Professional Documents

Culture Documents

TDEC-500: Electronic Control System

TDEC-500: Electronic Control System

Uploaded by

Андрей ЗайчиковOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDEC-500: Electronic Control System

TDEC-500: Electronic Control System

Uploaded by

Андрей ЗайчиковCopyright:

Available Formats

Twin Disc Electronic Controls TDEC-500

TDEC-500

ELECTRONIC CONTROL SYSTEM

The TDEC-500 is the latest state-of-the-art full authority

microprocessor-based electronic control system

for Twin Disc automatic transmission systems used

in heavy duty, off-highway applications.

FEATURES & BENEFITS: APPLICATIONS:

• Built-in-test (BIT) diagnostics • Military Vehicles

• Health and trend capability with fault isolation via user • Oil Field Pressure Pumping Rigs

accessible fault and status codes for all operational modes • Heavy-Duty Off-Road Vehicles

• Interactive command console and display • ARFF Vehicles

• Non-volatile memory and real time clock for expanded fault • Railway

snapshot and duty cycle logging

• Mobile Applications (e.g. pumping) using Twin Disc

• Increased fault tolerance Power Shift Transmission Systems

• More than a shift control, the TDEC-500 integrates the

transmission, engine and other vehicle systems

• Faster shifts, rapid vehicle acceleration and precise control

of vehicle speed ENVIRONMENTAL STANDARD:

• Flexibility to tailor features and operation for optimum • Tested to Twin Disc standard, which is based on

performance SAE J1455 and includes: salt spray, temperature and

humidity, immersion, pressure wash, vibration

• Optimized gearshift performance in oil field pressure pumping and mechanical shock

applications for precise control of the high-pressure piston

pump and an optimized line test mode specifically developed • EMC (radiated, conducted, electrical transients) standards

for Twin Disc power shift transmission systems include: SAE J1113, ISO 7637, EN 13309 and CISPR 25

• Highly configurable I/O for maximum flexibility and application • Complies with EU Directive 2009/19/EC

integration • RoHS compliant

• E-mark available

Specifications subject to change without prior notice in the interest of continual product improvement.

Contact your local Twin Disc representative for engineering specifications. Patent pending.

Scan QR code to see Twin Disc‘s entire Industrial product line.

For nearly a century, we’ve been

putting horsepower to work by

designing, engineering and manufac-

TDEC-500 SPECIFICATIONS turing rugged-duty industrial products.

Processor: Freescale 32 BIT MPC5554 132 MHz Our products and our reputation are

Voltage: 12 VDC to 24 VDC nominal bolted to the most renowned engine

Mounting orientation: Unrestricted manufacturers and equipment OEMs

in the world. Our mission is to make

Communications: SAE J1939 data link and USB are standard

your machines and vehicles more

Protection Class: IP 67 productive, more durable, more

operator-friendly, more cost-effective.

TDEC-500 DISPLAY SPECIFICATIONS From design and installation

Display: 3.8’’ (97 mm) QVGA (320 x 240 pixels) monochrome transflective LCD consultation through after-sale

with white LED dimming backlight support, Twin Disc and its distributors

Viewing Angle: +/- 55° horizontally; +45°/-60° vertically are committed to your business.

No one knows more about managing

Voltage: 6-36 VDC; reverse polarity protected

horsepower in more ways than

Operating Temperature: -40°C to 85°C

Twin Disc.

Storage Temperature: -40°C to 85°C

Mounting Orientation: 3.36’’ (85.3mm) opening PTOS • TRANSMISSIONS • CLUTCHES

ELECTRONIC SHIFT CONTROLS • GEARBOXES

Communications: Dual CANbus J1939

PUMP DRIVES • TORQUE CONVERTERS

Protection Class: IP 66 and 67 HYDRAULIC PTO PRODUCTS

Pushbuttons provide access to control systems diagnostics

TDEC-500 RANGE SELECTOR SPECIFICATIONS

Twin Disc offers a variety of options for range selectors, including push button J1939 selectors (shown)

and discrete switch selectors with a lever or rotary switch.

281 117

110

231

84

174

80

Consult Twin Disc Applications Engineering for more information.

Twin Disc, Incorporated

Racine, Wisconsin 53403 USA

Twin Disc, Incorporated reminds users of these products that their safe operation depends on use in compliance Phone +1-262-638-4000

with engineering information provided in our catalog. Users are also reminded that safe operation depends Fax +1-262-638-4482

on proper installation, operation and routine maintenance and inspection under prevailing conditions. It is the www.twindisc.com

responsibility of users (and not Twin Disc, Incorporated) to provide and install guards or safety devices which

may be required by recognized safety standards or by the Occupational Safety and Health Act of 1970 and its

subsequent provisions. TD-Bulletin-TDEC500

© 2015, Twin Disc, Incorporated

United States of America • Australia • Belgium • Canada • China • India • Italy • Singapore • Switzerland Printed in the USA - 05/2015

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Fuse Box Diagram Nissan Note and Relay With Assignment and LocationDocument18 pagesFuse Box Diagram Nissan Note and Relay With Assignment and LocationJakovNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ME8091-Automobile Engineering QP - by WWW - LearnEngineering.inDocument16 pagesME8091-Automobile Engineering QP - by WWW - LearnEngineering.inmohanpusNo ratings yet

- 2019 Yamaha YZF-R3Document3 pages2019 Yamaha YZF-R3Dede Iskandar RianziNo ratings yet

- 1997 Harley Davidson Softail Models Parts CatalogDocument498 pages1997 Harley Davidson Softail Models Parts CatalogcoyoteassasinNo ratings yet

- Apsl0167 1101,13Document2 pagesApsl0167 1101,13HILLNo ratings yet

- 420 Vs 420 XE Features Comparison - DetailDocument32 pages420 Vs 420 XE Features Comparison - Detail953997601No ratings yet

- Iae V2500Document15 pagesIae V2500Bilal Qureshi100% (2)

- Lecture 3Document14 pagesLecture 3Benedicto MugongoNo ratings yet

- Automobile EngineeringDocument120 pagesAutomobile EngineeringGopu Thirupathi ReddyNo ratings yet

- DG 99 002 - e 05-99 StellgerĂ TeDocument27 pagesDG 99 002 - e 05-99 StellgerĂ TeSidali KilardjNo ratings yet

- 480CK Wheel TractorDocument276 pages480CK Wheel TractorAdam SeimNo ratings yet

- Level 4 Coc-1-3Document11 pagesLevel 4 Coc-1-3Abdulkerim SebreNo ratings yet

- 260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerDocument4 pages260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- 20ME901 Automobile Engineering Unit 5Document90 pages20ME901 Automobile Engineering Unit 56044 sriramNo ratings yet

- Schuler TuningDocument2 pagesSchuler TuningAman AroraNo ratings yet

- Index PagesDocument50 pagesIndex PagesMTK2016No ratings yet

- Dodge Caliger Tech DataDocument8 pagesDodge Caliger Tech DataMshiboniumNo ratings yet

- 518 HV FHD (Ta 55°C) - Equipment Data Sheet (Rev 01)Document2 pages518 HV FHD (Ta 55°C) - Equipment Data Sheet (Rev 01)Gerard HoffardNo ratings yet

- TM 9-2520-234-34P Technical Manual: Headquarters, Department of The Army December 1991Document160 pagesTM 9-2520-234-34P Technical Manual: Headquarters, Department of The Army December 1991Steve WaismanNo ratings yet

- Ecu List 8.1.1 New Features ListDocument74 pagesEcu List 8.1.1 New Features Listluat1983No ratings yet

- Repair Manual ZF 45-1 Workshop MaunalDocument85 pagesRepair Manual ZF 45-1 Workshop MaunalBertrand Legendre100% (1)

- ZF6S 850 GB Luxura EnviroDocument38 pagesZF6S 850 GB Luxura EnviroPRASUN NATHNo ratings yet

- Product Information: R1300GII RSL - 10DEC04-00Document696 pagesProduct Information: R1300GII RSL - 10DEC04-00MAYCON ALEX OSORES INOCENTENo ratings yet

- 7J English BrochureDocument11 pages7J English BrochureSérgio Vinícius B.No ratings yet

- Real-Life Comparison Between Diesel AND Electric CAR Energy ConsumptionDocument21 pagesReal-Life Comparison Between Diesel AND Electric CAR Energy ConsumptionsaipallaviNo ratings yet

- Time Domain AnalysisDocument10 pagesTime Domain Analysissriramoj100% (1)

- 20ME901 Automobile Engineering Unit 1Document87 pages20ME901 Automobile Engineering Unit 16044 sriramNo ratings yet

- 963C Caterpillar Systems Operation.Document63 pages963C Caterpillar Systems Operation.Baron KasoziNo ratings yet

- IdentificationDocument8 pagesIdentificationpikipelukiNo ratings yet

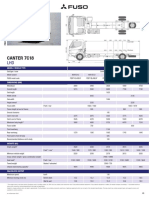

- Canter 7C18: Model / Vehicle Type 7C18Document2 pagesCanter 7C18: Model / Vehicle Type 7C18СТОЯН КЪНАЛИЕВNo ratings yet