Professional Documents

Culture Documents

An Falla Ac Discos

Uploaded by

Freddy Arratia HerreraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Falla Ac Discos

Uploaded by

Freddy Arratia HerreraCopyright:

Available Formats

® Failure Analysis • Installation & Maintenance

a good name in industry Freedom Disc Couplings (Page 1 of 4)

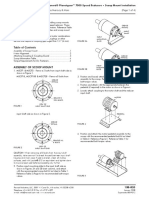

TABLE OF CONTENTS DETECTION

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1 A disc coupling is easily inspected. Visual analysis may point

General Information . . . . . . . . . . . . . . . . . . . . . . . . . Page 1 to possible drive system problems. Proper evaluation of the

Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1 disc packs and connecting parts may save considerable

Detection of Disc Pack Trouble . . . . . . . . . . . . . . . . . . Page 1 maintenance costs and downtime. When a multiple blade disc

Analysis of Failed Disc Couplings . . . . . . . . . . . . . . . . Page 2 coupling starts to fail, it is usually from the outer disc of the

Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4 laminated pack and progresses towards the center of the

pack. See Figure 1.

INTRODUCTION

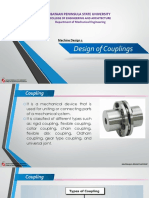

A disc coupling serves as a mechanical device, which

connects shafts of two separate machines and accommodates

small amounts of shaft misalignment. The purpose of this

manual is to review the areas in which disc couplings have

experienced difficulties and to identify the various types and

probable causes of failures.

Figure 1

N-HUB N-HUB Because of this progression, the deterioration of the disc pack

A D may be detected before ultimate failure.

DETECTION OF DISC PACK TROUBLE (with

guard removed and equipment not in service)

NOTE: Disc pack trouble can also be detected when the

equipment is in operation, such as with a strobe light.

C BE C However, the use of mirrors or a protective shield such as

plexiglass should be placed between the coupling and the

observer.

GENERAL INFORMATION The following are some of the more evident visual inspection

A flexible disc coupling is designed for long life when criteria and recommended corrective procedures.

operated within the torque and alignment limits as set forth in

the catalog and installation instructions. The information 1. Fine line cracking starting in the outer disc, tangent to the

provided here may also be used for visual determination of washer O.D. This is an indication of misalignment and can

the condition of the disc packs. be seen by looking at the outside edge of the disc pack.

The installation of a flexible disc coupling is critical. Various Misalignment can be caused by any combination of the

problems could arise during mounting of the hubs and the following: angular, parallel, and axial.

coupling assembly process. Burrs, dirt, and grit on either the 2. Reddish brown color bleeding out between disc laminations

shaft or in the bores can cause the hubs to gall during at the O.D. of the disc packs. This is an indication of

mounting. Poorly fitted keys can also gall and not seat fretting and/or chemical attack of the disc material. This is

correctly. more prevalent in Type FD style disc coupling as the Type

Concentrated heat on the hubs will cause distortion. The FDP disc pack has thin shims separating the individual

coupling must be properly assembled and the locknuts discs to prevent fretting corrosion, however this may be

tightened in accordance with the installation instructions. observed on the Type FDG/FDP packs due to chemical

Loose bolts will cause elongation of the disc bolt holes and attack.

eventual failure of the discs or the bolts.

3. Disc pack is wavy and dimension between flange faces is

The most common form of failure in disc couplings is fatigue either smaller or larger than indicated in the installation

due to excessive disc flexure. This is usually caused by poor

instructions or applicable assembly drawing. This indicates

initial alignment of the connected machines. It also can be

that the coupling has been installed in a compressed

brought about by operational conditions. The following

discussion presents some ideas to assure that the coupling is condition (smaller dimension) or in an elongated position

operating satisfactorily. (larger dimension). This could also indicate that the

equipment has shifted closer or further apart axially during

operation. Check for shaft thermal growth conditions.

Realign axial position of equipment so the coupling

operates with a neutral, flat disc pack.

The Falk Corporation, P.O. Box 492, Zip 53201-0492 478-980

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131 April 2004

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com NEW

Installation & Maintenance • Failure Analysis ®

(Page 2 of 4) Freedom Disc Couplings a good name in industry

4. Disc packs (both ends) are wavy. One end is compressed,

and the other end is elongated. Moving the center member HOLE ELONGATION

towards the elongated end can reverse the conditions. This CRACK

is called “oil canned” disc packs. The disc pack has no

neutral center where it remains flat and parallel with the

end flanges.

This condition can be the result of:

1) Tightening the disc pack locknuts while the disc packs

are in the compressed or elongated position, such as

assembling adapter couplings in a vertical condition on

a bench. The spacer weight can compress the lower

disc pack and the adapter weight can compress the Figure 2

upper disc pack. This can also occur when installing a

spacer or floating shaft coupling in a vertical 2. Individual discs from a Type FDG disc pack or the bushing

application without supporting the spacer. unitizing the Type FDP disc pack embedded into a bolt

2) Tightening of disc pack locknuts while coupling is body is usually the result of a loose bolt or a severe torque

misaligned or other end of spool is hanging overload. See Figure 3.

unsupported.

3) Bound up bolt(s) in the bolt hole(s).

4) Damaged discs, which could be caused by abnormal

running conditions, misuse or loose bolts.

To correct “oil canned" disc packs:

1) Loosen all the disc pack locknuts. Correct the axial

spacing of the coupling as necessary with the coupling

aligned and spacer fully supported. If “oil canned”

conditions disappear, retorque locknut while coupling is

in its neutral position.

2) If (1) above is not successful, determine that all bolts,

with locknuts loose, can be turned by hand. If any bolts

are tight, the bolt holes should be cleaned out by lightly

reaming the flange so that the bolt turns by hand in the

Figure 3

hole. Reassemble and torque the locknuts while

coupling is in its neutral position.

3) If the discs in the pack are permanently deformed, A bolt failure such as in Figure 3 can also occur with a

replace the disc pack with a new one and reassemble loose bolt, which may show no apparent damage to the

the coupling. A severe torque overload, abnormal axial disc pack. Replace the bolt and disc pack. Tighten the

loads, or even loose bolts could cause this permanent locknuts to the proper torque. Try to avoid torquing the bolt

deformation. The cause of the deformation must be through the head as insufficient bolt stretch may occur and

corrected before restart. there is a possibility of galling the bolt in the bolt hole. See

The coupling, as finally assembled, should have a neutral Figure 4 for an example of a failed Type FDG disc and bolt

center where the center member is free to float axially without due to a loose bolt or severe torque overload.

snapping from one end to the other when moved by hand.

ANALYSIS OF FAILED DISC COUPLINGS

In the event of a coupling failure, a thorough investigation

should be made to determine the cause. The most common

causes of failure are improper coupling selection, improper

assembly, excessive misalignment, and corrosive attack:

1. Disc broken through the bolt hole indicates loose coupling

bolts. See Figure 2. Replace disc pack and tighten locknuts

to specified torque value. Note: Type FD bolts are “oiled” Figure 4

and Type FDG/P bolts are not.

478-980 The Falk Corporation, P.O. Box 492, Zip 53201-0492

April 2004 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

NEW Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

® Failure Analysis • Installation & Maintenance

a good name in industry Freedom Disc Couplings (Page 3 of 4)

An example of a bolt that has been embedded by a disc pack yields where a slight opening as in Figure 8 may

bushing in a Type FDP disc pack can be seen in Figure 5. be observed. This indicates improper coupling selection or

a momentary system torque overload.

Figure 5

3. Discs broken adjacent to the washer face usually indicates

excessive shaft misalignment during operation. See Figure 6.

This type of disc failure usually starts with the outer disc and

progresses inward through the disc pack. Realign equipment Figure 8

and replace both disc packs. Make hot check of alignment

to assure it is within coupling misalignment capacity. If a bulged or bowed condition appears in only one

chordal section, there may be a loose bolt on one side of

CRACK

the distortion. Loosen all coupling locknuts and unseat the

bolts. The bulge should release and flatten out. Retorque

locknuts. If distortion does not disappear, replace disc pack

and retorque locknuts.

Note: During normal operation, a slight opening may be

observed in the compressed leg. This should not be a

cause for concern. However, openings should not be

observed in the tensile leg.

6. Occasionally a Freedom disc coupling hub shank failure is

encountered. These failures generally consist of cracks

Figure 6 extending through the hub shank at a keyway corner or

through a set screw if one is used. See Figure 9.

4. Disc broken adjacent to washer face with fretting corrosion

present in the area of crack usually indicates excessive

shaft misalignment during operation. Also, iron oxide will

most likely be evident on the outside of disc pack. See

Figure 7.

CRACK CORROSION

Figure 7

5. The disc pack has a severe bulge near the center or is

bowed toward one flange in alternate chordal sections,

which are the compression link(s). See Figure 8. Figure 9

This condition is a result of a large torque overload

induced into the system, beyond the peak overload

capacity of the coupling. The remaining disc pack chordal

sections, tension links, will be straight and tight until the

The Falk Corporation, P.O. Box 492, Zip 53201-0492 478-980

3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone : 414-342-3131 April 2004

Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com NEW

Installation & Maintenance • Failure Analysis ®

(Page 4 of 4) Freedom Disc Couplings a good name in industry

It is possible to have disc coupling hubs fail over the

keyway from a combination of hoop stress produced by

an interference fit and a high tensile stress as a result of

excessive torque loads transmitted through the key.

These types of failures can also be traced to poor

installation practices, such as hubs forced onto shaft radii,

keys oversize for hub or shaft keyways, set screws being

tightened on hot hubs used for interference fits, or

excessive interference fit between shaft and hub. This type

of failure will typically occur if the conditions are right at or

near maximum published bores. In order to prevent hub

fractures, it is necessary that couplings be selected using

the proper service factor for the application based on

motor capacity. If a brake is involved in the system, then

the coupling should be selected on the brake capacity.

SUMMARY

The Falk Corporation disc couplings are designed for infinite

life. They must be properly selected, installed and aligned to

assure reliable service. Because of the design principle,

catastrophic failures are very rare. One final thing that we

would like to stress is that disc packs, bolts, and washers

cannot be substituted for “standard” off the shelf components.

The components in Falk disc couplings are made to tight

tolerances and the use of unspecified or off the shelf

components will lead to coupling failure.

478-980 The Falk Corporation, P.O. Box 492, Zip 53201-0492

April 2004 3001 W. Canal St., Zip 53208-4200, Milwaukee, WI USA Telephone: 414-342-3131

NEW Fax: 414-937-4359 e-mail: falkinfo@falkcorp.com web: www.falkcorp.com

You might also like

- Manual Técnico de Bomba Vertical SCHURCODocument45 pagesManual Técnico de Bomba Vertical SCHURCOJuan J Sierra100% (1)

- Turbine Overhauling ProceduresDocument75 pagesTurbine Overhauling ProceduresShankar Jha100% (1)

- Pump ManualDocument42 pagesPump Manualnelforu100% (2)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- SRL CompressorsDocument20 pagesSRL Compressorssthe03No ratings yet

- 45 Series E Frame Service Manual (520L0606 REV A)Document28 pages45 Series E Frame Service Manual (520L0606 REV A)Sasko Dimitrov100% (1)

- Coupling NBKDocument5 pagesCoupling NBKrahmanfaham100% (1)

- Pioneer Avic-N4 x3 crt3971 SM (ET)Document296 pagesPioneer Avic-N4 x3 crt3971 SM (ET)Handy HandNo ratings yet

- Monitoring Thomas Disc CouplingsDocument4 pagesMonitoring Thomas Disc CouplingsEdgar CanelasNo ratings yet

- Installation Instructions: Installation Instructions For Type SK - U Rupture Disk and Union UR Safety HeadDocument4 pagesInstallation Instructions: Installation Instructions For Type SK - U Rupture Disk and Union UR Safety HeadJulio Cesar ReyesNo ratings yet

- Rupture Disk PDFDocument12 pagesRupture Disk PDFTushar LanjekarNo ratings yet

- Disc Couplings - Failure AnalysisDocument4 pagesDisc Couplings - Failure Analysisfuzhi2016No ratings yet

- Toshiba VTD2032Document66 pagesToshiba VTD2032thomas-stentzelNo ratings yet

- Toshiba VTD1552Document65 pagesToshiba VTD1552thomas-stentzelNo ratings yet

- Preparation and Installation of The ULTRX HP (DD) Rupture Disc / ULTRX Double Disc Holder AssemblyDocument6 pagesPreparation and Installation of The ULTRX HP (DD) Rupture Disc / ULTRX Double Disc Holder AssemblyPaul LauNo ratings yet

- Pioneer DVH 335u, DVH 3390ubDocument124 pagesPioneer DVH 335u, DVH 3390ubnikola1660No ratings yet

- Features: Clarion Product Registration InformationDocument36 pagesFeatures: Clarion Product Registration InformationDanaandJune LelandNo ratings yet

- EN23193 442C BrochureDocument5 pagesEN23193 442C Brochuresf wNo ratings yet

- Problem With Disk Pack CouplingDocument4 pagesProblem With Disk Pack CouplingMiguelNo ratings yet

- Toshiba VTD1551Document65 pagesToshiba VTD1551thomas-stentzelNo ratings yet

- Toshiba VTD1432Document66 pagesToshiba VTD1432thomas-stentzelNo ratings yet

- Service Manual: HCD-V8800Document88 pagesService Manual: HCD-V8800RidwanNo ratings yet

- Avh P5150DVDDocument204 pagesAvh P5150DVDJosé Cavalcanti Da RéNo ratings yet

- Pioneer Avh-P3100dvd p3150dvd SMDocument190 pagesPioneer Avh-P3100dvd p3150dvd SMRogerio E. SantoNo ratings yet

- Deh 20 UbDocument73 pagesDeh 20 UbDimitar MirchevNo ratings yet

- Disc Coupling Installation and Maintenance GuideDocument4 pagesDisc Coupling Installation and Maintenance Guidemarcelo castilloNo ratings yet

- Pelco DX4000 Hard Drive ReplacementDocument12 pagesPelco DX4000 Hard Drive Replacementseanll2563No ratings yet

- Pioneer Avh-P4150dvd SM PDFDocument200 pagesPioneer Avh-P4150dvd SM PDFAnd BNo ratings yet

- Pioneer Dvh-3150ub Dvh-3190ub Crt4283 Car DVD RecieverDocument128 pagesPioneer Dvh-3150ub Dvh-3190ub Crt4283 Car DVD Recievergebapo100% (1)

- Crimping Die Assemblies 58166 - For Shielded Data Link (SDL) ConnectorsDocument5 pagesCrimping Die Assemblies 58166 - For Shielded Data Link (SDL) ConnectorszavabossNo ratings yet

- Avhp 5150 DVDXNRCDocument204 pagesAvhp 5150 DVDXNRCccoakxeikibdxayqvxNo ratings yet

- Pioneer Deh-50ubDocument72 pagesPioneer Deh-50ubFazier3548100% (2)

- Kenwood KDC-BT50U, KDC-5047U, KMR-440UDocument60 pagesKenwood KDC-BT50U, KDC-5047U, KMR-440UMikeNo ratings yet

- Assembly Guidelines For QFN (Quad Flat No-Lead) and DFN (Dual Flat No-Lead) PackagesDocument33 pagesAssembly Guidelines For QFN (Quad Flat No-Lead) and DFN (Dual Flat No-Lead) PackagespadrititaNo ratings yet

- Audiovox Rampage ACC-56 OM IMDocument20 pagesAudiovox Rampage ACC-56 OM IMRyan OfstieNo ratings yet

- NVR Quick Start Guide BDDocument2 pagesNVR Quick Start Guide BDlakhtenkovNo ratings yet

- Barracuda 9 Disc Drive ST19171N/W/WD/WC/DC: Installation GuideDocument48 pagesBarracuda 9 Disc Drive ST19171N/W/WD/WC/DC: Installation GuidetimannokaffNo ratings yet

- MDX Ca580Document152 pagesMDX Ca580Олексій РапінчукNo ratings yet

- pioneer_deh-5300_5350ubDocument66 pagespioneer_deh-5300_5350ubrudineimarafonNo ratings yet

- EK IM Notice Montage EKwaterblock CPUDocument13 pagesEK IM Notice Montage EKwaterblock CPUMaphteachNo ratings yet

- Kpijci ft4240Document6 pagesKpijci ft4240HéctorNo ratings yet

- Deh 2150ubDocument73 pagesDeh 2150ubCm ElectronicaNo ratings yet

- 267 4010 Kenwood KDC 105u ManualDocument32 pages267 4010 Kenwood KDC 105u ManualDeusvaldir Luiz MachadoNo ratings yet

- DPX-5050 DPX-5030 DPX-4020: Instruction ManualDocument40 pagesDPX-5050 DPX-5030 DPX-4020: Instruction ManualChinoMorenoNo ratings yet

- Installation / Wire Connection Guide: Before StartingDocument9 pagesInstallation / Wire Connection Guide: Before StartingDario Eyner Choque CastroNo ratings yet

- Samsung Dvd-V3650 Chassis Diva Training ManualDocument202 pagesSamsung Dvd-V3650 Chassis Diva Training ManualPaulo Henrique SNo ratings yet

- Installation PracticeDocument16 pagesInstallation PracticeramsesiNo ratings yet

- KRC-266 KRC-266S: Instruction ManualDocument21 pagesKRC-266 KRC-266S: Instruction ManualIan HughesNo ratings yet

- pioneer_deh-73_7300_7350btDocument76 pagespioneer_deh-73_7300_7350btrudineimarafonNo ratings yet

- CDP Xe510Document32 pagesCDP Xe510VladTănaseNo ratings yet

- Manual KenwoodDocument26 pagesManual KenwoodImam MuchtarNo ratings yet

- JVC Car Stereo System KD-R326Document18 pagesJVC Car Stereo System KD-R326Dwi AntoNo ratings yet

- Pioneer Avic d1Document276 pagesPioneer Avic d1Barbossa Jack SparrowNo ratings yet

- Pioneer Avh p4100dvdDocument204 pagesPioneer Avh p4100dvdsatinmarkNo ratings yet

- Instructions: DVD/CD Receiver KD-ADV6270/KD-DV6200Document135 pagesInstructions: DVD/CD Receiver KD-ADV6270/KD-DV6200José olivaNo ratings yet

- Deh 5250SDDocument80 pagesDeh 5250SDAnderson Azevedo MarquesNo ratings yet

- pioneer_dvh-p4150ub_dvh-p4190ub_crt4282_car_dvd_receiverDocument128 pagespioneer_dvh-p4150ub_dvh-p4190ub_crt4282_car_dvd_receiverAquino Sound EletrônicaNo ratings yet

- 53a39340587a3 (Kenwood KDC-MP102U)Document44 pages53a39340587a3 (Kenwood KDC-MP102U)Rox DiazNo ratings yet

- Instruction Manual: Optical Fiber Fusion SplicerDocument52 pagesInstruction Manual: Optical Fiber Fusion SplicerWiliam Alves de SalesNo ratings yet

- Installation Instructions: and Owners ManualDocument12 pagesInstallation Instructions: and Owners ManualPedroni Jair PedroniNo ratings yet

- Manufacturing Design Checklist Updated 03-26-07Document23 pagesManufacturing Design Checklist Updated 03-26-07abhi_cat16No ratings yet

- 05 rm4 DisassyDocument10 pages05 rm4 Disassyme academyNo ratings yet

- Handbook of 3D Integration, Volume 1: Technology and Applications of 3D Integrated CircuitsFrom EverandHandbook of 3D Integration, Volume 1: Technology and Applications of 3D Integrated CircuitsPhilip GarrouNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- Gain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipFrom EverandGain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipNo ratings yet

- Large Gear Drives: A Good Name in IndustryDocument8 pagesLarge Gear Drives: A Good Name in IndustryFreddy Arratia HerreraNo ratings yet

- Sizes Mercury & Mars (Page 1 of 4) : Figure 3ADocument4 pagesSizes Mercury & Mars (Page 1 of 4) : Figure 3AFreddy Arratia HerreraNo ratings yet

- An Falla Ac SteelFlexDocument8 pagesAn Falla Ac SteelFlexFreddy Arratia HerreraNo ratings yet

- An Falla Ac G20Document7 pagesAn Falla Ac G20Freddy Arratia HerreraNo ratings yet

- Keys, Couplings, and Design CalculationsDocument39 pagesKeys, Couplings, and Design CalculationsJerricho De CastroNo ratings yet

- Coupling Catalog PDFDocument22 pagesCoupling Catalog PDFManick Raj JNo ratings yet

- Select the Correct Bell-Housing and Drive CouplingDocument26 pagesSelect the Correct Bell-Housing and Drive CouplingFernando FernandezNo ratings yet

- 14W4 Ipc Motor Rev 3 15dic2001Document556 pages14W4 Ipc Motor Rev 3 15dic2001fredy SanchezNo ratings yet

- Pres NeoDocument52 pagesPres Neonikko50% (2)

- Fire Protection ServicesDocument10 pagesFire Protection ServicesHeyaStanNo ratings yet

- GREENLEE Hyd Punch DriverDocument10 pagesGREENLEE Hyd Punch Driverfafejaya13No ratings yet

- TLD WSP-900 Water Truck SpecsDocument2 pagesTLD WSP-900 Water Truck SpecsPhat DinhNo ratings yet

- TUTORIAL 3 Design of Shaft Key and CouplingDocument2 pagesTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- Mech 3 Module 3 Unit 2 (Flanged Bolt Couplings)Document11 pagesMech 3 Module 3 Unit 2 (Flanged Bolt Couplings)Seusthe Narag CabadolNo ratings yet

- AL-KOmatic AL-KOmatic Service HandbookDocument72 pagesAL-KOmatic AL-KOmatic Service Handbookvali_monroe100% (1)

- ME 363 Mechanical of Machinery Lab Semester: 422: Report #1: Hook's CouplingDocument11 pagesME 363 Mechanical of Machinery Lab Semester: 422: Report #1: Hook's CouplingAyoub MohamedNo ratings yet

- Manual GeislingerDocument36 pagesManual GeislingerEge CNo ratings yet

- QuickFlex Coupling CatalogDocument68 pagesQuickFlex Coupling CatalogRiaz EbrahimNo ratings yet

- 6 Coup LNGDocument57 pages6 Coup LNGVIJIOCLNo ratings yet

- Speed Monitor Swe-Compact: Opto-ElectronicDocument6 pagesSpeed Monitor Swe-Compact: Opto-ElectronicRenzo Malcolm Garcia PickmannNo ratings yet

- Martin Flexible Couplings CatalogDocument37 pagesMartin Flexible Couplings CatalogJean CarlosNo ratings yet

- Flowtite GRP Non-Pressure Pipe Systems: Technical Product DataDocument52 pagesFlowtite GRP Non-Pressure Pipe Systems: Technical Product Datakimik47No ratings yet

- Mechanical EngineeringDocument132 pagesMechanical EngineeringKarl KaushalNo ratings yet

- Rotary Tillers: RTA2064, RTA2072, RTR2064 & RTR2072Document28 pagesRotary Tillers: RTA2064, RTA2072, RTR2064 & RTR2072JRNo ratings yet

- Machine Design 1 - Coupling DesignDocument15 pagesMachine Design 1 - Coupling DesignBRYAN PINGOLNo ratings yet

- Variable Speed Fluid CouplingsDocument22 pagesVariable Speed Fluid Couplingsalex24arulNo ratings yet

- Installation Manual: Families BW 190 BW 250 BW 360 BW 460 BW 750Document124 pagesInstallation Manual: Families BW 190 BW 250 BW 360 BW 460 BW 750Sam Running BearNo ratings yet

- CatalogoDocument300 pagesCatalogotecnicoNo ratings yet