Professional Documents

Culture Documents

14 DBlatt05 2011 E - Air

14 DBlatt05 2011 E - Air

Uploaded by

AntonioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14 DBlatt05 2011 E - Air

14 DBlatt05 2011 E - Air

Uploaded by

AntonioCopyright:

Available Formats

MOULDINGSANDMANAGEMENT 2020

Measuring the exhaust airflow

from the cooler

air_control Air pressure measurement

Sand intake

Sand outlet

Water inlet

Supply air / fan

Exhaust air Oldsand hopper

Cyclone

Electrode 1

Dust scale

The task:

In the process of cooling the used sand, the flow of air is an important component. The air picks up the water that evaporates, although there is a limit to

how much it can absorb. The evaporation process is energy intensive and uses the heat energy from the warm used sand. Irregular airflow creates fluctua-

tions in the cooling because different amounts of water evaporate. An appropriate measuring device should monitor the flow of air continuously.

The used sand should be cooled evenly.

Approach: Advantages:

The warm waste air that comes out of the cooler This method of measuring airflow has a number

is heavily contaminated with dust, while the high of advantages.

proportion of bentonite hardens on the surfaces 1. Permanent monitoring of the flow of air in the

very quickly in the saturated state. Under these cooler is possible.

circumstances, measuring devices quickly lose 2. Fluctuations can be identified when pipes

their accuracy, with the result that they can only become clogged.

be used if they do not come into direct contact 3. The simple design, which includes visualisa-

with the exhaust air. If a sensor is used for tion and data recording, can be integrated into

dynamic air pressure measurement against the the control system.

airflow, it quickly becomes clogged.

Optimisation (options):

Solution:

The static air pressure gauge does not have a Measurement of the quantity of dust

sensor that is exposed directly to the air. The The quantity of dust extracted by the exhaust

flow of air creates a vacuum that is recorded by air has a significant effect on the quality of the

a sensor installed outside the exhaust air pipe. sand. Variations in the quantity of dust removed

The airflow can then be determined using a are reflected in the quality levels. A weighing de-

special recalibration process. vice in the exhaust pipe of the cyclone measures

the quantity of dust.

DBlatt05-2011-E

datec

Dosier- und Automationstechnik GmbH · Alte Salzdahlumer Str. 203 · D - 38124 Braunschweig

Fon + 49 531 26408 - 0 · Fax + 49 531 26408 -20 · E-Mail info@datec.org · Internet www.datec.org

You might also like

- DOOM Survival Guide 2.2Document306 pagesDOOM Survival Guide 2.2mugspsu89100% (1)

- DMSO The DMSO Handbook - A New Paradigm in Healthcare MMS (Das DMSO Handbuch Von Dr. Hartmut Fischer)Document276 pagesDMSO The DMSO Handbook - A New Paradigm in Healthcare MMS (Das DMSO Handbuch Von Dr. Hartmut Fischer)Ramona Vintila100% (1)

- Earth Science Reviewer Quarter 2Document6 pagesEarth Science Reviewer Quarter 2Windy Kyle LimNo ratings yet

- Bovis Units in Everyday Life PDFDocument131 pagesBovis Units in Everyday Life PDFdulce como la miel100% (1)

- Air and Water Quality Monitoring FinalDocument34 pagesAir and Water Quality Monitoring FinalJulius ChavezNo ratings yet

- 028 Flare Gas Metering (English)Document12 pages028 Flare Gas Metering (English)Sergio A. Rdz. F.No ratings yet

- Astm D5957-98Document5 pagesAstm D5957-98Michael Villaluz100% (2)

- Introduction Venturi ScrubberDocument3 pagesIntroduction Venturi ScrubberNurul HazimahNo ratings yet

- 5.energy Audit of CW SystemDocument39 pages5.energy Audit of CW Systembharadwaj037No ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Direct and Indirect Measurement of SoilDocument14 pagesDirect and Indirect Measurement of SoilGu GuimaNo ratings yet

- Plate Heat ExchangerDocument7 pagesPlate Heat ExchangerDilipNo ratings yet

- Chapter 4 Mass Balances CompleteDocument33 pagesChapter 4 Mass Balances Completekhairitajurus100% (1)

- Material Data Safety Sheet Jet A1 ShellDocument10 pagesMaterial Data Safety Sheet Jet A1 ShellAdnan Haji HarbiNo ratings yet

- Module 2Document60 pagesModule 2ABDULLA MOHAMED AHMED JASIM ASHOORNo ratings yet

- MSDS EpdmDocument8 pagesMSDS EpdmUlfa Intan PratiwiNo ratings yet

- TLE AFA6 Mod1 Importance of Planting Trees v2Document22 pagesTLE AFA6 Mod1 Importance of Planting Trees v2Vergel Nogal100% (2)

- Bag HouseDocument55 pagesBag HousegovardhanNo ratings yet

- EHD211000 Standard Program Documentation ENG K216 2016Document69 pagesEHD211000 Standard Program Documentation ENG K216 2016gonzalo.lartec2369No ratings yet

- Figure 1. Ejector System For Soybean Oil DeodorizerDocument11 pagesFigure 1. Ejector System For Soybean Oil DeodorizerjarofidzNo ratings yet

- Dust SuppressionDocument10 pagesDust SuppressionHiran WittachyNo ratings yet

- Fundamentals of Natural Gas Water Vapor MeasurementDocument4 pagesFundamentals of Natural Gas Water Vapor MeasurementSalman AbuzuhairaNo ratings yet

- Dust Suppression SystemDocument7 pagesDust Suppression SystemHarish AG workNo ratings yet

- Experiment 4Document11 pagesExperiment 4mirza farhanNo ratings yet

- Catalogo Sensor SS 20 501 y 502Document2 pagesCatalogo Sensor SS 20 501 y 502bcjalNo ratings yet

- Hot Extraction Vs InsituDocument5 pagesHot Extraction Vs Insitupradeep.selvarajan100% (1)

- MeasurIT Flexim Application Natural Gas 0809Document1 pageMeasurIT Flexim Application Natural Gas 0809cwiejkowskaNo ratings yet

- LL Dimgatestat PDFDocument12 pagesLL Dimgatestat PDFsalasineNo ratings yet

- I (Unit-II)Document44 pagesI (Unit-II)TanmaySardanaNo ratings yet

- HVAC-Deep Vacuum PDFDocument8 pagesHVAC-Deep Vacuum PDFCliff BurtonNo ratings yet

- Application of Measuring Gas Flow in The DowncomerDocument4 pagesApplication of Measuring Gas Flow in The DowncomerAhmad NilNo ratings yet

- Soil Guidance NotesDocument15 pagesSoil Guidance NotesAkil MarzukiNo ratings yet

- Pgjonline-Com-MagaDocument9 pagesPgjonline-Com-MagaJagdish mogaNo ratings yet

- Brochure Ventiladores OeldeDocument6 pagesBrochure Ventiladores OeldeJorge CarignanoNo ratings yet

- Air Pollution Sampling and Measurement: - by G.Naga ThulasiDocument19 pagesAir Pollution Sampling and Measurement: - by G.Naga ThulasisaiganeshmadasuNo ratings yet

- Mist/Steam Cooling For Advanced Turbine SystemsDocument15 pagesMist/Steam Cooling For Advanced Turbine SystemsRAVI KUMARNo ratings yet

- Bag Filter Dust Collector DesignDocument3 pagesBag Filter Dust Collector DesignArvind VagananthanNo ratings yet

- 2017 ClAire TB16-CompleteContinuousMonitoringInUnderfloorVoidsDocument5 pages2017 ClAire TB16-CompleteContinuousMonitoringInUnderfloorVoidsKenneth UgaldeNo ratings yet

- Leak Detection in Water-Distribution Pipe System: June 2018Document5 pagesLeak Detection in Water-Distribution Pipe System: June 2018Sai PhanindraNo ratings yet

- Design and Analysis of Cyclone SeparatorDocument6 pagesDesign and Analysis of Cyclone Separatormr. dossNo ratings yet

- Conditioning of Steam & Air NotesDocument22 pagesConditioning of Steam & Air Notesbonginkosi mathunjwaNo ratings yet

- TOWARDS THE OPTIMIZATION OF FLOTATION COLUMNS USING P - 2007 - IFAC ProceedingsDocument6 pagesTOWARDS THE OPTIMIZATION OF FLOTATION COLUMNS USING P - 2007 - IFAC ProceedingssmeykelNo ratings yet

- Air Scrubber ReportDocument10 pagesAir Scrubber ReportAzrol Azmir LongNo ratings yet

- Devices For Field Determination of H O in Natural GasDocument4 pagesDevices For Field Determination of H O in Natural GasJosé Hernández VázquezNo ratings yet

- Mi 2009 2 en Ap 1Document4 pagesMi 2009 2 en Ap 1Antonio VazquezNo ratings yet

- Tech Note Water Treatment Plant Dehumidiifer Sizing Guide Application Note DA112Document4 pagesTech Note Water Treatment Plant Dehumidiifer Sizing Guide Application Note DA112Samra MuzaferovicNo ratings yet

- Compressed Air in Pharmaceutical ApplicationsDocument3 pagesCompressed Air in Pharmaceutical ApplicationsDamien MarleyNo ratings yet

- Rain Gauge Sensor: Theodor Friedrichs & CoDocument1 pageRain Gauge Sensor: Theodor Friedrichs & CoAnonymous Buo5Kp9VKqNo ratings yet

- ES 200 - S2 - Air - L6 - 18oct 2021Document36 pagesES 200 - S2 - Air - L6 - 18oct 2021vishal kumarNo ratings yet

- PDF Sensorsairconditioningautomotive An1Document4 pagesPDF Sensorsairconditioningautomotive An1vampire.bliss2006No ratings yet

- Heat and Mass Transfer Process in Exhaust Wet ScrubberDocument5 pagesHeat and Mass Transfer Process in Exhaust Wet ScrubberGracylla RoseNo ratings yet

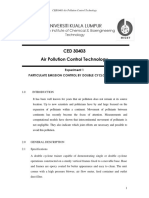

- Experiment 2 - Particulate Emission of Cyclones SystemDocument5 pagesExperiment 2 - Particulate Emission of Cyclones SystemHusna AtiqahNo ratings yet

- Experiment 2 - CyclonesDocument5 pagesExperiment 2 - CyclonesAhmad DanialNo ratings yet

- MeasurIT Flexim ADM7407 Application Lignite Surface Mining 0809Document1 pageMeasurIT Flexim ADM7407 Application Lignite Surface Mining 0809cwiejkowskaNo ratings yet

- Dust Emission Measurement in Quarries With The FW 56D/T 10Document2 pagesDust Emission Measurement in Quarries With The FW 56D/T 10Naser JahangiriNo ratings yet

- Kunal - Dry Fog PaperDocument17 pagesKunal - Dry Fog PaperSK ChaulyaNo ratings yet

- Sampling Method EPA Approved and InhouseDocument9 pagesSampling Method EPA Approved and InhouseFarhan TaseenNo ratings yet

- En - GMD-13 Information-Brochure 1.0Document12 pagesEn - GMD-13 Information-Brochure 1.0Alexis BerrúNo ratings yet

- Measuring and Recording WeatherDocument8 pagesMeasuring and Recording WeatherzoeNo ratings yet

- IOM - Farr Gold Series GSP 4 UK EnglishDocument32 pagesIOM - Farr Gold Series GSP 4 UK EnglishJulio CNo ratings yet

- Null 1Document23 pagesNull 1Ali Raza MeharNo ratings yet

- Practical Guild Airflow MeasurementDocument20 pagesPractical Guild Airflow MeasurementJason NguyenNo ratings yet

- Innovative Flow Measurement Used in The Field of Process EngineeringDocument3 pagesInnovative Flow Measurement Used in The Field of Process EngineeringKarl WeierstrassNo ratings yet

- Give Your Plant A Dust Control Tune-Up: Burning PRB CoalDocument4 pagesGive Your Plant A Dust Control Tune-Up: Burning PRB CoalD Gopala Krishnam RajuNo ratings yet

- Review On Condenser Air Leak Test: International Journal of Pure and Applied Mathematics No. 16 2018, 3197-3205Document10 pagesReview On Condenser Air Leak Test: International Journal of Pure and Applied Mathematics No. 16 2018, 3197-3205Amir AbbaszadehNo ratings yet

- Duct TypesDocument4 pagesDuct Typeschathura buddhikaNo ratings yet

- Sps His Pressure or Airflow SensorsDocument4 pagesSps His Pressure or Airflow SensorsNishant ShuklaNo ratings yet

- 17.2 P1 - MeteorologyDocument41 pages17.2 P1 - MeteorologyNelum PereraNo ratings yet

- AGRICULTURAL MECHANIC1 Lab Exe. 3Document10 pagesAGRICULTURAL MECHANIC1 Lab Exe. 3Charmae BrutasNo ratings yet

- Me Reporting ContentDocument10 pagesMe Reporting ContentALLEN MAACNo ratings yet

- Baumueller dst2 135 400 en 1119Document180 pagesBaumueller dst2 135 400 en 1119enisNo ratings yet

- StreamflowDocument72 pagesStreamflowdzikrydsNo ratings yet

- 01 Water Resources PDFDocument69 pages01 Water Resources PDFLaurice VillaflorNo ratings yet

- ESM 425 Lab Wk1 Units WatershedsDocument5 pagesESM 425 Lab Wk1 Units WatershedsOcto ChowNo ratings yet

- Ateneo de Davao University High School: Science 1 Unit PlanDocument3 pagesAteneo de Davao University High School: Science 1 Unit PlanRijane Mae Aguilar LabadNo ratings yet

- HACCP SummaryDocument14 pagesHACCP SummaryMuhammad Amir AkhtarNo ratings yet

- Consolidation FirstdayDocument8 pagesConsolidation Firstdaysharkondiet100% (1)

- Different Irrigation SystemsDocument4 pagesDifferent Irrigation SystemsAzad SamiNo ratings yet

- CE-402: Irrigation Engineering Irrigation, Indus Basin Irrigation System, Irrigation Types and MethodsDocument55 pagesCE-402: Irrigation Engineering Irrigation, Indus Basin Irrigation System, Irrigation Types and MethodsSajadNo ratings yet

- Kishanganga Hydroelectric PlantDocument3 pagesKishanganga Hydroelectric PlantAbirami BaskaranNo ratings yet

- Case Study - ALBANIA - ENDocument9 pagesCase Study - ALBANIA - ENYemi FajingbesiNo ratings yet

- Thermal Test Procedure For Box-Type Solar Cookers'IDocument8 pagesThermal Test Procedure For Box-Type Solar Cookers'Irejeesh_rajendran100% (1)

- Latent Heat VaporizationDocument3 pagesLatent Heat VaporizationerorkinNo ratings yet

- Imdakm Abdussalam Omar 1984Document182 pagesImdakm Abdussalam Omar 1984onlynameNo ratings yet

- Today's Plan - GlaciersDocument31 pagesToday's Plan - GlaciersAdil Javed ChaudharyNo ratings yet

- Environmental Chemistry 10th Manahan Solution ManualDocument36 pagesEnvironmental Chemistry 10th Manahan Solution Manualoutformimperialbi45100% (43)

- Fluidized Bed Freezer Quotation (MELIDocument8 pagesFluidized Bed Freezer Quotation (MELIrichardNo ratings yet

- Alodine 1132 Touch-N-PrepDocument3 pagesAlodine 1132 Touch-N-PrepEduardo NozalNo ratings yet

- Group 4 Environmental Chem Paper NewDocument30 pagesGroup 4 Environmental Chem Paper NewdwiNo ratings yet