Professional Documents

Culture Documents

141 R1 MOW Fixed Lifeline System Installation - Aprooved

141 R1 MOW Fixed Lifeline System Installation - Aprooved

Uploaded by

Rijal0 ratings0% found this document useful (0 votes)

31 views24 pagesOriginal Title

141 R1 MOW fixed lifeline system installation - aprooved

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views24 pages141 R1 MOW Fixed Lifeline System Installation - Aprooved

141 R1 MOW Fixed Lifeline System Installation - Aprooved

Uploaded by

RijalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

LOGOS TeamworX

A> TATA

Developm:

METHOD OF FIXED LI

‘NO DOC. : (4! rATA-LWH4/MPP/II1/2023

ent of LOGOS Metrolink Logistic Hub

Warehouse - 4

PROJECT

[FELINE SYSTEM INSTALLATION

a

Line syste

also 1A ma

usr be stall product C¥eseron8) cerngied

venir YET

‘APPROVED

aiMar _[Tangwage check

REVI | 2028 | in sequence

‘Approved

Contractor om HSE

nev | pare | DESCRIPTION Ta

Tatamulla Nusantara

ae PT. Teamwork indonesia Losos

Note

vastallars, and wsptcor|

‘Method Of Work

Fixed Lifeline System Instatlation

METHOD OF WORK

FIXED LIFELINE SYSTEM INSTALLATION

LOGOS WAREHOUSE 4PROJECT

1. INFORMATION 1. INFORMASI

The Logos WH4 project has work items for Pada proyek Logos Warehouse 4

fixed lifeline system installation. All roofing terdapat item pekerjaan, untuk

components must be installed strictly in pemasangan lifeline fix system.

accordance to shop drawing and» Semua_komponen tap harus

specification. Rooftop access shall be — dipasang sesuai dengan gambar

prepared and safe for worker. Installation

must be assist by certified worker or

specialized worker.

kerja dan spesifikasi. Akses atap

harus disiapkan dan aman bagi

pekerja. Pemasangan harus dibantu

oleh pekerja bersertifikat atau

pekerja khusus.

2. TOOLS & MATERIAL USED 2 ALAT& MATERIAL YANG

DIGUNAKAN

A. Tools Needs A. Kebutuhan peralatan

- Scaffolding (worker access) - Scaffolding (akses pekerja)

= Mobile Scaffolding = Mobile Scaffolding

- Drill Machine - Mesin Bor

= Torque Wrench - Kunci Momen

- Screw Driver - Screw Driver

- Protective Personal Equipément (helm - APD (helm dengan tali dagu,

with chinstrap, gloves, safetys shoes, sarung tangan, sepatu safety,

safety googles, full body harness kacamata pelindung, full body

double lanyard) harness double lanyard)

B. Material Needs B. Kebutuhan Material

- Cross arms: 6061 T6 Alumunium + Cross arms: 6061 T6 Alumunium

Anodized

Logos Warehouse 4 Project

Anodized

ail Tara «sie:

Teaming Vion inte Rell,

~ Anchor point: 316 Stainless Steet

~ Kliplok clips: 6061 T6 Alumunium

Anodized

- Kliplok clips

grub screws

M10x25 $S316 Grade A4-70

(a):

~ Kliplok clips hex bolt (B): M12x25

$8316 Grade A4-70

3. MANPOWER

- Site Manager

+ Supervisor

= Surveyor

+ Scaffolder

~ Inspector Seaffolder

- HSE in charge

- Certified/ Specialized Worker

4, Sequence

A. Preparation

+ Roof access from designated access

point using scaffolding / mobile

scaffolding for vertical fall protection

= Installation of carmantel in roof in the

fixed lifeline system installation area

for the safety of workers in working in

height

~ Workers are equipped with full body

hamess double lanyard during

installation of roof fixed lifeline

system

- Identification and marking of anchor

Logos Warehouse 4 Project

A

. PEKERJA

Method Of Work

Fixed Lifeline System Installation

= Anchor point: 316 Stainless Steel

+ Kliplok 6061 76

Alumunium Anodized

clips:

- Kliplok clips grub screws (A).

M10x25 $8316 Grade A4-70

- Kliplok clips hex bolt

MI2x25 $5316 Grade A4-70

= wire COPE: Stamlecs Heal C2

Bm 7x19 Trabsg) 24 kN

ceieaatiny WANE: 80 AN 8 Heslogy

A 6 posinon

@:

Site Manager

Supervisor

Surveyor

Scaffolder

Inspector Scaffolder

HSE in charge

Certified/ Specialized Worker

Langkah Kerja

Persiapan

Akses atap dari titik akses yang

ditentukan menggunakan scaffolding /

mobile scaffolding untuk perlindungan

vertikal

Pemasangan karmantel pada atap

pada pemasangan lifeline fixed system

untuk keamanan pekerjaan saat

bekerja di ketinggian

Pekerja dilengkapi dengan full body

harness double lanyard selama

pemasangan lifeline fixed system atap

Identifikasi dan marking posisi

ee thod Of Work

Fixed Lifeline syten em. = stallation

post installation position on the roof pemasangan anchor post pada panel

panel based on shop drawing, The tap berdasarkan shop drawing. Base

base plate should be positioned above plat harus berada diatas kedua sisi

both side lap joints of the roof sheets, sambungan roof sheets

$e

oo $04 se tat tt tt tf

ii ir

Hh NL zal a

ih jn Ws I A

} va

Assembly Line

eta

———

C. For Kliplok Post Assembly

~ Place cross beam over Kliplok and

insert 2 hex bolts 10x25 into the beam

and Kliplok below. Place the stee!

washer onto the bolt and tighten bolt

to the correct torque setting of 17 Nm,

making certain the cross beam and

kliplok clamps are secured

Method Of Work

Fixed Lifeline System Installation

CG. Pemasangan Post Kliplok

+ Tempatkan cross beam diatas kliplok

dan masukan 2 baut hex 10x25 ke

dalam balok dan kliplok di bawahnya.

Tempatkan steel washer pada baut

dan kencangkan baut dengan setting

, 25 Nw

torque yang benar yaitut7'Nm,

pasttkan cross beam dan penjepit “IC, *

Miplok terpasang dengan baik b> \ogo«

=

~ Insert | hex bolt 12x25 through plain

washer, anchor and beam. Place the

washer and nyloc nut onto the bolt.

Tighten nut and bolt to the correct,

torque settings of 17 Nm making

certain the cross beam and anchor are

secured

+ Masukkan | baut hex 12:25 melalui

‘washer polos, angkur dan balok.

Tempatkan wahser dan mur nyloc

pada baut. Kencangkan mur dan baut

dengan setting torque yang benar

aire Win, ‘dition cross beam dan

angkur terpasang dengan baik

ee

4

Logos Warehouse 4 Project

+ The impact kliplok post is ready to be

installed on roof profile as part of the

system,

D. Installing Extremity Anchor Post

- The post clamp comes complete with

pre-installed hex bolts & grub screws.

Slightly loosen all grubs allowing the

clamp to be installed directly over the

Kliplok roof profile. Ensure the flat

side of each clamp should be below

the lip of each cliplok roof profile. Fix

the square tube roof post on the anchor

clamp beam with hex bolts

Method Of Work

Fixed Lifeline System Installation

+ Tiang kliplok impak siap dipasang

pada profil atap sebagai bagian dari

sistem

D. Pemasangan Extremity Anchor Post

~ Post clamp dilengkapi dengan baut

hex & sekrup grub yang sudah

dipasang sebelumnya. Kendurkan

sedikit semua grub sehingga penjepit

dapat dipasang langsung di atas profil

atap kliplok. Besser st datar dari

setiap penjepit di bagian bawah setiap

profil atap cliplok. Kencangkan

square tube atap pada balok penjepit

angkur dengan baut hex

Logos Warehouse 4 Project

TATA oe

(PT TATAMULIA NUSANTARAINDAM

“Leng Vikan inte Realty Method Of Work

Fixed Lifeline System Installation

~ Tighten all fasteners with the correct - Kencangkan semua penguat dengan

torque torsi yang benar

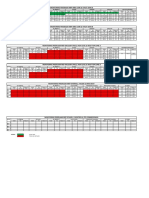

Type Grub Screw Hex Bolt Hex Bott

Size(own) 10x25 10x28 12x28

Qty 6 2 1 check

Torque 1S Atiin Sry Approved tier

29 hm 23 Nin ~ 50 Hm PrOAUCK brochue

E. Installing Intermediate Anchor Post E. Pemasangan Intermediate Anchor

Post

~ Fix two Kliplok clamps to the roof ~ Pasang dua klem kliplok ke profil

profile crown. Mount the intermediate crown atap. Pasang braket perantara

bracket on the anchor post beam with pada balok angkur dengan baut hex

hex bolts

~ Insert the cable through the

intermediate tube. Pull the cable

manually to reduce the sag in the

adjacent span

Logos Warehouse 4 Project

~ Masukkan kabel melalui tabung

erantara. Tarik kabel secara manual

untuk mengurangt kendur pada

bentang yang berdekatan

Altar A 22:

Ses

- Fix aU bolt to prevent the cable from

loosening. Remove the U bolts after

the lifeline is connected to the

tensioner and then the pretension is

applied to the entire lifeline

Method Of Work

Fixed Lifeline System Installation

~ Kencangkan baut U untuk mencegah

kabel kendor. Lepaskan baut U setelah

tali pengikat terhubung ke tensioner

dan kemudian pretension diterapkan

ke seluruh tali pengikat

TATA ote:

Rasy

Vion

Applying tension to the line, Hold the =

tensioner eye with spanner. Insert the

tensioning tool in the housing of the

tensioner and rotate the tensioner in

clockwise direction, Rotate it until

reasonable tension is achieved in the

cable and the L plate of the tension

indicator is in contact with the shock

absorber coil. Tighten both the chuck

nuts

Use the attachment device with the

designated lanyard to test the entire

lifeline system

ty

Safety Requirements

The conditions and precautions listed

in the project specifications should be

followed as requirements

All staff involved in the project must

Logos Warehouse 4 Project

L

‘Method Of Work

Fixed Lifeline System Installation

Menerapkan tegangan pada garis.

Pegang mata penegang dengan kunci

pas. Masukkan alat penegang ke dalam

rumah tensioner dan putar tensioner

searah jarum jam. Putar hingga

tercapai tegangan yang wajar pada

kabel dan pelat L indikator tegangan

bersentuhan dengan koil peredam kejut.

Kencangkan kedua mur chuck

UPWARD PULL FOR |

TENSION

Gunakan perangkat tambahan dengan

tali pengikat yang telah ditentukan

untuk menguji seluruh sistem lifeline

Kebutuhan Safety

Kondisi dan tindakan pencegahan yang

tercantum dalam spesifikasi proyek

harus diikuti sebagai persyaratan

Semua staf yang terlibat dalam proyek

Al TATA 21815)

teasing Vin ine Really

be trained on safety, health and

environmental health related to the

work. health and environment related

to the work

~ Only trained personnel with relevant

experience shall be allowed to handle

machinery

- Appropriate signage, barriers, and

lighting and other safeguards should

be provided appropriate to the nature

and location of the work. All

operations shall be carried out in

accordance with the safety

requirements of the consultant

- Installation for safety slings, safety

system in the process of process, the

tool we use is a triangle that will be

installed on the roof and after the

installation will be stretched on the

roof. and after the installation will be

stretched wire sling that serves as a

body hook safety rope

Logos Warehouse 4 Project

‘Method Of Work

Fixed Lifeline System Installation

harus dilatih tentang keselamatan,

kesehatan, dan kesehatan lingkungan

‘yang terkait dengan pekerjaan.

kesehatan dan lingkungan yang terkait

dengan pekerjaan

Hanya personel terlatih dengan 7 g\v %

pengalaman yang relevan yang. es yerr

diizinkan untuk menangani permesinan

Rambu-rambu, pembatas, dan

‘penerangan yang tepat serta

perlindungan lainnya harus disediakan

sesuai dengan sifat dan lokasi

pekerjaan, Semua operasi harus

dilakukan sesuai dengan persyaratan

keselamatan dari konsultan,

Pemasangan untuk safety sling, sistem

keamanan dalam proses pengerjaan,

alat yang kami gunakan adalah segitiga

yang akan dipasang di atap dan setelah

pemasangan akan dibentangkan di

tap. dan setelah pemasangan akan

dibentangkan wire sling yang berfungsi

sebagai tali pengaman pengait badan.

LOGOS TeamworX Als TATA

Development of LOGOS Metrolink Logistic Hub

Warehouse - 4

PROJECT

EIV,

UFE es

METHOD OF FIXED LINE SYSTEM INSTALLATION

NO DOC. : 141 /ATA-LWH4/MPP/IIL/2023 7.5 MAR 202

om eae fy

Pingones |

mt

we"

le 23

APPROVED ‘APPROVED WITH NOTE REJECTED

wal |

Dan ® i

23/03/2023 an z

f Prepared | Checked ‘Approved Approved ‘Acknowledged

Contractor om HSE Owner

rev | oare | escrow

Frama toes | ramen 1000s

Notes

aoe

check bahasa dala largkah kerja clan perbaks

“Abe TATA, si

ay Vie te Relity

Method Of Work

Fived Line System Installation

METHOD OF WORK

FIXED LINE SYSTEM INSTALLATION

‘LOGOS WAREHOUSE 4 PROJECT

1, INFORMATION

The Logos WH4 project has work items

for fixed line system installation. All

roofing components must be installed

strictly in accordance to shop drawing and

specification. Rooftop access shall be

prepared and safe for worker, Installation

must be assist by certified worker or

specialized worker.

TOOLS & MATERIAL USED

A. Tools Needs

- Scaffolding (worker access)

- Mobile Scaffolding

- Drill Machine

- Torque Wrench

- Wrench

- Screw Driver

- PPE (helm, gloves, safetys hoes,

safety googles, full body hamess,

resepirator)

B. Material Needs

- Cross arms: 6061 T6 Alumunium

Anodized

Logos Warehouse 4 Project

1, INFORMASI

Proyek Logos WH4 memiliki item

pekerjaan untuk instalasi Cisten

a»

Saluran tetap,)Semua Komponen atap

harus dipasang sesuai dengan gambar

kerja dan spesifikasi. Akses atap harus

disiapkan dan aman bagi pekerja,

Pemasangan harus dibantu oleh

pekerja bersertifikat atau pekerja

Khusus,

2. ALAT & MATERIAL YANG

DIGUNAKAN

A. Kebutuhan peralatan

+ Scaffolding (Akses pekerja)

- Mobile scaffolding

- Mesin Bor

- Kunci Momen

- Kunci pass

ant

+ Serew Driver in

+ APD (helm, sarung tangan, sepatu

safety, kacamata pelindung, full body

harness|resepirator)~

cami ry °

B. Kebutuhan Material

= Cross arms: 6061 16 Alumunium

Anodized

Cnn

teeing Winn te Reality

= Anchor point: 316 Stainless Stee!

~ Kliplok clips: 6061 T6 Alumunium

Anodized

~ Kliplok clips grub serews (A):

M10x25 $$316 Grade A4-70

~ _Kliplok clips hex bolt (B): M12x25

$8316 Grade A4-70

3. MANPOWER

- Site Manager

~ Supervisor

~ Surveyor

~ Scaffolder

~ Inspector Scaffolder

- HSE in charge

~ Centified/ Specialized Worker

4. Sequence

‘A. Preparation

- Roof access from designated access

points using scaffolding/mobile

scaffolding for vertical fall protection.

~ Installation of carmantel in the fixed

line installation area for the safety of

workers in working at height.

~ Workers are equipped with full body

harness during installation of roof

fixed line system.

Logos Warehouse 4 Project

Method Of Work

Fixed Line System Installation

~ Anchor point: 316 Stainless Steel

- Kliplok clips: 6061 T6 Alumuraium

Anodized

- Kliplok clips grub screws (A):

‘M10x25 SS316 Grade 44-70

Kliplok clips hex bolt (B): M12x25

‘S316 Grade A4-70

3. PEKERJA

= Site Manager

= Supervisor

= Surveyor

- Scaffolder

- Inspector Scaffolder

- HSE in charge

- Certified! Specialized Worker

4, Langkah Kerja

A. Persiapan

- Akses atap dari titik akses yang

ditentukan menggunakan

_seafoling/ ‘mobile scaffolding untuk

~ perlindungan j jatuh vertikal maksudngs begin

: Pemasangan carmantel pada area

gosh Sp osang dian

pemasangan fixed line, untuk

keamana pekerja dalam bekerja di

ketinggian.

- Pekerja dilengkapi dengan body

harness double lanyard di seluruh

‘tubuh selama pemasangan sistem

saluran tetap atap.. @

_fluran ‘etap. ae

~ Identifkasi dan marking posisi

vaing san inte Rit

~ Identification and marking of anchor

post installation position on the roof

panel based on shop drawing. The

base plate should be positioned above kedua sambuns

both side lap joints of the roof sheets.

Method Of Work

Fixed Line System Installation

_pemasangan anchor post pada panel

atap berdasarkan shopdrawing.

ie Pela das dasar harus diposisikan di atas

‘samping Jembaran atap.

ain “pa. >

B. Fixed Life Line Components

Assembly

im inn

(eral

i val cit

‘Ail

Alm rasre, ste

feng Vion int Rat

C. For Kliplok Post Assembly

= Place cross beam over Kliplok and

insert 2 hex bolts 10x25 into the beam

and Kliplok below. Place the stee!

Method Of Work

‘Fixed Line System Installation

G. Pemasangan Post Kliptok

= Tempatkan cross beam di atas

Kliplok dan masukkan 2 baut hex

10x25 ke dalam baiok dan Kliplok di

washer onto the bolt and tighten bolt bawahnya, Tempatkan mesin euct

to the correct torque setting of 17 Nm, _baja pada baut dan kencangkan baut

making certain the cross beam and ke pengaturan torsi yang benar yeaitu

Mliplok clamps are secured, 17 Nm, pastikan klem cross beam

dan Kliplok terpasang dengan baik,

1 2

is

i)

~ Insert 1 hex bolt 12x25 through plain - Masukkan 1 baut hex 12x25 melalui

‘washer, anchor and beam. Place the washer polos, jangkar dan balok.

washer and nyloc nut onto the bolt. Tempatkan washer dan mur nyloc

Tighten nut and bolt to the correct pada baut. Kencangkan mur dan

torque settings of 17 Nm making aut ke pengaturan torsi yang benar

certain the cross beam and anchor are

secured.

yaitu 17 Nm untuk memastikan balok

silang dan jangkar terpasang.

Logos Warehouse 4 Project

<> TATA ini

ang Vein te Rat Method Of Work

Fixed Line System Installation

‘The impact kliplok post is now ready

to be installed on roof profile as part of dipasang pada profil atap sebagai

the system. agian dari sistem.

Tiang hliplok benturan sekarang siap

D. Installing Extremity Anchor Post D, Pemasangan extremity Anchor Post

- The post clamp comes complete with Post clamp dilengkapi dengan haut

pre-installed hex bolts & grub screws. hex & sekrup grub yang sudah

Slightly loosen all grubs allowing the dipasang sebelumnya. Kendurkan

clamp to be installed directly over the sedikit semua grub yang

Kiplok roof profile. Ensure the flat 2 _memungkinkunclamp dipasang

side of each clamp should be below “angsung di atas profil atap Kliplok,

the lip of each cliplok roof profile. Fix Pastikan rata sisi datar dari setiap

the square tube roof post on the anchor ‘penjepit harus berada di bawah bibir

clamp beam with hex bolts setiap profil atap liplok. Pasang

Hang atap tabung persegi pada balok

anchor clamp dengan baut hex.

Logos Warchouse 4 Project

<> TATA «

ving Von inte Rail

Tighten all fasteners with the correct

torque

Tyee (Grub Screw

Siem) 10305

ay 6

Torque 151m

E, Installing Intermediate Anchor Post

Fix two Kliplok clamps to the roof

profile crown. Mount the intermediate

bracket on the anchor post beam with

hex bolts.

Method Of Work

‘Fixed Line System Installation

- Kencangkan semua penguat dengan

‘momen torsi yang benar.

Hex Bott Hex Bott

10x25 12X05

2 1

7H 17m

E, Pemasangan Intermediate Anchor

Post

= Pasang dua klem Miplok ke mahkota

profil atap. Pasang braket perantara

pada balok tiang jangkar dengan

aut hex.

Insert the cable through the

intermediate tube, Pull the cable

‘manually to reduce the sag in the

adjacent span.

~ Masukkan kabel melalui tabung

‘perantara, Tarik kabel secara

‘manual untuk mengurangi kendur

‘pada bentang yang berdekatan.

Fl

——

‘Logos Warehouse 4 Project

TATA 21'25

tenn Vienne Raby

Fix a U bolt to prevent the cable from

loosening. Remove the U bolts after

the lifeline is connected to the

tensioner and then the pretension is

applied to the entire lifeline,

Method Of Work

Fixed Line System Installation

~ Kencangkan baut U untuk mencegah

kabel kendor. Lepaskan baut U

setelah tali pengikat terhubung ke

tensioner dan kemudian pretension

diterapkan ke seluruh tali pengikat.

4

ere

oO

Installing Corner Anchor Post

After Anchor Post installed on the roof

as shown in steps above, insert the

cable through the comer tube, Pull the

cable manually to reduce the sag in the

adjacent span.

Fix a U bolt to prevent the cable from

loosening. Remove the U bolts after

the lifeline is connected to the

Logos Warehouse 4 Project

F. Pemasangan Corner Anchor Post

- Setelah Anchor Post terpasang di

tap seperti yang ditunjukkan pada

Jangkah di atas, masukkan kabel

‘melalui tabung sudut. Tarik kabel

secara manual untuk mengurangi

kendur pada bentang yang

berdekatan,

- Kencangkan baut U untuk mencegah

kabel kendor. Lepaskan baut U

setelah kabel penggantung

<> TATA «=:

ening eke Reality

tensioner and then the pretension is

applied to the entire lifeline,

G. Installing the shock absorber into

the Anchor Post Extremity

= Insert the connector D shackle to the

Shock absorber eye (fig 1), then

‘connect the other connector D shackle

to the tensioner (fig 2).

~ Apply tension to the cable until the L

tension indicator plate touches the

spring,

aff i fl Ie

Se t a

the tensioner with swaging

~ Insert the 7x19 8mm diameter wire

ropelcable into the swage tube.

Logos Warehouse 4 Project

fa

rt

Method Of Work

Fixed Line System Installation

terhubung ke tensioner dan

kemudian pretension diterapkan ke

seluruh kabel penggantung.

G. Pemasangan Shock Absoner ke

Dalam Anchor Post Extremity

= Masukkan konektor D shackle ke

mata peredam kejut (gbr 1),

‘Temudian samburgkan koneltor D

shackle lainnya ke tensioner (gbr 2).

- el ]

Ct

A= Sa—

TI

~ Berikan tegangan pada kabel hingga

‘pelat indikator tegangan L

‘menyentuh pegas.

&

L Plate

H. Pemasangan Tensioner dengan

Swaging

- Masukkan tali/kabel kawat

berdiameter 7x19 8mm ke dalam

tabung swage.

wae

~ The swage tube has markings to

identify exact positions of crimping.

Place the swage tube on the hex loc

die of a hydraulic crimping tool.

Ensure that the mark on swage tube is

in the center of the die. Operate the

machine to start the swaging

operation. Repeat the process for all

markings, (rotate the Swage at 90

degrees after each swaging)

‘Method Of Work

Fived Line System Installation

7 STRANDS

oF savers

Tabung swage memiliki tanda untuk

mengidentifikasi posisi crimping

Yang tepat. Tempatkan swage tube

pada cetakan hex loc alat crimping

hidrolik. Pastikan tanda pada tabung

swage berada di tengah cetakan,

Operasikan mesin untuk memulat

operasi swaging. Ulangi proses ini

untuk semua penandaan, (putar

‘Swage pada 90 derajat setelah setiap

swaging)

~ Install the cable extremity directly to

the end of 8 mm wire rope. Swage the

cable using swaging hand tool and hex

lock dies at 6 position

Logos Warehouse 4 Project

Pasang ujung kabel secara langsung

ke ujung tali kawat 8 mm. Swage

kabel menggunakan alat tangan

swaging dan kunci hex mati pada

posisi 6

Method Of Work

Fixed Line System Installation

~ Applying tension to the line. Hold the

tensioner eye with spanner. Insert the

tensioning tool in the housing of the

tensioner and rotate the tensioner in

clockwise direction. Rotate it until

reasonable tension is achieved in the

cable and the L plate of the tension

indicator is in contact with the shock

absorber coil. Tighten both the chuck

nuts.

- Menerapkan tegangan pada kabel.

Pegang mata penegang dengan

unei pas. Masukkan alat penegang

‘ke dalam rumah penegang dan putar

penegang searah jarum jam. Putar

hingga tercapai tegangan yang

wajar pada kabel dan pelat L

indikator tegangan bersentuhan

dengan koil peredam kejut.

Kencangkan kedua mur chuck.

Use the attachment device with the

designated lanyard to test the entire

lifeline system,

UPWARD PULL FOR

TENSION

Gunakan perangkat tambahan

dengan tali pengikat yang telah

ditentukan untuk menguji seluruh

sistem tali pengaman.

ty

Logos Warehouse 4 Project

Al TATA «=i

1B

nt Reality

Safety Requirements

‘The conditions and precautions listed

in the project specifications should be

followed as requirements.

All staff involved in the project must

be trained on safety, health and

environmental health related to the

‘work, health and environment related

to the work.

Only trained personnel with relevant

experience shall be allowed to handle

machinery

Appropriate signage, barriers, and

lighting and other safeguards should

be provided appropriate to the nature

and location of the work. All

‘operations shall be carried out in

accordance with the safety

requirements of the consultant.

Installation for safety slings, safety

system in the process of process, the

tool we use is a triangle that will be

installed on the roof and after the

installation will be stretched on the

roof. and after the installation will be

stretched wire sling that serves as a

body hook safety rope.

Logos Warehouse 4 Project

L

Method Of Work

Fixed Line System Installation

Kebutuhan Safety

Kondisi dan tindakan pencegahan

yang tercantum dalam spesifikasi

proyek harus diikuti sebagai

persyaratan,

Semua staf yang terlibat dalam

proyek harus dilatih tentang

keselamatan, kesehatan dan

Kesehatan lingkungan yang terkait

dengan pekerjaan. kesehatan dan

lingkungan yang terkait dengan

pekerjaan.

Hanya personil terlatih dengan

pengalaman yang relevan yang

diizinkan untuk menangani mesin

Rambu-rambu, pembatas, dan

‘penerangan yang tepat serta

erlindungan lainnya harus

disediakan sesuai dengan sifat dan

lokasi pekerjaan. Semua operasi

harus dilakukan sesuai dengan

persyaratan keselamatan dari

Konsultan,

Pemasangan untuk safety sling,

sistem keamanan dalam proses

pengerjaan, alat yang kami gunakan

adalah segitiga yang akan dipasang

di atap dan setelah pemasangan

akan dibentangkan di atap. dan

setelah pemasangan akan

dibentangkan kawat sling yang

berfuungsi sebagai tali pengaman.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Platform Column Layout PlanDocument17 pagesPlatform Column Layout PlanRijalNo ratings yet

- Daily Menpower WH-4 17 April 2023Document2 pagesDaily Menpower WH-4 17 April 2023RijalNo ratings yet

- Daily Menpower WH-4 10 April 2023Document2 pagesDaily Menpower WH-4 10 April 2023RijalNo ratings yet

- Monitoring Pekerjaan Mep WH4Document2 pagesMonitoring Pekerjaan Mep WH4RijalNo ratings yet

- BMB Mapping Girt, Roof, and Louvre 15.04Document4 pagesBMB Mapping Girt, Roof, and Louvre 15.04RijalNo ratings yet

- TODA Business Trip Shedule On 18th April Ver1Document1 pageTODA Business Trip Shedule On 18th April Ver1RijalNo ratings yet

- Zimbra - PCH Standart KomplainDocument6 pagesZimbra - PCH Standart KomplainRijalNo ratings yet

- BMB Mapping Girt and Roof 11.04Document3 pagesBMB Mapping Girt and Roof 11.04RijalNo ratings yet