Professional Documents

Culture Documents

Design and Construction of Internet of Things (IoT) Based Generator Monitoring System

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Construction of Internet of Things (IoT) Based Generator Monitoring System

Copyright:

Available Formats

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Design and Construction of Internet of Things (IoT)

Based Generator Monitoring System

1

Oladoyin, A. E

1

Olaleye, O.O

1

Ikueyemi D

1

Adeleke, A.E

1

Etoh, H

1

Ogunsola, T

1

Department of Marine Engineering Maritime Academy of Nigeria Oron, Akwa Ibom State

2

Adeyi, A.A

2

Department of Electrical Electronics Engineering, Maritime Academy of Nigeria, Oron, Akwa Ibom State. Nigeria

Abstract:- This project presents an internet of things I. INTRODUCTION

(IoT) based generator monitoring system of engine

performance, stability, oil level and battery level The traditional method of checking generator’s

equipped with mobile app control. An Internet of Things working parameters such as determining the fuel level using

is an interconnected system of distinctively addressable dipstick or fuel gauge, ascertaining oil and jacket water

physical items with various degrees of processing, pressure, and temperature by looking at the gauge do not

sensing, and actuation capabilities that share the ability only take time but also lead to stress of being in the working

to interoperate and communicate through the Internet as area at all time. Manual systems like this are prone to

their joint platform. On board a ship power supply is incessant failures which may hinder operations because of

essential as such even ashore. At shore, generators are inadequacy. Although most generator sets now have their

manually monitored by site operators and the process of operation parameters displayed on a screen for easy access

monitoring engine performance are not sufficient for the person in charge but with the introduction of Internet

enough which has led to frequent engine break down, of things (IoT) based monitoring system, a person may

and excess cost of maintenance. There have been cases of never have to visit the generator room except during

power outage for days and weeks because of maintenance or repair as the system will not only reduce

unprofessional practices and carelessness of engine incessant checks and perform the same function but also

operators there by impacting huge loses. This problem send the information wirelessly including diagnosis to the

has lingered and caused serious concerns. Therefore, this operator’s device for necessary actions.

work introduced Wi-Fi enable internet of things (IoT)

based remote monitoring process to address the However, in engineering or science, the role of internet

unprofessional practices of engine operators. The system cannot be overemphasized since most of the work being

uses Gyroscope sensor, Magnetic field instrument sensor done revolve around it. The Internet of things (IoT)

(MGF), MG-Oil quality sensor and DS18B20 for the describes exactly the network of physical objects - “things”

effective monitoring of the generators parameters being that are embedded with sensor components, software, and

mentioned above. However, low power and low cost other technologies to connect and exchange data with other

microcontroller ESP32 board and i2C module also devices and systems over the Internet (Emodi et al, 2015).

provide a very flexible pattern for sharing operational Thus, the main objective of the Internet of Things is to make

data through Wi-Fi. Advance C++ programming it possible for objects to be connected with other objects,

language was also used to establish a stable individuals, at any time or anywhere using any network,

communication cycle. The system transmitter was path or service. The Internet of Things (IoT) is gradually

carefully designed and tested. The result shows that the being regarded as the subsequent phase in the Internet

developed system perfectly starts the generator and evolution. IoT will make it possible for ordinary devices to

monitored the oil level, battery health, stability, engine be linked to the internet in order to achieve countless

performance and transmitted the status via wireless disparate goals.

connection to the operator’s mobile phone. With this,

generators can be monitored remotely with a high According to (Yusuf, Bedine, Mahmoud, Hani, 2019),

working efficiency. estimates of 28 billion IoT devices were connected since the

birth of the internet in 1983. This means that there are more

Keywords:- Internet of Things, Mobile App Control, IoT devices in the world than there are non-IoT devices. As

Transmitter, Wi-fi Enabled IoT. the internet continues to evolve, it has become more than a

simple network of computers, but rather a network of

various devices, while IoT serves as a network of various

IJISRT23MAR1758 www.ijisrt.com 2306

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

“connected” devices (Miraz H. M, Ali M., Excell P.S and energy (kWh) generated. The measurement data can then be

Picking R, 2018). used for offline analysis of the performance condition of the

generator or to determine the length of time to the next

In this dawn of technological age, information can periodic maintenance. Furthermore, if there are more

now be shared over the Internet among devices like recording of data or parameters of operation of the generator

vehicles, smartphones, cameras, toys, buildings, home set, it can be used for failure analysis and this give rise to

appliances, industrial systems and countless others this project.

regardless of their sizes and functions, they are capable of

accomplishing smart reorganizations, tracing, positioning, Therefore, this project is stipulated to tackle the

control, real-time monitoring and process control. The problem of generator set failure during operation due to

Internet of Things has components ranging in complexity, delay in response by the person in charge of running

from simple identification tags to complex machine- physical checks on the generator set and to prevent

machine communication, cameras, smart watches as well as corrective maintenance and poor use of generator set which

electronic identification tagging of cargoes (Jeremy, 2013). contributes to continual repair and also limit physical

checkup of the system especially when the generator set is

The Internet of Things (IoT) is expected to continue installed in a tight space or contaminated with poisonous

expanding its reach as regards the number of devices and fumes or gases.

functions, which it can run. This is evident from the

ambiguity in the expression of “Things” which makes it This project will develop an operation monitoring

difficult to outline the ever-growing limits of the IoT. While system of the generator set by measuring several generator

commercial success continues to materialize, the IoT operating parameters such as fuel level, temperature and

constantly offers a virtually limitless supply of output power. So that the performance of the generator can

opportunities, not just in businesses but also in research. be analyzed to determine if it is still following the operating

Accordingly, the understudy addresses the potential of IoT standards or there is a decline in performance.

on generator as a monitoring system.

The aim of this project is to design and construct an

Generally, generator sets or Genset, both diesel and internet of things-based generator monitoring system.

gasoline fuel, have been widely used both as main or backup The objectives of this project are:

power generation or main and auxiliary power supply as

regards on-board ships. In Engineering, the working To design and construct an IoT-based generator

principle of the generator to produce electricity is based on monitoring system using Gyroscope sensor, Magnetic

the work of the combustion engine, which generates electric field instrument sensor (MGF), MG-Oil quality sensor,

power as the generator rotates. In locations that are DS18B20 for the effective monitoring of the generators.

unreached by National electricity supply like in ships during To develop a modern controlling system in a generator

voyage, network masts or field area without electricity, engine that will use sophisticated communication

generators are used as the primary source of electricity modules, such as low cost highly efficient ESP32 board

generation. In urban areas, especially in commercial and i2C module which will provide a very flexible

buildings such as banks, shopping malls and so on; pattern of use by sharing operational data through Wi-

generators are used as backup power, when there is no Fi.

electricity from National electricity supply. To make use of advance C++ programming language so

as to establish a stable communication cycle.

In addition, generators are equipped with electrical

indicators, like the output voltage, current and frequency but II. HISTORY OF INTERNET OF THINGS (IOT)

despite all these, human beings are prone to errors, they may

contribute to failures of engines due to delays in response The term “internet of things’ also known as “cyber-

time, inadequate fueling of tanks, inability to spot leakages physical systems” at the macro level, was first coined by

in tanks and so on (Edem and Ezeofor, 2018). The IoT Kevin Ashton in his presentation made to Procter and

system will be more efficient in this aspect as it is system of Gamble (P&G) in 1999 (Kevin, 2009). Kevin was working

various indicators that give some information about the in Massachusetts’ Institute of Technology (MIT) AutoID

current performance of the generator or time into the next Laboratory to improve P&G business by linking its supply

periodic maintenance. If the generator is used as the main chain with Radio-Frequency Identification (RFID)

power to support field operations, the generator must be in information to the internet (Yusuf, Bedine, Mahmoud, Hani,

good condition, so it can be assured that there will be no 2019). Internet of things extensively, is a system consisting

problem. of networks of actuators, sensors, and smart objects whose

purpose is to interconnect ‘all’ things, including day-to-day

Moreover, if the generator set develops fault when it is and industrial objects, in such a way as to make them

already under operation, it undoubtedly hinders the work intelligent, programmable, and more competent of

significantly. To solve these problems, a monitoring system interacting with humans and each other. (Institute of

of generator operation is needed. The system can record the Electrical and Electronics Engineers Standards Association

historical data of the generator parameters, starting from the (IEEE-SA), 2015). The concept of IoT is not new. Because

measurement of fuel level, engine temperature and also total programable Logic Controller (PLC) in 1970s is a micro-

IJISRT23MAR1758 www.ijisrt.com 2307

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

model of the IoT system that was widely used to control Smart, 2015) developed a smart generator monitoring

machines and processes within a factory. A PLC consists of system using micro-controller and relay to detect the power

output (example for digital or analog data), inputs (examples failure, communicate to microcontroller which makes

for sensors, actuators, and on & off switches), Central decision and finally alert the authorized person which enable

Processing Unit (CPU), and communication between the observer to keep track of the system and address any

components. The PLC systems were within a factory, not problem that arise.

connected to the internet and cloud. There is no unique

definition available for IoT that is admissible by the world In the field of agriculture, a based monitoring and

community of users. The optimal definition for the IoT controlling system to gather information on the farmland

would be an open and comprehensive networks of such as humidity and luminance so as to guide the farmers

intelligent objects that have the capacity to auto organize, on their farming activities was designed by (BulliBabu,

share information, data and transformation in the Jonathan, Cherishma, Lakshmi and Keshav, 2015)

environment”. The internet of things has components that

range in complexity, from simple identification tags to Mohammad, Musse, Bishwajeet, Hardik, Shayla and

complex machine-to-machine communication, cameras and Izzul (2021) worked on the internet of things based smart

radio frequency identification tagging of shipments in the electricity monitoring and control system using usage data.

supply chain are examples (Jeremy, 2013). Their work presented an integration of both hardware and

software. The software is used to monitor power usage and

Review of Related Works the consumption of household appliances and control system

Several studies related to the development of a fuel through overcurrent relay and notification of any mis-

monitoring system have been carried out, among others. The matches. The developed systems consist of Arduino UNO, a

ESP-8266 control module, which has Wi-Fi communication WiFi module (ESP8266), a relay, a low current sensor

facilities and ease of making internet connections, was used. breakout (ACS712), and a liquid crystal display (LCD). The

The system built was intended to monitor the condition of proposed system displayed the voltage, current, and power

the fuel level and operation status of the generator, whether consumption where the web or mobile application is used to

it is in an on or off condition. The test results obtained from visualize the data and trigger alarm, when necessary. They

the design is to get a system that provides continuous data to were able to measure overcurrent or circuit overloading

the operation of the generator and to provide ease of earlier based on advanced IoT applications where

delivery and displaying of data of all the activities of the consumers’ alarm triggers.

system as a whole through the internet (Firdaus., Murti and

Nugraha, 2017). In their system configuration, “Thing- Speak”, an open

source IoT application was used to store and retrieve data

Obikoya (2014) developed a fuel level monitoring via Hypertext Transfer Protocol (HTTP) over the internet or

system. In his study, the measurement of the fuel level used Local Area Network (LAN). Their work explains the

a resistance method from the fuel float sensor. However, compatibility of Thin-Speaks with the ESP8266 Wi-Fi

(Edem and Ezeofor, 2018) also researched on the module for analysis and storage of data from the sensor

development of a generator fuel monitoring system and based on IoT.

battery level using Global System for Mobile

Communications GSM infrastructure. In this study, the Hyun, Ryu and Jun, (2016) designed and constructed a

Atmega328 microcontroller is used as a controller and the smart emergency generator monitoring system through IoT

HC-SR04 sensor as a level gauge, through ultrasonic using IEC 61850 to provide emergency generator status to

method. The monitoring system sends information related to the user. The IEC 61850 gateways receive the data from

fuel and battery level conditions of the generator using the sensors (temperature, pressure, fuel flow) in the emergency

SMS feature via the AT command. generator. The hardware of the system includes 4 to 20mA

sensors, Controller, IEC 61850 gateway which has ARM

(Ghulam, Syed, Shoaib, Muhammed, Muhammad and Cortex M5 series 500MHz CPU, 512MB Ram, Flash

Abdul, 2021) Proposed architecture-based on an IoT memory, it supported IEC 61840 Group 1 MMS protocol

solution-consists of different sensors, namely a current and RS 485 based 2 Channel communications (Half Duplex

transformer for measuring load, fuel gauge for fuel level Mode) and an Ethernet Modem wireless router is used for

monitoring and temperature measurement with the energy LAN connection that supports 4G LTE gateway and

module to determine the power factor of the system. The 802.11b/g/n standard. In further researches, Jawad et.al

Arduino Mega controller and ESP 8266 Module for sending (2020) designed and operation and fault monitoring system

data to the i-cloud were used. of electric generator using IoT. Aduino controller board,

ADC converter, esp8266Wifi module were used. The

Several other studies have shown that the development instruction was programmed using IDE (Integrated

of a generator operation monitoring system is used to Development Environment).

conduct maintenance planning based on running time to

detect damage of the generator by analyzing the quality of Based on this review, the project will focus on IoT

the generated power, detect the generator failure based on based generator monitoring system which is software and

measurements of working temperature and generator oil hardware based, providing ease in the operation and

level. (Boopathi, Jagadeeshraja, Manivannan, Dhanasu and monitoring of generators. The operating information will be

IJISRT23MAR1758 www.ijisrt.com 2308

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

shared over Wi-Fi connection. The user will be provided manufacturer’s data book. Transformer was used to step

with a mobile application installed in a smartphone which down the 240V alternating current (AC) mains voltage of

will always display a simulation of the generator’s internal the genset to about 12V AC. The rectifying diodes were

combustion, engine performance graph, engine temperature, used to converts the AC voltage to DC voltage. Electrolytic

fuel consumption, engine frequency, total energy produced, capacitor of 1000µF/35V was used to filter ripples and

voltage and current bar. An amazing feature is its ability to regulator of 7805 used to capture exactly +5V DC needed.

turn ON and switch OFF the genset remotely through the

mobile application, whenever the generator develops an Generator Engine

issue, an alarm will be sent to the user through the Wi-Fi In this study, a Single phase 2430watts Firman

which covers the range of 500m from the generator, Gasoline generator is monitored with a special transducer

indicating areas of error and corrective measures. This offers installed on it, to generate the electrical characteristics as

a user-friendly and flexible mode of operation. well as the signal which will further be analyzed using

microcontroller.

Moreover, operating history of the generator will be

saved in the phone application for references, which will be

useful during surveys in case of sales, repairs, and

maintenance as well as to ascertain possible deviation from

the historical pattern of operation.

III. MATERIALS

The device being used consists of active and passive

electronic components, coupled with a microcontroller

system and a few sensors, which are further, systematize to

provide a real-time status of an engine using internet

communication.

A. The Materials Selected for this Project Work:

ESP32 board

i2C module

Boost converter module

3.7v lithium battery

Gyroscope sensor

DS18b sensor

MGF sensor

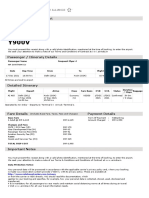

Fig 1 3-Dimensional Design of the Generator set.

MG-Oil quality sensor

HC-SRO4 Ultrasonic Sensor

The various parameters being monitored on the

Buzzer generator are features which contribute to the optimal

Resistors functioning of the system.

Capacitors

12v relays Generator Output

This part of the assembly incorporates the alternating

B. This is Grouped into the following: current line which is fed to the house or for use. The lines

are connected in a way such that the automatic changeover

Power Supply Module system will properly switch into available lines once the

2430 watts single phase Gasoline Generator set generator is running.

Sensor Module

System Control Module Automatic Changeover

Wi-Fi Module This is a simple electronic gadget that provides an

System Display Module automatic switch over between the gridline and generator or

the switch inverter.

C. Each Module is Explained below Including how they

Interact to Achieve the Desired System Objectives for Sensor Module

More Understanding: In order to monitor the vital health statues of a

generator, various physical and electrical parameters are

Power Supply Module: needed to be monitored which will be compared to their

The +3.7v Lithium battery direct current (DC) power quantity in order to adequately state the health statues of an

supply for the system was designed based on the voltage engine system.

required to power each component as specified in the

IJISRT23MAR1758 www.ijisrt.com 2309

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

These Parameters Include;

Physical Quantity:

Temperature

Fuel level

Oil quality

Gyration /acceleration

Electrical Quantity

Voltage

Current

Running frequency

Power/energy

These and many more parameters, which are so

essential that once we can easily measure them correctly, we Fig 3 Pinout of the HC-SRO4 Sensor

can actually state using a well refine predative analysis to

state the health statues of the generator. Table 1 Main Specifications of the HC-SRO4 Ultrasonic

distance sensor

To monitor these given quantities, we are using these Parameter Value

set out sensors. Operating Voltage 5V DC

Operating Current 15mA

Digital Temperature Sensor (DS18B20): Min. Range 2.54cm/1 inch

This is 1-Wire digital temperature sensor from Maxim Max Range 400cm/13 feet

IC. Reports degrees in Celsius with 9 to 12-bit precision, Operating frequency 40 kHz

from -55 to 125 (+/-0.5). Each sensor has a unique 64-Bit Accuracy 3mm

Serial number etched into it - allows for a huge number of Measuring Angle <15o

sensors to be used on one data bus. Dimension 45 x 20 x 15mm

Gyroscope Sensor (MPU6050):

The project is designed to showcase at all times, the

angle of rotation of the generator’s crankshaft. MPU6050

sensor module with complete 6-axis Motion Tracking

Device were used. It combines 3-axis Gyroscope, 3-axis

accelerometer and digital motion processor, all in a small

package. It also has additional features of on-chip

Temperature sensor and I2C bus interface to communicate

with the microcontrollers. If 3-axis Magnetometer is

connected to auxiliary I2C bus, then MPU6050 can provide

complete 9-axis Motion Fusion output.

Fig 2 Digital Temperature Sensor (DS18B20)

(Source: Pinterest.com).

Fuel Level Sensor (HC-SRO4 Ultrasonic Distance

Sensor):

This is a distance sensor incorporated in the

monitoring system of this project to monitor fuel level as it

can report the range of objects from 2cm to 400cm (about an

inch to 13 feet) away. It can operate using a low power

(suitable for battery operated devices), affordable, easy to

interface and extremely popular with Arduino. The sensor is

composed of two ultrasonic transducers. One is transmitter Fig 4 MPU6050 Sensor

which outputs ultrasonic sound pulses and the other is (Source: GY-521 Accelerometer Gyroscope Module.

receiver which listens for reflected waves. (eitkw.com))

IJISRT23MAR1758 www.ijisrt.com 2310

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The MPU6050 consist of 3-axis Gyroscope with Micro Acceleration along the axes deflects the movable mass.

Electro Mechanical System (MEMS) technology. It is used

to detect rotational velocity along the X, Y, Z axes as shown This displacement of moving plate (mass) unbalances

in below figure. the differential capacitor which results in sensor output.

Output amplitude is proportional to acceleration.

16-bit ADC is used to get digitized output.

The full-scale ranges of acceleration are +/- 2g, +/- 4g,

+/- 8g, +/- 16g.

When the device is placed on a flat surface it will

measure 0g on X and Y axis and +1g on Z axis.

MG-Oil Quality Sensor (OQS):

The sensor is a live, highly flexible, and cost-effective

condition-based monitoring solution, designed to be

permanently installed within any lubrication system on any

type of machine. Over 60 times more sensitive to oil

contamination than any other dielectric constant measuring

Fig 5 Rotational velocity along the X, Y, Z axes. sensor, it provides real-time monitoring of water ingress and

Source: Sensors Modules Mpu6050 Gyroscope oxidation levels.

Accelerometer Temperature Sensor (electronicwings.com)

Electrical Sensor (PZEM-004T) Multifunction Power

When the gyros are rotated about any of the sense axes, Monitoring:

the Coriolis effect causes a vibration that is detected by The PZEM-004T circuit is used for measuring AC

a MEM inside MPU6050. Root Mean Square (RMS) voltage, current and power

The resulting signal is amplified, demodulated, and (single phase). The unit easily interfaces with Arduino and

filtered to produce a voltage that is proportional to the other hardware using the code. The circuit comes with a

angular rate. TTL to USB adapter wire for easy connection to a computer

This voltage is digitized using 16-bit ADC to sample or microcontroller.

each axis.

The full-scale ranges of output are +/- 250, +/- 500, +/-

1000, +/- 2000.

This measures the angular velocity along each axis in

degree per second unit.

The MPU6050 consist 3-axis Accelerometer with Micro

Electro Mechanical (MEMs) technology. It was used to

detect angle of tilt or inclination along the X, Y and Z

axes as shown in the figure below:

Fig 7 PZEM-004T Multifunction Power Monitoring

(Source: AC Multifunction Meter Watt Power Volt Amp

Current Test Module PZEM-004T New | eBay)

Specifications:

Working voltage: 80 ~ 260VAC

Fig 6 Angle of inclination along X, Y and Z axes for the Test Voltage: 80 ~ 260VAC

3-axes accelerometer. Rated power: 100A / 22000W

(Source: MPU6050 (Gyroscope + Accelerometer + Operating frequency: 45-65Hz

Temperature) Sensor Module |... (electronicwings.com). Measurement accuracy: 1.0.

IJISRT23MAR1758 www.ijisrt.com 2311

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

This module serves all these basic requirements of Peripherals Capacitive touch, ADC

measurement PZEM-004T as a separate board. The physical (analog to digital converter,

dimensions of the PZEM-004T board is 3.1×7.4 cm. The DAC (digital to analog

PZEM-004T module is bundled with 33mm diameter converter), I2C (Inter-

current transformer coil. Integrated Circuit), UART

(universal asynchronous

The main part of the PZEM-004T module is the receiver/transmitter), CAN

SD3004 chip from the SDIC Microelectronics Co., Ltd. In 2.0 (Controller Area

addition, the board having the EEPROM from Atmel (now Network), SPI (Serial

microchip) 24C02C which is a 2K bit Serial Electrically Peripheral Interface), I2S

Erasable PROM with a voltage range of 4.5V to 5.5V with (Integrated Inter-IC Sound),

More than 1 million Erase/Write Cycles and 200+ Years RMII (Reduced Media-

Data Retention. Independent Interface),

PWM (Pulse Width

System Control Module (ESP32 Microcontroller): Modulation), and more.

ESP32 is in the series of low power and low cost chip

microcontroller. It comes up with already integrated dual The ESP32 board was programmed using Arduino

mode Bluetooth and Wi-Fi. It is especially aimed to provide IDE

versatility, robustness and reliability in a large number of

applications. Some applications in which this System Display Module (i2C module (16 x 2 LCD)):

microcontroller is extensively used are MP3 decoding, voice A 16 x 2 LCD is used by the system to display the

encoding and music streaming. Best RF and power parameters being measured, some in percentage as it

performance can be easily achieved using this operates. Each character is displayed in 5x7 pixel matrix as

microcontroller. ESP32 comes up with a USB port so we the data is sent from the microcontroller.

can say that it is plug and play devices i.e. plug in cable and

your device is turned on and you are able to program it just System Design:

like Arduino development boards. In this design, the building block or working principle

of the system is evidently presented using a simple block

diagram below.

Fig 8 ESP32 Microcontroller

(Source: Esp32 Esp-wroom-32 Esp32 Esp-32s Development

Board Wi-fi Bluetooth Ultra-low Power Consumption Dual

Cores Esp32 Board - Integrated Circuits - AliExpress)

Table 2 Specification of ESP32 Microcontroller

Component Value

Number cores 2 (dual core) Fig 9 Block Diagram of the System

Wi-Fi 2.4 GHz up to 150 Mbits/s

Bluetooth BLE (Bluetooth Low Figure 9 is further elaborated using the simple circuit

Energy) and legacy diagram presented below.

Bluetooth

Architecture 32 bits

Clock frequency up to 240 MHz

RAM 512 KB

Pins 30 or 36 (depends on the

model)

IJISRT23MAR1758 www.ijisrt.com 2312

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig 10 The Circuit Diagram

Fig 12Microcontroller Interactions with the Sensors

Software Component

The software aspect of this project involves

Fig 11 The interface of the designed Monitoring System

application development with friendly user interface using

the advanced C++ for compiling set of commands necessary

In the design process, all the sensors are embedded to

for the smooth operation of the monitoring system, used also

the micro controller via its pin, as all the data are processed

as the system Algorithm for the microcontroller.

and analyzed for use as shown in Figure 12:

IJISRT23MAR1758 www.ijisrt.com 2313

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Data Logging: generator, national grid supply for domestic consumption

Blynk is an IoT platform for iOS or Android and solar panel with national grid supply as the primary

smartphones that is used to control Arduino, Raspberry Pi reference. These two systems worked independently while

and Node MCU via the Internet. This application is used to their data were uploaded to the cloud through Wi-Fi and

create a graphical interface or human machine interface shared to the phone application via the same network.

(HMI) by compiling and providing the appropriate address

on the available widgets.

Blynk was designed for the Internet of Things. It can control

hardware remotely, it can display sensor data, store data,

visualize and so on.

Android Application:

With Blynk, you can create smartphone applications

that allow you to easily interact with microcontrollers or

even full computers such as the Raspberry Pi.

IV. SYSTEM SETUP

At the Completion of the Project Design and

Construction, there were Two Independently

Addressable Systems which are:

Mechanical System and

Electrical System

Mechanical System

This system was responsible for measuring and

sharing the mechanical parameters of the single phase 2430 Fig 14 The Electrical System Circuit Board

watts gasoline generator. These parameters are oil level, oil Plugged for Testing

quality, gyroscopic orientation and running temperature.

Fig 13 The Mechanical system loading for wi-fi connection

during testing (Source: Author’s work, 2022) Fig 15 The Gyroscope Sensor Showing the Position of the

Generator Set During Testing

Electrical System

The electrical system was responsible for measuring

and sharing the electrical parameters of the single phase

2430 watts gasoline generator. These parameters are

frequency, voltage, current, energy consumed, battery

voltage and running hour. This system also served as an

automatic change-over as it is fitted with inputs for

IJISRT23MAR1758 www.ijisrt.com 2314

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig 16 The Phone Application Interface before Testing

V. RESULT AND DISCUSSION

The monitoring system was installed, turned on and

tested. The application was installed on a smartphone and

the Wi-Fi connection was established using ESP BOARD as

the network name and esp12345 as the password

immediately after which the internet connection was

established between the system and the phone. The

generator set was turned on from the smartphone and the

intended measurable working parameters were clearly

displayed on the mobile application while the buzzers,

sensors, and modules interact efficiently, sending the right

information for necessary action as expected without any

discrepancy. The result was completely a successful one as

the system was able to prove its efficiency. The time interval

in switching the generator and the grid lines by the system

was completely exceptional, due to the fact that its interval

is not up to a second, rather in mili second without

interruption.

Fig 17 FThe Electrical System Circuit LCD Board

Displaying Generator Operating Volts, Current and Power

IJISRT23MAR1758 www.ijisrt.com 2315

Volume 8, Issue 3, March – 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The simulation of the IoT based generator monitoring REFRENCES

system with mobile phone application was done to showcase

the performance of the system. The parameters were [1]. Boopathi, Jagadeeshraja, Manivannan, Dhanasu and

monitored by reading the voltage variations in the generator Smart. (2015). Generator monitoring system in

set, mapped in digital form using the necessary sensors and industry using micro-controller. American Journal of

modules where applicable. The data is sent to the Electrical Power and Energy Systems, 45-50.

microcontroller which processed it and sent it to the mobile [2]. BulliBabu, Jonathan, Cherishma, Lakshmi and

application in discrete values. Keshav. (2015). GSM based Heart Rate and

Temperature monitoring system.

VI. CONCLUSION [3]. Jeremy Crump. (2013). Time for debate about the

societal impact of the Internet of Things. The policy

This project showed that management cannot be and Internet Blog.

achieved without measuring, and measuring can only be [4]. Edem and Ezeofor. (2018). IoT Based Monitoring of

achieved by monitoring. For ship managers, malls owner Generator's Fuel & Levels in Base Station Cell Sites

and other industrialist who want to keep a close eye on their With SMS Alert. Global Scientific Journals, 36, 37-

generators, the internet of things (IoT) based generator 39.

monitoring system is a dream come true. This project [5]. Edem and Ezeofor. (2018). IoT Based Monitoring of

reduces stress, decreases maintenance costs, and reduces the Generator's Fuel &Battery Levels in Based Station

frequency and severity of breakdowns. It will enable site Cell Sites with SMS alert. Global Scientific Journals,

engineers to focus on other core tasks or sit back and 37.

monitor through their phones while taking actions only [6]. Firdaus., Murti and Nugraha. (2017). CONTROL

when required. SYSTEMS AND MONITORING GENSET VIA

INTERNET. e-proceeding of Engineering, 36.

In simple terms, this project of internet of things [7]. Ghulam, Syed, Shoaib, Muhammed, Muhammad and

connects physical objects to a network. Ashore, IoT devices Abdul. (2021). An IoT-Generator for Power

can include smart light bulbs, moisture sensors to water your Monitoring and Load Management with Power Factor

plants, and a growing range of health-tracking gadgets. IoT Improvement. Engineering Proceedings, 1-4.

blurs the line between physical and digital objects by [8]. Hyun, Ryu and Jun. (2016). Smart Emergency

connecting the physical and digital worlds. By providing a Generator Montoring System through IoT using

continuous stream of data, IoT unlocks the power of big IEC61850. Indian Journal of Science and Technology

data, artificial intelligence (AI) and machine learning (ML). [9]. Institute of Electrical and Electronics Engineers

Standards Association (IEEE-SA). (2015). IEEE

This project thrived through a lot of limitations some Standards Association. Institute of Electrical and

of which still remained as constraints but these can be Electronics Engineer Inc. Internet of Things (IoT)

conquered. Ecosystem Study.

[10]. Kevin. (2009). That internet of things' thing,. Radio

RECOMMENDATION Frequency Identification development.

[11]. Miraz H. M, Ali M., Excell P.S and Picking R.

The technological advancement of this era gave birth (2018). Internet of Nano-Things, Things and

to this project but the limitations we had prevented us from Everything: Future Growth Trends. Future Internet,

unlocking its full potential. The initial plan for this project 68.

was to develop a monitoring system for a wide variety of [12]. Mohammad, Musse, Bishwajeet, Hardik, Shayla and

marine diesel engine as applicable onboard vessel. Due to Izzul. (2021). Internet of things-Based Smart

the global inflation, there is hike in prices of components Electricity Monitoring and Control System using

and other materials which could have been used to fulfil the Usage Data. Hindawi Wireless Communication and

intended target but now limited the project to only the Mobile Computing, 16.

2430watts single phase gasoline engine. This project can be [13]. Obikoya. (2014). Design, Construction and

upgraded to an impressive extent suitable for onboard Implementation of a remote fuel-level monitoring

application in the Nigeria Shipping industry and in the system. EURASIP Journal on Wireless

monitoring of generators in industries for efficiency, as it Communication and Networking, 83.

has been observed that so much is being spent on the repairs [14]. Yusuf, Bedine, Mahmoud, Hani. (2019). An

and maintenance of the gensets yet the output is poor as Extended review on Internet of Things (IoT) and its

evident in the epileptic power supply that has crippled Promising Application. Communication on Applied

business in Nigeria. Electronics/ Foundation of Computer Science, 2394-

4714.

IJISRT23MAR1758 www.ijisrt.com 2316

You might also like

- TANCA 2022 Information BookletDocument57 pagesTANCA 2022 Information Bookletmohana priyaNo ratings yet

- Bharat - The Neo India Report - FINALDocument40 pagesBharat - The Neo India Report - FINALAdityaSarafNo ratings yet

- 63b3033d-a734-4f0d-9f44-11651425564eDocument4 pages63b3033d-a734-4f0d-9f44-11651425564eRenuka DigheNo ratings yet

- Web Techology PresentationDocument25 pagesWeb Techology PresentationGowtham P BNo ratings yet

- Lec02 Ae Ms14Document59 pagesLec02 Ae Ms14Mohsin Abbas ZafarNo ratings yet

- Ahmedabad To Delhi J3E3RL: Go First G8-720Document3 pagesAhmedabad To Delhi J3E3RL: Go First G8-720mayur dhandeNo ratings yet

- MT7601BE DS-EN - Rev0.90Document7 pagesMT7601BE DS-EN - Rev0.90Vishal dtuNo ratings yet

- 30-Apr-2022 06-Mar-2023 20-Apr-2023 1100 Hrs - 1400 HrsDocument3 pages30-Apr-2022 06-Mar-2023 20-Apr-2023 1100 Hrs - 1400 HrssapramyaNo ratings yet

- Petrol Forecourt Desig - Campbell Rigg AgencyDocument6 pagesPetrol Forecourt Desig - Campbell Rigg AgencyJames CNo ratings yet

- Choose An Outbound Flight: FlightsDocument1 pageChoose An Outbound Flight: FlightsVishnu SamyNo ratings yet

- 3BSE008516R1: AI810 Analog Input 8 CHDocument3 pages3BSE008516R1: AI810 Analog Input 8 CHsantechsystemsNo ratings yet

- The New India Assurance Co. Ltd. (Government of India Undertaking)Document3 pagesThe New India Assurance Co. Ltd. (Government of India Undertaking)kalair motorsNo ratings yet

- SRSDocument107 pagesSRSIlma MujeebNo ratings yet

- Government of Telangana Layout Regularisation Scheme - 2020 - Wangapally Grama PanchayatDocument2 pagesGovernment of Telangana Layout Regularisation Scheme - 2020 - Wangapally Grama PanchayatFINANCIAL LITERACYNo ratings yet

- SAP HANA in Healthcare Real-Time Big Data AnalysisDocument25 pagesSAP HANA in Healthcare Real-Time Big Data AnalysisKESHAVA HBNo ratings yet

- Aon CoCubes Candidate Interface Manual ETDocument5 pagesAon CoCubes Candidate Interface Manual ETSaloni KantNo ratings yet

- Mum To Vadodra 24 Jan 2023Document2 pagesMum To Vadodra 24 Jan 2023Priyank UpadhyayNo ratings yet

- PRC - Ece - EorDocument1 pagePRC - Ece - EorLogic CircuitNo ratings yet

- UnlockedDocument21 pagesUnlockedRakesh dasNo ratings yet

- Red Hat Virtualization-4.4-Planning and Prerequisites Guide-En-UsDocument38 pagesRed Hat Virtualization-4.4-Planning and Prerequisites Guide-En-UsAnoopNo ratings yet

- Print ConfirmationDocument2 pagesPrint ConfirmationNimish PavanNo ratings yet

- A Seminar Report On Wireless ElectricityDocument30 pagesA Seminar Report On Wireless ElectricityDhananjayNo ratings yet

- Power Car RB LetterDocument5 pagesPower Car RB Letterമിസ്റ്റർ പോഞ്ഞിക്കരNo ratings yet

- Affiliated To Kurukshetra University, Kurukshetra (Approved by AICTE, New Delhi)Document21 pagesAffiliated To Kurukshetra University, Kurukshetra (Approved by AICTE, New Delhi)Divjot BatraNo ratings yet

- Saidur Rahman CVDocument3 pagesSaidur Rahman CVSaidur hridoyNo ratings yet

- PreviewInsertApplication - NVS RecruitmentDocument3 pagesPreviewInsertApplication - NVS RecruitmentINFATUATIONNo ratings yet

- A Novel Approach To The Weight and Balance Calculation For The de Haviland Canada DHC-6 Seaplane OperatorsDocument10 pagesA Novel Approach To The Weight and Balance Calculation For The de Haviland Canada DHC-6 Seaplane OperatorsAI Coordinator - CSC JournalsNo ratings yet

- Electronic Reservation Slip (ERS) : Passenger DetailsDocument2 pagesElectronic Reservation Slip (ERS) : Passenger DetailsrajendranrajendranNo ratings yet

- Loan Ledger - LIC HFL - Customer PortalDocument1 pageLoan Ledger - LIC HFL - Customer PortalCode With KrishnabNo ratings yet

- Shukul Wealth Advisory Claim Form Details: 1. Submit Your Personal Details For Claim On EmailDocument3 pagesShukul Wealth Advisory Claim Form Details: 1. Submit Your Personal Details For Claim On Emailandrew punekarNo ratings yet

- Btech CertificatesDocument6 pagesBtech CertificatesSuresh VadlamudiNo ratings yet

- MODULE2NJDocument104 pagesMODULE2NJSidharth MishraNo ratings yet

- RecruitmentNotifications - TPCODL - 24072020Document1 pageRecruitmentNotifications - TPCODL - 24072020Sunny Rath100% (1)

- Khwahish - Tec CertificateDocument6 pagesKhwahish - Tec CertificateVIJAY PATELNo ratings yet

- EV Standards & Research Avenues GHRaisoni Pune DR Vora 141221Document123 pagesEV Standards & Research Avenues GHRaisoni Pune DR Vora 141221Kamal VoraNo ratings yet

- IKM Online Assessment ResultDocument1 pageIKM Online Assessment ResultpattabhikvNo ratings yet

- Final Center List Feb 2023Document81 pagesFinal Center List Feb 2023Huba ZehraNo ratings yet

- Design and Implementation of A Solar Plant and Irrigation System With Remote Monitoring and Remote Control InfrastructureDocument12 pagesDesign and Implementation of A Solar Plant and Irrigation System With Remote Monitoring and Remote Control InfrastructureDesalegn Imana AtomsaNo ratings yet

- 1SVR550217R4100 CT Sde Time Relay Star Delta 1c o 0 3 30s 24vac DC 220 240vacDocument2 pages1SVR550217R4100 CT Sde Time Relay Star Delta 1c o 0 3 30s 24vac DC 220 240vacPezzolato100% (1)

- Dealer InvoiceDocument1 pageDealer Invoicebujii bujiiNo ratings yet

- 2022be313-5-Au Portfolio AnalysisDocument5 pages2022be313-5-Au Portfolio AnalysisKhawaja HamzaNo ratings yet

- Railway Recruitment Boards: Government of India Ministry of Railways CEN 01/2019Document1 pageRailway Recruitment Boards: Government of India Ministry of Railways CEN 01/2019gaurav kumarNo ratings yet

- Future Generali India: Insurance Company LimitedDocument2 pagesFuture Generali India: Insurance Company Limitedstar pandiNo ratings yet

- ReportDocument34 pagesReportVaishnaviNo ratings yet

- Sabarinathansethuraman - 13 Yrs - SLN Developer - AMD - BangaloreDocument7 pagesSabarinathansethuraman - 13 Yrs - SLN Developer - AMD - BangaloreVinodh KumarNo ratings yet

- Co Mprehens Ive Po Licy Co Mprehens Ive Po Licy: Acko AdvantageDocument6 pagesCo Mprehens Ive Po Licy Co Mprehens Ive Po Licy: Acko AdvantageRajesh NatarajanNo ratings yet

- STTP BrochureDocument2 pagesSTTP BrochurehemantNo ratings yet

- HR ArmaanDocument84 pagesHR Armaanzomaan mirzaNo ratings yet

- Thunder CFW High Performance Versatile FirewallDocument12 pagesThunder CFW High Performance Versatile FirewallNajib NdutNo ratings yet

- Project Report Guidelines For BBA Final Year PDFDocument12 pagesProject Report Guidelines For BBA Final Year PDFSunmon TueNo ratings yet

- FibeAir IP 20N Technical Description 10.0 Rev A.08Document450 pagesFibeAir IP 20N Technical Description 10.0 Rev A.08Juan Deivi SantosNo ratings yet

- Trips Flight DownloadETicket-7Document4 pagesTrips Flight DownloadETicket-7sahil kumarNo ratings yet

- Subhash Kumar Chaudhary-CVDocument2 pagesSubhash Kumar Chaudhary-CVUgrasen Chaudhary100% (1)

- WSN in Agriculture Using MLDocument23 pagesWSN in Agriculture Using MLAlexander Merejildo TomaláNo ratings yet

- Atap Jemuran Otomatis Menggunakan Sensor Hujan Dan Sensor Cahaya Berbasis Arduino UnoDocument6 pagesAtap Jemuran Otomatis Menggunakan Sensor Hujan Dan Sensor Cahaya Berbasis Arduino UnoRafli PangoNo ratings yet

- TikTok Technical Analysis 17 Jul 2022. Media ReleaseDocument15 pagesTikTok Technical Analysis 17 Jul 2022. Media Releasejordan zapataNo ratings yet

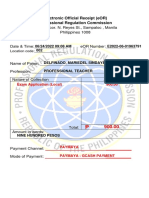

- Electronic Official Receipt (eOR) Professional Regulation CommissionDocument1 pageElectronic Official Receipt (eOR) Professional Regulation CommissionMax zeo VilloteNo ratings yet

- DetailedscheduleDocument26 pagesDetailedscheduleAaradhya MishraNo ratings yet

- Asad FarooqDocument4 pagesAsad FarooqWaseem AbbasNo ratings yet

- Persentation ON Internet of ThingsDocument16 pagesPersentation ON Internet of ThingsArpit Jain EENo ratings yet

- Sustainable Energy Consumption Analysis through Data Driven InsightsDocument16 pagesSustainable Energy Consumption Analysis through Data Driven InsightsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Vertical Farming System Based on IoTDocument6 pagesVertical Farming System Based on IoTInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Entrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisDocument10 pagesEntrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Influence of Principals’ Promotion of Professional Development of Teachers on Learners’ Academic Performance in Kenya Certificate of Secondary Education in Kisii County, KenyaDocument13 pagesInfluence of Principals’ Promotion of Professional Development of Teachers on Learners’ Academic Performance in Kenya Certificate of Secondary Education in Kisii County, KenyaInternational Journal of Innovative Science and Research Technology100% (1)

- Ambulance Booking SystemDocument7 pagesAmbulance Booking SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Utilization of Waste Heat Emitted by the KilnDocument2 pagesUtilization of Waste Heat Emitted by the KilnInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Digital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaDocument10 pagesDigital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Detection and Counting of Fake Currency & Genuine Currency Using Image ProcessingDocument6 pagesDetection and Counting of Fake Currency & Genuine Currency Using Image ProcessingInternational Journal of Innovative Science and Research Technology100% (9)

- An Overview of Lung CancerDocument6 pagesAn Overview of Lung CancerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Osho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)Document8 pagesOsho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)International Journal of Innovative Science and Research TechnologyNo ratings yet

- An Efficient Cloud-Powered Bidding MarketplaceDocument5 pagesAn Efficient Cloud-Powered Bidding MarketplaceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Designing Cost-Effective SMS based Irrigation System using GSM ModuleDocument8 pagesDesigning Cost-Effective SMS based Irrigation System using GSM ModuleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Impact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaDocument6 pagesImpact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Effect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictDocument13 pagesEffect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Computer Vision Gestures Recognition System Using Centralized Cloud ServerDocument9 pagesComputer Vision Gestures Recognition System Using Centralized Cloud ServerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Tix: Automated Bus Ticket SolutionDocument5 pagesAuto Tix: Automated Bus Ticket SolutionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Examining the Benefits and Drawbacks of the Sand Dam Construction in Cadadley RiverbedDocument8 pagesExamining the Benefits and Drawbacks of the Sand Dam Construction in Cadadley RiverbedInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Industry That Capitalizes Off of Women's Insecurities?Document8 pagesAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyNo ratings yet

- Forensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsDocument12 pagesForensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Predictive Analytics for Motorcycle Theft Detection and RecoveryDocument5 pagesPredictive Analytics for Motorcycle Theft Detection and RecoveryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparative Evaluation of Action of RISA and Sodium Hypochlorite on the Surface Roughness of Heat Treated Single Files, Hyflex EDM and One Curve- An Atomic Force Microscopic StudyDocument5 pagesComparative Evaluation of Action of RISA and Sodium Hypochlorite on the Surface Roughness of Heat Treated Single Files, Hyflex EDM and One Curve- An Atomic Force Microscopic StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoDocument6 pagesStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningDocument8 pagesUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersDocument33 pagesCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Blockchain Based Decentralized ApplicationDocument7 pagesBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Health Care SystemDocument8 pagesSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Visual Water: An Integration of App and Web To Understand Chemical ElementsDocument5 pagesVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueDocument2 pagesParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaDocument6 pagesFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldDocument6 pagesImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Project Digital Quiz EssentialsDocument8 pagesProject Digital Quiz EssentialsOliver C SilvanoNo ratings yet

- Hmi System AddressDocument11 pagesHmi System AddressAquasoul CoNo ratings yet

- GA-Q67M-D2H-B3 (Rev. 1.0) Placas-Mãe - GIGABYTE BrazilDocument1 pageGA-Q67M-D2H-B3 (Rev. 1.0) Placas-Mãe - GIGABYTE Brazilxwfk7c5d6vNo ratings yet

- Magellan Basic ManualDocument147 pagesMagellan Basic Manuallab arafiq100% (1)

- Genetic - Algorithms - Traveling - Salesman - ProblemDocument15 pagesGenetic - Algorithms - Traveling - Salesman - ProblemSandeep RoyNo ratings yet

- Emerging Technologies - Understanding Blockchain EconomyDocument59 pagesEmerging Technologies - Understanding Blockchain EconomyUjjwal SinhNo ratings yet

- UNIT-4 Designing Your User Interface With ViewsDocument50 pagesUNIT-4 Designing Your User Interface With ViewsAbhay PawarNo ratings yet

- UntitledDocument260 pagesUntitledZidni ZiyadahNo ratings yet

- FAQ - Tcs IlpDocument27 pagesFAQ - Tcs IlptkkhhaarreeNo ratings yet

- Bda r16 Csdlo7032 QPDocument4 pagesBda r16 Csdlo7032 QPyo fireNo ratings yet

- DP-2840 PR en 0012Document126 pagesDP-2840 PR en 0012khodan.workNo ratings yet

- Matrix Logger With Logger Version 11 Quick Operating InstructionsDocument11 pagesMatrix Logger With Logger Version 11 Quick Operating InstructionsMohamedNo ratings yet

- Expires 3 15 2021 Lenel-OnGuard-SubscriptionSoftwareDocument11 pagesExpires 3 15 2021 Lenel-OnGuard-SubscriptionSoftwareCamilo HigueraNo ratings yet

- ABECS ProposalDocument82 pagesABECS ProposalIfaa HaileNo ratings yet

- AI Assignment # 1Document11 pagesAI Assignment # 1Rafshan ImbisaatNo ratings yet

- BC-5000 BC-5150 Installation Guide - V7.0 - ENDocument41 pagesBC-5000 BC-5150 Installation Guide - V7.0 - ENKevin BravoNo ratings yet

- The Real Power of The Digital PlatformDocument14 pagesThe Real Power of The Digital PlatformNhat Nam PhanNo ratings yet

- TSI User ManualDocument176 pagesTSI User ManualROQ rafNo ratings yet

- C++ Viva QuesDocument16 pagesC++ Viva QuesAkhil SainiNo ratings yet

- Screenshot 2023-04-12 at 11.39.42 PMDocument21 pagesScreenshot 2023-04-12 at 11.39.42 PMFatma Amro AliNo ratings yet

- Voltage Mode Multiplying DAC Reference DesignDocument16 pagesVoltage Mode Multiplying DAC Reference DesignMouloud IbelaidenNo ratings yet

- DS AP570SeriesDocument7 pagesDS AP570SeriesadinNo ratings yet

- Instrucciones 3c509b IsaDocument2 pagesInstrucciones 3c509b Isabats bengueNo ratings yet

- Parent Mobile App FeaturesDocument3 pagesParent Mobile App FeaturesAbhimatNo ratings yet

- Xerox EX-i C60/C70 Print Server Powered by Fiery: World-Class Color With Workflow Tools That Put You in CommandDocument2 pagesXerox EX-i C60/C70 Print Server Powered by Fiery: World-Class Color With Workflow Tools That Put You in Commandchrisban35No ratings yet

- ABB EVI ProductLeaflet HVC-OpportunityCharging ND WebDocument2 pagesABB EVI ProductLeaflet HVC-OpportunityCharging ND WebAl RANo ratings yet

- Tactical LAN Managment (FM 24-7)Document135 pagesTactical LAN Managment (FM 24-7)mikaelNo ratings yet

- Ethernet Ip (Me0278 10d)Document340 pagesEthernet Ip (Me0278 10d)juan carlos basilioNo ratings yet

- Fall 2022 - CS610P - 2Document3 pagesFall 2022 - CS610P - 2Noor FatimaNo ratings yet

- LTE Timers - T300, T301, T303, T304, T305, T310, T311, T320, T321Document2 pagesLTE Timers - T300, T301, T303, T304, T305, T310, T311, T320, T321vishalkavi18No ratings yet