Professional Documents

Culture Documents

BR - Success Story - PTE - 4page - Eng - S

Uploaded by

ABOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR - Success Story - PTE - 4page - Eng - S

Uploaded by

ABCopyright:

Available Formats

S U C C E S S S T O R Y | R U B B E R

Hägglunds drive systems

are indispensable for

rubber compounder PTE

P O LY M E R - T E C H N I K E L B E | SUCCESS STORY

Hägglunds drive systems

are indispensable for PTE

Headquartered in Wittenberg, Germany, Polymer-Technik Elbe listening ear, they also secured a solu-

GmbH (PTE) is a leading producer of rubber compounds for tion. In less than 24 hours, the part

automotive engineering, construction, medical technology and had been specially delivered to Cleve-

other sectors. With additional operations in France, China and land and dispatched by plane to

Mexico – and Hägglunds hydraulic direct drive systems from Mexico.

Bosch Rexroth – the company is positioned to succeed in a “In huge companies there are lots of

changing global market. rules, but these guys were so open-

minded and helped out without any

bureaucracy,” Keil says. “That superior

Delivering when it matters most the Spider control system of our Häg- service meant we could limit our force

While at the 2019 International Elasto- glunds drive systems,” Keil recalls. majeure situation to just two weeks,

mer Conference in the US city of Cleve- “50% of our capacity was down, so it which is incredible. There you can

land, Ohio, PTE Managing Director Dr. was force majeure – we couldn’t keep really talk about minimizing downtime.”

Wolfgang Keil received a disturbing our promises to our customers.”

phone call from the company’s recently Knowing that Bosch Rexroth was show- Vital advantages on the factory floor

opened factory in Mexico. “Due to a ing at the same exhibition, Keil took a Having used them for over 25 years,

power grid issue, the main board had brisk walk to the drive supplier’s stand. PTE today has a fleet of almost 50

failed and we needed a spare part for Not only did the staff there offer a Hägglunds drive systems that are inte-

S U C C E S S S T O R Y | P O LY M E R - T E C H N I K E L B E

PTE is global company Here their production

plant in Mexico.

the problems fewer and the work more

pleasant. Above all, Keil praises the

drives’ torque capabilities and indus-

try-leading safety.

“After a stop, we can easily go from

zero to mixing speed with no problem

thanks to the high torque,” Keil

explains. “But the quick-stop function

on roll mills is the strongest feature,

because it makes these workplaces

really safe. In an emergency situation,

we can stop the mills immediately

– say, in just one or two centimeters .

PTE today has a fleet of almost 50 Hägglunds drive systems that are integral to its

With an electromechanical drive and

compounding business. breaker, that kind of precision simply

wouldn’t be possible.”

gral to its compounding business. Keil mounted directly on the shaft. That

was deeply impressed by the flexibility very compact design is a strong advan- An asset that follows everywhere

of the Hägglunds team in Cleveland, tage that helps us save space and Speed and agility are important on

and he is similarly enthusiastic about create a better working environment for PTEs equipment, but also for PTE’s

the drive systems themselves. the operators.” business, especially as uncertainties in

“From a layout and design perspective, Keil notes that the compounding envi- the automotive sector raise questions

the hydraulic drive systems are very ronment can be dusty, hot and noisy. for the rubber industry as a whole. The

flexible,” Keil explains. “You have just a However, the enclosed design and low company’s expansions into France

cabinet and pumps, with the motor noise output of Hägglunds drives make (2005), China (2006 and 2018) and

P O LY M E R - T E C H N I K E L B E | S U C C E S S S T O R Y

The quick-stop function on rolling mills, which Bosch Rexroth offers, makes the workplace really safe. In an emergency situation, the sys-

tems can be stopped immediately. ness.

Mexico (2016) have been strategically Meeting tomorrow’s demands with remain part of its recipe for growth.

important, offering multiple ways to hydraulics “We’ve invested heavily in Hägglunds

protect profitability. In truth, PTE did try other drive sys- drives since 1993,” Keil says. “We

“We serve the rubber industry, and tems on its first roll mills in China. believe in quality and technology, and

depending on its development we’ll be However, the experience is not one Keil installing state-of-the-art equipment is

more successful or less successful. But wants to repeat. “Starting in Wuxi was still our policy. We’re working on differ-

going global was the right decision for a huge risk with a lot of cost pressure, ent strategies to grow, but they will be

us. Even as a smaller player, working in so we decided not to use hydraulics based on technology and technical

different regions gives us sourcing there,” he explains. “Looking back, that customer service. So we’ll see what

advantages and flexibility for what the was a failure. Electromechanical drives the development of the drive technol-

future brings. Mexico was our best demand a lot more space, create a lot ogy brings in coming years.”

market in 2019, for example,” Keil says. of noise and require much more fre-

quent maintenance. Yet they supply

At every site PTE operates, Hägglunds less torque. Hydraulic drive technology

drive systems are a part of the equa- offers a lot of advantages that we don’t

tion. “At PTE we have very standardized want to miss.”

downstream equipment,” Keil says. As PTE addresses new challenges,

“Hägglunds drive technology belongs including tighter CO2 regulations and

to that standard layout – so it’s not demands to reduce energy consump-

open for discussion.” tion, Keil says Hägglunds drives will

You might also like

- Modern Approaches to Discrete, Integrated Component and System Reliability Engineering: Reliability EngineeringFrom EverandModern Approaches to Discrete, Integrated Component and System Reliability Engineering: Reliability EngineeringNo ratings yet

- 2023-05 SafeAI Electrication+Autonomy WPDocument26 pages2023-05 SafeAI Electrication+Autonomy WPJose Miguel VargasNo ratings yet

- Don’t Digitise Your Rubbish: Integrate, Simplify, and Systematise Your Operations FirstFrom EverandDon’t Digitise Your Rubbish: Integrate, Simplify, and Systematise Your Operations FirstNo ratings yet

- Hex 922e - 925e t4f 44 PG Broch A4Document44 pagesHex 922e - 925e t4f 44 PG Broch A4davi henrique boazNo ratings yet

- Hills Biscuits Case StudyDocument1 pageHills Biscuits Case Studynandika300No ratings yet

- JUNE - 2002: The Indispensable Tool For Converters of Flexible PackagingDocument6 pagesJUNE - 2002: The Indispensable Tool For Converters of Flexible PackagingFelipeAndrésLondoñoGrandaNo ratings yet

- 'Even Bigger Wind Turbines - It's A Choice For Customers, Optimise One Project or Deliver Two' - Vestas CTO - RechargeDocument2 pages'Even Bigger Wind Turbines - It's A Choice For Customers, Optimise One Project or Deliver Two' - Vestas CTO - RechargeJoão Mendonça SantosNo ratings yet

- LR oilandgas-GB 04Document12 pagesLR oilandgas-GB 04deepakNo ratings yet

- Is Modularization Right For Your ProjectDocument6 pagesIs Modularization Right For Your Projectalinawaz91No ratings yet

- JPT 2018-09Document124 pagesJPT 2018-09NadirNo ratings yet

- TSMC - Company Head YC Chao Talks About The Deep-Pocketed CIGSSe Thin-Film Start-UpDocument3 pagesTSMC - Company Head YC Chao Talks About The Deep-Pocketed CIGSSe Thin-Film Start-UpSeason LeeNo ratings yet

- Futuro CombustiblesDocument6 pagesFuturo CombustiblesIsamar LópezNo ratings yet

- Bolting Solutions CatalogDocument74 pagesBolting Solutions Catalogcyrano1091No ratings yet

- Diesel Progress - November 2022-20Document2 pagesDiesel Progress - November 2022-20ovz07333nezid.comNo ratings yet

- Northvolt Ett SkellefteåDocument10 pagesNorthvolt Ett SkellefteåFrancisco de Asís Galván DíazNo ratings yet

- Diesel Progress - November 2022-15Document2 pagesDiesel Progress - November 2022-15Matias121212No ratings yet

- Revista Spectrum Plastics 2010Document32 pagesRevista Spectrum Plastics 2010Antonio ZambranoNo ratings yet

- Floating Good Ideas: Special Technology SupplementDocument4 pagesFloating Good Ideas: Special Technology SupplementRoberto carlos cuello GomezNo ratings yet

- CPC 100 Article 43 Possibilities 1 System OMICRON Magazine 2015 ENUDocument4 pagesCPC 100 Article 43 Possibilities 1 System OMICRON Magazine 2015 ENUFabio NovagaNo ratings yet

- The Leading-Edge Diesel Rotary Uninterruptible Power Supply SystemDocument36 pagesThe Leading-Edge Diesel Rotary Uninterruptible Power Supply SystemEhab AllazyNo ratings yet

- Rajawali Investment Safeguards ProductionDocument2 pagesRajawali Investment Safeguards ProductionindrayunitaNo ratings yet

- Ad01jul2010fullad PDFDocument36 pagesAd01jul2010fullad PDFAlex BjNo ratings yet

- JPT 2017 SeptiembreDocument112 pagesJPT 2017 Septiembreabraham dominguezNo ratings yet

- Is Bigger Better?: The Multiple Benefits of Modularization in Heavy Industrial ConstructionDocument8 pagesIs Bigger Better?: The Multiple Benefits of Modularization in Heavy Industrial ConstructionTino FerinandaNo ratings yet

- 20-20 Vision - Retos de Desarrollo MciDocument5 pages20-20 Vision - Retos de Desarrollo MciDanny RodriguezNo ratings yet

- Wago-ACSPL Ship Building - Automation & ControlsDocument24 pagesWago-ACSPL Ship Building - Automation & ControlsPAULNo ratings yet

- Petroleum Company Improves Real-Time Information Sharing With RigsDocument5 pagesPetroleum Company Improves Real-Time Information Sharing With RigsmanjithgnairNo ratings yet

- JPT July PDFDocument132 pagesJPT July PDFAdri Coca SuaznabarNo ratings yet

- Motion Control South Africa - Mag 1095Document44 pagesMotion Control South Africa - Mag 1095Daniel SchermanNo ratings yet

- PV Magazine Sept 2017-MinDocument1 pagePV Magazine Sept 2017-MinEmmvee SolarNo ratings yet

- Focus: Optimised Efficiency For The Paper IndustryDocument24 pagesFocus: Optimised Efficiency For The Paper IndustryZoran BadurinaNo ratings yet

- Minerals Focus 1 2012 enDocument68 pagesMinerals Focus 1 2012 enRodrigo VieiraNo ratings yet

- KUKADocument4 pagesKUKAUmesh SNo ratings yet

- Adapt Fast or Disappear: Logistics & TransportDocument20 pagesAdapt Fast or Disappear: Logistics & TransportKiran KhatpeNo ratings yet

- Diagram 160Document44 pagesDiagram 160Phương TrầnNo ratings yet

- Product Ranges AesSealDocument28 pagesProduct Ranges AesSealabdul roufNo ratings yet

- Systems: Lubrication & Filtration, Turbine FoundationsDocument52 pagesSystems: Lubrication & Filtration, Turbine FoundationsSuriya KJNo ratings yet

- POM Case - Crompton GreavesDocument8 pagesPOM Case - Crompton GreavesDhanush KumarNo ratings yet

- 20220201-Special FB Gigapress EnglishDocument8 pages20220201-Special FB Gigapress EnglishVo Trong KhangNo ratings yet

- CM - 2010 - 2 - AlbDocument20 pagesCM - 2010 - 2 - AlbPriya AnugNo ratings yet

- RAychem Case AnalysisDocument11 pagesRAychem Case AnalysisRalph Vuitton100% (2)

- Is Bigger BetterDocument8 pagesIs Bigger BetterGaurang VadorNo ratings yet

- 187 CT 0209Document1 page187 CT 0209keath71No ratings yet

- Railway Coupling - FTRN Series - ESCO Group - 1Document11 pagesRailway Coupling - FTRN Series - ESCO Group - 1Eman FaroukNo ratings yet

- NWHA Tech Weld Procedure Process 2014Document88 pagesNWHA Tech Weld Procedure Process 2014AlbertoNo ratings yet

- Rittal Industry Solutions 5 645Document88 pagesRittal Industry Solutions 5 645ShivamNo ratings yet

- Giga Casting Technology TrendDocument25 pagesGiga Casting Technology TrendGsp TonyNo ratings yet

- PTQ 2013 - Revamps - ScribdDocument68 pagesPTQ 2013 - Revamps - Scribdratninp9368No ratings yet

- Sulzer Turbines 1Document12 pagesSulzer Turbines 1ABHIRAM RNo ratings yet

- USP-E Master Brochure 2022Document14 pagesUSP-E Master Brochure 2022Ali EsentürkNo ratings yet

- Ceylex EngineeringDocument24 pagesCeylex EngineeringhbenlatifNo ratings yet

- DC Sept08 RackandPinionWEBDocument5 pagesDC Sept08 RackandPinionWEBJosé TimanáNo ratings yet

- de Original 1.0Document5 pagesde Original 1.0Deepak SinghNo ratings yet

- Steinmueller Broschuere 1Document46 pagesSteinmueller Broschuere 1andri.motoGNo ratings yet

- WL 835h - 848h t3 24p Brochure A4Document13 pagesWL 835h - 848h t3 24p Brochure A4Luis Felipe Arboleda PuertaNo ratings yet

- 08-136univ - Metallocene Final PDFDocument8 pages08-136univ - Metallocene Final PDFAlex Jhon100% (1)

- Cellular Manufacturing Is A Model For WorkplaceDocument4 pagesCellular Manufacturing Is A Model For WorkplacePrashant AroraNo ratings yet

- Simulation Optimization Decision Support System For Ship Panel Shop OperationsDocument9 pagesSimulation Optimization Decision Support System For Ship Panel Shop Operationsfilipeacribeiro26No ratings yet

- Is Arc 2013 Paper 127Document11 pagesIs Arc 2013 Paper 127cesar vicente reyes garciaNo ratings yet

- MK PP VR Do en 201Document22 pagesMK PP VR Do en 201Masood AkhtarNo ratings yet

- Sika PDS - E - Sikagard - 705 LDocument3 pagesSika PDS - E - Sikagard - 705 Llwin_oo2435No ratings yet

- Earthquake in TaguigDocument4 pagesEarthquake in TaguigDianca Zyra Rodil-CabanelaNo ratings yet

- CS-ME-13 R0 SFFECO - Fire Extinguisher Dry Chemical Powder & Co2 - TSDDocument1 pageCS-ME-13 R0 SFFECO - Fire Extinguisher Dry Chemical Powder & Co2 - TSDAamer Abdul MajeedNo ratings yet

- Department: First Year Name of Subject: Engg. Mechanics Unit Number: 04 (Analysis of Structure)Document2 pagesDepartment: First Year Name of Subject: Engg. Mechanics Unit Number: 04 (Analysis of Structure)JayNo ratings yet

- Carte Tehnica Excavator VolvoDocument12 pagesCarte Tehnica Excavator VolvoCiufudean AdrianNo ratings yet

- WBNR La Auto BCM SpanishDocument41 pagesWBNR La Auto BCM SpanishHaragopal KrishnaNo ratings yet

- Creeping Flow Near A Rotating Sphere PDFDocument10 pagesCreeping Flow Near A Rotating Sphere PDFne gerek var anonimNo ratings yet

- IV I Results Nov 2015Document91 pagesIV I Results Nov 2015Ann ThomasNo ratings yet

- SEMIKRON Product Catalogue 2014 2015Document167 pagesSEMIKRON Product Catalogue 2014 2015cesar oliveira0% (1)

- Exp-3 (Speed Control by V-F MethodDocument4 pagesExp-3 (Speed Control by V-F MethoduttamNo ratings yet

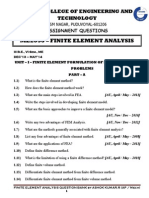

- Assignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Document85 pagesAssignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Ashok Kumar Rajendran100% (9)

- Changed Chart(s) Since Disc 16-2012 ADD Added Chart, REV Revised Chart, DEL Deleted Chart. ACT Procedure Ident Index Rev Date Eff DateDocument98 pagesChanged Chart(s) Since Disc 16-2012 ADD Added Chart, REV Revised Chart, DEL Deleted Chart. ACT Procedure Ident Index Rev Date Eff DateFercho Anaya MNo ratings yet

- Guide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1Document51 pagesGuide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1António FerreiraNo ratings yet

- Csi Sap2000 Example 1-008Document4 pagesCsi Sap2000 Example 1-008Juan Pablo González CarballoNo ratings yet

- LODLOD Church Cost Proposal For Supply of Labor of 6" CHB With Lintel Beam/ColumnDocument1 pageLODLOD Church Cost Proposal For Supply of Labor of 6" CHB With Lintel Beam/ColumnJeve MilitanteNo ratings yet

- Column ChromatographyDocument9 pagesColumn ChromatographyMd Shahjalal Sagor67% (3)

- Bricks ComparisonDocument13 pagesBricks ComparisonMd. Numan HossainNo ratings yet

- Comb - Chemkin - Format PDFDocument5 pagesComb - Chemkin - Format PDFMUHAMMAD FAREEZ IZWAN BIN ABDUL JALILNo ratings yet

- B Indice F400 EDocument8 pagesB Indice F400 EIslam ShoukryNo ratings yet

- Westfalia Cycle CarrierDocument20 pagesWestfalia Cycle CarrierBarry John FitzGeradNo ratings yet

- Aqueous EquilibriumDocument7 pagesAqueous EquilibriumWONG TSNo ratings yet

- 350W AmplifierDocument5 pages350W AmplifiermoisesNo ratings yet

- Instructors Special Forces Demolition Training HandbookDocument137 pagesInstructors Special Forces Demolition Training HandbookJames Meadows94% (16)

- Busbar Design GuideDocument22 pagesBusbar Design Guidejohnwu_2009100% (6)

- Commander SE - Advanced User Guide PDFDocument195 pagesCommander SE - Advanced User Guide PDFJuan David Ardila TorresNo ratings yet

- Inspection & Maintenance of Dams: Dam Safety GuidelinesDocument79 pagesInspection & Maintenance of Dams: Dam Safety Guidelinesvishu1909100% (1)

- Chapter 5Document64 pagesChapter 5pintu13No ratings yet

- Cat Reforming Part 2 3 PDF FreeDocument68 pagesCat Reforming Part 2 3 PDF FreeLê Trường AnNo ratings yet

- 2 TensionDocument28 pages2 TensionRICKY IVANNo ratings yet

- KM Adhikarya - TBK KomplitDocument15 pagesKM Adhikarya - TBK KomplitHelloMotion AcademyNo ratings yet