Professional Documents

Culture Documents

Inspection Form: Helmets

Inspection Form: Helmets

Uploaded by

Joaquim DiasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Form: Helmets

Inspection Form: Helmets

Uploaded by

Joaquim DiasCopyright:

Available Formats

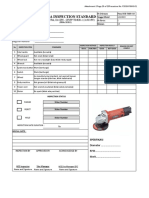

PPE Inspection

Inspection form

• In addition to routine checks for each use, PPE should regularly undergo a detailed inspection by a competent person. Petzl recommends an

inspection every 12 months and after any exceptional event in the life of the product.

• PPE inspection should be conducted with the manufacturer's Instructions for Use.

Download the instructions at PETZL.COM.

HELMETS

User information PPE information

Surname Model

Address Serial number

Year of manufacture

Date of purchase

Identifier Date of first use

Manufacturer: Petzl, ZI Cidex 105A - 38920 Crolles - France

Good condition (G) To monitor (TM) To repair (TR) Do not use, retire (R) Not applicable

1. Known product history

Usage conditions or exceptional event during use (examples:

fall or fall arrest, use or storage at extreme temperatures,

modification outside manufacturer's facilities...) :

2. Preliminary observations

• Verify the presence and legibility of the serial number and the CE mark.

• Verify that the product lifetime has not been exceeded.

• Compare with a new device to verify there are no modifications or missing elements.

3. Checking the shell

• Check the condition of the outside of the shell (marks, impacts, deformation, cracks, burns, wear, signs of chemical products...).

• Check the condition of the inside of the shell (marks, deformation, cracks, missing parts...). WARNING: do not remove the liner that is attached to the

shell.

• Remember: personalizing or marking the helmet must not be done with chemical products. Use water-based adhesives for any marking.

• Check the condition of the slots and holes for mounting accessories (deformation, cracks...).

• Check the condition and function of the ventilation shutters (for VERTEX VENT, ELIOS...).

4. Checking the liner

• Check the condition of the liner (marks, deformation, cracks, missing parts...).

Remove the comfort parts to inspect the hidden areas.

WARNING: do not remove the liner that is attached to the shell.

5. Checking the cradle (webbing head harness)

• Check the condition of the straps and their attachments to the shell (wear, cuts, burns, deformation of plastic pieces).

6. Checking the headband

• Check the condition of the headband and its attachments to the shell (wear, deformation, missing parts...).

If necessary, remove the foams or comfort parts to inspect the hidden areas.

7. Checking the adjustment system

• Check the condition of the adjustment system and its attachments to the shell (wear, deformation, missing parts...).

• Check the function of the adjustment system.

Operate the adjustment system in both directions. Pull on the system to verify that it does not lose its adjustment setting.

8. Checking the chin strap

• Check the condition of the chin strap and the adjustment parts (wear, cuts, burns, deformation of plastic pieces).

Move the keepers and plastic pieces to inspect any hidden areas on the straps.

• Check the condition of the chin strap buckle (wear, deformation, breakage). Test the reliability of the fastening by pulling gently on the chin strap.

9. Checking the comfort foams

• Check the condition of the comfort foams. If necessary, remove them for washing or replacement.

10. Checking the headlamp clips

• Check the condition of the headlamp clips (wear, deformation, missing parts...).

11. Checking accessories

• If accessories are mounted on the helmet, check their condition and make sure they are working properly (face shield, headlamp...).

Comments (detail here any defects found on the product and accomplished tasks)

VERDICT Inspected by

Product fit to remain in service Company

Product unfit to remain in service Date Next inspection date

PPE INSPECTION - Inspection form - HELMETS (271114)

1/1

You might also like

- Bobcat Daily Inspection Checklist: Operator's Name: Signature Badge No. BOBCAT Body No.: Model: Project/FacilityDocument1 pageBobcat Daily Inspection Checklist: Operator's Name: Signature Badge No. BOBCAT Body No.: Model: Project/FacilityMuhammad Farooq Awan100% (5)

- 802 Operator ManualDocument52 pages802 Operator ManualeastNo ratings yet

- JHA PaintingDocument12 pagesJHA Paintingeast100% (1)

- Risk Assessment Lifting OperationsDocument5 pagesRisk Assessment Lifting OperationsHưng Hoàng Duy100% (1)

- PPE Hazard Assessment Certification Form: (Use A Separate Sheet For Each Job/task or Work Area)Document3 pagesPPE Hazard Assessment Certification Form: (Use A Separate Sheet For Each Job/task or Work Area)eastNo ratings yet

- Health and Safety Improvement PlanDocument3 pagesHealth and Safety Improvement Planeast67% (3)

- Inspection Procedure: Grillon LanyardDocument5 pagesInspection Procedure: Grillon LanyardUlviyye ElesgerovaNo ratings yet

- Fall Restraint, Fall Arrest and The Hierarchy of Fall ProtectionDocument1 pageFall Restraint, Fall Arrest and The Hierarchy of Fall ProtectioneastNo ratings yet

- Checklist For Equipment Inspection Circular SawDocument2 pagesChecklist For Equipment Inspection Circular SawUMMU AIMAN BINTI AYUBNo ratings yet

- ContiTech RubberTrack Manual WarrantyGuide enDocument61 pagesContiTech RubberTrack Manual WarrantyGuide eneastNo ratings yet

- 01backing CircleofSafetyDocument2 pages01backing CircleofSafetyeastNo ratings yet

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDocument7 pagesProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistnasirNo ratings yet

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Gear InspectionDocument6 pagesGear Inspectionbh hbNo ratings yet

- JSA For Demobilization WorksDocument2 pagesJSA For Demobilization WorksIanne Dee85% (13)

- DRIVER's HandbookDocument37 pagesDRIVER's HandbookeastNo ratings yet

- State Hazcom TestDocument2 pagesState Hazcom TesteastNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Inspection Procedure: Professional HarnessesDocument9 pagesInspection Procedure: Professional Harnesseschanks498No ratings yet

- Getting Approval To Deliver Managing Safely v5Document6 pagesGetting Approval To Deliver Managing Safely v5eastNo ratings yet

- A1Z5L2 - Appendix VI - Valve Commissioning Checklist - USDocument1 pageA1Z5L2 - Appendix VI - Valve Commissioning Checklist - USAlpesh PatelNo ratings yet

- Safety Harness Inspection Checklist 1Document1 pageSafety Harness Inspection Checklist 1Erica Araceli Gallegos AriasNo ratings yet

- How To Validate An AutoclaveDocument3 pagesHow To Validate An AutoclaveqhpuongNo ratings yet

- Team Building PDFDocument91 pagesTeam Building PDFeastNo ratings yet

- Piping Codes List of Piping Codes Is HereDocument8 pagesPiping Codes List of Piping Codes Is Hereabidaliabid1No ratings yet

- DJi F450 Quadcopter How To Build Home BuiltDocument12 pagesDJi F450 Quadcopter How To Build Home BuiltgenmassaNo ratings yet

- Four Bar LinkageDocument13 pagesFour Bar LinkageMBHladilekNo ratings yet

- Broken Needle PolicyDocument9 pagesBroken Needle Policyelisav89% (9)

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDocument7 pagesProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistCristian Jhair PerezNo ratings yet

- ASTM Compass G ListDocument6 pagesASTM Compass G ListWalter Trajada100% (1)

- StaticCalc Duct Sizing CalculatorDocument14 pagesStaticCalc Duct Sizing CalculatorSteve WanNo ratings yet

- KeMotion E Web PDFDocument26 pagesKeMotion E Web PDFanderson tartaia100% (1)

- Detailed Lesson PlanDocument6 pagesDetailed Lesson PlanMichelle Anne Legaspi Bawar88% (17)

- Engineering College in HaryanaDocument9 pagesEngineering College in HaryanaUjjawal Mathur100% (1)

- Checklist - Backup Device - Petzl ASAP-LOCKDocument1 pageChecklist - Backup Device - Petzl ASAP-LOCKMax BeeksNo ratings yet

- Checklist - Ascenders - Petzl Hand & Chest - 050717Document1 pageChecklist - Ascenders - Petzl Hand & Chest - 050717Max BeeksNo ratings yet

- Verif EPI Connexion Suivi enDocument1 pageVerif EPI Connexion Suivi enFarid KurniadiNo ratings yet

- Checklist - Lanyard - Petzl ABSORBICA-I-YDocument1 pageChecklist - Lanyard - Petzl ABSORBICA-I-YMax BeeksNo ratings yet

- Inspection Form: Frame-Loaded Rope ClampDocument1 pageInspection Form: Frame-Loaded Rope ClampDimasDianaFerreiraNo ratings yet

- Verif EPI Degaines Procedure enDocument2 pagesVerif EPI Degaines Procedure eninternetNo ratings yet

- Verif EPI Harnais SPORT Procedure enDocument4 pagesVerif EPI Harnais SPORT Procedure enisacc palacios gamarraNo ratings yet

- Verif EPI Casques PRO Procedure EN PDFDocument6 pagesVerif EPI Casques PRO Procedure EN PDFDimasDianaFerreiraNo ratings yet

- PETZL - William Screw-LockDocument22 pagesPETZL - William Screw-LockForbez3No ratings yet

- Verif EPI Harnais PRO Procedure enDocument6 pagesVerif EPI Harnais PRO Procedure enDimasDianaFerreiraNo ratings yet

- PPE Inspection Form: Historical CheckDocument1 pagePPE Inspection Form: Historical CheckJUNIORMORGANNo ratings yet

- Verif EPI Longes Procedure enDocument5 pagesVerif EPI Longes Procedure enDarwin AndyNo ratings yet

- Longdar SM906 InspectionDocument2 pagesLongdar SM906 InspectionLê Anh MinhNo ratings yet

- Verif EPI Harnais PRO Suivi EN PDFDocument1 pageVerif EPI Harnais PRO Suivi EN PDFDimasDianaFerreiraNo ratings yet

- Verif EPI Sangleamarrage Procedure FRDocument2 pagesVerif EPI Sangleamarrage Procedure FRinternetNo ratings yet

- Harness: PPE Inspection FormDocument1 pageHarness: PPE Inspection FormJUNIORMORGANNo ratings yet

- Crampons: PPE Inspection FormDocument1 pageCrampons: PPE Inspection FormJUNIORMORGANNo ratings yet

- Verif EPI Bloqueur Procedure EN PDFDocument6 pagesVerif EPI Bloqueur Procedure EN PDFdsn_sarmaNo ratings yet

- Drilling Machine Check ListDocument1 pageDrilling Machine Check ListKhalid IrfanNo ratings yet

- Verif EPI Poulies Procedure ENDocument3 pagesVerif EPI Poulies Procedure ENaliya azharNo ratings yet

- Full-Body Harnesses: Inspection ChecklistDocument1 pageFull-Body Harnesses: Inspection ChecklistMark Israel DirectoNo ratings yet

- Verif EPI Harnais PRO Procedure EN PDFDocument6 pagesVerif EPI Harnais PRO Procedure EN PDFDimasDianaFerreiraNo ratings yet

- B16 CrollDocument24 pagesB16 CrollJuan Manuel Rodriguez ArbelaezNo ratings yet

- Verif EPI GRIGRI Procedure enDocument3 pagesVerif EPI GRIGRI Procedure eninternetNo ratings yet

- Form-HSE-TMR-010 Gerinda InspectionDocument1 pageForm-HSE-TMR-010 Gerinda Inspectionkenia infoNo ratings yet

- Helmet: Historical CheckDocument1 pageHelmet: Historical CheckRahmahani SetiawatiNo ratings yet

- Layered Process Audit ChecklistDocument1 pageLayered Process Audit ChecklistMuniyappan TNo ratings yet

- Itens de Aparência: Frisos Da Porta: Ano Iv - #34 Abril de 2012Document4 pagesItens de Aparência: Frisos Da Porta: Ano Iv - #34 Abril de 2012RenanNo ratings yet

- Penetrometer MANUALDocument4 pagesPenetrometer MANUALafzal baigNo ratings yet

- Bomba de Agua 4" SM20 Manual de ServicioDocument24 pagesBomba de Agua 4" SM20 Manual de ServicioHolman Sánchez OlguínNo ratings yet

- Fall Protection Inspection RecordsDocument3 pagesFall Protection Inspection RecordsMuthu KrishanNo ratings yet

- Manual Esmerilhadeira Lixadeira STANLEY GR29 UWDocument22 pagesManual Esmerilhadeira Lixadeira STANLEY GR29 UWWilliamNo ratings yet

- Verif EPI IDS IDL RIG Procedure enDocument5 pagesVerif EPI IDS IDL RIG Procedure enAldisley OliveiraNo ratings yet

- DEKRA Certification Group: Henk Kormelink Product Expert Industrial Components IEC Member IEC 121A/MT6, IEC 121B/MT2Document14 pagesDEKRA Certification Group: Henk Kormelink Product Expert Industrial Components IEC Member IEC 121A/MT6, IEC 121B/MT2MuraryspottyNo ratings yet

- GR29 Users Manual 2014Document19 pagesGR29 Users Manual 2014AUDRANNo ratings yet

- 8 - GEST 17 492 Edition 2 - Appendix 4 Field Test ReportDocument3 pages8 - GEST 17 492 Edition 2 - Appendix 4 Field Test ReportAdemilson JuniorNo ratings yet

- PRES-M-09 Rotating Equipment - Gas TurbinesDocument2 pagesPRES-M-09 Rotating Equipment - Gas Turbinessalamlin100% (1)

- Bench Cutting Machine Inspection ChecklistDocument1 pageBench Cutting Machine Inspection Checklistjunnukhan40No ratings yet

- AS200 Elastomeric Spray Product Data SheetDocument3 pagesAS200 Elastomeric Spray Product Data SheetJhon DewantoNo ratings yet

- EX600 DeviceNet Manual APR 08Document91 pagesEX600 DeviceNet Manual APR 08Esteban GonzalooNo ratings yet

- Omc Clarification Sheet: Standard(s) (Incl. Year) Sub-Clause(s) For Secretariat Use OnlyDocument2 pagesOmc Clarification Sheet: Standard(s) (Incl. Year) Sub-Clause(s) For Secretariat Use OnlyBala JiNo ratings yet

- Annual&100 Check ListDocument13 pagesAnnual&100 Check ListTarek ElghazzalyNo ratings yet

- Verif EPI-ASAP-procedure-ENDocument4 pagesVerif EPI-ASAP-procedure-ENAditya GandhiNo ratings yet

- Halliburton: SafetyDocument1 pageHalliburton: SafetyKhalfan Al HabsiNo ratings yet

- NCPL-SEM - Quality Assurance Process V1.0Document7 pagesNCPL-SEM - Quality Assurance Process V1.0QAD LotusNo ratings yet

- Check List For Standing Seam.Document2 pagesCheck List For Standing Seam.rashid khattakNo ratings yet

- Warman-Flow System Maintenance ChecklistDocument2 pagesWarman-Flow System Maintenance ChecklistWilliam EvansNo ratings yet

- 1234-ENG - Behavior in Heat 060906Document5 pages1234-ENG - Behavior in Heat 060906Uday SharmaNo ratings yet

- What Are The Labeling Requirements?: Global Harmonization System - LabelingDocument2 pagesWhat Are The Labeling Requirements?: Global Harmonization System - LabelingeastNo ratings yet

- Global Harmonization System - The Pictogram: What Are Pictograms?Document2 pagesGlobal Harmonization System - The Pictogram: What Are Pictograms?eastNo ratings yet

- Water Conservation February 2012: Environmental Training Training Month DateDocument1 pageWater Conservation February 2012: Environmental Training Training Month DateeastNo ratings yet

- April: Why Safety Belts?Document1 pageApril: Why Safety Belts?eastNo ratings yet

- Crowcon Detective Transportable Gas MonitorDocument5 pagesCrowcon Detective Transportable Gas MonitoreastNo ratings yet

- 06 Hot Work PermitDocument1 page06 Hot Work PermiteastNo ratings yet

- Ultra-High Pressure Water Jet: Baseline Report: Weces VedDocument38 pagesUltra-High Pressure Water Jet: Baseline Report: Weces VedeastNo ratings yet

- BASF - Job Vacancy Ad - EHS OfficerDocument1 pageBASF - Job Vacancy Ad - EHS OfficereastNo ratings yet

- Safe Management of Health Care WasteDocument20 pagesSafe Management of Health Care WasteeastNo ratings yet

- Director Leadership: Directors and Board Members Have The Key RoleDocument5 pagesDirector Leadership: Directors and Board Members Have The Key RoleeastNo ratings yet

- Hazard Identification, Risk Assessment and Controls (HIRAC) LogDocument5 pagesHazard Identification, Risk Assessment and Controls (HIRAC) LogeastNo ratings yet

- Keep Your Cool in Hot WeatherDocument3 pagesKeep Your Cool in Hot WeathereastNo ratings yet

- Aggressive DrivingDocument8 pagesAggressive DrivingeastNo ratings yet

- Nas 1790Document4 pagesNas 1790Sagar PawarNo ratings yet

- Esay Pact Rele, ContactoresDocument84 pagesEsay Pact Rele, ContactoresMarlene RuizNo ratings yet

- LOADMASTER Se7510 Indicator 10052001aDocument32 pagesLOADMASTER Se7510 Indicator 10052001aRoberto Augusto Aristizabal MorenoNo ratings yet

- High Demand Occupations in Manitoba: Report OnDocument22 pagesHigh Demand Occupations in Manitoba: Report OnzubimehNo ratings yet

- Domestic Gas Stove Testing With Use of LPG: IS 4246: 2002 Bureau of Indian Standards (Fifth Revision)Document5 pagesDomestic Gas Stove Testing With Use of LPG: IS 4246: 2002 Bureau of Indian Standards (Fifth Revision)Quality Royal HomeNo ratings yet

- 80 FFC Flat Cables AxonDocument56 pages80 FFC Flat Cables AxonAchifievNo ratings yet

- KAT-A 2429 EROX-F Edition5 05-12-2012 EN 01Document3 pagesKAT-A 2429 EROX-F Edition5 05-12-2012 EN 01Gabriela AxinteNo ratings yet

- 19Document218 pages19Anz PompayNo ratings yet

- Repsol Isplen Pr210x6eDocument2 pagesRepsol Isplen Pr210x6eSérgio BarbosaNo ratings yet

- Mpecs 2016 PDFDocument333 pagesMpecs 2016 PDFVishal HandeNo ratings yet

- A1321 2 3 DatasheetDocument13 pagesA1321 2 3 DatasheetEwerton BianchiNo ratings yet

- Linear Programming: Chapter 13 SupplementDocument35 pagesLinear Programming: Chapter 13 SupplementDevharsh TrivediNo ratings yet

- British Steel European Sections Product RangeDocument9 pagesBritish Steel European Sections Product Rangerezetane mohamed amineNo ratings yet

- Rombis Company OverviewDocument10 pagesRombis Company OverviewRadu Ioan BalanNo ratings yet

- Series Capacitor Compensated AC Filterless Flexible LCC HVDC With Enhanced Power Transfer Under Unbalanced FaultsDocument12 pagesSeries Capacitor Compensated AC Filterless Flexible LCC HVDC With Enhanced Power Transfer Under Unbalanced FaultsTRIAD TECHNO SERVICESNo ratings yet

- Air Pollution1Document14 pagesAir Pollution1KrishnaNo ratings yet

- Fuel Cells For Portable PowerDocument186 pagesFuel Cells For Portable PowerVivek PatelNo ratings yet

- Junbond High Quality Neutral Silicone Sealant Technical Data Sheet!Document2 pagesJunbond High Quality Neutral Silicone Sealant Technical Data Sheet!Junbond silicone sealantNo ratings yet

- Deviation Lab Report (Keq)Document5 pagesDeviation Lab Report (Keq)niteeshsettypalliNo ratings yet

- Fantom x8 RhythmsDocument20 pagesFantom x8 RhythmsroaldmahlNo ratings yet