Professional Documents

Culture Documents

Strengths Weaknesses: First 3 Days Analysis of Production State

Uploaded by

Mohammed abdulwahedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strengths Weaknesses: First 3 Days Analysis of Production State

Uploaded by

Mohammed abdulwahedCopyright:

Available Formats

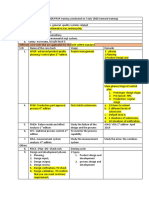

First 3 days Analysis of Production state

Strengths Weaknesses

1- High technology machinery, especially in 1- Production area is not well organized

(tape line, looms, printers) (rolls scatter randomly)

2- Lack of space in the production area

3- Printing machine is not used wisely

4- No procedure to control printing process

5- There is no traceability during different

production stages and for finish products

6- Operators do not know the daily

production target to be achieved, so less

efficiency exists

7- Operators need more training on-work

training, for example 1- tape line, how to

change products without scrapping in

color 2- printing, check before and during

printing

8- There are no approved samples from

customers of the current produced

brands

9- Time consumption (wasted) during

product changeover or roll to roll change

is not controlled for looms & cuttings

Opportunities Threatens

1- Create more space by using 5S method, 1- Risk of rejection due to unavailability of

5S is Japanese workplace organization approved samples from customers.

method, summarized as follow:

a. Sort

b. Set in order

c. Shine

d. Standardize

e. Sustain

2- Find a better flow of production process

by using or manipulate dead space

between loading gate and printing side

wall (inlet of rolls to printing stage)

3- Find a proper solution for color scarp of

tape line (color changeover)

4- Getting all labors to know what are the

specifications of different products, daily

production target, everyday questionare

for those whose production is low

You might also like

- C4 Turtle Diagram Process Design ProcessDocument1 pageC4 Turtle Diagram Process Design Processcao thanh quocNo ratings yet

- CBM ReviewerDocument12 pagesCBM RevieweranniezabateNo ratings yet

- Sas6 Bam199Document7 pagesSas6 Bam199Jovelyn UbodNo ratings yet

- Process Selection LecDocument35 pagesProcess Selection LecMekaiel Amil MekaielNo ratings yet

- MGT4 1Document2 pagesMGT4 1InserahNo ratings yet

- Ch5 New Process DesignDocument56 pagesCh5 New Process Designmd1nemesis1No ratings yet

- Electives ReviewerDocument15 pagesElectives ReviewerPaulene Marie SicatNo ratings yet

- Production Planning and ControlDocument12 pagesProduction Planning and Controlsai mohanNo ratings yet

- Notes Taken During 3 July APQP PPAP ClassDocument2 pagesNotes Taken During 3 July APQP PPAP Classrosemarie tolentinoNo ratings yet

- Job ProductionDocument4 pagesJob ProductionTiana 'Chandie' ChandlerNo ratings yet

- Methods of ProductionDocument17 pagesMethods of ProductionTyler IlesNo ratings yet

- Lay Out OptimizationDocument43 pagesLay Out OptimizationRagul VinothNo ratings yet

- POM Unit 1 FDocument10 pagesPOM Unit 1 FRitikshankar YadavNo ratings yet

- Process Layout: 1. Explain Different Types of Facility Layout and Their Strength and WeaknessDocument14 pagesProcess Layout: 1. Explain Different Types of Facility Layout and Their Strength and WeaknessSamuel DebebeNo ratings yet

- Batch, Label, Production Confirmations in Shop FloorDocument7 pagesBatch, Label, Production Confirmations in Shop FloorAnkur JindalNo ratings yet

- Facility or Plant Design and Layout - Introduction 1 PDFDocument46 pagesFacility or Plant Design and Layout - Introduction 1 PDFHeia LaviosaNo ratings yet

- Chapter 14: The Production CycleDocument9 pagesChapter 14: The Production CycleLet it beNo ratings yet

- Introduction To Production and Operations Management PDFDocument6 pagesIntroduction To Production and Operations Management PDFTin PortuzuelaNo ratings yet

- Ch. 6: Process Selection & Facility LayoutDocument2 pagesCh. 6: Process Selection & Facility LayouttejaNo ratings yet

- IARE PPC Lecture NotesDocument65 pagesIARE PPC Lecture NotesJaveed802No ratings yet

- PP Discrete Vs RepetitiveDocument6 pagesPP Discrete Vs RepetitiveDzn100% (3)

- Lean Manufacturing: Presented By: M. OsamaDocument17 pagesLean Manufacturing: Presented By: M. OsamaMehreen SheykNo ratings yet

- T2 VSA With RequirementDocument8 pagesT2 VSA With RequirementSandeep K Malhotra100% (3)

- Preliminary Steps in HACCP ApplicationDocument3 pagesPreliminary Steps in HACCP Applicationkolita kamalNo ratings yet

- Types of Production SystemDocument4 pagesTypes of Production SystemDemi DelizoNo ratings yet

- Lean ManufacturingDocument18 pagesLean ManufacturingSakib ZamanNo ratings yet

- Unit - 1 PART - 1Document5 pagesUnit - 1 PART - 1Manjunath ReddyNo ratings yet

- Chapter 9Document20 pagesChapter 9Fadel Khalif MuhammadNo ratings yet

- Lecture 5 (B) - Facilities Layout Nov 2022Document26 pagesLecture 5 (B) - Facilities Layout Nov 2022dub911No ratings yet

- Apply Quality StandardsDocument27 pagesApply Quality StandardsChristian BehilNo ratings yet

- Work Design and LayoutDocument10 pagesWork Design and LayoutSaif MohammadNo ratings yet

- THE Conversion Cycle: James A. Hall 7 EditionDocument59 pagesTHE Conversion Cycle: James A. Hall 7 EditionSarah GNo ratings yet

- Production ManagementDocument21 pagesProduction ManagementRahul PuriNo ratings yet

- Kel 2 - MjoDocument12 pagesKel 2 - MjohatchifaNo ratings yet

- DQ047-01 Manufacturing Systems: Production System (Manufacturing System)Document4 pagesDQ047-01 Manufacturing Systems: Production System (Manufacturing System)saten lalNo ratings yet

- Kenana Mehsen Exercise CDocument3 pagesKenana Mehsen Exercise CSamNo ratings yet

- Basic Layout Types: 1. Product Layouts 2. Process Layouts 3. Fixed-Position Layout 4. Hybrid/Combination LayoutsDocument16 pagesBasic Layout Types: 1. Product Layouts 2. Process Layouts 3. Fixed-Position Layout 4. Hybrid/Combination LayoutsAnaya MalikNo ratings yet

- CH 8 Facility Layout - Part1Document29 pagesCH 8 Facility Layout - Part1Muhammad FurqanNo ratings yet

- Lean Construction: Unit 1: Variation in Production SystemsDocument3 pagesLean Construction: Unit 1: Variation in Production SystemsMohamed AhmedNo ratings yet

- "The Conversion Cycle": Two Subsystems: - Ends With Completed Product Sent To The Finished Goods WarehouseDocument2 pages"The Conversion Cycle": Two Subsystems: - Ends With Completed Product Sent To The Finished Goods WarehouseKaren CaelNo ratings yet

- Production Planning and ControlDocument36 pagesProduction Planning and ControlPadmavathi Putra LokeshNo ratings yet

- Software Life Cycle ModelsDocument15 pagesSoftware Life Cycle Modelsumang patelNo ratings yet

- K012556370 PDFDocument8 pagesK012556370 PDFVan ToanNo ratings yet

- Design and Managing Design processes-REPORT POMDocument22 pagesDesign and Managing Design processes-REPORT POMellaiza ledesmaNo ratings yet

- LeanDocument25 pagesLeanAPOORVANo ratings yet

- MM ZG512 Manufacturing Strategy: Rajiv Gupta BITS Pilani Live Lecture 5Document41 pagesMM ZG512 Manufacturing Strategy: Rajiv Gupta BITS Pilani Live Lecture 5Mohammed ImranNo ratings yet

- Types of Production SystemDocument6 pagesTypes of Production SystemkshitijNo ratings yet

- Entrep Lesson 1 2Document2 pagesEntrep Lesson 1 2quandtshoNo ratings yet

- Ie 457 - ReferenceDocument30 pagesIe 457 - ReferencesannikimyoungNo ratings yet

- Midterm Case Study HRDocument25 pagesMidterm Case Study HRmohamedNo ratings yet

- CHAPTER 7 - The Conversion CycleDocument6 pagesCHAPTER 7 - The Conversion CycleAngela Marie PenarandaNo ratings yet

- CH 4-Plant LayoutDocument13 pagesCH 4-Plant LayoutLakshit MittalNo ratings yet

- 1 Umberla ActivityDocument1 page1 Umberla Activitykaruna karanNo ratings yet

- Plant-Layout NotesDocument17 pagesPlant-Layout NotesRahul DesaiNo ratings yet

- Factors To Consider: - Available Capacity - Expertise - Quality Considerations - The Nature of Demand - Cost - RisksDocument4 pagesFactors To Consider: - Available Capacity - Expertise - Quality Considerations - The Nature of Demand - Cost - RisksHanna Mary RamoNo ratings yet

- OpmtqmDocument4 pagesOpmtqmJayson ZonsaNo ratings yet

- Intro To POMDocument12 pagesIntro To POMmuneerppNo ratings yet

- Answer Question 3Document2 pagesAnswer Question 3MAXSWELL MANGGIE ZAMRYNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Epson EcoTank L6460 - L6490Document2 pagesEpson EcoTank L6460 - L6490arif setiawanNo ratings yet

- Discrete Time Convolution PDFDocument1 pageDiscrete Time Convolution PDFDela Natalia MalauNo ratings yet

- PreMid NotesDocument35 pagesPreMid NotesKurt Stephenje P. SajulgaNo ratings yet

- Long Term Evolution: Author: Badal MishraDocument19 pagesLong Term Evolution: Author: Badal Mishrabadal mishraNo ratings yet

- Hackster News - Hackster - IoDocument4 pagesHackster News - Hackster - IomrjunoonNo ratings yet

- Orca Share Media1678577044291 7040462411179493427Document12 pagesOrca Share Media1678577044291 7040462411179493427Zarylle De AsasNo ratings yet

- Lightning Eliminators & Consultants, Inc. Lightning Eliminators & Consultants, IncDocument4 pagesLightning Eliminators & Consultants, Inc. Lightning Eliminators & Consultants, IncDuyên Nguyễn NgọcNo ratings yet

- Ec8381 Fundamentals of DS in C LaboratoryDocument112 pagesEc8381 Fundamentals of DS in C LaboratorysaraswathiNo ratings yet

- Composite Structures: A. Manalo, T. Aravinthan, W. Karunasena, A. TicoaluDocument9 pagesComposite Structures: A. Manalo, T. Aravinthan, W. Karunasena, A. Ticoalupradeep kankeriNo ratings yet

- Manitou 6400seriesDocument19 pagesManitou 6400seriesДенис ЧерныйNo ratings yet

- Ec3491 CT Iat 1Document2 pagesEc3491 CT Iat 1Dr.M.SubbulakshmiNo ratings yet

- The Use Of-Critical Path Modeling To Analyze Production in Underground MinesDocument15 pagesThe Use Of-Critical Path Modeling To Analyze Production in Underground MinesRENZO ANDRE GONZALES MALDONADONo ratings yet

- Human Activity RecognitionDocument10 pagesHuman Activity RecognitionSita Putra TejaNo ratings yet

- Lynx Door Operator TechService2Document30 pagesLynx Door Operator TechService2Mike SharpeNo ratings yet

- Update InstructionsDocument6 pagesUpdate InstructionsManikandan MNo ratings yet

- The Experience MapDocument9 pagesThe Experience MapHasan Basri KartalNo ratings yet

- Project Measurements: Period in Project:: Date: Project Accounting Number: Project Phase: Source FilesDocument4 pagesProject Measurements: Period in Project:: Date: Project Accounting Number: Project Phase: Source FilesInfo CosmodotNo ratings yet

- Bosch Leisure Batteries L4 PDFDocument4 pagesBosch Leisure Batteries L4 PDFsimon_someone217No ratings yet

- Present Scenario of Social Media and Its Implication On StudentsDocument5 pagesPresent Scenario of Social Media and Its Implication On Studentsvinay kumarNo ratings yet

- Honda PCX Manual EN PDFDocument142 pagesHonda PCX Manual EN PDFbutata02No ratings yet

- Ptest 2022Document3 pagesPtest 2022Shubham Singh YadavNo ratings yet

- Standard Photo Print SizesDocument2 pagesStandard Photo Print SizesAPLCTNNo ratings yet

- Supply Chain & Logistics Management Questions AnswersDocument6 pagesSupply Chain & Logistics Management Questions AnswersAmrita PatilNo ratings yet

- 18me710 - Industrial Engineering: Hybrid LayoutDocument21 pages18me710 - Industrial Engineering: Hybrid LayoutHALO MC NOBLE ACTUALNo ratings yet

- ELECRODE STORAGeDocument4 pagesELECRODE STORAGeGuruchell ChellguruNo ratings yet

- Installation and Operation Manual: SPM-A SynchronizerDocument32 pagesInstallation and Operation Manual: SPM-A SynchronizerJhezy Andron AndronNo ratings yet

- Hacking Satellite TV Receivers Are Those IoT Devices Secure - by SofianeDocument48 pagesHacking Satellite TV Receivers Are Those IoT Devices Secure - by SofianeEric ZachowNo ratings yet

- Management: Organization StructureDocument26 pagesManagement: Organization StructureAlvin OroscoNo ratings yet

- Research Status Title Publication DateDocument8 pagesResearch Status Title Publication DateHarsheen SawhneyNo ratings yet

- Inventaris Lsa & FfaDocument8 pagesInventaris Lsa & FfaRoby AditamaNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)