Professional Documents

Culture Documents

024 Dr. Chandrashekhar Bendigeri 2011 Studies On Electromechanical

Uploaded by

Bhuvaneshwar PatilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

024 Dr. Chandrashekhar Bendigeri 2011 Studies On Electromechanical

Uploaded by

Bhuvaneshwar PatilCopyright:

Available Formats

Dr. Chandrashekhar Bendigeri et al.

/ International Journal of Engineering Science and Technology (IJEST)

STUDIES ON ELECTROMECHANICAL

BEHAVIOR OF SMART STRUCTURES

BY EXPERIMENT AND FEM

DR. CHANDRASHEKHAR BENDIGERI

Department of Mechanical Engineering, UVCE, Bangalore University,

Bangalore-560 001, India

And

RITU TOMAR

Faculty, Dept of Physics, Research Center,

Sambhram Institute of Technolgy Bangalore-560 097, India

Abstract

The formulation of the finite element for static analysis has been presented based on isoparametric

formulation. The element considered in the present study is eight noded hexahedral elements. A computer

code based on the above formulation has been developed using MATLAB software to solve the three

dimensional structures integrated with piezoelements. The experiments have been conducted on the

piezoelectric smart structures consisting aluminum beam with piezoelectric materials for deformation

due to applied voltage, steel beam with piezoelectric materials for deformation due to applied voltage and

finally natural frequency for aluminum beam with piezoelectric materials natural frequency is estimated

by application of electromechanical behavior of piezomaterial. The results obtained were used for

validating the present finite element code developed and found to have good agreement

Key Words

Smart structures, Piezoelectric, electromechanical, Finite Element and MATLAB

Introduction

The development of smart composites offers great potential for advanced aerospace structural applications.

Piezoelectric material can be employed as both actuators and sensors in the development of these structures by

taking advantage of direct and converse piezoelectric effects. The effective use of such material on different

application can be done if their behavior is well understood (T. S. Tzou and C. I. Tsen,1990; Sung kyu and

Charles Keillers, 1992; Bahu Sun and Dahuang. 2001). The Finite element method can be used so that number

of iteration can be done to understand and optimize the process. The effective numerical and experimental

methods are needed to evaluate behavior and applications of piezoelectric structures subjected to

electromechanical loading (Benjeddou, and A. Trindade, 1999; B. L. Wang and N. Noda., 2001). In the present

work formulation of a finite element has been done. The implementation of the above formulation has been

done using MATLAB software. The developed code is validated using number of problems involving different

materials such as isotropic, orthotropic and piezoelectric materials and a combination of these materials. One

such example is piezo electric actuation of carbon epoxy beam has been discussed in detail in this paper. The

present solution are compared with result obtained by experimental approaches

Constitutive Equation

The basic constitutive equations for the linear theory of piezoelectric are as follows (IEEE std, 1988).

C d E

D d T b E (1)

where {σ }= {σ11,σ 22, σ 33,σ 23, σ 13 & σ 12}T is the stress vector, {ε} = {ε11,ε 22, ε 33, ε 23, ε13 & ε 12}T Strain

tensor, {E} = {E1,E2 &E3}the electric field, {D} ={D1, D2, &D3}, the electric displacement or Electric flux

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2134

Dr. Chandrashekhar Bendigeri et al. / International Journal of Engineering Science and Technology (IJEST)

density vector, [C] the elasticity constants matrix, [b] the dielectric constants matrix, [d] the piezoelectric

coupling coefficients matrix or Piezoelectric constants

( E F Crawley and K.B. Lazarus, 1991; Kekana and P. Tabakov, 2005).

Finite Element modeling

In the finite element formulation, the displacements u, v, w and the potentials are approximated as functions of

the nodal displacements u n and nodal potential n where n is node number of the element and the nodal shape

functions N i such that

{u} [ N u ]{u n }

(2)

{} [ N ]{ n }

The electric field vector of an element is represented as follows

{E} E x , E y , E z T (3)

where

Ei i (4)

Consequently

{ } [ Bu ]{u n }

(5)

{E} [ B ]{ n }

The matrix [ Bu ] and [ B ] contains the derivatives of the shape functions for the displacements and potentials

which is written as follows

x 0 0

0 0

y

0 0 z

[ Bu ] [N ] (6)

0 z y u

z 0 x

y x 0

x

[ B ] y [ N u ] (7)

z

The external virtual work done by the external mechanical and electrical forces is

Wmech

e

u n {F }

(8)

Welect

e

n {Q}

Where {F } , {Q} are external mechanical force and electrical charge vectors. Consequently, mechanical and

electrical equilibrium equations can be written as follows

u [B ] ([c][B ]{u }[d][B]{ })dVu {F}

T

n u u n n n (9)

and

[B ] ([d]T [Bu ]{un}[b][B ]{n})dV n {Q} (10)

T

n

or

([Bu]T[c][Bu]dV){un}([Bu]T[d][B]dV){n}{F}

(11)

([B]T[d]T[Bu]dV){un}([B]T[b][B]dV){n}{Q}

The stiffness matrices are defined as follows

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2135

Dr. Chandrashekhar Bendigeri et al. / International Journal of Engineering Science and Technology (IJEST)

[ K uu ] [ Bu ]T [c]Bu ] dV

v

[ K ] [ B ]T [b]B ] dV

v

(12)

[ K u ] [ B ]T [d ]T Bu ] dV

v

[ K u ] [ K u ]T

[ K uu ]{u n } [ K u ]{ n } {F }

[ K u ]{u n } [ K ]{ n } {Q}

Thus, (13)

[ K uu ] [ K u ] {u n } {F }

[ K u ] [ K ] { n } {Q}

[ K ]{u} {F } (14)

The above equations are included in formulation of element to add the capability to analyses of piezoelectric

smart structures and the same is coded using MATLAB software.

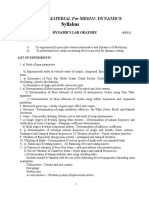

Experiment Conducted Using Piezoelectric Material

For the purpose of validating the result of developed finite element code experiment was carried out. In this

section a brief description of instrumentation used during the experimentation with smart materials is given.

Figure 1 shows the different instrumentation and a smart beam used in current program (S. Raja and P.

Bhattacharya, 2002)

a. Function Generator: Used for generation of signal

b. Piezo Sensing System : Used for sensing the voltage

c. Active Band Pass Filter : Used for filtering the waves

d. Piezo Actuation System :Used for generation of low current and high voltage source

for driving piezo-actuator

e. Dimmerstat with power transformer: Used to obtain variable DC supply

f. Linear variable differential transformer: Used for measuring the displacement.

Figure 1. The smart structure and the instrumentation used

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2136

Dr. Chandrashekhar Bendigeri et al. / International Journal of Engineering Science and Technology (IJEST)

Experiment 1

Experiment and analysis of smart beam subjected to voltage

A thick beam made of aircraft quality aluminum alloy is used for conducting experiment. The piezoelectric

patch is mounted on this beam and subjected to electric field. The block diagram of the experiment is shown in

the Figure 2. Geometry of the smart beam is shown in Figure 3(a), and its finite element model is shown in the

Figure 3(b).This case study involves the combination of isotropic and piezoelectric materials.

(A) Specimen preparation

The aluminum beam is machined as per the dimension mentioned in the Figure 3(a). The piezoelectric materials

made of PZT and manufactured by Sparkler Ceramics, Pune is used in the present studies. The piezoelectric

material is fixed on the beam. The procedure for fixing the piezo is explained below

The emery sheet of zero number is used to rub the beam where piezoelectric material is supposed to be

fixed.

The carbon tetra chloride is used for cleaning the surface with pure cotton

The exact location of PZT supposed to fix on the beam is marked.

Araldite consisting of harder and adhesive is mixed thoroughly until the mixture becomes uniform

(white colour).

The araldite is smeared on the PZT as well as on the marked place for PZT on the beam

The PZT is put on the beam and is pressed. Then for twenty four hours it is kept at room temperature

for curing.

The PZT is supplied with leads known as pig tail from the manufacturer and consisting of positive and

negative terminals

Another terminal made of small copper strip is used to connect to pig tail and there by connected to the

instrumentation of the experiment (Asan Gani and M. Salami, 2003)

(B) Experimental procedure

The procedure for conducting the experiment is as follows

The aluminum beam with piezoelectric material is clamped tightly at one side as cantilever.

The variable DC supply (Dimmerstat with power transformer, variable DC supply 0-200V and 1A) is

applied to PZT on the beam

The supplied voltage to the PZT on beam causes it to deflect.

The deflection thus obtained at tip the beam is measured using linear variable differential transformer

with specification of ±1mm, max output 5V, number of digits 5, excitation voltage 1V and frequency 4 KHz

Figure 2 The block diagram of the experiment for smart beam

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2137

Dr. Chandrashekhar Bendigeri et al. / International Journal of Engineering Science and Technology (IJEST)

(a)Geometry of the smart beam

(b) Finite element model

Figure 3 Geometry of an aluminum beam with piezo actuator and finite element model

(C) Finite element analysis of the beam

The finite element model of the beam is shown in Figure 3(b) and one end of the beam is fixed (Uz=Uy=Uz=0).

The finite element model has 184 elements. The voltage is applied on piezoelement from 50 to 200V insteps of

50V and the resulting tip deflection is determined. These results are given in the Table 1. The present FE results

are compared with experimental results and results obtained using closed form solution. The results of the three

methods are given in Table 1. As can be seen from the table they are in good agreement.

The deflection is determined analytical method using the equations 15

m*t

b

* l (15)

2 I b Eb

Where, is the deflection m is the moment generated due voltage applied is given by equation

6 * d 31 * V EI b * EI c

m *

tc tb 3EI b 4 EI c

Ib moment inertia of the beam

Ic moment inertia of the piezomaterial

d31= piezoelectric constant

V voltage applied

Eb modulus of the beam

l length of the beam

tc thickness of the piezomaterial

tb thickness of the beam

3

wt

and I b b b =520.833 mm4 (16)

12

3

wc t c

Ic =2.0833 mm4 (17)

12

Substituting the value of moment of inertia of the beam and piezomaterial from equations 16 and 17 in 15 and

also substituting other values related to configuration of the problem one can get the final displacement as

follows. For 50 volts substituting the values in the above equation 15 we get

=24 m

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2138

Dr. Chandrashekhar Bendigeri et al. / International Journal of Engineering Science and Technology (IJEST)

Table 1 Comparison of experimental, Analytical and FE results for the smart beam

Sl no Voltage Deflection( m)

applied Analytical Experiment Present code

( Volts)

1 50 24 25 23

2 100 48 51 46

3 150 72 71 69

4 200 96 95 93

Experiement 2

Experiment and analysis of smart beam (Steel and PZT)

An active structural member made of steel, PZT crystal (i.e Lead Zirconium Titanite) is used in this experiment.

Figure 4 shows the geometry of the cantilever beam with piezoelectric actuator. Figure 5 shows the

corresponding the FE model. The finite element model of this configuration consists of 184 elements and 411

nodes.

Figure 4 Dimensions of a beam with piezoelectric material

Figure 5 FE model of the beam with piezo patch

(A) Experimental procedure

LVDT was used to measure static deflection of tip of the beam at the free end of the beam. The signals from the

LVDT were transmitted to displacement indicator, which displays the displacement as output. A block diagram

for the measurement of deflection of beam subjected to voltage is similar to the one shown in the Figure 2

The LVDT was placed at the tip of the beam and the initial deflection was noted. Then voltage to the piezo is

varied from 50 to 200 volts. For the each voltage increment, the corresponding deflection is measured. The

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2139

Dr. Chandrashekhar Bendigeri et al. / International Journal of Engineering Science and Technology (IJEST)

Figure 6 shows the comparison of the result of static deflection of piezoelectric beam with present results. The

comparison shows good correlation between the two.

Deflection of smart beam

0.15 Present code

Experiment

Deflection (mm)

0.1

0.05

0

0 100 200 300

Voltage (volts)

Figure 6 Comparison of static deflection of piezoelectric smart beam

Experiment 3

Experiment and analysis of smart beam subjected to free vibration

Free Vibration Analysis of smart beam made of Al alloy with PZT patch has been carried out. Figure 7 show the

geometry of the cantilever beam with piezoelectric and Figure 8 shows the FE model. The model consists of 124

elements and 294 nodes. The block diagram of the experimental setup is shown in the Figure 9. A brief

description of the experimental procedure is given below

A) Experimental procedure

The function generator will generate a sine wave at 10v and this is passed on to the piezo actuator drive

amplifier where it is amplified from 10V to 145V and connected to actuator.

Then frequency from the signal generator is increased gradually and passed on to the actuator.

An oscilloscope is attached to sensor and the high amplitude reading on CRO corresponds to the

natural frequency.

First and second natural frequencies are determined experimentally. The high frequencies could not be measured

due to the limitations of the instrumentation used in the present studies.

Figure 7 Diagram of an Al beam with piezoelectric material

Figure 8 F E model of smart beam

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2140

Dr. Chandrashekhar Bendigeri et al. / International Journal of Engineering Science and Technology (IJEST)

Figure 9The block diagram for the free vibration test of piezoelectric smart structure

Using the present code, a normal mode analysis is carried out to obtain the fundamental natural frequency for

the smart beam with PZT. The results that are obtained from the present code are compared with results

obtained by analytical calculations which is determined using the following equations

(B) Analytical method

Analytical equations pertaining to first fundamental frequency of the beam is given below

Circular frequency ω = Ct *a (18)

L2

Where Ct has the value 3.52 for mode I

22.4 for mode II

61.7 for mode III

121 for mode IV

Where is given as follows

a= E*I (19)

*A

bd 3

and the moment of inertia (I)= (20)

12

Natural Frequency FZ (21)

2 *

The configuration of the present problem is as follows

Length=L=200mm

Width of the beam (b) =25mm

Depth of the beam (d) = 3mm

Area of cross section (A) =75mm2

Substituting the values of present configuration in the equation 19 and 20 we get following values

Moment of inertia I =56.2 mm4

and a= 4409585

Substituting the value of a in equation 18 we obtain the Circular frequency

ω =388 rad/sec and using equation 21 we obtain first natural frequency as 61 Hz

Similarly the circular frequency for the second mode is obtained using the equation 18 with the value of Ct as

22.4 and hence the natural frequency is obtained by equation 21 as 393 Hz

The natural frequencies for the present configuration are determined by analytical, experimental and finite

element analysis. Table 2 shows comparison of Natural frequencies of piezoelectric smart beam.

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2141

Dr. Chandrashekhar Bendigeri et al. / International Journal of Engineering Science and Technology (IJEST)

Table 2 Comparison of natural frequencies of smart beam obtained using analytical, experimental and present code

Sl Analytical Experiment Present code

no. method

Natural Natural Natural

Frequency Frequency Frequency

(Hz) (Hz) (Hz)

1 61 58 59

2 393 380 384

3 1082 1043

4 2122 2081

(C)Finite element analysis

In the experiment due to limitation of instruments determination of higher natural frequencies is not possible.

Hence only first two natural frequencies has been determined from the experiment as seen in the Table 2. How

ever the analytical and finite element approach can compute the natural frequency of higher modes. As can be

seen from Table 2 the natural frequency of the smart beam has good agreement among different approach of

estimation.

Conclusions

The finite element code for analysis of smart structures is developed using MATLAB programming language.

Also experiment was carried out on the smart beam with piezoelectric material attached and related instruments

are discussed. Simple experiments are devised to obtain static and dynamic behavior of the smart structure.

These experimental results were also useful to validate the present code. The developed code is validated by

comparing the results of experiments carried out by using piezoelectric material in combination other materials

such as steel and aluminum. The finite element code developed for structure analysis and electromechanical

analysis of the smart composite structure is found to have good agreement with the experimental results.

References

[1] T. S. Tzou and C. I. Tsen. 1990. Distributed piezoelectric sensor/Actuators design for dynamic measurement/control of distributed

parameter systems - A piezoceramic finite element approach, J of Sound Vibrations .

[2] Sung kyu and Charles Keillers. 1992. Finite element analysis of composite structures containing distributed piezoceramic sensors and

actuators. AIAA J, Vol. 30, No. 3.

[3] Bahu Sun and Dahuang. 2001. Vibration suppression of laminated beams with a piezoelectric damping layer. Composite Structures,

Vol. 53, pp 437- 447

[4] Benjeddou, and A. Trindade.1999. New shear actuated smart structure beam finite element”, AIAA J, Vol. 37, No. 3.

[5] B. L. Wang and N. Noda.2001. Design of smart functionally graded thermo-piezoelectric composite structure. J of Smart Materials and

Structures, Vol. 10.

[6] S.Y. Wang, S. T. Quek and K. K. Ang.2001. Vibration control of smart piezoelectric composite plates. J of Smart Materials and

Structures, Vol. 10, pp 637-644.

[7] IEEE std, 1988, IEEE Standard on Piezoelectricity – ANSI/IEEE Std 176.

[8] E F Crawley and K.B. Lazarus. 1991.Induced Strain actuation of Isotropic and Anisotropic plate. AIAA Journal, 29, 944 – 951.

[9] Kekana and P. Tabakov. 2005. Static control of composite plates using piezoelectric sensor and actuator techniques. J of Smart

Material and Structure, Vol. 14, pp 349-353.

[10] S. Raja and P. Bhattacharya,. 2002. Influence of one and two dimensional piezoelectric actuation on active vibration control of smart

panels. J of Aerospace Science and Technology, pp 209-216.

[11] Asan Gani and M. Salami 2003. Active Vibration control of beam with piezoelectric patches: real-time implementation with xPC

target. IEEE Proceedings.

ISSN : 0975-5462 Vol. 3 No. 3 March 2011 2142

You might also like

- Modelling and Eigen Frequency Analysis of Piezoelectric Cantilever BeamDocument8 pagesModelling and Eigen Frequency Analysis of Piezoelectric Cantilever BeamTI Journals PublishingNo ratings yet

- Finite Element Modeling of Piezoelectric StructuresDocument17 pagesFinite Element Modeling of Piezoelectric StructuresAmir JoonNo ratings yet

- 1A DefectDocument8 pages1A Defectdaniel_sa2011No ratings yet

- Modelling and Optimisation of A Bimorph Piezoelectric Cantilever Beam in An Energy Harvesting ApplicationDocument16 pagesModelling and Optimisation of A Bimorph Piezoelectric Cantilever Beam in An Energy Harvesting Applicationiusley.slNo ratings yet

- Vibration Energy Harvesting Using Single and Comb-Shaped Piezoelectric Beam Structures: Modeling and SimulationDocument7 pagesVibration Energy Harvesting Using Single and Comb-Shaped Piezoelectric Beam Structures: Modeling and SimulationAmir JoonNo ratings yet

- 31 Asif1Document5 pages31 Asif1Vijay KumarNo ratings yet

- Study On Improvement of Damping in Jointed Cantilever Beams Using FEMDocument8 pagesStudy On Improvement of Damping in Jointed Cantilever Beams Using FEMHamed MasterNo ratings yet

- Mechanical Buckling of Engesser-Timoshenko Beams With A Pair of Piezoelectric LayersDocument4 pagesMechanical Buckling of Engesser-Timoshenko Beams With A Pair of Piezoelectric LayersehsanNo ratings yet

- Jurnal IlmiahDocument8 pagesJurnal IlmiahnarutomovieNo ratings yet

- RRCM 0003Document21 pagesRRCM 0003Rahul N SagarNo ratings yet

- Extended Abstract (R)Document3 pagesExtended Abstract (R)Eshwar G PawarNo ratings yet

- EMI TechniqueDocument0 pagesEMI Techniqueluvjoshi1989No ratings yet

- Electronic Structure of GaN Nanotubes - Sodre J M Et Al - C R Chimie Vol 20 Issue 2 P 190-196Document7 pagesElectronic Structure of GaN Nanotubes - Sodre J M Et Al - C R Chimie Vol 20 Issue 2 P 190-196Brandon YorkNo ratings yet

- Lossy CalculationsDocument4 pagesLossy CalculationsGiri ReddyNo ratings yet

- SAW& ComsolDocument5 pagesSAW& Comsollabirint10No ratings yet

- Modeling of A Cantilever Beam For Piezoelectric Energy HarvestingDocument7 pagesModeling of A Cantilever Beam For Piezoelectric Energy HarvestingAbu Bakr M. SaeedNo ratings yet

- Design OptimisationDocument14 pagesDesign OptimisationAbirami RajagopalNo ratings yet

- Quantum Hydrodynamic Simulation of Discrete-Dopant Fluctuated Physical Quantities in Nanoscale FinFETDocument3 pagesQuantum Hydrodynamic Simulation of Discrete-Dopant Fluctuated Physical Quantities in Nanoscale FinFETPratap Kumar DasNo ratings yet

- Distribution of Electrical Current Density Into Planar Magnetic Components According To FrequencyDocument7 pagesDistribution of Electrical Current Density Into Planar Magnetic Components According To FrequencyIJAR JOURNALNo ratings yet

- Design & Development of Helmholtz Coil For Hyperpolarized MRIDocument6 pagesDesign & Development of Helmholtz Coil For Hyperpolarized MRIJosué Daniel Meneses DíazNo ratings yet

- Broadside suspended stripline 3 dB couplers design procedureDocument6 pagesBroadside suspended stripline 3 dB couplers design procedureBen WalpoleNo ratings yet

- Simulation of Piezoelectric Devices by Two - and Three-Dimensional Finite ElementsDocument15 pagesSimulation of Piezoelectric Devices by Two - and Three-Dimensional Finite Elementszhangcwy1225No ratings yet

- Finite Element Modeling of Smart Piezoelectric Beam UsingDocument8 pagesFinite Element Modeling of Smart Piezoelectric Beam Usingelifnurselcuk99No ratings yet

- Instrument For Real-Time Measurements of Airgap Flux Distribution of On-Load Synchronous GeneratorsDocument4 pagesInstrument For Real-Time Measurements of Airgap Flux Distribution of On-Load Synchronous GeneratorsGanti KameshNo ratings yet

- On Finite Element Analysis of Steel and RC Beams: Performance of Different ElementsDocument6 pagesOn Finite Element Analysis of Steel and RC Beams: Performance of Different ElementsmrinmoyNo ratings yet

- IEEE Journal of Quantum ElectronicsDocument6 pagesIEEE Journal of Quantum ElectronicsAkshay GuptaNo ratings yet

- Novel Methods For Axial Fan Impeller Geometry Analysis and Experimental Investigations of The Generated Swirl Turbulent FlowDocument12 pagesNovel Methods For Axial Fan Impeller Geometry Analysis and Experimental Investigations of The Generated Swirl Turbulent Flowbalaji2661989No ratings yet

- Resolving Structural Contributions To The Electric-Field-Induced Strain in Lead-Free (1 X) Ba (ZR Ti) O X (Ba Ca) Tio PiezoceramicsDocument9 pagesResolving Structural Contributions To The Electric-Field-Induced Strain in Lead-Free (1 X) Ba (ZR Ti) O X (Ba Ca) Tio PiezoceramicsSamah SamahNo ratings yet

- Determination of Natural Frequency of Euler's Beams Using Analytical and Finite Element MethodDocument75 pagesDetermination of Natural Frequency of Euler's Beams Using Analytical and Finite Element MethodAnonymous oYSrguZNo ratings yet

- Comsol For InductionDocument9 pagesComsol For Inductioninfo5280No ratings yet

- Cable Net StructuresDocument18 pagesCable Net StructuresRimon GawandeNo ratings yet

- Electric Field and Potential Distributions Along Surface of Silicone Rubber Polymer Insulators Using Finite Element MethodDocument6 pagesElectric Field and Potential Distributions Along Surface of Silicone Rubber Polymer Insulators Using Finite Element Methodostojic007No ratings yet

- Analysis of Planar Dipole Antenna With Arlor Material of Different Di-ElectricsDocument4 pagesAnalysis of Planar Dipole Antenna With Arlor Material of Different Di-ElectricsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analytical Calculation For DC Inductances of Rectangular Spiral Inductors With Finite Metal Thickness in The PEEC FormulationDocument3 pagesAnalytical Calculation For DC Inductances of Rectangular Spiral Inductors With Finite Metal Thickness in The PEEC FormulationshuangwenNo ratings yet

- The Influence of Broken Cables On The Structural Behavior of Long-Span Cable-Stayed BridgesDocument10 pagesThe Influence of Broken Cables On The Structural Behavior of Long-Span Cable-Stayed BridgesMashudi AliNo ratings yet

- Superlattices and Microstructures: B. Ghebouli, M.A. Ghebouli, N. Bouarissa, M. FatmiDocument12 pagesSuperlattices and Microstructures: B. Ghebouli, M.A. Ghebouli, N. Bouarissa, M. Fatmipoonamsingh08_declNo ratings yet

- Shinozuka 1990 - Stochastic Methods in Wind Engineering PDFDocument15 pagesShinozuka 1990 - Stochastic Methods in Wind Engineering PDFWasim IlyasNo ratings yet

- Investigation of Diverse Characteristics of Strained III-V Nitride Quantum WellDocument4 pagesInvestigation of Diverse Characteristics of Strained III-V Nitride Quantum WellUlhasNo ratings yet

- Ijetr022484 PDFDocument4 pagesIjetr022484 PDFsonawaneulhas292No ratings yet

- Andjelkovic Vladimir MetalDocument15 pagesAndjelkovic Vladimir MetalIzetNo ratings yet

- Finite Deformation Continuum Model For Single-Walled Carbon NanotubesDocument9 pagesFinite Deformation Continuum Model For Single-Walled Carbon NanotubesEduardo GarciaNo ratings yet

- Application of Pds-Fem To Seismic Failure Analysis of Reinforced Concrete Bridge PierDocument8 pagesApplication of Pds-Fem To Seismic Failure Analysis of Reinforced Concrete Bridge Pierdenniecivil342No ratings yet

- Optimal Energy Density Piezoelectric Twisting Actuators: Benjamin M. Finio and Robert J. WoodDocument6 pagesOptimal Energy Density Piezoelectric Twisting Actuators: Benjamin M. Finio and Robert J. WoodHumair ShaheenNo ratings yet

- Nanocrystal Embedded MOS Non Volatile Memory Devices: Prof. C. K. SarkarDocument40 pagesNanocrystal Embedded MOS Non Volatile Memory Devices: Prof. C. K. SarkarS.R.SriramNo ratings yet

- Progress in Electromagnetics Research M, Vol. 30, 253-269, 2013Document17 pagesProgress in Electromagnetics Research M, Vol. 30, 253-269, 2013Gilberto MejiaNo ratings yet

- Split-Deflection Method of Classical Rectangular Plate AnalysisDocument4 pagesSplit-Deflection Method of Classical Rectangular Plate AnalysisJASH MATHEWNo ratings yet

- Analytical solution for static analysis of composite laminates induced by piezoelectric actuatorsDocument6 pagesAnalytical solution for static analysis of composite laminates induced by piezoelectric actuatorsbluemoon1172No ratings yet

- Finite Element Modeling of Concrete Beams Prestressed With External TendonsDocument8 pagesFinite Element Modeling of Concrete Beams Prestressed With External TendonsviniciusltNo ratings yet

- Analysis and Design of Microstrip Patch Antenna Loaded With Innovative Metamaterial StructureDocument7 pagesAnalysis and Design of Microstrip Patch Antenna Loaded With Innovative Metamaterial Structurecontrivers1No ratings yet

- Efficient Modeling of Spatially Incoherent Sources Based On Wiener Chaos Expansion Method For The Analysis of Photonic Crystal SpectrometersDocument8 pagesEfficient Modeling of Spatially Incoherent Sources Based On Wiener Chaos Expansion Method For The Analysis of Photonic Crystal Spectrometersjulianli0220No ratings yet

- Aps 2001Document4 pagesAps 2001alcamposNo ratings yet

- Wake Potential of Penetrating Ionsin Amorphous Carbon Target Using Quantum Harmonic Oscillator (QHO) ModelDocument6 pagesWake Potential of Penetrating Ionsin Amorphous Carbon Target Using Quantum Harmonic Oscillator (QHO) ModelInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Si3N4 VNUJ 2022Document10 pagesSi3N4 VNUJ 2022Vinh LeNo ratings yet

- Ing Sismica Pentamode 2016Document10 pagesIng Sismica Pentamode 2016ponjoveNo ratings yet

- Reliability-Based Interaction CurveDocument8 pagesReliability-Based Interaction CurveEnida MataNo ratings yet

- Vol_16_Special_Issue_2023_43-49 (1)Document7 pagesVol_16_Special_Issue_2023_43-49 (1)teguhNo ratings yet

- Design and Optical Properties of Two-Dimensional Photonic Crystals: A Finite-Difference Time-Domain Numerical Simulation StudyDocument6 pagesDesign and Optical Properties of Two-Dimensional Photonic Crystals: A Finite-Difference Time-Domain Numerical Simulation StudyEkin KaracaNo ratings yet

- Analysis of Stress in Anchorage Zone Using AnsysDocument5 pagesAnalysis of Stress in Anchorage Zone Using Ansysmishranamit2211No ratings yet

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Organic Light-Emitting Transistors: Towards the Next Generation Display TechnologyFrom EverandOrganic Light-Emitting Transistors: Towards the Next Generation Display TechnologyNo ratings yet

- 2 Canada-Us Cansmart Workshop: 10 - 11 October 2002, Montreal, Quebec, CanadaDocument7 pages2 Canada-Us Cansmart Workshop: 10 - 11 October 2002, Montreal, Quebec, CanadaBhuvaneshwar PatilNo ratings yet

- (Donald J. Leo) Engineering Analysis of Smart Mate PDFDocument569 pages(Donald J. Leo) Engineering Analysis of Smart Mate PDFEclys Montenegro100% (5)

- 007 Amit Singh 2002 Active Passive Vibration Reduction of Periodic 1-DDocument13 pages007 Amit Singh 2002 Active Passive Vibration Reduction of Periodic 1-DBhuvaneshwar PatilNo ratings yet

- 001 A Benjeddou 2000 Advances in Piezoelectric Nite Element Modeling ofDocument17 pages001 A Benjeddou 2000 Advances in Piezoelectric Nite Element Modeling ofBhuvaneshwar PatilNo ratings yet

- A Multi-Agent System For Bushing Condition MonitoringDocument6 pagesA Multi-Agent System For Bushing Condition MonitoringBhuvaneshwar PatilNo ratings yet

- 3814 GY VD AC - 901 - 2101 IS01 Structural Calculation NotesDocument272 pages3814 GY VD AC - 901 - 2101 IS01 Structural Calculation Notesgchaves504No ratings yet

- Concrete Slab Design Using Mathcad PDFDocument7 pagesConcrete Slab Design Using Mathcad PDFDiaconu SofiaNo ratings yet

- DESIGN CALCULATIONS - GL-03 2509 - 4.0mDocument17 pagesDESIGN CALCULATIONS - GL-03 2509 - 4.0mmsiddiq1No ratings yet

- Large Deformation BeamDocument10 pagesLarge Deformation BeamAdimasu AyeleNo ratings yet

- Dom Lab ManuelDocument56 pagesDom Lab ManuelMartin De Boras PragashNo ratings yet

- Theory of Structure 1Document10 pagesTheory of Structure 1Anil Thapa100% (1)

- Design Industrial BuildingsDocument38 pagesDesign Industrial Buildingsdmardetk100% (1)

- Floor Slab Design "DDM"Document142 pagesFloor Slab Design "DDM"batistathegameNo ratings yet

- Formulas For Dynamics Acoustics and Vibration - 2015 - Blevins - Appendix A Approximate Methods For Natural FrequencyDocument8 pagesFormulas For Dynamics Acoustics and Vibration - 2015 - Blevins - Appendix A Approximate Methods For Natural FrequencyYOGESH S 17MER227No ratings yet

- Analysis and Behaviour of High Cantilever Retaining WallDocument15 pagesAnalysis and Behaviour of High Cantilever Retaining WallfreezefreezeNo ratings yet

- CFS Designer User Manual: Comprehensive Guide to Cold-Formed Steel and HSS Analysis SoftwareDocument44 pagesCFS Designer User Manual: Comprehensive Guide to Cold-Formed Steel and HSS Analysis SoftwareCarsonBakerNo ratings yet

- Performance Study On Prestressed Concrete Girder Bridge: KeywordsDocument5 pagesPerformance Study On Prestressed Concrete Girder Bridge: KeywordsVikramNo ratings yet

- 2005 - Robertson, I. N. 2005 - Prediction of Vertical Deflections For A Long-Span Prestressed Concrete Bridge StructureDocument8 pages2005 - Robertson, I. N. 2005 - Prediction of Vertical Deflections For A Long-Span Prestressed Concrete Bridge StructureAzharu ZainunniamNo ratings yet

- r09222502 Mechanics of SolidsDocument9 pagesr09222502 Mechanics of SolidsNida Bagoyboy NatichoNo ratings yet

- A Concept Exploration Method For Product Family DesignDocument598 pagesA Concept Exploration Method For Product Family DesignHariton FloreaNo ratings yet

- Member Design: Deep Rafter StabilityDocument6 pagesMember Design: Deep Rafter StabilityEmanuel FelisbertoNo ratings yet

- Murray Roberts calculation sheet for Eskom Medupi crawl beamDocument23 pagesMurray Roberts calculation sheet for Eskom Medupi crawl beamMbalekelwa MpembeNo ratings yet

- Inspection Report of Film ShootDocument3 pagesInspection Report of Film ShootrohitNo ratings yet

- 200x200x9 Steel Beam AnalysisDocument5 pages200x200x9 Steel Beam AnalysisSupun Aravinda JayawardhaneNo ratings yet

- 5 Bending StressDocument23 pages5 Bending Stressmuhamadsaidi100% (1)

- Design Calculation For External Pipe Rack Section PK 12 - Grid 90 To 109Document24 pagesDesign Calculation For External Pipe Rack Section PK 12 - Grid 90 To 109Dass DassNo ratings yet

- (2017) Performance of Wulung Bamboo Reinforced Concrete BeamsDocument10 pages(2017) Performance of Wulung Bamboo Reinforced Concrete BeamsAlpin MaulidinNo ratings yet

- CD 354 Revision 1 Design of Minor Structures-WebDocument64 pagesCD 354 Revision 1 Design of Minor Structures-Webgaurav sharmaNo ratings yet

- Estimating Crack Widths in Steel Fibre-Reinforced ConcreteDocument12 pagesEstimating Crack Widths in Steel Fibre-Reinforced ConcreteRm1262No ratings yet

- Experimental Investigation On Behavior of Bamboo Reinforced Concrete MemberDocument5 pagesExperimental Investigation On Behavior of Bamboo Reinforced Concrete MemberesatjournalsNo ratings yet

- Deflection According To Aci and BsDocument16 pagesDeflection According To Aci and Bsronison78100% (4)

- Design of Track Slab Reinforcement for Sitaburdi StationDocument2 pagesDesign of Track Slab Reinforcement for Sitaburdi Stationabdul samadNo ratings yet

- BUILT-IN BEAMSDocument9 pagesBUILT-IN BEAMSDaniel MukuhaNo ratings yet

- BS - Reinforced Masonry Design GuideDocument76 pagesBS - Reinforced Masonry Design Guidescgengineer100% (7)

- Gunt Experiment On DeflectionDocument28 pagesGunt Experiment On DeflectionMercyAgbenegoNo ratings yet