Professional Documents

Culture Documents

Bag Filter Dust Collector Design

Uploaded by

Arvind Vagananthan0 ratings0% found this document useful (0 votes)

5 views3 pagesThis document summarizes the design details of a bag filter dust collector system. It describes the stack design, pulse jet cleaning system, filter bags used, and issues with low differential pressure readings. It also proposes adding temperature and air flow rate measurements, addressing the hard to read compressed air pressure gauge, and using jumbo bags for hopper discharge as required by regulations. Notes indicate written notifications have been submitted and that chimney emission testing will be outsourced after the plant is running.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the design details of a bag filter dust collector system. It describes the stack design, pulse jet cleaning system, filter bags used, and issues with low differential pressure readings. It also proposes adding temperature and air flow rate measurements, addressing the hard to read compressed air pressure gauge, and using jumbo bags for hopper discharge as required by regulations. Notes indicate written notifications have been submitted and that chimney emission testing will be outsourced after the plant is running.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views3 pagesBag Filter Dust Collector Design

Uploaded by

Arvind VagananthanThis document summarizes the design details of a bag filter dust collector system. It describes the stack design, pulse jet cleaning system, filter bags used, and issues with low differential pressure readings. It also proposes adding temperature and air flow rate measurements, addressing the hard to read compressed air pressure gauge, and using jumbo bags for hopper discharge as required by regulations. Notes indicate written notifications have been submitted and that chimney emission testing will be outsourced after the plant is running.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

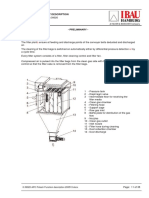

Bag Filter Dust Collector Design

No Parameter Design Details

1 Stack design The stack does not have rain cap, so it has drain line at the

bottom of the stack to drain the rainwater.

The sampling point location is 5D away from the nearest

disturbance, whereas D is the diameter of the chimney.

2 Pulse jet cleaning system There are total of 48 filter bags inside the filter housing. Each

row has 8 filter bags so total there are 6 rows.

Each row has one blow pipe to transport the compressed air to

clean the filter bags.

The On-time and Off-time can be found and set from

electronic timer controller.

3 Filter bag The filter bag used is polyester, which is good for abrasiveness.

However, it is only fair for both alkaline and acid. We might

need to change the filter bag very frequently.

4 Differential pressure gauge When dust collector system is running, the differential

pressure gauge showed 0.1 - 0.15kPa, which is very low and

out of operating range from DOE standards (0.5 - 1.5kPa)

Proposal

No Parameters Details Instruments Remarks

1 Temperature measurement There is no temperature measurement for incoming Digital thermometer Temperature measurement is

flow into dust collector. part of the daily monitoring

parameter as required by DOE

standards.

2 Air flow rate measurement There is no air flow rate measurement for outgoing Digital pitot tube Air flow rate measurement is

flow from dust collector. part of the daily monitoring

parameter as required by DOE

standards.

3 Compressed air pressure The compressed air pressure gauge is hard to read - Compressed air pressure

measurement because it located at high position. measurement is part of the

daily monitoring parameter as

required by DOE standards.

Have to use stairs to take the

reading.

4 Hopper Discharge The current waste bag is not jumbo bag. - As mentioned in DOE written

notification, the discharge is

considered as scheduled waste

and should put inside jumbo

bag.

Notes:

Written notification and written declaration have been submitted to DOE.

Chimney stack emission test has to outsource for third party to carry out. For new plant, the test has to be completed after the plant start running

for 3-4 months. After that, the test needs to carry out once every year.

You might also like

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- Final Process Engineering Course Material-8Document229 pagesFinal Process Engineering Course Material-8Sathish Rajan100% (3)

- Environmetal Management PlanDocument4 pagesEnvironmetal Management PlanNev DelgadoNo ratings yet

- Astm D6938-17Document10 pagesAstm D6938-17Nelson MonteroNo ratings yet

- Operation Principal of Sewage Treatmentplant and Point of MDocument12 pagesOperation Principal of Sewage Treatmentplant and Point of MKo Gyi BakaNo ratings yet

- Millipore Filter Integrity Test MethodsDocument12 pagesMillipore Filter Integrity Test Methodsmcarjona1100% (2)

- ASTMD6830 - 02 - Standard Test MethodDocument8 pagesASTMD6830 - 02 - Standard Test MethodKaffel100% (1)

- Pulse Jet Dust Collector: Learner GuideDocument37 pagesPulse Jet Dust Collector: Learner GuideRobson DE Freitas WerlingNo ratings yet

- Adr SlideDocument0 pagesAdr SlidemisadjoleNo ratings yet

- Gold Extraction With Halogens: J.-M. Lalancette, B. Dubreuil, D. Lemieux and C. ChouinardDocument16 pagesGold Extraction With Halogens: J.-M. Lalancette, B. Dubreuil, D. Lemieux and C. ChouinardLudwig Kommer100% (2)

- PolymersPlusExamplesandApplications PDFDocument342 pagesPolymersPlusExamplesandApplications PDFDavid Alemán SánchezNo ratings yet

- Mnchip Routine MaintenanceDocument8 pagesMnchip Routine Maintenancedmantsio100% (1)

- External Air Audit Report (Priority)Document2 pagesExternal Air Audit Report (Priority)Public DemandNo ratings yet

- D4448-01 (2013) Standard Guide For Sampling Ground-Water Monitoring WellsDocument17 pagesD4448-01 (2013) Standard Guide For Sampling Ground-Water Monitoring WellsKartika Rahmayani Djauhari100% (1)

- Module 2 Marine Oil PurifierDocument13 pagesModule 2 Marine Oil PurifierSrilecumy MaranNo ratings yet

- BS EN ISO 5175-1 (2017) FBA'sDocument22 pagesBS EN ISO 5175-1 (2017) FBA'sPC100% (1)

- Bag HouseDocument55 pagesBag HousegovardhanNo ratings yet

- Bag Filter ComponentsDocument6 pagesBag Filter ComponentsAhmad Dagamseh100% (2)

- Baghouse 130218005547 Phpapp01Document54 pagesBaghouse 130218005547 Phpapp01Suraj ShindeNo ratings yet

- Baghouse 130218005547 Phpapp01Document54 pagesBaghouse 130218005547 Phpapp01Vishal HiremathNo ratings yet

- Metodod Adecuados para Monitoreo de PM2.5 en Aire Incluye Fotos Impactador HV pm2.5Document61 pagesMetodod Adecuados para Monitoreo de PM2.5 en Aire Incluye Fotos Impactador HV pm2.5anthony guillermo vilca vargasNo ratings yet

- En - GMD-13 Information-Brochure 1.0Document12 pagesEn - GMD-13 Information-Brochure 1.0Alexis BerrúNo ratings yet

- Filtration Efficiency Impact Compressor Health GTIF Technical Article International Filtration News April2015Document4 pagesFiltration Efficiency Impact Compressor Health GTIF Technical Article International Filtration News April2015mazouz.lmfNo ratings yet

- 14 DBlatt05 2011 E - AirDocument1 page14 DBlatt05 2011 E - AirAntonioNo ratings yet

- E39 Ahsop 02Document17 pagesE39 Ahsop 02Sanjit SinghNo ratings yet

- Standard Test Procedures Manual: 1. ScopeDocument14 pagesStandard Test Procedures Manual: 1. ScopeTemur LomidzeNo ratings yet

- 2023-07-28 - Proposed Sewage SystemDocument3 pages2023-07-28 - Proposed Sewage SystemEstêvão KayokaNo ratings yet

- LT-SDF-6 Cylinder Dust Collector Operation Manual - 316Document14 pagesLT-SDF-6 Cylinder Dust Collector Operation Manual - 316EloiNo ratings yet

- Asut 09 01 08 PapDocument16 pagesAsut 09 01 08 PapExynos SamNo ratings yet

- Astm F 2519-05Document20 pagesAstm F 2519-05Maki Salim HussainNo ratings yet

- CRB Whitepaper Vapor Hydrogen Peroxide Decontamination WebDocument8 pagesCRB Whitepaper Vapor Hydrogen Peroxide Decontamination WebVictor LeiNo ratings yet

- Delft Hydraulics: Taco Air and Dirt Separator 4903AD-4Document9 pagesDelft Hydraulics: Taco Air and Dirt Separator 4903AD-4wilxjNo ratings yet

- Initial QualificationDocument28 pagesInitial QualificationWiktor PszczółkowskiNo ratings yet

- Filtering Samples To On-Line Process AnalyzersDocument5 pagesFiltering Samples To On-Line Process AnalyzersAftab AliNo ratings yet

- In-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Document10 pagesIn-Place Density and Water Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Nick AndroulakisNo ratings yet

- Duct TypesDocument4 pagesDuct Typeschathura buddhikaNo ratings yet

- Installation, Operating & Maintenance Manual: Turbine Flow MetersDocument12 pagesInstallation, Operating & Maintenance Manual: Turbine Flow MetersFurqanNo ratings yet

- Astm E1973 - 1 (En)Document4 pagesAstm E1973 - 1 (En)Dinesh SaiNo ratings yet

- PS1411 DC StandardsDocument5 pagesPS1411 DC StandardsGiovanny MosqueraNo ratings yet

- 2.4 Urgency Handling: 3.1 Brief IntroductionDocument46 pages2.4 Urgency Handling: 3.1 Brief IntroductionClip nhungcaunoihayNo ratings yet

- In-Place HEPA Filter Penetration Test: ArticleDocument24 pagesIn-Place HEPA Filter Penetration Test: ArticleIon CorbuNo ratings yet

- Feature-Moisture in Power 4ppDocument4 pagesFeature-Moisture in Power 4ppZero123No ratings yet

- Air Pollution Control System: Performance Monitoring Data Analysis & InterpretationDocument24 pagesAir Pollution Control System: Performance Monitoring Data Analysis & InterpretationizanfadlullahNo ratings yet

- Chapter2 Lab WorksheetDocument3 pagesChapter2 Lab WorksheetKunakorn KunthamasNo ratings yet

- Irjet V7i61334Document5 pagesIrjet V7i61334hussein.najm2009No ratings yet

- Biology HL - Laboratory Worksheets - Second Edition - Pearson 2014Document48 pagesBiology HL - Laboratory Worksheets - Second Edition - Pearson 2014Gunay OmarovaNo ratings yet

- Low Level Sodium in High Purity Water by Graphite Furnace Atomic Absorption SpectrosDocument5 pagesLow Level Sodium in High Purity Water by Graphite Furnace Atomic Absorption SpectrosDoicielNo ratings yet

- D3919-08 Standard Practice For Measuring Trace Elements in Water by Graphite Furnace Atomic Absorption SpectrophotometryDocument8 pagesD3919-08 Standard Practice For Measuring Trace Elements in Water by Graphite Furnace Atomic Absorption Spectrophotometryastewayb_964354182No ratings yet

- WaterDocument33 pagesWaterahmedNo ratings yet

- MC55UVM6Document28 pagesMC55UVM6Ujianto Timotius NugrohoNo ratings yet

- Pulse Jet Cleaning Collectors Preventative MaintenanceDocument2 pagesPulse Jet Cleaning Collectors Preventative Maintenanceehsan.aziziNo ratings yet

- Krutikaa - Thesis Proposal Ventilation SystemsDocument7 pagesKrutikaa - Thesis Proposal Ventilation SystemsKrutikaaNo ratings yet

- D 5011 - 17 PDFDocument29 pagesD 5011 - 17 PDFShaker Qaidi0% (1)

- Particle Filter Penetration FlyerDocument2 pagesParticle Filter Penetration Flyergr8swapNo ratings yet

- Sampling Ground-Water Monitoring Wells: Standard Guide ForDocument17 pagesSampling Ground-Water Monitoring Wells: Standard Guide ForPranavaDartNo ratings yet

- Experiment Bag FilterDocument5 pagesExperiment Bag FilteranasNo ratings yet

- Air Monitoring EquipmentsDocument4 pagesAir Monitoring EquipmentsDarius DsouzaNo ratings yet

- 04.section 2 Approach FinalDocument7 pages04.section 2 Approach FinalSoon LeeNo ratings yet

- Sterile-. Liquid-Filters. Specification GuidelineDocument2 pagesSterile-. Liquid-Filters. Specification GuidelinegernogueraNo ratings yet

- RASI800MCERTS Portable Emissions AnalyserDocument7 pagesRASI800MCERTS Portable Emissions AnalyserAbderrahmaneAdaneNo ratings yet

- D4188-13 Standard Practice For Performing Pressure In-Line Coagulation-Flocculation-Filtration Test in WaterDocument4 pagesD4188-13 Standard Practice For Performing Pressure In-Line Coagulation-Flocculation-Filtration Test in Waterastewayb_964354182No ratings yet

- Effect of Purging FTIR SpectrometerDocument4 pagesEffect of Purging FTIR Spectrometer응오황타이바오/환경·기후기술트랙No ratings yet

- DVC750LZX1 ManualDocument12 pagesDVC750LZX1 ManualBryan KhoNo ratings yet

- Mi 2009 2 en Ap 1Document4 pagesMi 2009 2 en Ap 1Antonio VazquezNo ratings yet

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- Nuclear RadiationDocument26 pagesNuclear RadiationosamaalazbNo ratings yet

- 6.4 - DNA Replication and Repair (Text RefDocument2 pages6.4 - DNA Replication and Repair (Text RefReeNo ratings yet

- Jotashield Topcoat SilkDocument3 pagesJotashield Topcoat SilkajuhaseenNo ratings yet

- Semisolid Dosage Forms PDFDocument69 pagesSemisolid Dosage Forms PDFRahul LakhaniNo ratings yet

- GIC DevelopmentDocument12 pagesGIC DevelopmentJinny ShawNo ratings yet

- CPP 20220411175754709142Document197 pagesCPP 20220411175754709142Ronit NigamNo ratings yet

- Wartsila o e W 50df TRDocument16 pagesWartsila o e W 50df TRNoel MejiaNo ratings yet

- Bio Polishing EnzymeDocument3 pagesBio Polishing Enzymefebry_yulindraNo ratings yet

- The Pressure - Enthalpy ChartDocument12 pagesThe Pressure - Enthalpy ChartJohnMerrNo ratings yet

- Cazn2016 PDFDocument50 pagesCazn2016 PDFJose perezNo ratings yet

- GL XX Mobilgard DEO SeriesDocument2 pagesGL XX Mobilgard DEO SeriesRidho ArdiansyahNo ratings yet

- 01 The Chemical WorldDocument1 page01 The Chemical WorldTewodirosNo ratings yet

- Journal - PET Recycling Evaluation of The Solid State Polymerization ProcessDocument7 pagesJournal - PET Recycling Evaluation of The Solid State Polymerization Processy.s.6saputroNo ratings yet

- TABLE 13-1 Constant-Pressure Liquid-Vapor Equilibrium Data For Selected Binary SystemsDocument4 pagesTABLE 13-1 Constant-Pressure Liquid-Vapor Equilibrium Data For Selected Binary SystemsThaly MejiaNo ratings yet

- Me22 E02 Tumangan M1a2Document4 pagesMe22 E02 Tumangan M1a2Jihoo JungNo ratings yet

- Filtration and CrystallizationDocument12 pagesFiltration and CrystallizationDamani RobertsNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument12 pagesCambridge International General Certificate of Secondary EducationZo775 YoutubeNo ratings yet

- Welding Procedure Specification - Kel 3Document4 pagesWelding Procedure Specification - Kel 3Helmi KusumaNo ratings yet

- KP - Method - Description-Dragica Vasileska PDFDocument51 pagesKP - Method - Description-Dragica Vasileska PDFombraga1896No ratings yet

- Neopor TMDocument2 pagesNeopor TMNurettinAlpNo ratings yet

- FIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )Document10 pagesFIG. 4-8 Charts For OVER 4 In. (100 MM) : (A) Random Rounded Indications (See Note (1) )mahmoud_allam3No ratings yet

- MSDS To 1020 60 SNXDocument8 pagesMSDS To 1020 60 SNXdeiva balanNo ratings yet

- ES 13 - 3rd Long Exam CoverageDocument7 pagesES 13 - 3rd Long Exam CoverageMaj DelfinNo ratings yet

- Material Astm A283 Grade CDocument1 pageMaterial Astm A283 Grade CramdikaNo ratings yet

- Seminar ReportDocument17 pagesSeminar Reportapi-3706848100% (1)