- LED Value Slim Downlight 15 W 4000 K enDocument3 pagesLED Value Slim Downlight 15 W 4000 K enArsalan Ullah KhanNo ratings yet

- DX Luminaire 9jJmocS9QZCuFJ24cwe9WADocument1 pageDX Luminaire 9jJmocS9QZCuFJ24cwe9WAArsalan Ullah KhanNo ratings yet

- Product Data Sheet: Automatic Powerlogic PFC Capacitor Bank, 450kvar Dr3,8 With Incomer CB XXB 400V 60HzDocument3 pagesProduct Data Sheet: Automatic Powerlogic PFC Capacitor Bank, 450kvar Dr3,8 With Incomer CB XXB 400V 60HzArsalan Ullah KhanNo ratings yet

- Details Folder (30 Mva)Document10 pagesDetails Folder (30 Mva)Arsalan Ullah KhanNo ratings yet

- Load - Flow - Study - Case 3Document1 pageLoad - Flow - Study - Case 3Arsalan Ullah KhanNo ratings yet

- HITW-DH002 White Tank DetailsDocument1 pageHITW-DH002 White Tank DetailsArsalan Ullah KhanNo ratings yet

- Amenzade Yu.a. - Theory of Elasticity-Mir (1979)Document284 pagesAmenzade Yu.a. - Theory of Elasticity-Mir (1979)Javier100% (1)

- Weirs: 2. Open Channel Flow 4. Flumes IndexDocument25 pagesWeirs: 2. Open Channel Flow 4. Flumes IndexlordsethdarknessNo ratings yet

- Astm E1975 - 1 (En)Document17 pagesAstm E1975 - 1 (En)Dinesh Sai100% (1)

- Seminar 2 of 2021-Multispectral Spectroscopy-Aster Imagery Processing For Mineral ExplorationDocument15 pagesSeminar 2 of 2021-Multispectral Spectroscopy-Aster Imagery Processing For Mineral Explorationmartin nyakinyeNo ratings yet

- Underground-Sprayed Concrete BrochureDocument12 pagesUnderground-Sprayed Concrete BrochureEngTamerNo ratings yet

- SG5.0 20RT UEN Ver13 202101Document105 pagesSG5.0 20RT UEN Ver13 202101Asep SaepudinNo ratings yet

- Cross Border Pack 2 SumDocument35 pagesCross Border Pack 2 SumYến Như100% (1)

- Autodesk Inventor Practice Part DrawingsDocument25 pagesAutodesk Inventor Practice Part DrawingsCiprian Fratila100% (1)

- Hemiplegia LectureDocument37 pagesHemiplegia LectureRancesh FamoNo ratings yet

- Abortion Remedies From A Medieval Catholic Nun (!) - JSTOR DailyDocument12 pagesAbortion Remedies From A Medieval Catholic Nun (!) - JSTOR DailysiesmannNo ratings yet

- Morris 2Document22 pagesMorris 2IsmaelLouGomezNo ratings yet

- Dividing Fractions : and What It MeansDocument22 pagesDividing Fractions : and What It MeansFlors BorneaNo ratings yet

- 4.5.redistrribution - PBR Quiz AnswersDocument4 pages4.5.redistrribution - PBR Quiz AnswersffbugbuggerNo ratings yet

- Homework 3rd SteelDocument4 pagesHomework 3rd SteelPiseth HengNo ratings yet

- Lecture On Metallurgical BalancesDocument14 pagesLecture On Metallurgical BalancesVladimir LopezNo ratings yet

- Module I: Introduction To Environmental PollutionDocument14 pagesModule I: Introduction To Environmental PollutionAman John TuduNo ratings yet

- Piyush Group 3-2Document40 pagesPiyush Group 3-2Biren PatelNo ratings yet

- Svabodhodaya-Mañjarī by VāmanadattaDocument15 pagesSvabodhodaya-Mañjarī by Vāmanadattajuan pablo mejia100% (1)

- CE-401CE 2.0 Network Diagrams 2015Document83 pagesCE-401CE 2.0 Network Diagrams 2015Shubham BansalNo ratings yet

- Whitepaper - Loadspreading and SeafasteningDocument3 pagesWhitepaper - Loadspreading and SeafasteningtyuNo ratings yet

- Squad3.fire NSD GPMDocument7 pagesSquad3.fire NSD GPMMac CorpuzNo ratings yet

- Q4 Lesson 3 Hinge Theorem and Its ConverseDocument36 pagesQ4 Lesson 3 Hinge Theorem and Its ConverseZenn Tee100% (1)

- Atomic Structure RevisionDocument4 pagesAtomic Structure RevisioncvNo ratings yet

- List of Japanese Company in IndiaDocument2 pagesList of Japanese Company in Indiakaushalshinde317No ratings yet

- THESISDocument44 pagesTHESISRowena Shaira AbellarNo ratings yet

- Teiaiel - Visions of The FutureDocument2 pagesTeiaiel - Visions of The FutureMarkosNo ratings yet

- MV "RS Mistral": 712 TEU Geared Cellular Container VesselDocument1 pageMV "RS Mistral": 712 TEU Geared Cellular Container VesselMeryNo ratings yet

- CMC 2023 Senior Category Question BankDocument5 pagesCMC 2023 Senior Category Question BankNikita AgrawalNo ratings yet

- Faculty Profile: Dr. Injam Siva ParvathiDocument9 pagesFaculty Profile: Dr. Injam Siva ParvathiMr. Y. RajeshNo ratings yet

- Coffee Vibes: Here Is Where Your Presentation BeginsDocument86 pagesCoffee Vibes: Here Is Where Your Presentation Beginssyeda salmaNo ratings yet