Professional Documents

Culture Documents

Analysis Guide For Machine Designers: White Paper

Uploaded by

Khalid KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis Guide For Machine Designers: White Paper

Uploaded by

Khalid KhanCopyright:

Available Formats

ANALYSIS GUIDE FOR

MACHINE DESIGNERS

White Paper

SUMMARY

This guide describes the key design performance issues facing machine designers

and manufacturers, and identifies the benefits of using SOLIDWORKS® analysis

software in the product development cycle. SOLIDWORKS software can be applied

to almost any machine design field, from automation tooling to wrapping machines,

to analyze a broad range of concerns. Its powerful analysis types—static, motion,

thermal, vibration, fluid-flow, and nonlinear—will ensure that your product meets

design requirements and is reliable in the field.

Analysis Guide for Machine Designers 1

INTRODUCTION

Analysis and simulation software is an indispensable tool in the development of large-scale

machinery. These tools allow the developer to evaluate designs early in the design cycle,

determine causes of premature failures in the field, quickly explore design changes aimed at

reducing cost and weight, and determine the product’s factor of safety. Use of analysis tools is

of particular value to machine designers due to the size and complexity of the systems they are Analysis tools can identify

developing. Analysis tools can identify design issues that may elude a designer’s review simply design issues that may elude a

because of the dynamic nature of machinery’s many moving parts. designer’s review simply because

of the dynamic nature of

machinery’s many moving parts.

Figure 1: Inner arm of robot designed by Fanuc Robotics

The unyielding demands upon machinery manufacturers by customers and the market to create

systems that are cheaper, more reliable, and more productive necessitate that companies that

wish to remain successful utilize all the tools available to them. These analysis tools reduce product

development costs through a reduction of late engineering changes. They ensure products reach

the market promptly, allowing the product to capture the largest piece of the market possible.

Finally, it allows engineers to experiment with materials and designs that can result in products

of minimal weight and cost. Analysis software enables engineers to simulate design performance

and identify and address potential design problems before prototyping and production.

ANALYSIS AT THE FOREFRONT OF MACHINE DESIGN

PRODUCT DEVELOPMENT

Regardless of the specific application, machine designers are under pressure from their

customers: increase reliability and longevity; be quicker to market with new, improved products;

reduce product weight and cost; and increase productivity. Working in this type of environment,

engineers have little time to produce multiple prototypes and use trial and error to gain a better

understanding of the physical behavior of their designs. Yet, that information is vital for producing

innovative, high-quality products.

Figure 2: Fanuc Robotics takes full advantage of solid modeler in SOLIDWORKS Simulation.

Analysis tools help machine designers understand the physical behavior of their designs quickly

without resorting to expensive prototypes and physical tests that extend the product design cycle.

Analysis tools can substantially reduce the number of ECOs, missed deadlines due to redesigns

late in the design cycle, and costly redesigns at manufacturing time. All of these markedly

decrease development costs and time-to-market. Further, these tools increase communication

between design, sales, marketing, manufacturing, and the customer through their easy-to-read

and -understand graphical results.

Analysis Guide for Machine Designers 1

APPLICATION AREAS

• Production Equipment: Hallmark Cards, food production

• Industrial Robots and Robotic Systems: design optimization, failure analysis

• Industrial Food Machinery

• Packaging Equipment

• Electromechanical Systems: heating

• Printed Circuit Boards: semiconductors, heat sinks, MEMS

• Cooling Systems: fans, motors, air flows

• Electronic Systems: antennas, transmitters, switches

• Automation Tooling

• Aerating Machines, for beverages

• Bag Opening, Filling, and Closing Machines

• Bottling Machinery: washing, sterilizing, filling, capping, and labeling

• Bread-wrapping Machines

• Carton-packing Machines

• Label Moisteners, industrial type

• Labeling Machinery, industrial type

• Wrapping Machines

SCOPE OF ANALYSIS

• Design verification/validation: Will this design work? Will this design behave

the way I think it will?

• Relative merit: Which of these candidate designs is the best? How can

I weed out and eliminate poor-functioning designs?

• Proof of concept: Testing radical new concepts without producing prototypes

• Durability and reliability: Fatigue/failure analysis, drop tests, shake

simulations

TIGHT INTEGRATION WITH 3D CAD

The SOLIDWORKS 3D CAD software system, the standard for 3D design, is tightly integrated

with all major CAD software. This means that engineers can use SOLIDWORKS analysis Using computational model and

software directly on the CAD model and do not need to remodel designs to take advantage of analysis software to perform

analysis technology. “what if” evaluations saves time

and money and can help to

improve design performance.

Figure 3: Hallmark Cards designs card-manufacturing machinery using SOLIDWORKS Simulation.

Analysis Guide for Machine Designers 2

“WHAT IF” STUDIES

A clear advantage of performing “virtual” testing using computer simulations over physical

testing, beyond the cost and time savings, is the ability to quickly compare many designs

incorporating different materials, part geometries, assembly configurations, subsystems, and

more. Using analysis to conduct “what if” studies—what if I tried this material, or what if I used

this type of mechanism—can help engineers identify the best material and mechanical design

for a particular function. Using computational model and analysis software to perform “what

if” evaluations saves time and money and can help to improve design performance. By coupling

analysis studies with Configuration Management, the designer can quickly converge on the best-

form design solution over many degrees of freedom.

Figure 4: Modular and custom air handlers are ideal products for analysis because they must be able to heat, cool, humidify, and dehu-

midify air as well as filter particles.

POWERFUL ANALYSIS TYPES—STATIC, MOTION, THERMAL, VIBRATION,

FLUID-FLOW, NONLINEAR

Machine designers must work with systems of amazing complexity and variability.

The kinematics and dynamics of all of the system’s moving parts and their potential for

interference requires a great amount of design effort. Thermal effects of the heat-producing Companies that use analysis

components upon the rest of the systems can be difficult to predict and design around. Vibration to address these issues at

and other structural issues can lead to part failures, poor performance, and other operational the design state develop a

issues. Companies that use analysis to address these issues at the design state develop a clear clear advantage over

advantage over their competitors. SOLIDWORKS analysis software helps to ensure that these their competitors.

considerations are addressed early in the product development cycle, enabling manufacturers to

accelerate time-to-market and reduce development costs while producing higher-quality products

with fewer warranty issues. Using a range of analysis technologies, SOLIDWORKS software helps

engineers to ensure that a product’s behavior will be within design limits, reliable, and free of the

risk of thermal, electromagnetic, or stress-induced failures.

Figure 5: Calculating the critical forces of a roller on a sheeter head takes just minutes for Casa Herrera.

Analysis Guide for Machine Designers 3

• Static analysis is a tool that empowers the machine designer to avoid catastrophic immediate

or long-term failure modes and determine if redesign of one or more of the core elements

is necessary. Designers can study the stresses or deflections in the device and compare it

against allowable levels to predict failure. SOLIDWORKS Simulation has the ability to analyze

shells using SOLIDWORKS software surfaces and by extracting mid surfaces of thin-walled

structures, particularly useful in machines that incorporate sheet metal in their designs.

Through static analysis, designers can optimize geometries, minimize weight and material

usage, and determine the factor of safety built into each of their machines.

• Motion analysis is also extremely valuable in the development of machinery in that machines

are, by their nature, extremely complex, dynamic assemblies. Running motion analysis

allows designers to perform “virtual testing” before manufacturing physical prototypes,

saving time and money during the iterative design cycle. Changes prior to “cutting metal”

are far cheaper and quicker to enact. Motion analysis allows the designer to learn more about

the machinery in the concept phase and perform dynamic interference detection prior to

building engineering models.

• Thermal analysis is critically important in machine design. Managing temperature, whether

it’s of printed circuit boards, mechanical devices, or of fluidic systems can be an important Using SOLIDWORKS Simulation

design challenge that an engineer must overcome. SOLIDWORKS Simulation analysis analysis software,

software can perform steady-state or transient thermal analysis on parts or assemblies. After an engineer can simulate

meshing the design, the designer sets any relevant constraints, then sets power or heat flux the natural frequencies of

conditions associated with a geometrical feature of the model. Because component material a part or assembly.

properties include thermal conductivity, coefficient of thermal expansion, and heat capacity,

the designer gets a realistic prediction of temperature distributions under prescribed loads

and operating conditions.

Figure 6: End-of-arm automation tooling designed by Pushcorp, Inc.

• Vibration analysis is valuable in many types of machinery products. Many have motors,

pumps, and other vibration sources that can adversely affect performance of surrounding

electronic and mechanical devices. Optimal performance, with a minimal amount of adverse

effects on these components, requires an understanding of the natural frequencies at which

a component or assembly will vibrate and the impact of any stresses or deflections that may

occur. Using SOLIDWORKS Simulation, an engineer can simulate the natural frequencies of

a part or assembly and use this information to modify the design or materials used to avoid

resonance and deflection in certain areas or improve performance. Random vibration analysis

can also help engineers stiffen electrical systems that are designed to survive earthquakes

and represent a more cost-effective approach than conducting physical shake tests. Analysis

can be used to minimize frequency and vibration to minimize the perturbations’ effects on

the system performance.

Analysis Guide for Machine Designers 4

Figure 7: Neumag improves nozzle design with SOLIDWORKS Flow Simulation.

• Fluid-flow analysis has a number of applications in the machine design domain. Fluid-flow

properties play a large role in heat transfer analysis. Large machinery generally has large Large machinery generally has

heat sources, such as power supplies and motors, that require active cooling. Convective and large heat sources such as power

conjugative heat transfer are dependent on fluid-flow properties. Fluidic systems such as supplies and motors that require

hydraulics can also be modeled and their designs evaluated. This analysis can be used in the active cooling.

design process of fluidic components such as nozzles, valvings, pump systems, and lubrication

systems. Whatever a manufacturer’s analytical needs, SOLIDWORKS Flow Simulation offers

high-powered computational flow dynamics (CFD) analysis for understanding the impact of

fluid flow on temperature in electrical systems.

• Nonlinear analysis gives electronics and electrical product designers the ability to evaluate

product performance within a complex, 3D-simulated environment, giving them a far more

accurate determination of the different factors that may cause a device to fail. Nonlinear

analysis tools are effective for analyzing static and dynamic problems with geometric

and material nonlinearity, hyperelasticity, creep, thermo-plasticity, and viscoelasticity.

SOLIDWORKS Simulation Premium nonlinear analysis software can also analyze nonlinear

contact problems involving surface interactions of models with or without friction.

Figure 8: Cyclonic Inertial Separator by David Rachels and engineering team.

Analysis Guide for Machine Designers 5

ASSEMBLY ANALYSIS

Large-scale assembly analysis is absolutely critical for machinery designers. Industrial machinery by

its nature contains many complex subassemblies of many parts. As such, analysis on machine designs

requires a wide range of attachment, interconnection, and encapsulation methods. Designers require

that analysis run on their parts, subassemblies, and full assemblies. These assemblies can be affected

by heat, pressure, vibration, impacts, and electromagnetic fields at all levels of the design.

Figure 9: Chuck designed by Speedgrip Chuck Inc.

SOLIDWORKS Simulation enables engineers to simulate all of these behaviors by allowing for

the analysis of small or large CAD assemblies. The software allows engineers to assign different

materials to different parts of the assembly and specify how the components will interact with

each other. SOLIDWORKS Simulation assembly gap/contact analysis allows you to simulate

various real-life conditions for large machines.

SOLIDWORKS Simulation

Many of what in the past have been physical tests on large machines can now be moved to

assembly gap/contact analysis

computer simulations. Drop tests, to ensure that shipping does not damage the machinery,

allows you to simulate various

can be performed during the design phase and easier, less costly changes can be made prior to

real-life conditions for

physical prototyping and manufacturing. Thermal analysis can ensure that no components within

large machines.

the system become overheated and can aid in designing appropriate heating and cooling systems

within the machinery. Sources of vibration within a system can be modeled and their effects on

surrounding components studied. This allows for effective isolation systems to be developed early

in the design cycle.

3D VISUALIZATION

SOLIDWORKS Simulation analysis tools enable analysis of machinery and large-scale industrial

products at the component, assembly, and system levels.

• 3D visualization provides a designer with a first check of design intent, proper operation, and

aesthetics as the project develops.

• 3D CAD enables the designer to view a product design from all angles and examine the

internal parts of the product throughout the design process. This gives designers a clear and

accurate review of parts and assemblies early in the design cycle.

• 3D visualization reduces communication and fabrication errors, saving

development time by more effectively conveying design information, so

that designers can find problems early in the design cycle.

• Designers can view the product from all sides and look inside by hiding the outer enclosure

or other parts.

• 3D animations of simulations allow you to see how the machinery functions

in the real world.

• Section plots allow you to see simulation results inside the part and not just

on the surface.

Analysis Guide for Machine Designers 6

or registered trademarks of Dassault Systèmes or its subsidiaries in the U.S. and/or other countries. All other trademarks are owned by their respective owners. Use of any Dassault Systèmes or its subsidiaries trademarks is subject to their express written approval. MKMACWPENG0415

Figure 10: The Johnson Corporation designs systems for process industries.

©2014 Dassault Systèmes. All rights reserved. 3DEXPERIENCE®, the Compass icon and the 3DS logo, CATIA, SOLIDWORKS, ENOVIA, DELMIA, SIMULIA, GEOVIA, EXALEAD, 3D VIA, 3DSWYM, BIOVIA, NETVIBES, and 3DEXCITE are commercial trademarks

DESIGN COMMUNICATION AND COLLABORATION TOOLS

• Section plots allow you to see simulation results inside the part and not just on the surface.

• Collaboration tools offer new ways for machinery designers to work more effectively with

other members of the development team. The ability to share design resources over the Collaboration tools offer new

Internet benefits all machinery designers, from independent consultants to engineers in large ways for machinery designers

multinational corporations. to work more effectively with

other members of the

• SOLIDWORKS Simulation analysis tools allow designers to share analysis results in various

development team.

formats such as:

- HTML reports of analysis results

- VRML files

- AVI files

- SOLIDWORKS eDrawings® files

CONCLUSION

Machinery manufacturers face relentless demands by customers and the market to create

systems that are cheaper, more reliable, and more productive. Companies that wish to

remain successful utilize all the tools available to them. With analysis and simulation tools,

the developer can evaluate designs early in the design cycle, determine causes of premature

failures in the field, quickly explore designs changes aimed at reducing cost and weight, and

determine the product’s factor of safety. Analysis tools are particularly valuable to machine

designers due to the size and complexity of the systems they are developing. SOLIDWORKS

simulation and analysis tools reduce product development costs, ensure products reach

the market promptly, and allow engineers to experiment with materials and designs that

can result in products of minimal weight and cost.

Our 3DEXPERIENCE® platform powers our brand applications, serving 12 industries, and provides a

rich portfolio of industry solution experiences.

Dassault Systèmes, the 3DEXPERIENCE® Company, provides business and people with virtual universes to imagine sustainable innovations. Its

world-leading solutions transform the way products are designed, produced, and supported. Dassault Systèmes’ collaborative solutions foster social innovation,

expanding possibilities for the virtual world to improve the real world. The group brings value to over 190,000 customers of all sizes in all industries in more than

140 countries. For more information, visit www.3ds.com.

Americas Europe/Middle East/Africa Asia-Pacific

Dassault Systèmes Dassault Systèmes Dassault Systèmes K.K.

175 Wyman Street 10, rue Marcel Dassault ThinkPark Tower

Waltham, Massachusetts CS 40501 2-1-1 Osaki, Shinagawa-ku,

02451-1223 78946 Vélizy-Villacoublay Cedex Tokyo 141-6020

USA France Japan

You might also like

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)

- Analysis Guide For Machine Designers EnglishDocument9 pagesAnalysis Guide For Machine Designers EnglishNurul HudaNo ratings yet

- Solidworks WhitePaper Industry Sim Analysis Machines PDFDocument9 pagesSolidworks WhitePaper Industry Sim Analysis Machines PDFMuhammad Salim Abdul AzisNo ratings yet

- Analysis Guide Machine Design WP ENGDocument10 pagesAnalysis Guide Machine Design WP ENGPrithviraj Daga100% (3)

- Solidworks Solutions: The Power You Need To Drive InnovationDocument6 pagesSolidworks Solutions: The Power You Need To Drive Innovationsamar2011No ratings yet

- 3DS SWK DtoM Brochure A4 071017 PDFDocument6 pages3DS SWK DtoM Brochure A4 071017 PDFsankarNo ratings yet

- MEC435 Chapter6Document39 pagesMEC435 Chapter6Amir AzimNo ratings yet

- CATIA V5, SOLIDWORKS, NX CAD, AutoCAD Mechanical, ANSYS Workbench, HVAC, Revit MEP, ANSYS Fluent/CFD, Reverse Engineering, GD&T Software Course OverviewsDocument30 pagesCATIA V5, SOLIDWORKS, NX CAD, AutoCAD Mechanical, ANSYS Workbench, HVAC, Revit MEP, ANSYS Fluent/CFD, Reverse Engineering, GD&T Software Course Overviewscadd puthurNo ratings yet

- BR Industry-Machinery LTR WDocument8 pagesBR Industry-Machinery LTR Wbagwanjaved2010No ratings yet

- Machine Design P1-25Document11 pagesMachine Design P1-25Carl Vincent TaboadaNo ratings yet

- 3DS 2017 SWK Simulation DatasheetDocument6 pages3DS 2017 SWK Simulation DatasheetThomz AsadinawanNo ratings yet

- Design To Manufacturing SolutionDocument6 pagesDesign To Manufacturing SolutionsfghjkNo ratings yet

- UNIT 1 Lecture 1 CAD AutoDocument21 pagesUNIT 1 Lecture 1 CAD AutoMohd InayathNo ratings yet

- Autocad Project Report (Without Notes)Document13 pagesAutocad Project Report (Without Notes)Harpreet Harry0% (1)

- Moving From One System To Many: Software Product Lines: Re-Using Architectural AssetsDocument13 pagesMoving From One System To Many: Software Product Lines: Re-Using Architectural AssetsjayasreeNo ratings yet

- LCI Report Config - EnglDocument19 pagesLCI Report Config - EnglMihai Cristian LascuNo ratings yet

- Computer Aided Design: Lecture NotesDocument61 pagesComputer Aided Design: Lecture NotesbalacoeusNo ratings yet

- Faster, Easier Simulation Helps You Create Better ProductsDocument8 pagesFaster, Easier Simulation Helps You Create Better ProductsAbdelrahman MagdyNo ratings yet

- MEC435 Chapter6 v1.0Document22 pagesMEC435 Chapter6 v1.0HilmyZulkifliNo ratings yet

- Optimize Designs and Reduce Costs with 3D Tolerance SimulationDocument2 pagesOptimize Designs and Reduce Costs with 3D Tolerance SimulationWayuNo ratings yet

- CAE and CAM Research Report SummaryDocument12 pagesCAE and CAM Research Report Summaryshaharyar ahmedNo ratings yet

- Role of computers in streamlining product developmentDocument10 pagesRole of computers in streamlining product developmentssdeepthiNo ratings yet

- Program - DELMIA - Operations Engineering - ArticulateDocument19 pagesProgram - DELMIA - Operations Engineering - ArticulateCaleb Quiros SeguraNo ratings yet

- Simufact - Professional Forming SimulationDocument12 pagesSimufact - Professional Forming SimulationMrLanternNo ratings yet

- ME 473 Unit 6ADocument19 pagesME 473 Unit 6AAma Serwaa YeboahNo ratings yet

- Design Automation 2010 Eng FinalDocument12 pagesDesign Automation 2010 Eng Finalakhilesh120No ratings yet

- Me8691 LNDocument60 pagesMe8691 LNDhaneshwaran V (Dhanesh)No ratings yet

- NI Mechatronics Machine Design GuideDocument46 pagesNI Mechatronics Machine Design GuideGautam TyagiNo ratings yet

- AA V2 I1 Full VersionDocument48 pagesAA V2 I1 Full Versionfajardo_luismNo ratings yet

- NX Nastran: Answers For IndustryDocument20 pagesNX Nastran: Answers For IndustryuismechprojectNo ratings yet

- ME-311 IntrodcutionDocument44 pagesME-311 IntrodcutionNakshatra Patil 4-Year B.Tech. Mechanical EngineeringNo ratings yet

- 2012 Inventor Overview BrochureDocument16 pages2012 Inventor Overview BrochurejtpmlNo ratings yet

- Unit I Fundamentals of Computer GraphicsDocument25 pagesUnit I Fundamentals of Computer GraphicsChockalingamNo ratings yet

- NX NastranDocument13 pagesNX NastranedusaikiNo ratings yet

- Computer Aided DesignDocument51 pagesComputer Aided DesignshranjuNo ratings yet

- Designfor ProductionDocument4 pagesDesignfor ProductionSupinder RawatNo ratings yet

- Experience Meets SimulationDocument8 pagesExperience Meets SimulationMrLanternNo ratings yet

- What Is Cae?: Hawaiyu Geng: Manufacturing Engineering Handbook, CHP 9Document1 pageWhat Is Cae?: Hawaiyu Geng: Manufacturing Engineering Handbook, CHP 9Sufian HijazNo ratings yet

- Product Lifecycle ManagementDocument21 pagesProduct Lifecycle ManagementSwarnim SinghNo ratings yet

- Teamcenter For Systems EngineeringDocument17 pagesTeamcenter For Systems EngineeringSenad BalicNo ratings yet

- How PLM Help in Reuse DesignDocument14 pagesHow PLM Help in Reuse DesignStrawberiMaduNo ratings yet

- CHAPTER 1 (A) : ObjectivesDocument9 pagesCHAPTER 1 (A) : ObjectivesMuhammadRamdanMohdSulaimanNo ratings yet

- 1 s2.0 0094114X9090035I MainDocument17 pages1 s2.0 0094114X9090035I MainAlief RachmanNo ratings yet

- Cad Notes PDFDocument61 pagesCad Notes PDFSuresh Natarajan100% (3)

- Inventor Pro 2010Document32 pagesInventor Pro 2010bdi_ro100% (1)

- Intro To HypermeshDocument35 pagesIntro To HypermeshAryan GuptaNo ratings yet

- SolidWorks BrochureDocument2 pagesSolidWorks BrochureNatarajan RamamoorthyNo ratings yet

- Unit 37: Virtual EngineeringDocument29 pagesUnit 37: Virtual Engineeringamdan srlNo ratings yet

- 2 - Moldflow Adviser 2019 BrochureDocument4 pages2 - Moldflow Adviser 2019 BrochureAhmedBraham100% (1)

- SolidWorks Premium - DS - 2013 PDFDocument8 pagesSolidWorks Premium - DS - 2013 PDFE Cos LopezNo ratings yet

- Simulia Isight Brochure PDFDocument6 pagesSimulia Isight Brochure PDFlingesh1892No ratings yet

- DEI Desktop Engineering Software and Services GuideDocument31 pagesDEI Desktop Engineering Software and Services Guidejitendramahajan9No ratings yet

- UNit - III Product Design Tools-1Document74 pagesUNit - III Product Design Tools-1Sandeep ChandNo ratings yet

- P&ID Validation with Process Simulation Improves Plant DesignDocument10 pagesP&ID Validation with Process Simulation Improves Plant DesignaghilifNo ratings yet

- Module 5Document19 pagesModule 5vijaykumar327No ratings yet

- Computer Aided Design and ManufacturingDocument62 pagesComputer Aided Design and Manufacturingmanu33% (3)

- Latina Constant Rose-Mary Reynolds BYDocument20 pagesLatina Constant Rose-Mary Reynolds BYRosemaryReynoldsNo ratings yet

- To Understand The Application of Computers in Various Aspects of Manufacturing Viz., Design, Proper Planning, Manufacturing Cost, Layout & Material Handling SystemDocument33 pagesTo Understand The Application of Computers in Various Aspects of Manufacturing Viz., Design, Proper Planning, Manufacturing Cost, Layout & Material Handling Systemmkumar_234155No ratings yet

- WEEKLY MODULE 1 Earth ScienceDocument1 pageWEEKLY MODULE 1 Earth Sciencemichael sto domingoNo ratings yet

- 1946 Shanley The Column Paradox J Aero SciDocument1 page1946 Shanley The Column Paradox J Aero Scitraders joeNo ratings yet

- Hermite-Sobolev and Closely Connected Orthogonal PolynomialsDocument15 pagesHermite-Sobolev and Closely Connected Orthogonal PolynomialsCharaf EL HAMINo ratings yet

- Maintenance Plant Balance Sections 5-6 Scrubber and Grinding Mill Equipment SelectionDocument22 pagesMaintenance Plant Balance Sections 5-6 Scrubber and Grinding Mill Equipment SelectionJr.JeanNo ratings yet

- Tehnicni Program SESSION 2018Document34 pagesTehnicni Program SESSION 2018kenlavie2No ratings yet

- Lecture 3 - Protein Adsorption Part 1 PDFDocument17 pagesLecture 3 - Protein Adsorption Part 1 PDFWesley ChiangNo ratings yet

- Complete Solar Energy Masterclass For Elec - Engineer Ahmed MahdyDocument159 pagesComplete Solar Energy Masterclass For Elec - Engineer Ahmed Mahdyae6037100No ratings yet

- PCV CableDocument12 pagesPCV CableMahamud MusaNo ratings yet

- Lecture-Note of Chapter 4 From LemmiDocument34 pagesLecture-Note of Chapter 4 From LemmiMustefa UsmaelNo ratings yet

- Gravitational Field Tutorial PHY101Document7 pagesGravitational Field Tutorial PHY101kalahanmoonga82No ratings yet

- Calculate the equivalent diameter of a 190 mm x 520 mm rectangular ductDocument10 pagesCalculate the equivalent diameter of a 190 mm x 520 mm rectangular ductKlaikangwol AnuwarnNo ratings yet

- VEML6075: Vishay SemiconductorsDocument11 pagesVEML6075: Vishay Semiconductorsyaumil akbarNo ratings yet

- Physics: Michelle Lao NMAT Review 2020 July 2020 Trans 01Document6 pagesPhysics: Michelle Lao NMAT Review 2020 July 2020 Trans 01Klee KazuhaNo ratings yet

- Bare Overhead Transmission Conductors ": Selection and Application"Document23 pagesBare Overhead Transmission Conductors ": Selection and Application"Adnan KhanNo ratings yet

- Diffraction GratingDocument4 pagesDiffraction GratingEddy RichardsNo ratings yet

- 0580 IGCSE Mathematics - Useful FormulaeDocument3 pages0580 IGCSE Mathematics - Useful FormulaeSupermartin767No ratings yet

- CIE de 2000Document4 pagesCIE de 2000Ibatin Noa LaboratorioNo ratings yet

- AayanDocument11 pagesAayanZunaira SafdarNo ratings yet

- AcidEtching_WalkerDocument11 pagesAcidEtching_WalkermikeherrNo ratings yet

- 3G3mx2-v2 Ds e 1 1 csm1126864Document54 pages3G3mx2-v2 Ds e 1 1 csm1126864Pertti HänninenNo ratings yet

- An Alternative Mathematical Model For Special Relativity Guy Tsabary and Aviv CensorDocument17 pagesAn Alternative Mathematical Model For Special Relativity Guy Tsabary and Aviv CensorYotam KatzirNo ratings yet

- Sludge Transfer Pump - Nmr-601 M13-G-0950A/B: Upgrade Pier Marine Facilities at TanajibDocument53 pagesSludge Transfer Pump - Nmr-601 M13-G-0950A/B: Upgrade Pier Marine Facilities at TanajibchaitanyaNo ratings yet

- List ProfessorsDocument6 pagesList ProfessorsDonny pasaribuNo ratings yet

- 08 Ws5-SizeDocument2 pages08 Ws5-SizepcchemistryNo ratings yet

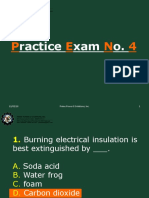

- Practice Exam No. 4 2018 PDFDocument43 pagesPractice Exam No. 4 2018 PDFJevan CalaqueNo ratings yet

- Specific Heat Capacity Calculations of MetalsDocument2 pagesSpecific Heat Capacity Calculations of MetalsAntoine RobertsNo ratings yet

- Torque Team V-Belt: Installation GuideDocument2 pagesTorque Team V-Belt: Installation GuideMary Huaylla ANo ratings yet

- Electric Traction - ReferenceDocument19 pagesElectric Traction - ReferenceShrestha SanjuNo ratings yet

- Glider Aerobatics ManualDocument36 pagesGlider Aerobatics ManualmichetraviNo ratings yet

- Western Region-Ordinary Members PDFDocument21 pagesWestern Region-Ordinary Members PDFjaydeep daveNo ratings yet