Professional Documents

Culture Documents

Seminar Report Plastic Solar Cell

Uploaded by

Sonus DelexOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seminar Report Plastic Solar Cell

Uploaded by

Sonus DelexCopyright:

Available Formats

Government Polytechnic College, Pala

GOVERMENT POLYTECHNIC COLLEGE PALA

DEPARTMENT OF ELECTRICAL AND

ELECTRONICS ENGINEERING

SEMINAR REPORT

ON

PLASTIC SOLAR CELL TECHNOLOGY

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

GOVERNMENT POLYTECHNIC COLLEGE,

PALA

DEPARTMENT OF

ELECTRICAL & ELECTRONICS ENGINEERING

CERTIFICATE

This is to certify that the Seminar Report titled ― PLASTIC SOLAR CELL

TECHNOLOGY‖ was presented by ALAN THOMAS(REG NO: 2003087) a

student of 6th semester Electrical & Electronics Engineering in partial fulfilment of

requirement for the award of Diploma in Electrical & Electronics Engineering under

the department of Technical Education, GOVERNMENT OF KERALA during the

academic year of 2022-2023 under my guidance.

Certified that, this is the bonafide record of Seminar conducted by the above

student.

Internal Examiner Head of section

External Examiner

Place: Govt. Polytechnic College Pala

Date:

Department of EEE 2022-2023 2

Government Polytechnic College, Pala

DECLARATION

I, ALAN THOMAS, hereby declare that this seminar report on “PLASTIC

SOLAR CELL TECHNOLOGY”, submitted for partial fulfilment of requirement

for the award of Diploma in Electrical & Electronics Engineering under the

department of Technical Education, GOVT OF KERALA. This submission represents

my ideas in my own words and where ideas or words of others have been included, I

have adequately and accurately cited and referenced the original sources. I also declare

that I have adhered to ethics of academic honesty and integrity and have not

misrepresented or fabricated any data or idea or fact or source in my submission. I

understand that any violation of the above will be a cause for disciplinary action by the

institute and or the University and can also evoke penal action from the sources which

have thus not been properly cited or from whom proper permission has not been

obtained. This report has not been previously formed the basis for the award of any

degree, diploma or similar title of any other University.

ALANT THOMAS

Department of EEE 2022-2023 3

Government Polytechnic College, Pala

ACKNOWLEDGEMENT

―Achievement is finding out what you would be doing, what you have to do. The

higher the summit, higher will be the climb.‖

It has been rightly said that we are build on the shoulders of others but the

satisfaction that accompanies the successful completion of any task would be

incomplete without the mention of the people who made it possible.

First of all I thank the god of almighty for the successful completion of this

seminar of mine.

I am extremely thankful to our principal Mrs. ANI ABRAHAM. for the careful

and precious guidance which were extremely valuable for the seminar.

Also my sincere thanks to Head of department Smt. BINU B.R, also Sri. Nevin

Jose, and all the teaching staff who provided invaluable support by guiding me

through the entire preparation period for the seminar, and also keeping me updated

with the rules, regulations, format and also the deadlines.

Finally, I thank my classmates and all others who have helped me directly or indirectly

with constant encouragement, constructive criticisms and valuable suggestions to

bring out this report a successful work.

Department of EEE 2022-2023 4

Government Polytechnic College, Pala

ABSTRACT

This paper represents a review on recent developments in PLASTIC SOLAR CELL

TECHNOLOGY. Solar cells that are primarily of the conventional type. Photovoltaic

(PV) cells are comprised of unique materials called semiconductors, the most common

of which being silicon. When light strikes the cell, some of it is absorbed by the

semiconductor material. This indicates that the absorbed light energy is transmitted to

the semiconductor electrons are knocked loose and allowed to move freely as a result

of the energy. In addition, all PV cells features one or more electric fields that act to

push electrons released by light absorption to travel in a specific direction we can pull

this current off the top and bottom of the PV cell and use it externally by installing

metal contacts on the top and bottom of the cell

Solar cells use freely available sunlight to make electricity. At the present time, solar

electricity does not come cheap, because solar panels are rather expensive. And the

cost of solar panel is comparatively high so as a solution scientists have been working

on the new technology of plastic solar cell

Now imagine that we could reduce costs by printing solar panels Plastics are made of

polymers, which are very long molecules which is having more benefits than

compared to a conventional solar cell

Department of EEE 2022-2023 5

Government Polytechnic College, Pala

CONTENTS

No Page no

1 INTRODUCTION 8

1.1 GLOSSARY 9

2 CONVENTIONAL SOLAR CELL 10

2.1 WORKING OF A CONVENTIONAL SOLAR CELL 11

2.2 APPLICATIONS OF CONVENTIONAL SOLAR CELL 12

3 PLASTIC SOLAR CELL 13

3.1 WORKING OF PLASTIC SOLAR CELL 14-15

3.2 THE SMALL POLYMERS 16

3.3 SPECIAL ADDITIVE 17

3.4 NEW EXPERMENTAL SETUP 18-19

3.5 ADVANTAGES OF PLASTIC SOLAR CELL 20

3.6 DIS ADVANTAGES OF PLASTIC SOLAR CELL 21

4 CONCLUSION 22

5 REFERENCE 23

Department of EEE 2022-2023 6

Government Polytechnic College, Pala

LIST OF FIGURES

No Page no

1 SILICON SOLAR CELL 10

2 CONVENTIONAL SOLAR CELL 11

3 DIAGRAM OF A PLASTIC SOLAR CELL. 14

4 TOP VIEW MICROSCOPIC IMAGE OF A BAD

SOLAR CELL (LEFT) AND A GOOD SOLAR CELL

(RIGHT), TAKEN WITH AN ELECTRON

16

MICROSCOPE

5 PLASTIC SOLAR CELLS ARE MADE BY SPIN 17

COATING.

6 DIAGRAM OF HOW THE SPECIAL ADDITIVE 19

WORKS.

Department of EEE 2022-2023 7

Government Polytechnic College, Pala

CHAPTER 1

INTRODUCTION

With the ever-increasing demand of electrical energy everyone is looking towards Sun

as a source of electrical energy along with its role as an important source of thermal

energy. The sun always shines and provides energy to the earth in the form of light,

even on cloudy days. Solar panels convert this light into electricity.

The most commonly known fact about solar energy is that it represents a clean, green

source of energy. Solar power is a great way to reduce your carbon footprint. There‘s

nothing about solar power that pollutes mother nature. Solar power doesn‘t release any

greenhouse gasses, and except for needing a source of clean water to function, it uses

absolutely no other resources. Hence, it‘s safe and environmentally-friendly. Yet,

people are still in doubt why solar energy is good. Solar power is self-sufficient and

installing solar panels on your roof is a safe and easy path to contribute to a

sustainable future.

At the heart of all photovoltaic devices are two separate layers of materials, one with

an abundance of electrons those function as a ‗Negative pole‘ and one with an

abundance of holes(vacant positively charged energy spaces) that functioned as a

‗positive pole‘. When photons from the Sun are absorbed, their energy is transferred

to the extra electron in negative pole, causing them to flow to positive pole & creating

new holes that start flowing to the negative pole, thus producing electrical current

which can be used to power other devices.

Department of EEE 2022-2023 8

Government Polytechnic College, Pala

GLOSSARY

Active layer: the most important layer of plastic solar cells. This layer is where

sunlight is converted into charge.

Additive: An additive is a small chemical, which can be added to the ink, but does

not remain in the solar cell after the ink dries.

Electron microscope: A normal microscope uses light to see very small things.

However, if things are too small to see with a normal microscope, we need to use an

electron microscope. As the name implies, electrons are used instead of light.

Ink: A combination of liquid and solid materials that can be printed or coated onto a

surface. During printing or coating, the liquids evaporate and the solids remain on the

surface.

Interface: The boundary between two materials.

Polymer: A long molecule that looks like cooked spaghetti, but is a million times

smaller. Plastics contain polymers.

Spin coating: A coating method to make very thin films. A droplet of ink is put on a

glass slide, which is then rotated at high speed to spread the ink. After spreading, the

ink dries and a very thin layer is left on the glass.

Department of EEE 2022-2023 9

Government Polytechnic College, Pala

CHAPTER 2

CONVENTION SOLAR CELL

A solar cell, or photovoltaic cell, is an electronic device that converts the energy of

light directly into electricity by the photovoltaic effect, which is a physical and

chemical phenomenon.[1] It is a form of photoelectric cell, defined as a device whose

electrical characteristics, such as current, voltage, or resistance, vary when exposed to

light. Individual solar cell devices are often the electrical building blocks of

photovoltaic modules, known colloquially as solar panels. The common single

junction silicon solar cell can produce a maximum open-circuit voltage of

approximately 0.5 to 0.6 volts.

Solar cells are described as photovoltaic, regardless of whether the source is sunlight

or artificial light. In addition to producing energy, they can be used as a photodetector

(for example infrared detectors), detecting light or other electromagnetic radiation near

the visible range, or measuring light intensity.

The operation of a photovoltaic (PV) cell requires three basic attributes:

The absorption of light, generating excitons (bound electron-hole pairs),

unbound electron-hole pairs (via excitons), or plasmons.

The separation of charge carriers of opposite types.

The separate extraction of those carriers to an external circuit.

SILICON SOLAR CELL

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

2.1 WORKING OF A CONVENTIONAL SOLAR CELL

When light shines on a photovoltaic (PV) cell – also called a solar cell – that light may

be reflected, absorbed, or pass right through the cell. The PV cell is composed of

semiconductor material; the ―semi‖ means that it can conduct electricity better than an

insulator but not as well as a good conductor like a metal. There are several different

semiconductor materials used in PV cells.

When the semiconductor is exposed to light, it absorbs the light‘s energy and transfers

it to negatively charged particles in the material called electrons. This extra energy

allows the electrons to flow through the material as an electrical current. This current

is extracted through conductive metal contacts – the grid-like lines on a solar cells –

and can then be used to power your home and the rest of the electric grid.

The effeciency of a PV cell is simply the amount of electrical power coming out of the

cell compared to the energy from the light shining on it, which indicates how effective

the cell is at converting energy from one form to the other. The amount of electricity

produced from PV cells depends on the characteristics (such as intensity and

wavelengths) of the light available and multiple performance attributes of the cell.

CONVENTIONAL SOLAR CELL

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

2.2APPLICATIONS OF CONVENTIONAL SOLAR CELL

Solar farms

. Many acres of PV panels can provide utility-scale power—from tens of megawatts to

more than a gigawatt of electricity. These large systems, using fixed or sun-tracking

panels, feed power into municipal or regional grids.

Transportation

PV can provide auxiliary power for vehicles such as cars and boats. Automobile

sunroofs can include PV for onboard power needs or trickle-charging batteries.

Lightweight PV can also conform to the shape of airplane wings to help power high-

altitude aircraft.

Military uses

Lightweight, flexible thin-film PV can serve applications in which portability or

ruggedness are critical. Soldiers can carry lightweight PV for charging electronic

equipment in the field or at remote bases.

Building related needs

In buildings, PV panels mounted on roofs or ground can supply electricity. PV

material can also be integrated into a building‘s structure as windows, roof tiles, or

cladding to serve a dual purpose. In addition, awnings and parking structures can be

covered with PV to provide shading and power.

Stand alone power

In buildings, PV panels mounted on roofs or ground can supply electricity. PV

material can also be integrated into a building‘s structure as windows, roof tiles, or

cladding to serve a dual purpose. In addition, awnings and parking structures can be

covered with PV to provide shading and power.

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

CHAPTER 3

PLASTIC SOLAR CELL

Scientists recently found a new way to make solar panels: by printing them! Most

people think about printing things like books, but we can also use a special kind of

printers to print objects made out of plastics. Plastics are made of polymers, which are

very long molecules. Under a very strong microscope, polymers look like cooked

spaghetti, but, in fact, they are a million times smaller. To print plastics, you simply

replace the ink cartridge in your printer at home with ―plastic ink.‖ The plastic ink is a

combination of two polymers dissolved in a liquid. When printed, the liquid dries and

the two polymers form a thin film. For solar cells, we use a special type of polymer

that can convert sunlight into electricity.

Plastic solar cells can be printed on large rolls of flexible foil. Recently, 100 m-long

solar panels were printed. Using these cheap solar panels, only around 1.5% of the

energy in the sunlight is converted to electricity. This efficiency is still low compared

to the expensive solar panels you can buy now, which can convert 15–20% of the

sun‘s energy into electricity. But the future looks bright. In laboratories around the

world, small plastic solar cells are already being made with much higher efficiencies,

up to about 12%

One of the tricks to increase the efficiency is adding a special additive to the plastic

ink before printing. This special additive was found by accident [4], but if we want to

improve the efficiency of the plastic solar panels even further, we need to know why

this special additive works. Understanding how plastic solar cells work is not easy.

many scientists have worked on this topic .

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

3.1 WORKING OF PLASTIC SOLAR CELL

Plastic solar cells consist of a plastic layer on glass or a flexible foil. In the lab, we use

glass plates with a transparent electric contact [the positive (+) pole]. On top of this

contact, we put the ink for the active layer, which is the part of the solar cell that

converts sunlight to electricity. This ink contains two polymers, a long green one and a

shorter red one. The polymers form a mixed layer, as shown in figure

On top of that layer, we put a metal layer, which functions as the negative (−) pole.

We then turn the whole stack of layers upside down such that sunlight can shine

through the glass into the active layer.

Diagram of a plastic solar cell.

Sunlight creates a plus (+) and a minus (−) charge at the interface between

two polymers. The (−) charge moves to the (−) pole of the solar cell and

the (+) charge to the (+) pole. These poles work just like those in a

battery, but are powered by the sun and never run out as long as the sun

shines.

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

The Structure of red and green polymers in Figure is requiredThere is a lot

of interface, or area of contact, between the two polymers. This is necessary,

because sunlight creates electrical charges only at the areas where the two

polymers are in contact. When the light is absorbed (the yellow star), positive (+)

and negative (−) electrical charges are generated. Normally, the + and − attract

each other and the energy is lost. In plastic solar cells, the red and green polymers

make sure the charges can be separated. The positive and negative charges then

move to the + and − poles. Now, light is converted to moving charges, which is

electricity! Think about how useful this is – we use free sunlight and two cheap

plastics to make electrical energy

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

3.2 THE SMALL POLYMERS

The green and red polymers are so small that we cannot see them easily, even when

using a normal microscope. But we can see them with an electron microscope, which

does not use light, but electrons to ―look‖ at the solar cells. In Figure

We show electron microscopic images of real plastic solar cells. These are images

looking down on the active layer. The two polymers show up as dark and bright areas

and not as red and green because electrons are ―colorblind.‖ On the left, a

poorly working plastic solar cell is shown. The large droplets create very little

interface and the efficiency is low: 1.5%. On the right, a much better plastic solar cell

is shown. The structure between dark and bright areas is now so small that it is

actually hard to see, but it means that there is a lot of interface. This allows for more

charges to be made and triples the efficiency to over 5%. These solar cells are still not

the best, but they can help us to understand how plastic solar cells work.

Top view microscopic image of a bad solar cell (left) and a good solar cell

(right), taken with an electron microscope

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

3.3 SPECIAL ADDITIVE

The additive is a slowly drying liquid, which is added to the ink in a small amount.

The active layers are made by a process called spin coating the ink, as shown in Figure

Spin coating is a technique to make thin films from an ink. The regular spin coating

process is shown on the top row of Figure . A drop of ink that contains the green and

red polymers in a liquid is put on a glass plate. By very fast rotation, a thin wet film

forms that dries within 1 s by evaporating the liquid. While drying, the red polymer

forms large droplets, which cause the poor performance. The bottom row shows the

same spin coating process after the additive is added to the ink. Now, drying takes

longer, about 5 s. As you see, no droplets are formed when using the special additive.

Plastic solar cells are made by spin coating.

Spin coating is a technique to make thin films. Here, a side view of this process is

shown. The top view looks like a pottery kick wheel. First (on the left), a droplet of

ink (either with or without the additive) is put on a glass plate. Then (middle), that

glass plate is rotated at high speed. Because of the rotation the ink droplet spreads out

and forms a thin film. Without additive, the ink is dry within 1 s and the red polymer

clusters in droplets (top right), which is bad for solar cell performance. With additive,

the drying takes longer and the red polymer is more spread out (bottom right), which is

good for solar cell performance

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

3.4 NEW EXPERIMENTAL SETUP

To study this drying process during the spin coating process, we had to build a new

experimental setup. In this setup, we shine a laser on the spinning glass plate. The

reflection of the laser changes when the droplets are formed. In this way, we found

that without additive the large droplets form in a late stage of the drying process, and

even later, the green polymer changes color! To understand what happens when the

color changes, we recall that the green component is a long polymer. We know that

long polymers can fold up, similar to how a snake curls up. The folding makes the

green polymers change their color to dark green. Using our special setup, we

determined the time at which the color changes and the folding happens. We

discovered that the effect of the special additive is to make the green polymer fold

earlier than it does without the additive, and even before the droplets would normally

form! The reason is that the additive and the green polymer do not like each other very

much. As a result, the green polymer folds up when it ―feels‖ the additive.the

red polymer does not form droplets. The folding of the green polymer holds back

droplet formation and results in better mixed layers.

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

Diagram of how the special additive works.

The top figure shows a small part of the ink droplet we put on the spin coater. We see

that the green polymers and the red polymers are mixed. During the spin coating,

the ink will dry. Without additive, we see a clustering of the red polymers. With

additive, we see something very different: the green polymers fold up. The folding

prevents the formation of the clusters of the red polymers.

Department of EEE 2022-2023 1

Government Polytechnic College, Pala

3.5. ADVANTAGES OF PLASTIC SOLAR CELL

The primary advantage of a plastic solar cell or OPV is its low cost compared to

other energy sources.

It is also typically much easier to make than traditional silicon-based

photovoltaic cells because it uses a thin film deposition technique which

allows for the use of low-cost materials like plastics instead of just silicon chips.

This type of cell has a much higher efficiency than traditional cells, meaning

that more light can be converted into electricity with less power loss due to heat

or air leakage as is common with other types of photovoltaics.

Additionally, this type of cell tends to be lightweight and flexible which makes

them ideal for rooftop installation projects where weight limitations are

especially important.

In addition, these plastic-based solar cells may not degrade as quickly or suffer

manufacturing flaws due to normal wear during shipping since they don't

require high temperatures and pressure like crystalline silicon - two factors that

impose long-term reliability issues over time with such photovoltaic

installations.

Plastic solar cells can be manufactured at room temperature without the

expensive equipment needed for silicon-based panels and so require little capital

investment from manufacturers as well as low labor costs, making them very

attractive products for many applications.

They also tend to work better when exposed to diffuse light rather than direct

sunlight which means they can perform even better on cloudy days compared

with their counterparts made from conventional photoelectric materials such as

polysilicon.

Department of EEE 2022-2023 2

Government Polytechnic College, Pala

3.6. DISADVANTAGES OF PLASTIC SOLAR CELL

One being that their performance in comparison with traditional crystalline

silicon PV systems could still be improved upon further before becoming

competitive in terms of pricing per wattage produced (especially when taking

into account total lifetime maintenance costs).

Another disadvantage associated with this technology is its lack of durability;

although there have been vast improvements in increasing longevity by

improving encapsulation techniques works during the fabrication process due

lately to malfunctions caused by moisture penetration leading to corrosion over

time – sometimes seen firsthand within only 2 – 3 years post installation

depending upon geographical setting & conditions experienced throughout said

timeline period out above-mentioned example cases applies particularly well

towards those situated near oceanic environments wind-driven sea spray

routinely coats PV surfaces regularly up a salt-laden environment

Lastly, this form factor remains limited in terms of performance output &

standing even amongst other prior mentioned varieties within the same niche

market regarding per wattage generated output-wise capacity still lags hence

why it vita anyone considering added instant benefits upon first use turns an eye

towards established competitors who boast larger maximum capacities overall

measured turn out rate values when selecting either residential/commercial

based models cited today throughout industry-standard catalogs worldwide

currently available.

Department of EEE 2022-2023 2

Government Polytechnic College, Pala

CHAPTER 4

CONCLUSION

Plastic solar cells have a huge potential because they can be printed cheaply on

large flexible foils. Their efficiency still needs improvement, but can be

improved threefold by adding a special additive to the printer ink. Since this

additive is very useful, we wanted to understand how it works. With a new

experimental setup designed to study the drying of the ink, we found that the

special additive controls folding of one of the two polymers. The folding

prevents large droplets and increases the amount of interface between the two

polymers in the active layer. The interface is very important the efficient

conversion of sunlight into electricity. In the past, solar cells were optimized by

lots of hard lab work and you had to be lucky to make a good cell. Now,

because we understand the process of the drying, we can think of even more

clever tricks to optimize these solar cells! In the future, this will hopefully lead

to cheap and efficient electricity production from printed solar panels

Department of EEE 2022-2023 2

Government Polytechnic College, Pala

CHAPTER 5

REFERENCES

U.S. Energy Information Administration. 2015. Monthly Energy Review.

Available from: http://www.eia.gov/

Krebs, F. C., Espinosa, N., Hösel, M., Søndergaard, R. R., Jørgensen, M. 2013.

25th anniversary article: rise to power – OPV-based solar parks. Adv. Mater.

26:29–39. Doi: 10.1002/adma.201302031

Yusoff, A. R. B. M., Kim, D., Kim, H. P., Shneider, F. K., da Silva, W. J., Jang,

J. 2015. High efficiency solution processed polymer inverted triple-junction

solar cells exhibiting conversion efficiency

Van Franeker J and Janssen R (2015) Plastic Solar Cells: Understanding the

Special Additive. Front. Young Minds.

Peet, J., Kim, J. Y., Coates, N. E., Ma, W. L., Moses, D., Heeger, A. J., et al.

2007. Efficiency enhancement in low-bandgap polymer solar cells by

processing with alkane dithiols.

Department of EEE 2022-2023 2

You might also like

- Advance Seminar on Plastic Solar CellsDocument20 pagesAdvance Seminar on Plastic Solar CellsAkhil GongalaNo ratings yet

- Report Infrared Solar CellDocument22 pagesReport Infrared Solar Cellabhishek5singh5surajNo ratings yet

- Infrared Plastic Solar CellDocument17 pagesInfrared Plastic Solar CellRajesh PandaNo ratings yet

- Seminar Report 3GN17ME055Document27 pagesSeminar Report 3GN17ME055Rahul KullkarniNo ratings yet

- Final Report of Solar TreeDocument28 pagesFinal Report of Solar TreeRajashekar ReddyNo ratings yet

- Plastic Solar Cells Report Part 2Document32 pagesPlastic Solar Cells Report Part 2IRSHAD PNo ratings yet

- Platic Solar CellDocument17 pagesPlatic Solar CellSachin UkkaliNo ratings yet

- Infra Red Plastic Solar CellDocument25 pagesInfra Red Plastic Solar CellRaghavendra Raghav100% (7)

- Seminar on Infrared Plastic Solar CellDocument19 pagesSeminar on Infrared Plastic Solar CellAbhishek BendaleNo ratings yet

- Plastic Solar Cell Technology: Submitted To: - Submitted byDocument37 pagesPlastic Solar Cell Technology: Submitted To: - Submitted bynavya100% (3)

- Infrared Plastic Solar Cell, 478Document19 pagesInfrared Plastic Solar Cell, 478Princess ShonaNo ratings yet

- Plastic Solar Cell Technology: by Muhammed Raslan S5 EL Rollno 37Document12 pagesPlastic Solar Cell Technology: by Muhammed Raslan S5 EL Rollno 37N ONo ratings yet

- Infrared Plastic Solar Cell-1Document16 pagesInfrared Plastic Solar Cell-1Sai PrakashNo ratings yet

- Infrared Plastic Solar Cells Overcome LimitationsDocument23 pagesInfrared Plastic Solar Cells Overcome LimitationsPriyanka50% (4)

- Solar CellDocument11 pagesSolar Cellapi-3808445100% (2)

- Infrared Plastic Solar CellDocument19 pagesInfrared Plastic Solar CellAjay Mv100% (2)

- Solar Cells: by Aman Shah and Nyla VaidyaDocument14 pagesSolar Cells: by Aman Shah and Nyla VaidyaNyla VaidyaNo ratings yet

- Seminar Report Solar TreeDocument30 pagesSeminar Report Solar TreeAshish Kumar100% (1)

- Infrared Plastic Solar Cell: AbstractDocument1 pageInfrared Plastic Solar Cell: AbstractChaitanya SammetaNo ratings yet

- Seminar Report 2Document23 pagesSeminar Report 2Mayank S.H88% (8)

- Infrared Plastic Solar CellDocument4 pagesInfrared Plastic Solar CellAjesh.V.RNo ratings yet

- Infrared Plastic Solar CellDocument19 pagesInfrared Plastic Solar CellManoj Raju KonduruNo ratings yet

- Compressed Air EngineDocument18 pagesCompressed Air EngineMahipalreddy VelmaNo ratings yet

- Report of Infrared Plastic Solar CellDocument22 pagesReport of Infrared Plastic Solar CellAjay Mv85% (54)

- Solar Mobile Charger With New TechniqueDocument19 pagesSolar Mobile Charger With New TechniqueSanjayNo ratings yet

- Solar Mobile ChargerDocument16 pagesSolar Mobile ChargerDivyanshu nagarNo ratings yet

- Seminar Report On Aluminum-Electrolytic-CapacitorDocument19 pagesSeminar Report On Aluminum-Electrolytic-CapacitorChitranshu Srivastav0% (2)

- Solar PanelsDocument15 pagesSolar PanelsIann Legaspi Raymundo100% (1)

- D7 Solar Panel DevicesDocument12 pagesD7 Solar Panel Devicesarunguptha_gs100% (1)

- LEP Display TechnologyDocument23 pagesLEP Display TechnologyitsmemonuNo ratings yet

- Nano Wire Full ReportDocument21 pagesNano Wire Full Reportnikhil210492100% (1)

- Solar Cell DefinitionDocument26 pagesSolar Cell Definitionrajani kanthNo ratings yet

- Solar RoadwaysDocument23 pagesSolar RoadwaysMohammed rafeeqNo ratings yet

- Solar Mobile Charger Seminar ReportDocument16 pagesSolar Mobile Charger Seminar ReportAkhila GottemukkulaNo ratings yet

- MEMS Technology Seminar Report SummaryDocument26 pagesMEMS Technology Seminar Report SummaryMadhura Medikeri0% (1)

- Paper Battery Seminar Report: Lightweight Power for IoT DevicesDocument17 pagesPaper Battery Seminar Report: Lightweight Power for IoT DevicesIshuNo ratings yet

- Solar Mobile Charger PDFDocument29 pagesSolar Mobile Charger PDFAayush guptaNo ratings yet

- Types of PV SystemsDocument10 pagesTypes of PV SystemsShivan MaharajNo ratings yet

- 6 Seminar Report - 07Document25 pages6 Seminar Report - 07vikasNo ratings yet

- Solar Mobile ChargerDocument39 pagesSolar Mobile ChargerWhada86% (7)

- MPPT Based PV System For Partial ShadingDocument73 pagesMPPT Based PV System For Partial ShadingSwarnav MajumderNo ratings yet

- MPPT Based PV System For Partial ShadingDocument70 pagesMPPT Based PV System For Partial ShadingSwarnav Majumder100% (1)

- Mass. It Is Approximately Equal To: Fig.1: Air Mass. Fig.2: Effect of AMDocument6 pagesMass. It Is Approximately Equal To: Fig.1: Air Mass. Fig.2: Effect of AMSajjad HossainNo ratings yet

- NANOELECTRONICS 1 (2) Seminar ReportDocument31 pagesNANOELECTRONICS 1 (2) Seminar ReportPramod RoyNo ratings yet

- Seminar Report On SolarmobilechargerDocument25 pagesSeminar Report On SolarmobilechargerSujana Suji100% (1)

- Solar Tracking System Increases PV Panel EfficiencyDocument17 pagesSolar Tracking System Increases PV Panel Efficiencysaga xNo ratings yet

- Thesis On Solar Power ProjectDocument113 pagesThesis On Solar Power ProjectYatheesh KaggereNo ratings yet

- Solar TreeDocument20 pagesSolar TreepavanNo ratings yet

- The Physics of Photovoltaics: An Analysis of Solar Panel Cost, Effectiveness and EfficiencyDocument26 pagesThe Physics of Photovoltaics: An Analysis of Solar Panel Cost, Effectiveness and Efficiencyraj1090No ratings yet

- Abstract of Solar CellDocument7 pagesAbstract of Solar CellnuraleeeNo ratings yet

- Solar Battery ChargerDocument32 pagesSolar Battery Chargerapi-298102482No ratings yet

- Solar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaDocument40 pagesSolar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaMr. K.S. Raghul Asst Prof MECHNo ratings yet

- An Introduction to Solar Tracking SystemsDocument35 pagesAn Introduction to Solar Tracking SystemspawantwrNo ratings yet

- Report On Solar PV TechnologiesDocument16 pagesReport On Solar PV Technologiessagar paneliyaNo ratings yet

- Triboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsDocument25 pagesTriboelectric Nanogenerators As New Energy Technology For Self-Powered Systems and As Active Mechanical and Chemical SensorsAnonymous AEicha08AF100% (1)

- Solar Photovoltaic SystemDocument60 pagesSolar Photovoltaic SystemUmeshNo ratings yet

- Cis Cigs Solar Cells3102Document26 pagesCis Cigs Solar Cells3102malika_83No ratings yet

- Akshay Prakash - Technical Seminar-FINAL-1Document28 pagesAkshay Prakash - Technical Seminar-FINAL-1Yashpreet B Voladoddi Dept of AI & MLNo ratings yet

- Seminar ReportDocument35 pagesSeminar Reporttanya RankawatNo ratings yet

- Group - 5 Project ReportDocument25 pagesGroup - 5 Project ReportSpace TechNo ratings yet

- Chromatpgraphy: Ms - Heena GoswamiDocument63 pagesChromatpgraphy: Ms - Heena GoswamiAaryana Anand100% (1)

- 4051BD DatasheetDocument6 pages4051BD DatasheetPowerLedPC Servicio Tecnico ElectronicoNo ratings yet

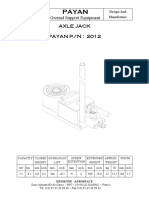

- Payan: Axle Jack PAYAN P/N: 2012Document38 pagesPayan: Axle Jack PAYAN P/N: 2012gmailNo ratings yet

- CV Ankit Gupta Manager DelhiDocument2 pagesCV Ankit Gupta Manager DelhiAnkit GuptaNo ratings yet

- History of Computer: Basic Computing Periods: Week 3 Living in The IT Era Maria Michelle VinegasDocument41 pagesHistory of Computer: Basic Computing Periods: Week 3 Living in The IT Era Maria Michelle VinegasMary Ianne Therese GumabongNo ratings yet

- RQ2203056Document1 pageRQ2203056suryaNo ratings yet

- Ajcpath140 0193Document10 pagesAjcpath140 0193Marinelle TumanguilNo ratings yet

- Dr. Vijaya Khader Dr. MC Varadaraj: Development TeamDocument9 pagesDr. Vijaya Khader Dr. MC Varadaraj: Development TeamKanchanNo ratings yet

- History and Working Principle of CNC MachinesDocument308 pagesHistory and Working Principle of CNC MachinesYash IngleNo ratings yet

- Translation Quality Assessment of Google Translate From English To KinyarwandaDocument64 pagesTranslation Quality Assessment of Google Translate From English To Kinyarwandanelmushimiyimana77No ratings yet

- JK Water Leaks AllDocument144 pagesJK Water Leaks Allkacos2000100% (5)

- S1 Hyd Thrust T+answersDocument22 pagesS1 Hyd Thrust T+answersprabathiyaNo ratings yet

- Manual LeTourneau L1850 Wheel Loader Rear Mounted StairwayDocument32 pagesManual LeTourneau L1850 Wheel Loader Rear Mounted StairwayRajeev PatelNo ratings yet

- Basic Numerical Skills MCQs set-1Document5 pagesBasic Numerical Skills MCQs set-1VenkataRamana IkkurthiNo ratings yet

- Ethereum Bányász KalkulátorDocument114 pagesEthereum Bányász KalkulátorKristóf KormányNo ratings yet

- Scheme of Work Form 2 English 2017Document8 pagesScheme of Work Form 2 English 2017Atikah AmaranNo ratings yet

- 01 03 01 Coolant TR0199 99 2091 enDocument18 pages01 03 01 Coolant TR0199 99 2091 enNelliNo ratings yet

- Benbri ProfileDocument32 pagesBenbri ProfileOlusola OluwaseunNo ratings yet

- Merge PDF Files Online. Free Service To Merge PDF - IlovepdfDocument3 pagesMerge PDF Files Online. Free Service To Merge PDF - IlovepdfAMIR RAZANo ratings yet

- Application Controls: Batch Processing Application AuditDocument34 pagesApplication Controls: Batch Processing Application AuditYanYan YumulNo ratings yet

- AtardecerDocument6 pagesAtardecerfranklinNo ratings yet

- 06.01.2021.warehouse ManagementDocument29 pages06.01.2021.warehouse ManagementArham OrbNo ratings yet

- Shell Mysella S6 N 40Document2 pagesShell Mysella S6 N 40Muhammad SaputraNo ratings yet

- Studi Pengaruh Waktu Pembakaran Terhadap Kuat Tekan BataDocument12 pagesStudi Pengaruh Waktu Pembakaran Terhadap Kuat Tekan BataIcha ChairunNo ratings yet

- PrePoMax-v1 3 3-ManualDocument43 pagesPrePoMax-v1 3 3-ManualMarcelo ResendeNo ratings yet

- Covid 19 ImpactDocument38 pagesCovid 19 ImpactNavneet NandaNo ratings yet

- Surface Vehicle Recommended PracticeDocument12 pagesSurface Vehicle Recommended Practiceferhat aydoganNo ratings yet

- Surface roughness modelling in super duplex stainless steel turningDocument16 pagesSurface roughness modelling in super duplex stainless steel turningfatinNo ratings yet

- Image Stitching Using Matlab PDFDocument5 pagesImage Stitching Using Matlab PDFnikil chinnaNo ratings yet

- ABB Electronic Protection DeviceDocument8 pagesABB Electronic Protection DeviceEl Haj BenazzouzNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Complete Electronics Self-Teaching Guide with ProjectsFrom EverandComplete Electronics Self-Teaching Guide with ProjectsRating: 3 out of 5 stars3/5 (2)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Winning in 2025: Digital and Data Transformation: The Keys to SuccessFrom EverandWinning in 2025: Digital and Data Transformation: The Keys to SuccessNo ratings yet

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Foundations of Western Civilization II: A History of the Modern Western World (Transcript)From EverandFoundations of Western Civilization II: A History of the Modern Western World (Transcript)Rating: 4.5 out of 5 stars4.5/5 (12)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)