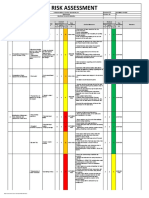

Risk Assessment: Spray Booth VOC

Date: 25th May 2022 Review Date: 25th May 2023

Site: Custom Coachworks

Hazards:

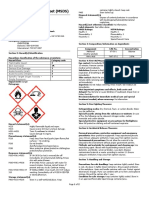

1. Exposure to Isocyanate paints and other contaminants through paint spraying

2. Fire or explosion due to build up of flammable vapors.

3. VOC exposure to the atmosphere.

Persons At Risk:

1. Operator

2. Authorised Visitors

3. Members of the Public

Risk Rating: (before control measures implemented)

Severity: 4 Likelihood: 4 Risk Rating: High Risk

Controls:

1. Breathing Air Quality Checks - Where breathing apparatus is required, the source of breathable air will be

subject to quarterly air quality checks to ensure there is no contamination with the breathable air. Records will

be maintained.

2. Maintenance and Inspection - Spraybooths will be inspected and maintained as per manufacturers specifications,

this will include periodic service and inspections from a competent engineer, gas safety inspections for ovens,

thorough examinations of extraction equipment, internal visual checks and and maintenance, spraybooth filter

changes etc. All records shall be maintained for review purposes.

3. PPE/RPE/BA - Management will ensure that adequate PPE/RPE/BA is used and that the operators has

been provided with training and information on the use, maintenance and storage. Breathing apparatus will

be visually inspected before use and inspected/serviced on a periodic basis. Face fit testing will be carried

out for all personnel required to wear RPE or BA. Beards or stubble will not be permitted with face masks.

if the operator wishes not to shave then a hood should be worn. Suitable footwear should be used whilst in

the spraybooth along with liquid repellent coveralls and nitrile gloves. There should be no exposed skin whilst

spraying.

4. Smoke clearance tests - Periodic (no more than annual) smoke clearance tests will be carried out by a competent

person in order to test the effectiveness of the LEV system.The clearance time will be posted upon all entry

routes to the spraybooth. All personnel will be informed of the clearance time and that the operator is not to

remove BA untill this time has passed and that no personnel should enter until this time has passed.

Generated by Canopy

c 6th June 2022 Page: 1

� 5. Training and information - Management will ensure that all personnel that requires access to or use of spraybooth

operations is provided with suitable training and information and is deemed competent by the employer. All

relevant safety information will be displayed including PPE signage, equipment operations, COSHH safety etc.

Risk Rating: (after successful implementation of controls)

Severity: 2 Likelihood: 1 Risk Rating: Low Risk

PPE:

Mandatory: Considered:

1. Overalls Y

2. Gloves Y

3. Respirator Y

Regulations:

1. Health and Safety at Work etc. Act 1974

2. The Management of Health and Safety at Work Regulations 1999

3. Personal Protective Equipment at Work Regulations 1992

4. The Provision and Use of Work Equipment Regulations 1998

5. Control of Substances Hazardous to Health 2002 (as amended)

6. Control of Noise at Work Regulations 2005

Further Comments / Observations / Recommendations:

This is a general risk assessment for spraybooth operations. Management is required to review this risk assessment

and ammend or update as required by specific circumstances.

Generated by Canopy

c 6th June 2022 Page: 2

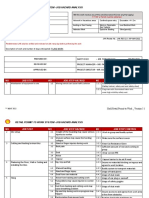

�Risk Rating Key:

Severity: Likelihood:

Fatality 5 Certain or imminent 5

Major injury, disabling illness, ma- 4 Very likely 4

jor damage

May happen 3

Lost time injury, illness, damage 3

Unlikely 2

Minor injury, minor damage 2

Very unlikely 1

Delay only 1

Risk Rating:

Very High Risk: 20 - 25 Immediate action required to stop the activity or reduce

the risk

High Risk: 12 - 19 Urgent action required, as soon as practicable and within

two weeks at the latest

Medium Risk: 8 - 11 Keep under regular review and investigate further mea-

sures to reduce the risk

Low Risk: 1-7 Acceptable risk

Generated by Canopy

c 6th June 2022 Page: 3