Professional Documents

Culture Documents

Emission Control System: Purpose

Uploaded by

clergeonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emission Control System: Purpose

Uploaded by

clergeonCopyright:

Available Formats

EC−1

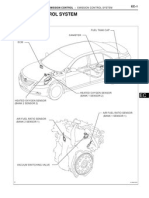

EMISSION CONTROL − EMISSION CONTROL SYSTEM

EMISSION CONTROL SYSTEM

EC05E−01

PURPOSE

The emission control systems are installed to reduce the amount of HC, CO and NOx exhausted from the

engine ((3), (4) and (5)), to prevent the atmospheric release of blow−by gas−containing HC (1) and evapo-

rated fuel containing HC being released from the fuel tank (2).

The function of each system is shown in the following table.

System Abbreviation Function

(1) Positive Crankcase Ventilation PCV Reduces HC

(2) Evaporative Emission Control EVAP Reduces evaporated HC

(3) Exhaust Gas Recirculation EGR Reduces NOx

(4) Three−Way Catalytic Converter TWC Reduces HC, CO and NOx

(5) Sequential Multiport Fuel Injection* SFI Injects a precisely timed, optimum amount of fuel for reduced

exhaust emissions

Remark: * For inspection and repair of the SFI system, refer to the SFI section in this manual.

1996 RAV4 (RM447U)

EC−2

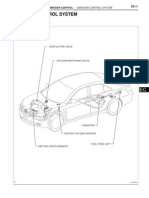

EMISSION CONTROL − PARTS LAYOUT AND SCHEMATIC DRAWING

PARTS LAYOUT AND SCHEMATIC DRAWING

EC05F−04

LOCATION

1996 RAV4 (RM447U)

EC−3

EMISSION CONTROL − PARTS LAYOUT AND SCHEMATIC DRAWING

EC05G−03

DRAWING

1996 RAV4 (RM447U)

EC−4 EMISSION CONTROL − POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEM

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM EC05H−04

INSPECTION

1. REMOVE PCV VALVE

2. INSTALL CLEAN HOSE TO PCV VALVE

Clean Hose

3. INSPECT PCV VALVE OPERATION

(a) Blow into the cylinder head side, and check that air

Cylinder Head Side N00929

passes through easily.

CAUTION:

Air Intake Do not suck air through the valve. Petroleum substances

Chamber inside the valve are harmful.

Side

(b) Blow air into the intake manifold side, and check that air

passes through with difficulty.

Clean Hose

If operation is not as specified, replace the PCV valve.

4. REMOVE CLEAN HOSE FROM PCV VALVE

5. REINSTALL PCV VALVE

N00930

6. VISUALLY INSPECT HOSES, CONNECTIONS AND

GASKETS

Check for cracks, leaks or damage.

P00989

1996 RAV4 (RM447U)

EC−5

EMISSION CONTROL − EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM

EVAPORATIVE EMISSION (EVAP)

CONTROL SYSTEM EC05I−03

INSPECTION

1. VISUALLY INSPECT LINES AND CONNECTIONS

Look for loose connections, sharp bends or damage.

2. VISUALLY INSPECT FUEL TANK

Look for deformation, cracks or fuel leakage.

3. VISUALLY INSPECT FUEL TANK CAP

Check if the cap and/or gasket are deformed or damaged.

If necessary, repair or replace the cap.

Gasket

Check Valve (Vacuum Valve) EC3069

4. DISCONNECT EVAP HOSES FROM CHARCOAL CAN-

ISTER

5. VISUALLY INSPECT CHARCOAL CANISTER

Look for cracks or damage.

S01428

Port E

6. CHECK FOR CLOGGED FILTER, AND STUCK CHECK

Port D VALVE AND DIAPHRAGM

Port A (a) Install a plug to port E.

(b) While holding port B closed, blow air (1.76 kPa, 18

gf/cm2, 0.26 psi) into port A and check that air flows from

Compressed port D.

Air

Port B

S01451

(c) While holding port B and port D closed, blow air (1.76 kPa,

18 gf/cm2, 0.26 psi) into port A and check that air does not

Port A Port D flow from port C.

Port C

Compressed

Air

Port B

S01452

1996 RAV4 (RM447U)

EC−6

EMISSION CONTROL − EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM

(d) Apply vacuum (3.43 kPa, 26 mmHg, 1.01 in.Hg) to port B,

check that the vacuum does not decrease when port C is

closed, and check that the vacuum decreases when port

C is released.

Port B

Port C

S01453

(e) While holding port C closed, apply vacuum (1.23 kPa, 9.2

Port A

mmHg, 0.36 in.Hg) to port A and check that air flows into

Port C

port B.

If a problem is found, replace the charcoal canister.

(f) Remove the plug.

7. RECONNECT EVAP HOSES

Port B 8. INSPECT VSV FOR EVAP (See page SF−45)

9. INSPECT VSV FOR VAPOR PRESSURE SENSOR (See

S01454 page SF−47)

10. INSPECT VAPOR PRESSURE SENSOR (See page

SF−55)

1996 RAV4 (RM447U)

EC−7

EMISSION CONTROL − EXHAUST GAS RECIRCULATION (EGR) SYSTEM

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

EC05J−03

COMPONENTS

1996 RAV4 (RM447U)

EC−10

EMISSION CONTROL − EXHAUST GAS RECIRCULATION (EGR) SYSTEM

14. REINSTALL EGR VALVE

(a) Install a 2 new gaskets and the EGR valve with the 2 nuts.

Torque: 13 N·m (130 kgf·cm, 9 ft·lbf)

(b) Install the EGR pipe with the 2 union nuts.

Torque: 59 N·m (600 kgf·cm, 43 ft·lbf)

15. REINSTALL THROTTLE BODY (See page SF−33)

S01616

1996 RAV4 (RM447U)

EMISSION CONTROL − THREE−WAY CATALYTIC CONVERTER (TWC) EC−11

SYSTEM

THREE−WAY CATALYTIC CONVERTER (TWC) SYSTEM

EC0FI−02

COMPONENTS

1996 RAV4 (RM447U)

EC−12 EMISSION CONTROL − THREE−WAY CATALYTIC CONVERTER (TWC)

SYSTEM

1996 RAV4 (RM447U)

EMISSION CONTROL − THREE−WAY CATALYTIC CONVERTER (TWC) EC−13

SYSTEM

EC05M−02

INSPECTION

1. CHECK CONNECTIONS FOR LOOSENESS OR DAMAGE

2. CHECK CLAMPS FOR WEAKNESS, CRACKS OR DAMAGE

3. CHECK FOR DENTS OR DAMAGE

If any part of the protector is damaged or dented to the extent that it contacts the TWC, repair or replace

it.

4. CHECK HEAT INSULATOR FOR DAMAGE

5. CHECK FOR ADEQUATE CLEARANCE BETWEEN CATALYTIC CONVERTER AND HEAT INSU-

LATOR

1996 RAV4 (RM447U)

EC−3

EMISSION CONTROL − PARTS LAYOUT AND SCHEMATIC DRAWING

EC05G−03

DRAWING

1997 RAV4 (RM505U)

EC−8

EMISSION CONTROL − EXHAUST GAS RECIRCULATION (EGR) SYSTEM

EC05K−02

INSPECTION

Cap

1. INSPECT AND CLEAN FILTER IN EGR VACUUM

Filter MODULATOR

(a) Remove the cap and filter.

(b) Check the filter for contamination or damage.

(c) Using compressed air, clean the filter.

(d) Reinstall the filter and cap.

HINT:

S01587

Install the filter with the coarser surface facing the atmospheric

side (outward).

Vacuum 2. INSTALL VACUUM GAUGE

Gauge Using a 3−way connector, connect a vacuum gauge to the hose

between the EGR valve and VSV.

3. INSPECT SEATING OF EGR VALVE

Start the engine and check that the engine starts and runs at

idle.

S01588

DLC1 4. CONNECT TERMINALS TE1 AND E1 OF DLC1

Using SST, connect terminals TE1 and E1 of the

TE1 DLC1

SST SST 09843−18020

E1

5. INSPECT VSV OPERATION WITH COLD ENGINE

(a) The engine coolant temperature should be below

55°C (131°F).

(b) Check that the vacuum gauge indicates zero at 2,500

S01261 rpm.

1997 RAV4 (RM505U)

EC−10

EMISSION CONTROL − EXHAUST GAS RECIRCULATION (EGR) SYSTEM

Engine (d) Start the engine, and maintain speed at 2,500 rpm.

Air

2,500 rpm (e) Repeat the above test. Check that there is a strong resis-

tance to air flow.

(f) Reconnect the vacuum hoses to the proper locations.

S01561

11. REMOVE THROTTLE BODY

(See page SF−33)

12. REMOVE EGR VALVE

13. INSPECT EGR VALVE

Check for sticking and heavy carbon deposits.

If a problem is found, replace the valve.

P02553

14. REINSTALL EGR VALVE

(a) Install a 2 new gaskets and the EGR valve with the 2 nuts.

Torque: 13 N·m (130 kgf·cm, 9 ft·lbf)

(b) Install the EGR pipe with the 2 union nuts.

Torque: 59 N·m (600 kgf·cm, 43 ft·lbf)

15. REINSTALL THROTTLE BODY

(See page SF−35)

S01616

1997 RAV4 (RM505U)

EC−2

EMISSION CONTROL − PARTS LAYOUT AND SCHEMATIC DRAWING

PARTS LAYOUT AND SCHEMATIC DRAWING

EC05F−04

LOCATION

1997 RAV4 (RM505U)

EMISSION SUB SYSTEMS - Exhaust Gas Recirculation

Exhaust Gas Recirculation System

The Exhaust Gas Recirculation (EGR) system is designed to reduce the amount of Oxides of

Nitrogen (NOx) created by the engine during operating periods that usually result in high

combustion temperatures. NOx is formed in high concentrations whenever combustion

temperatures exceed about 2500’F.

The EGR system reduces NOx production by recirculating small amounts of exhaust gases into

the intake manifold where it mixes with the incoming air/fuel charge. By diluting the air/fuel

mixture under these conditions, peak combustion temperatures and pressures are reduced,

resulting in an overall reduction of NOx output. Generally speaking, EGR flow should match the

following operating conditions:

• High EGR flow is necessary during cruising and mid-range acceleration, when

combustion temperatures are typically very high

• Low EGR flow is needed during low speed and light load conditions

• No EGR flow should occur during conditions when EGR operation could adversely affect

engine operating efficiency or vehicle driveability (engine warm up, idle, wide open

throttle, etc.)

EGR Impact on the Engine Control System

The ECM considers the EGR system an integral part of the entire Engine Control System (ECS).

Therefore, the ECM is capable of neutralizing the negative performance aspects of EGR by

programming additional spark advance and decreased fuel injection duration during periods of

high EGR flow. By integrating fuel and spark control with the EGR metering system, engine

performance and fuel economy can actually be enhanced when the EGR system is functioning

as designed.

Page 1 © Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

EMISSION SUB SYSTEMS - Exhaust Gas Recirculation

EGR Theory of Operation

The purpose of the EGR system is to precisely regulate EGR flow under different operating

conditions, and to override flow under conditions which would compromise good engine

performance. The precise amount of exhaust gas which must be metered into the intake

manifold varies significantly as engine load changes. This results in the EGR system operating

on a very fine line between good NOx control and good engine performance.

If too much exhaust gas is metered, engine performance will suffer. If too little EGR flows, the

engine may knock and will not meet strict emissions standards. The theoretical volume of

recirculated exhaust gas is referred to as EGR ratio. As the accompanying graph shows, the

EGR ratio increases as engine load increases.

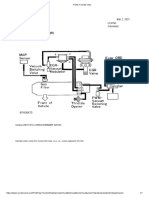

EGR System Components

To achieve this designed control of exhaust gas recirculation, the system uses the following

components:

• Vacuum Actuated EGR Control Valve

• EGR Vacuum Modulator Assembly

• ECM Controlled Vacuum Switching Valve (VSV)

EGR Control Valve

The EGR control valve is used to regulate exhaust gas flow to the intake system by means of a

pintle valve attached to the valve diaphragm. A ported vacuum signal and calibrated spring on

one side of the diaphragm are balanced against atmospheric pressure acting on the other side

of the diaphragm. As the vacuum signal applied to the valve increases, the valve is pulled

further from ifs seat. The key to accurate EGR metering is the EGR vacuum modulator

assembly which precisely controls the strength of the applied vacuum signal.

Page 2 © Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

EMISSION SUB SYSTEMS - Exhaust Gas Recirculation

EGR Vacuum Modulator

Because exhaust backpressure increases proportionally with engine load, the EGR vacuum

modulator uses this principle to precisely control the strength of the vacuum signal to the EGR

valve. The typical EGR control system uses two ported vacuum signals from the throttle body.

Port E is the first stage ported vacuum signal and Port R is the second stage ported vacuum

signal uncovered by the opening throttle valve.

When vacuum is applied from port E, the strength of the vacuum signal applied to the EGR

valve will be dependent on the amount of exhaust backpressure acting on chamber A of the

vacuum modulator. When vacuum is applied from port R, the strength of the vacuum signal

applied to the EGR valve will no longer be dependent on the strength of the exhaust

backpressure signal. During this mode, the EGR signal strength is determined solely by

Page 3 © Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

EMISSION SUB SYSTEMS - Exhaust Gas Recirculation

the strength of the vacuum signal from port E of the throttle body. The EGR vacuum modulator

provides the ability to precisely match EGR flow rate to amount of load applied to the engine.

ECM Controlled Vacuum Switching Valve (VSV)

In addition to the EGR modulator, an ECM controlled VSV is used to inhibit EGR operation

during conditions where it could adversely affect engine performance and vehicle driveability.

The EGR VSV can be either normally open or closed and installed in series between the

vacuum modulator and EGR valve or installed on a second port on the EGR valve. This VSV

controls an atmospheric bleed which inhibits EGR operation any time a given set of ECM

parameters are met.

ECM Override of EGR

As mentioned, the ECM is capable of inhibiting EGR flow through operation of the VSV bleed.

When the ECM determines an inhibit condition, it de-energizes the VSV, blocking the vacuum

signal to the EGR valve and opening the valve diaphragm to an atmospheric bleed. This

causes the EGR valve to close. Typical EGR inhibit parameters are shown below.

Variations on EGR VSV Placement

There are three basic variations of the EGR vacuum circuit depending on engine application.

All three systems function similarly, the only difference being the placement of the VSV in the

vacuum circuit and the logic of the VSV and ECM.

Page 4 © Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

EMISSION SUB SYSTEMS - Exhaust Gas Recirculation

EGR Fault Detection System

An EGR malfunction detection system is incorporated into the TCCS system to warn the driver

when the EGR system is not operating properly. The system uses an Exhaust Gas

Temperature (THG) sensor on the intake side of the EGR valve where it is exposed to exhaust

gas flow whenever the EGR valve opens.

The ECM compares the THG signal with parameters stored in memory. If EGR gas temperature

is determined to be too cold when the ECM has the EGR valve enabled, the MIL will be

illuminated, and a diagnostic code will be stored in ECM memory. This diagnostic configuration

allows the ECM to monitor entire EGR system operation.

EGR Effect On Emissions & Driveability

• Too little EGR flow may cause detonation and IM240 emissions failure for excessive NOx.

Because EGR tends to reduce the volatility of the air/fuel charge, loss of EGR typically

causes detonation to occur. If EGR is commanded but doesn't flow (restricted passage in

manifold, nonfunctional valve, etc.) severe detonation will occur.

• Too much EGR flow and/or excessive flow for driving conditions may cause stumble, flat

spot, hesitation, and surging. Because EGR dilutes the air/fuel charge, too much EGR for

a given engine demand can cause a misfire. It is not uncommon to see tip in hesitation,

stumble and surging when too much EGR is metered.

EGR System Functional Tests

On some OBD-II vehicles, the EGR system can be controlled using the active test feature of the

Diagnostic Tester. This is the easiest way to verify EGR system operation and can generally be

performed as follows:

• Start the engine and allow it to reach operating temperature

• Using the Diagnostic Tester, access the Active Test menu

• Select "EGR System" from the Active Test menu

• Raise engine speed and maintain a steady 3000 rpm

• Activate the EGR VSV (turn EGR On)

• You should notice a slight drop in engine speed and a rise in EGRT gas temperature as

EGR is activated

If engine speed and EGRT gas temperature does not change, the EGR system is not

functioning and the problem may be mechanical or electrical. If the rpm drop is very slight, the

problem may be a partially blocked or restricted EGR passage.

Page 5 © Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

EMISSION SUB SYSTEMS - Exhaust Gas Recirculation

EGR System Inspection

On other vehicles, the only way to accurately check the operation of the EGR system is to

perform a systematic inspection of the entire system. The following inspection procedures are

for a 95 5S-FE Camry:

• First, inspect the EGR modulator filter and, if necessary, remove and clean the filter with

compressed air.

• "Tee" a vacuum gauge into the vacuum line between the EGR valve and VSV.

• Start the engine and confirm that it does not run rough at idle. Note: This verifies that the

EGR valve is closed.

• Next, connect terminals TE1 to E1 at DLC 1.

• With coolant temperature cold (A/T: below 140' F, M/T: below 131' F) and engine at 2500

rpm, the vacuum gauge should indicate zero.

Note: This verifies that the VSV is inhibiting EGR flow during cold engine operations.

Page 6 © Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

EMISSION SUB SYSTEMS - Exhaust Gas Recirculation

• Next, warm the engine to operating temperature and maintain 2500 rpm. The vacuum

gauge should now indicate low vacuum (typically around 3")

Note: This verifies proper low vacuum signal to the EGR valve during light engine load

conditions.

• Next, with engine speed at 2500 rpm, connect the R port of the EGR modulator directly to

a manifold vacuum source. The vacuum gauge should now indicate high vacuum

(typically around 13") and the engine should run rough.

Note: This verifies proper high signal vacuum to the EGR valve when R port vacuum

overrides the backpressure modulator.

• Disconnect terminals TE1 and El at DLC1 and reattach the EGR hoses to their original

location.

Page 7 © Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

EMISSION SUB SYSTEMS - Exhaust Gas Recirculation

If the problem is related to the EGR valve itself, make sure heavy carbon deposits are not

keeping the valve unseated or causing it to stick when opening. Also, if EGR valve control is OK

remove the valve and check the EGR exhaust and intake passages for restrictions. Heavy

carbon deposits can be removed by using a special carbon scrapping tool.

This inspection example systematically confirms the integrity of the EGR valve, VSV,

backpressure modulator, system hoses, and EGR passages. Once the suspect

part/component is identified, it should be individually tested and then repaired or replaced as

necessary. Because slight model to model variations exist between EGR systems, refer to the

Repair Manual for specific EGR system inspection procedures.

Page 8 © Toyota Motor Sales, U.S.A., Inc. All Rights Reserved.

EC−7

EMISSION CONTROL − EXHAUST GAS RECIRCULATION (EGR) SYSTEM

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

EC05J−03

COMPONENTS

1997 RAV4 (RM505U)

You might also like

- Toyotau250 IntroductionDocument48 pagesToyotau250 IntroductionUka JosephNo ratings yet

- Vacuum DiagramDocument33 pagesVacuum DiagramSom & AlarmesNo ratings yet

- TM 9-2330-334-13P M1147 FMTV-LHST Trailer Part 3Document107 pagesTM 9-2330-334-13P M1147 FMTV-LHST Trailer Part 3AdvocateNo ratings yet

- (1AZ-FE) Sensors ECU and Fault CodesDocument20 pages(1AZ-FE) Sensors ECU and Fault CodesclergeonNo ratings yet

- 7.1. Emission Control SystemDocument18 pages7.1. Emission Control SystemChristian Icaza SamaniegoNo ratings yet

- Buffy RPG - The Dragon and The Phoenix - 4 Identity CrisisDocument26 pagesBuffy RPG - The Dragon and The Phoenix - 4 Identity CrisisTimothy BrannanNo ratings yet

- COPD medications and interventionsDocument34 pagesCOPD medications and interventionssaroberts2202100% (1)

- 2003 SV1000 Repair Manual Part 9: Emission Control InformationDocument17 pages2003 SV1000 Repair Manual Part 9: Emission Control Informationhn7410No ratings yet

- Cleaning Validation Master Plan PDFDocument9 pagesCleaning Validation Master Plan PDFBREWSKINo ratings yet

- Man Trans Overhaul PDFDocument30 pagesMan Trans Overhaul PDFDaniel OlariNo ratings yet

- Spraying TechniquesDocument12 pagesSpraying TechniquesX800XLNo ratings yet

- Cat Cb434c 534c 634c ST MatDocument43 pagesCat Cb434c 534c 634c ST MatMahmmod Al-Qawasmeh100% (2)

- Pajero Full 2008 15Document81 pagesPajero Full 2008 15Antonio Gaspar100% (1)

- Emissions Control SystemsDocument15 pagesEmissions Control SystemsTharsikan singamNo ratings yet

- EC (H4SO) Emission ControlDocument18 pagesEC (H4SO) Emission ControlHMs SamuelNo ratings yet

- Emission Control Systems Guide for 5S-FE EnginesDocument19 pagesEmission Control Systems Guide for 5S-FE EnginesMuhammad SafdarNo ratings yet

- EC (STi) 02 Emission ControlDocument18 pagesEC (STi) 02 Emission ControlGustavo RivasNo ratings yet

- Cummins 2 - of - 3Document100 pagesCummins 2 - of - 3totokNo ratings yet

- Emissions Control SystemDocument17 pagesEmissions Control SystemClaudio Godoy GallegosNo ratings yet

- Manuali Officina Yj/Xj 1993Document10 pagesManuali Officina Yj/Xj 1993stormchid100% (1)

- Emission Control System: Parts LocationDocument24 pagesEmission Control System: Parts LocationImran Sarwar100% (1)

- Emission Control Information and Wiring DiagramsDocument15 pagesEmission Control Information and Wiring DiagramsalessandroNo ratings yet

- Accelerator Control, Fuel & Exhaust System: Zd30Ddti Td27TiDocument12 pagesAccelerator Control, Fuel & Exhaust System: Zd30Ddti Td27TiHéctorHernándezDíazNo ratings yet

- InspDocument5 pagesInspIfex SalemNo ratings yet

- R-6 Relay ValveDocument6 pagesR-6 Relay ValveNelsonParedesNo ratings yet

- Emisie Suzuki VL800Document6 pagesEmisie Suzuki VL800Crisan SorinNo ratings yet

- 992g DIRECCION-FRENOSDocument49 pages992g DIRECCION-FRENOSJose Cruz RiosNo ratings yet

- 2GR-FE Emission ControlDocument23 pages2GR-FE Emission ControlLuks FernandezNo ratings yet

- Emission Control SystemsDocument22 pagesEmission Control Systemslone_anarchistNo ratings yet

- Emission Control ECDocument16 pagesEmission Control ECMattNo ratings yet

- Speed Control Diagnosis and TestingDocument1 pageSpeed Control Diagnosis and TestingEduardo MacMasterNo ratings yet

- Elantra 2.0 EC (137) G 2.0 MPIDocument23 pagesElantra 2.0 EC (137) G 2.0 MPIjoan velaNo ratings yet

- Typical Chemical Injection-SystemDocument3 pagesTypical Chemical Injection-SystemAymen BabourNo ratings yet

- Ec (2jz-Gte) PDFDocument12 pagesEc (2jz-Gte) PDFAshokNo ratings yet

- 04-Emission Control SystemDocument28 pages04-Emission Control SystemangelNo ratings yet

- Emission Control SystemDocument28 pagesEmission Control Systemsled novaNo ratings yet

- Ts 0223 1092 Installation InstructionsDocument6 pagesTs 0223 1092 Installation InstructionsJeremy GerlingNo ratings yet

- Emission Control SystemDocument18 pagesEmission Control SystemLacatusu MirceaNo ratings yet

- Subaru-Legacy 2005 EN Manual de Taller Control de Emisiones 17fbaf51b7Document9 pagesSubaru-Legacy 2005 EN Manual de Taller Control de Emisiones 17fbaf51b7miguelNo ratings yet

- Emission Control System: PurposeDocument12 pagesEmission Control System: PurposeHenry SilvaNo ratings yet

- Mitsubishi MSCA12YV ManualDocument32 pagesMitsubishi MSCA12YV Manualsansegundo79No ratings yet

- DTC P0441 Evaporative Emission Control System Incorrect Purge FlowDocument6 pagesDTC P0441 Evaporative Emission Control System Incorrect Purge FlowlabowlingNo ratings yet

- 2AZ-FE Emission ControlDocument25 pages2AZ-FE Emission ControlLuks FernandezNo ratings yet

- Reduce Emissions with Proper Emission Control System MaintenanceDocument16 pagesReduce Emissions with Proper Emission Control System MaintenancevixentdNo ratings yet

- Emission Control Systems: Efi EngineDocument69 pagesEmission Control Systems: Efi EngineWilmer HuangaNo ratings yet

- PCF Valve Guide Inspection GuideDocument13 pagesPCF Valve Guide Inspection GuideoscarNo ratings yet

- Specifications: Vehicle Emission Vacuum RoutingDocument4 pagesSpecifications: Vehicle Emission Vacuum RoutingCarlos VelázquezNo ratings yet

- Item Specification: Emission Control SystemDocument20 pagesItem Specification: Emission Control SystemZM OhnNo ratings yet

- Emission Control SystemDocument26 pagesEmission Control SystemnahomNo ratings yet

- System Saver Twin Air DryerDocument52 pagesSystem Saver Twin Air DryerSistem WabcoNo ratings yet

- Pulsed Secondary Air InjectionDocument3 pagesPulsed Secondary Air InjectionHugo Armando Garcia LepeNo ratings yet

- Gr00005800e 13aDocument129 pagesGr00005800e 13aLuis David Leon GarciaNo ratings yet

- Chery A19 SQR477F+EMISSION+CONTROL+SYSTEMDocument14 pagesChery A19 SQR477F+EMISSION+CONTROL+SYSTEMSuckmytickNo ratings yet

- Control Valves MaintenanceDocument78 pagesControl Valves MaintenanceRisimic NebojsaNo ratings yet

- Bendix E-2-E-3 BRAKE VALVES User ManualDocument4 pagesBendix E-2-E-3 BRAKE VALVES User ManualVOLVONo ratings yet

- Evaporative Emission Control LeakDocument8 pagesEvaporative Emission Control LeakDaniel Mamani ParedezNo ratings yet

- Propeller Shaft Diagnosis and Repair GuideDocument18 pagesPropeller Shaft Diagnosis and Repair GuideSergio EspinozaNo ratings yet

- MaintenanceDocument8 pagesMaintenancejasonphxNo ratings yet

- Group 25: General Description. - . - . - . - . Propeller Shaft Diagnosis - . Propeller Shaft - . - . - . - . - . - .Document16 pagesGroup 25: General Description. - . - . - . - . Propeller Shaft Diagnosis - . Propeller Shaft - . - . - . - . - . - .JBNo ratings yet

- Quad Valve Tri Valve HiDocument10 pagesQuad Valve Tri Valve HiOzan EgemenNo ratings yet

- Mangueiras de Recirculação - É o Do MeioDocument3 pagesMangueiras de Recirculação - É o Do MeioArtur ValNo ratings yet

- Bendix TC-2 Trailer Control Brake Valve: DescriptionDocument4 pagesBendix TC-2 Trailer Control Brake Valve: Descriptionjorge chavarriaNo ratings yet

- Item Specification: Emission Control SystemDocument19 pagesItem Specification: Emission Control SystemZM OhnNo ratings yet

- MODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 57-11-01 1. TitleDocument2 pagesMODEL 150 SERIES (1969 - 1976) : Supplemental Inspection Number: 57-11-01 1. TitleRebeca SerranoNo ratings yet

- Mszca 25 VBDocument28 pagesMszca 25 VBFrancisco Martin BurgosNo ratings yet

- MSB99E23001EDocument3 pagesMSB99E23001EWilson Jh100% (1)

- Forests Drying Strains Between Tangential and Radial Directions in Asian White BirchDocument8 pagesForests Drying Strains Between Tangential and Radial Directions in Asian White BirchclergeonNo ratings yet

- Climate Targets - Values and UncertaintyDocument1 pageClimate Targets - Values and UncertaintyclergeonNo ratings yet

- Climate and Atmospheric History of The Past 420,000 Years From The Vostok Ice Core, AntarcticaDocument8 pagesClimate and Atmospheric History of The Past 420,000 Years From The Vostok Ice Core, AntarcticaclergeonNo ratings yet

- Towards A European Jurisdiction Based On Brain Computer InterfacesDocument5 pagesTowards A European Jurisdiction Based On Brain Computer InterfacesclergeonNo ratings yet

- 1 s2.0 S030544030600077X Main PDFDocument11 pages1 s2.0 S030544030600077X Main PDFHoy1No ratings yet

- Climat TogoDocument126 pagesClimat TogoclergeonNo ratings yet

- Compressor Circuit: DescriptionDocument3 pagesCompressor Circuit: DescriptionclergeonNo ratings yet

- Testing Modern Human Out-Of-Africa Dispersal ModelDocument12 pagesTesting Modern Human Out-Of-Africa Dispersal ModelclergeonNo ratings yet

- DAvid Turnbull, Prehistoric Seafaring and Embodied CognitionDocument30 pagesDAvid Turnbull, Prehistoric Seafaring and Embodied CognitionclergeonNo ratings yet

- Differential Lock 99Document25 pagesDifferential Lock 99clergeonNo ratings yet

- 1997 Rav4 Vacuum DiagramsDocument1 page1997 Rav4 Vacuum DiagramsclergeonNo ratings yet

- A IntroductionDocument188 pagesA IntroductionEliseo RojasNo ratings yet

- Brake Valve By-PassDocument214 pagesBrake Valve By-PasstallermaeNo ratings yet

- 1995 Toyota MR2 For Ace Mechanics 123 Main Street San Diego Ca 92126Document1 page1995 Toyota MR2 For Ace Mechanics 123 Main Street San Diego Ca 92126clergeonNo ratings yet

- Chap3-2e SO2 Absorption ExampleDocument8 pagesChap3-2e SO2 Absorption Exampledarkelf_riderNo ratings yet

- Contractor base list in UsaDocument8 pagesContractor base list in Usamytech206No ratings yet

- Literature StudyDocument7 pagesLiterature StudySilver ShadesNo ratings yet

- 2020 FMGT 1013 - Financial Management RevisedDocument9 pages2020 FMGT 1013 - Financial Management RevisedYANIII12345No ratings yet

- Quiz 10Document6 pagesQuiz 10Kath RiveraNo ratings yet

- Gas Turbine Flow MeterDocument33 pagesGas Turbine Flow MeterKhabbab Hussain K-hNo ratings yet

- CPO Science Foundations of Physics: Unit 7, Chapter 24Document47 pagesCPO Science Foundations of Physics: Unit 7, Chapter 24dheerajbhagwatNo ratings yet

- Daniel Fast Recipes A Couple CooksDocument12 pagesDaniel Fast Recipes A Couple CooksmariamNo ratings yet

- Giáo trình TACN Đồ họa 1 - 2021 - chính thứcDocument57 pagesGiáo trình TACN Đồ họa 1 - 2021 - chính thứcHeo BiểnNo ratings yet

- Mercedes 220 AirmaticDocument7 pagesMercedes 220 AirmaticadinxNo ratings yet

- CA ruling on fertilizer disputeDocument16 pagesCA ruling on fertilizer disputeRuby Anna TorresNo ratings yet

- Ch1 SlidesDocument47 pagesCh1 SlidesPierreNo ratings yet

- DCM300E Clamp Meter Measures Earth Leakage CurrentDocument2 pagesDCM300E Clamp Meter Measures Earth Leakage CurrentKatamba RogersNo ratings yet

- Hdpe Guide PDFDocument81 pagesHdpe Guide PDFbalotNo ratings yet

- E44 - Wet Cooling Tower: InstructionsDocument3 pagesE44 - Wet Cooling Tower: InstructionsMarc AnmellaNo ratings yet

- Zenith 19M20 Sams 259 16Document26 pagesZenith 19M20 Sams 259 16dds94No ratings yet

- Surface Modification of Titanium Orthodontic ImplaDocument30 pagesSurface Modification of Titanium Orthodontic ImplaMary SmileNo ratings yet

- Bindura University of Science Education March - August 2015 Admissions PDFDocument12 pagesBindura University of Science Education March - August 2015 Admissions PDFLuke MadzikotoNo ratings yet

- CCPDocument2 pagesCCPsanojmk2004No ratings yet

- Clarke 1973 Loss of InnocenceDocument13 pagesClarke 1973 Loss of InnocencePaula TralmaNo ratings yet

- Name: K K ID#: Lab Partner: V S Date: Wednesday 22 Course Code: BIOL 2363 - Metabolism Title of Lab: Assay of Tissue GlycogenDocument7 pagesName: K K ID#: Lab Partner: V S Date: Wednesday 22 Course Code: BIOL 2363 - Metabolism Title of Lab: Assay of Tissue GlycogenKarina KhanNo ratings yet

- 2.1 Conditional Logic: Ladder ProgrammingDocument10 pages2.1 Conditional Logic: Ladder ProgrammingLuka NikitovicNo ratings yet

- S/4HANA Margin Analysis, Predictive Accounting, and Continuous CloseDocument27 pagesS/4HANA Margin Analysis, Predictive Accounting, and Continuous Closessbhagat001No ratings yet

- (Eng) Advanced Concept Training - 2d Concrete Members en 1992 - 2017Document69 pages(Eng) Advanced Concept Training - 2d Concrete Members en 1992 - 2017Muscadin MakensonNo ratings yet

- Ruud RAWL SplitDocument24 pagesRuud RAWL SplitElvis Ruben Piza MerchanNo ratings yet

- Constructors in JavaDocument5 pagesConstructors in JavaAnonymous GqTzzkOfNo ratings yet