Professional Documents

Culture Documents

Verif EPI-ASAP-procedure-EN

Uploaded by

Aditya GandhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Verif EPI-ASAP-procedure-EN

Uploaded by

Aditya GandhiCopyright:

Available Formats

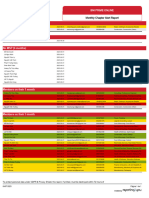

PPE Inspection

Inspection procedure

• In addition to routine checks for each use, PPE should regularly undergo a detailed inspection by a competent

person.

Petzl recommends an inspection every 12 months and after any exceptional event in the life of the product.

• PPE inspection should be done with the manufacturer's instructions available for reference. Download the instructions

at PETZL.COM

ASAP

B71 and B71AAA

1. Known product history

Any PPE showing unexpected degradation should be quarantined, pending a detailed inspection.

The user should:

- Provide precise information on the usage conditions.

- Report any exceptional event regarding his PPE.

(Examples: fall or fall arrest, use or storage at extreme temperatures, modification outside manufacturer's

facilities, etc.).

2. Preliminary observations

Verify the presence and legibility of the serial number and the CE mark.

Attention, the serial number code on our products is evolving. Two types of code will coexist.

See below for details on each serial number code.

Code A: Code B:

00 000 AA 0000 00 A 0000000 000

Year of manufacture Year of manufacture

Day of manufacture Month of manufacture

Name of Inspector Batch number

Incrementation Incrementation

Verify that the product lifetime has not been exceeded.

Compare with a new product to verify there are no modifications or missing parts.

3. Inspecting the frame

• Check the condition of the frame (marks, • Check the condition of the edges of the attachment hole (marks,

deformation, cracks, corrosion...). deformation, cracks are a sign of fall arrest).

ASAP B71

ASAP B71AAA

PPE INSPECTION - Inspection procedure - ASAP (030314) 1/4

3. Inspecting the frame

• ASAP B71 only:

• Check the condition of the wheel stop (marks, deformation, cracks are a sign of fall arrest).

Check the condition of the protective cover.

4. Inspecting the wheel

• Check the condition of the wheel (marks, deformation, cracks,

corrosion...).

Verify that all teeth are present and check their state of wear.

The wheel must not be fouled. If necessary, clean it with a brush,

possibly by applying solvent with a fine brush. Avoid getting any liquid

inside the mechanism.

• Check the rotation of the wheel.

Turn the wheel one complete revolution in both directions, making sure it

rotates smoothly, without catching.

ASAP B71 ASAP B71AAA

PPE INSPECTION - Inspection procedure - ASAP (030314) 2/4

5. Checking the arm and the safety catch

• Check the condition of the arm (marks, deformation, cracks, • Check the condition of the safety catch (marks, deformation,

corrosion...). cracks are a sign of fall arrest).

ASAP B71 ASAP B71AAA ASAP B71 ASAP B71AAA

• Check the effectiveness of the arm's return spring.

ASAP B71 ASAP B71AAA

6. Function test: sliding on the rope

• Install the ASAP on a compatible rope, check that it slides properly on

the rope in both directions.

ASAP B71 ASAP B71AAA

PPE INSPECTION - Inspection procedure - ASAP (030314) 3/4

7. Function test: grabbing and releasing the rope

• Install the ASAP on a compatible rope; test for

correct locking by pulling downward (direction

of a fall).

ASAP B71 ASAP B71AAA

• After locking, verify that releasing is normally carried out.

ASAP B71 ASAP B71AAA

8. Checking the condition of the OK TL connector

• For connector inspection, see the

inspection form for your connector

model at petzl.com.

PPE INSPECTION - Inspection procedure - ASAP (030314) 4/4

You might also like

- Verif EPI Bloqueur Procedure EN PDFDocument6 pagesVerif EPI Bloqueur Procedure EN PDFdsn_sarmaNo ratings yet

- Inspection Procedure: Grillon LanyardDocument5 pagesInspection Procedure: Grillon LanyardUlviyye ElesgerovaNo ratings yet

- Inspection Procedure: Professional HarnessesDocument9 pagesInspection Procedure: Professional Harnesseschanks498No ratings yet

- Verif EPI Degaines Procedure enDocument2 pagesVerif EPI Degaines Procedure eninternetNo ratings yet

- Verif EPI GRIGRI Procedure enDocument3 pagesVerif EPI GRIGRI Procedure eninternetNo ratings yet

- Verif EPI Harnais SPORT Procedure enDocument4 pagesVerif EPI Harnais SPORT Procedure enisacc palacios gamarraNo ratings yet

- Verif EPI Poulies Procedure ENDocument3 pagesVerif EPI Poulies Procedure ENaliya azharNo ratings yet

- Verif EPI Sangleamarrage Procedure FRDocument2 pagesVerif EPI Sangleamarrage Procedure FRinternetNo ratings yet

- SOP Overhead Crane-Rev.1Document5 pagesSOP Overhead Crane-Rev.1RonniNo ratings yet

- Verif Epi Protraxion Procedure enDocument4 pagesVerif Epi Protraxion Procedure eninternetNo ratings yet

- SF 11 23Document6 pagesSF 11 23Shivkumar JadhavNo ratings yet

- Checklist - Backup Device - Petzl ASAP-LOCKDocument1 pageChecklist - Backup Device - Petzl ASAP-LOCKMax BeeksNo ratings yet

- Verif EPI Harnais PRO Procedure enDocument6 pagesVerif EPI Harnais PRO Procedure enDimasDianaFerreiraNo ratings yet

- Bop Pressure Testing Procedure: Romfor International LTDDocument6 pagesBop Pressure Testing Procedure: Romfor International LTDSergio Fabian VasicekNo ratings yet

- LY38 Ops Manual PDFDocument36 pagesLY38 Ops Manual PDForlando chullo llave100% (1)

- Verif EPI Longes Procedure enDocument5 pagesVerif EPI Longes Procedure enDarwin AndyNo ratings yet

- SOP Mobile Crane-Rev.1Document7 pagesSOP Mobile Crane-Rev.1RonniNo ratings yet

- PRO12 2P621CT - Rev 7 - 09 19Document24 pagesPRO12 2P621CT - Rev 7 - 09 19Edwin Montenegro MurilloNo ratings yet

- Mechanical Integrity Inspection ExchangerDocument7 pagesMechanical Integrity Inspection ExchangerSyed Faraz Raza100% (1)

- Of in Service Storage Tank Inspection and Verification ChecklistDocument14 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- SGT - Le.014 Crane Inspection Type 1Document10 pagesSGT - Le.014 Crane Inspection Type 1ryangillespie100% (1)

- Crane ProceduresDocument67 pagesCrane ProceduresKen RanggaNo ratings yet

- Checklist - Ascenders - Petzl Hand & Chest - 050717Document1 pageChecklist - Ascenders - Petzl Hand & Chest - 050717Max BeeksNo ratings yet

- TF100-75 - Rynglok R5 Fittings AS-Cross ReferenceDocument4 pagesTF100-75 - Rynglok R5 Fittings AS-Cross ReferenceLorenzoTanNo ratings yet

- Inspection Form: Frame-Loaded Rope ClampDocument1 pageInspection Form: Frame-Loaded Rope ClampDimasDianaFerreiraNo ratings yet

- Gear InspectionDocument6 pagesGear Inspectionbh hbNo ratings yet

- Overhead CranesDocument50 pagesOverhead CraneshamzanusratNo ratings yet

- Maintenance Check Lists Iw Tele BoomsDocument6 pagesMaintenance Check Lists Iw Tele BoomsJoss RamosNo ratings yet

- Snap Attachment - CompressedDocument53 pagesSnap Attachment - CompressedAri RamadhanNo ratings yet

- 4fJ - L, - C: HalliburtonDocument4 pages4fJ - L, - C: HalliburtonKhalfan Al HabsiNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument16 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- Maintenance Y SERIESDocument10 pagesMaintenance Y SERIESStowartNo ratings yet

- Fall Protection Equipment Inspection ProgramDocument8 pagesFall Protection Equipment Inspection ProgramTristano EffendiNo ratings yet

- ZHENJIANG MARINE AUXILIARY MACHINERY WORKS - Ops & Maint - SH70 - 16Document19 pagesZHENJIANG MARINE AUXILIARY MACHINERY WORKS - Ops & Maint - SH70 - 16Amanda ViverosNo ratings yet

- Time Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckDocument17 pagesTime Limits/Maintenance Checks Unscheduled Maintenance Checks Inspection/CheckWalter TorenaNo ratings yet

- Verif EPI IDS IDL RIG Procedure enDocument5 pagesVerif EPI IDS IDL RIG Procedure enAldisley OliveiraNo ratings yet

- GM 002 AccessoriesDocument45 pagesGM 002 AccessoriesJohn DareNo ratings yet

- TDS Manual-TescoDocument33 pagesTDS Manual-TescoQAMAR ALI KHAN100% (1)

- A6V12101348Document6 pagesA6V12101348Junaid IftekharNo ratings yet

- H Tong Maintenance ManualDocument8 pagesH Tong Maintenance ManualBahman MatouriNo ratings yet

- Lathe Machine Safety OperatingDocument4 pagesLathe Machine Safety Operatingebad100% (1)

- Playstation 2 Scph30001 RDocument50 pagesPlaystation 2 Scph30001 RLobo BravoNo ratings yet

- CS76 Before OperationDocument4 pagesCS76 Before OperationJosé Carlos CarvalhoNo ratings yet

- Vehicle Lifts and Garage Jacking EquipmentDocument5 pagesVehicle Lifts and Garage Jacking EquipmentahmedNo ratings yet

- Before Operation 320C PDFDocument5 pagesBefore Operation 320C PDFFabian Ariza ArizaNo ratings yet

- Halliburton: S S7 JO/5//3Document4 pagesHalliburton: S S7 JO/5//3Khalfan Al HabsiNo ratings yet

- API 653 Tank InspectionDocument53 pagesAPI 653 Tank InspectionWàhränî Là Cläşş100% (3)

- 320C U Excavator-Before OperationDocument4 pages320C U Excavator-Before OperationPedro BarriosNo ratings yet

- Sinodrills SDA (V2020Document14 pagesSinodrills SDA (V2020JackChanNo ratings yet

- Slewing Jib CranesDocument2 pagesSlewing Jib CranesahmedNo ratings yet

- FFD - 4 - Maintenance Manual PDFDocument15 pagesFFD - 4 - Maintenance Manual PDFKaleb Z king webNo ratings yet

- Abbott i1000SR - PM ChecklistDocument7 pagesAbbott i1000SR - PM Checklistاكرم امينNo ratings yet

- AAX Tong MaintenanceDocument7 pagesAAX Tong MaintenanceBahman Matouri100% (1)

- Checklist - Lanyard - Petzl ABSORBICA-I-YDocument1 pageChecklist - Lanyard - Petzl ABSORBICA-I-YMax BeeksNo ratings yet

- Pre Operational InspectionDocument89 pagesPre Operational InspectionGustavo ArancibiaNo ratings yet

- Raiseboring Equipment Pilot Bits BrochureDocument4 pagesRaiseboring Equipment Pilot Bits BrochureDenisNo ratings yet

- V30ZMUDocument26 pagesV30ZMUmanuelsaenzNo ratings yet

- Crane OperationDocument67 pagesCrane OperationErc Nunez V100% (2)

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Scaffold Erection & DismantlingDocument6 pagesScaffold Erection & Dismantlingrakib ahsanNo ratings yet

- Din 1048Document8 pagesDin 1048Mostafa Hussein AbdouNo ratings yet

- Uniform Building By-Laws 1988-Pk.P.U. 21 - 1988Document173 pagesUniform Building By-Laws 1988-Pk.P.U. 21 - 1988Hazirah AmniNo ratings yet

- Mca - Bni Prime Online (202307)Document1 pageMca - Bni Prime Online (202307)phuocsixNo ratings yet

- Plaza Master Apr-2022Document12 pagesPlaza Master Apr-2022Raja SekharNo ratings yet

- Detail Gambar Perencanaan Teknis Jembatan Tajum KarangbawangDocument110 pagesDetail Gambar Perencanaan Teknis Jembatan Tajum KarangbawanggaliharumNo ratings yet

- Sur Construction PLC Priced Bill of Quantity FOR Tigray Health BoreauDocument26 pagesSur Construction PLC Priced Bill of Quantity FOR Tigray Health BoreauWelday GebremichaelNo ratings yet

- BCA Coretrade GuidebookDocument52 pagesBCA Coretrade GuidebookpostboxsgNo ratings yet

- SHM in CGC ZZ ZZ XX QP QM 00001 p01 Project Quality Plan (PQP)Document334 pagesSHM in CGC ZZ ZZ XX QP QM 00001 p01 Project Quality Plan (PQP)Akhtar JavedNo ratings yet

- Air Flow Louvers, Inc.: Model EA 403Document2 pagesAir Flow Louvers, Inc.: Model EA 403Aya EzzNo ratings yet

- Ultra-Low Head 8 8 (Steel) Steel Black Oxide (Hex Socket) Hex Socket 1.25 Standard Metric Coarse Standard (Round) Standard 10Document2 pagesUltra-Low Head 8 8 (Steel) Steel Black Oxide (Hex Socket) Hex Socket 1.25 Standard Metric Coarse Standard (Round) Standard 10YossiNo ratings yet

- Protectosil CIT PDFDocument3 pagesProtectosil CIT PDFFrancois-No ratings yet

- Abstract Estimate Based On Current RatesDocument2 pagesAbstract Estimate Based On Current RatesSandeep KolappuramNo ratings yet

- DWR 03-23Document1 pageDWR 03-23Nicon Famarin FameronagNo ratings yet

- Paroginog 5-231 Pa3Document3 pagesParoginog 5-231 Pa3Nhes Audrey ParoginogNo ratings yet

- DBG Sland Offshore DPR - 13.01.2021-045Document2 pagesDBG Sland Offshore DPR - 13.01.2021-045Yussuf DirieNo ratings yet

- Poc Submitted BQ Ceiling & PartitionDocument10 pagesPoc Submitted BQ Ceiling & PartitionJay JayNo ratings yet

- RA Bill Detail AbstractDocument33 pagesRA Bill Detail AbstractMohanraj SNo ratings yet

- Typical Advantages and Disadvantages: Design-Bid-Build Design-BuildDocument1 pageTypical Advantages and Disadvantages: Design-Bid-Build Design-Buildhanan awelNo ratings yet

- MEP 1st Fix Clearance For Ceiling WorkDocument3 pagesMEP 1st Fix Clearance For Ceiling WorklaraibNo ratings yet

- CHAPTER 5 (05:02) : Flexible Pavement DesignDocument43 pagesCHAPTER 5 (05:02) : Flexible Pavement DesignMuhd FareezNo ratings yet

- Detailed Calculation SheetDocument32 pagesDetailed Calculation SheetAwa SigeNo ratings yet

- Davco TTB 98Document2 pagesDavco TTB 98tlnrsNo ratings yet

- Power Plants ProjectDocument1 pagePower Plants ProjectHumberto LopezNo ratings yet

- Raptor Slim Kenter Shackle R5Document1 pageRaptor Slim Kenter Shackle R5mayankdixit2No ratings yet

- Attachment B PDFDocument2 pagesAttachment B PDFThinh NguyenNo ratings yet

- Analysis of IGI, Project ManagementDocument17 pagesAnalysis of IGI, Project ManagementpalaksharmapalakNo ratings yet

- MV - Interior Design RenderingDocument136 pagesMV - Interior Design RenderingALINo ratings yet

- Lesson No. 4 Building Bye-Laws NotesDocument19 pagesLesson No. 4 Building Bye-Laws Notes12483.2020No ratings yet

- Restoration of BuildingsDocument9 pagesRestoration of BuildingsFares El LabanNo ratings yet