Professional Documents

Culture Documents

Shaft Collar Construction Through Quicksand Ground Conditions by Peter White

Shaft Collar Construction Through Quicksand Ground Conditions by Peter White

Uploaded by

Asisipho MajaliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shaft Collar Construction Through Quicksand Ground Conditions by Peter White

Shaft Collar Construction Through Quicksand Ground Conditions by Peter White

Uploaded by

Asisipho MajaliCopyright:

Available Formats

www.groutingspecialist.

com

TEL: 905-361-4630 | EMAIL: peter.white@groutingspecialist.com

Shaft Collar Construction Through Quicksand Ground Conditions

Case Description

A mining contractor was constructing a surface collar for a new

ventilation shaft that was being developed by shaft sinking

methods through approximately 15 m of saturated granular

unconsolidated soil conditions.

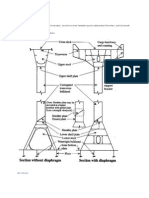

Solution Shaft Collar with sheet piles

The contractor's initial attempt at shaft collar excavation was to Chemical grouting was required to permanently stop all of the

install conventional pre-formed liner plate as excavation was residual quicksand inflow as the remaining soil was excavated

underway. This method of shaft collar construction was from within the shaft and to construct an adequate external

abandoned after a few meters of excavation due to lack of barrier that would withstand subsequent blasting during shaft

standup time of the unconsolidated soils and associated sinkholes excavation in rock.

that were occurring adjacent to the shaft perimeter.

Chemical grouting work commenced at the highest point along

The second attempt was to install a cylinder of vertical the rock - sheet pile interface and gradually proceeded down-

interlocking sheet piles within the previously placed rings of liner slope around both sides of the shaft excavation.

plates. As excavation proceeded within the sheet pile shaft lining,

problems with sinkholes continued as granular soil migrated Small diameter holes were drilled through the sheet piles about

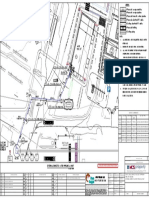

through openings between the sheet piles and the underlying 50 to 75 cm above the bedrock interface and spaced about 10 cm

bedrock. apart using an electric drill with a magnetic base. Holes typically

encountered flowing quicksand immediately after penetrating

Due to the solid nature of the bedrock underlying the site, it was the steel sheet pile, so plastic injection packers were quickly

not possible to embed the sheet pile toes. In addition, the installed to close the drill holes.

bedrock profile was smooth and sloping at a shallow angle,

resulting in openings beneath each of the individual sheet piles.

The contractor then installed 2 inch diameter steel pipes

adjacent to the sheet piles and undertook cement grouting to

construct a grouted toe at the interface between the sheet piles

and underlying rock. This cement grouting program provided

sufficient improvement to the surrounding ground conditions to

enable the shaft to be excavated down to the top of the sloping

rock interface.

At this point, the contractor observed continuous inflow of

quicksand and unsuccessfully attempted to use rags and wooden

wedges to control these inflows. Shaft collar excavation work

was at a standstill when the contractor called Peter White for

assistance.

Peter quickly determined that the required solution was Cement grouting through external grout pipes

chemical grouting outside the toe of the sheet piles to

completely consolidate an external ring of soil at the bedrock

interface.

5245 Creekbank Rd, Mississauga, ON L4W 1N3 TEL: 905-361-4630

EMAIL: peter.white@groutingspecialist.com | www.groutingspecialist.com

www.groutingspecialist.com

TEL: 905-361-4630 | EMAIL: peter.white@groutingspecialist.com

Shaft Collar Construction Through Quicksand Ground Conditions

After drilling a horizontal line of drill holes over a distance of 1 to

2 m, approximately 2 to 4 liters of water-activated chemical grout

was initially injected at each packer location.

The systematic process of packer removal, gradual deepening of

drill holes and injection of additional chemical grout was

undertaken until approximately 1 m of consolidated soil had been

achieved beyond the sheet pile perimeter.

It was then possible for the contractor to excavate additional soil

from the shaft bottom and expose more ungrouted sheet piles for

chemical grouting. Drilling and chemical grouting work was

labour-intensive, since all of the work was undertaken at the

bottom of the excavation using hand-held equipment.

After 10 days of chemical grouting work that consumed over

1,500 kg of chemical grout, all of the shaft bottom had been

excavated down to solid rock with no further water infiltration.

Sealing quicksand inflows at sheet pile – rock interface

Quicksand inflow at the bottom of the shaft Sealed sheet piles at bedrock contact

Peter White, P. Eng., is a senior engineer and grouting

specialist with over 25 years of experience working on

many different types of pressure grouting operations

at hundreds of project locations around the world.

5245 Creekbank Rd, Mississauga, ON L4W 1N3 TEL: 905-361-4630

EMAIL: peter.white@groutingspecialist.com | www.groutingspecialist.com

You might also like

- Eureka Tower BAP V 2003 - Slatter - TchepakDocument6 pagesEureka Tower BAP V 2003 - Slatter - TchepaklattmdyNo ratings yet

- Diaphragm Wall DesignDocument18 pagesDiaphragm Wall DesignJosé Chávez100% (3)

- Shaft Collar in Deep Overburden - Aur Resources - LouvicourtDocument8 pagesShaft Collar in Deep Overburden - Aur Resources - LouvicourtEEPNo ratings yet

- 07-02-157 Practical Soil Nail Wall Design and Constructability IssuesDocument11 pages07-02-157 Practical Soil Nail Wall Design and Constructability Issuesben indrawanNo ratings yet

- Successful Grout Curtain Installation Mean and MethodsDocument12 pagesSuccessful Grout Curtain Installation Mean and MethodsDarshan Babu AdhikariNo ratings yet

- Support of Deep Excavation in Soft Clay A Case History StudyDocument8 pagesSupport of Deep Excavation in Soft Clay A Case History StudyAlfredo A LopezNo ratings yet

- St. CloudDocument4 pagesSt. CloudDeaconescu_DanielNo ratings yet

- Hand Dug CaissonsDocument2 pagesHand Dug CaissonsEng Ly HengNo ratings yet

- Microsoft Word - Chap 03 Foundation TreatmentDocument18 pagesMicrosoft Word - Chap 03 Foundation TreatmentCristhian PardoNo ratings yet

- Kingston Sinkhole Second OpinionDocument8 pagesKingston Sinkhole Second OpinionDaily Freeman100% (1)

- Abstract:: A Case Study - Installation of Cut-Off Wall in Seyrantepe Dam ProjectDocument7 pagesAbstract:: A Case Study - Installation of Cut-Off Wall in Seyrantepe Dam ProjectsertackcdgNo ratings yet

- Pile FoundationDocument4 pagesPile Foundationbernie3sanders-1No ratings yet

- Shotcrete Use in The Southern Link Tunnel, Stockholm: Swedish National Road AdministrationDocument6 pagesShotcrete Use in The Southern Link Tunnel, Stockholm: Swedish National Road AdministrationHarold TaylorNo ratings yet

- Wilson1 RETC2011Document8 pagesWilson1 RETC2011markus morattiNo ratings yet

- Ground Improvement Techniques Assinment-1 PDFDocument4 pagesGround Improvement Techniques Assinment-1 PDFGetnet MesheshaNo ratings yet

- Geogrid Reinforced Light Weight Embankment On Stone ColumnDocument6 pagesGeogrid Reinforced Light Weight Embankment On Stone ColumnMohammad Munazir AliNo ratings yet

- A DSM Wall For Excavation SupportDocument14 pagesA DSM Wall For Excavation SupportmarmeiraisNo ratings yet

- Slurry Trench Stability AnalysisDocument7 pagesSlurry Trench Stability AnalysisAparna CkNo ratings yet

- Method Statement CMC HotakenaDocument7 pagesMethod Statement CMC HotakenaroshanNo ratings yet

- Foundation Treatment in DamsDocument43 pagesFoundation Treatment in Damsdeadromeo100% (4)

- Cut Off WallDocument10 pagesCut Off WallMining TurkeyNo ratings yet

- Installation of Drilled Case MicropilesDocument13 pagesInstallation of Drilled Case MicropilesAntonio MorenoNo ratings yet

- Cement Bentonite Slurry Wall StrengthDocument12 pagesCement Bentonite Slurry Wall StrengthvhgaitanNo ratings yet

- Intake Shaft Grout Curtain For The Niagara Tunnel Project-DFIDocument10 pagesIntake Shaft Grout Curtain For The Niagara Tunnel Project-DFIMohanakrishnan SNo ratings yet

- Diaphragm WallDocument5 pagesDiaphragm WallChandra Prakash Khatri0% (1)

- Basha Diaphragm WallDocument43 pagesBasha Diaphragm Wallletuananhb100% (4)

- Shaft SinkingDocument18 pagesShaft Sinkingarnab100% (1)

- Geotechnical Design of The Southern Motorway UnderpassDocument6 pagesGeotechnical Design of The Southern Motorway UnderpassMichael HiiNo ratings yet

- Art of Drilled Shaft ConstructionDocument15 pagesArt of Drilled Shaft ConstructionJose Leo MissionNo ratings yet

- 03 - BasementDocument28 pages03 - BasementTsz ching YipNo ratings yet

- Sprayed ConcreteDocument27 pagesSprayed ConcreteSharanu PujariNo ratings yet

- Problems Encountered in Diaphragm Wall ExcavationDocument5 pagesProblems Encountered in Diaphragm Wall ExcavationrasanavaneethanNo ratings yet

- Diaghragm Wall 2Document8 pagesDiaghragm Wall 2aramsayed100% (1)

- PID1226344 - Submitted PaperDocument9 pagesPID1226344 - Submitted PaperBiswajit dasNo ratings yet

- Pervious Concrete Pile: Yogesh R V M V Tarun Kumar Iddp Acsir Csir-CbriDocument12 pagesPervious Concrete Pile: Yogesh R V M V Tarun Kumar Iddp Acsir Csir-Cbriyogesh rvNo ratings yet

- Paper 06Document14 pagesPaper 06Samoon IbrahimNo ratings yet

- Slope Stabilisation by Soil Nails and Replacement by Anchored Bored Pile Wall For Area Development Ground Engineering February 2002Document4 pagesSlope Stabilisation by Soil Nails and Replacement by Anchored Bored Pile Wall For Area Development Ground Engineering February 2002Kenny CasillaNo ratings yet

- Well Sinking ProceduresDocument7 pagesWell Sinking ProceduresAjit ThapaNo ratings yet

- Spillway Completion ReportDocument54 pagesSpillway Completion ReportMaruf AzadNo ratings yet

- Deep Shaft Design and ConstructionDocument14 pagesDeep Shaft Design and ConstructionFabio Nascimento100% (3)

- Soil NailingDocument33 pagesSoil NailingNirav Patel75% (4)

- Difficulty in Sinking Well FoundationDocument22 pagesDifficulty in Sinking Well Foundationhussain9000100% (1)

- Underwater CONCRETINGDocument6 pagesUnderwater CONCRETINGKB GovardhanNo ratings yet

- 243 Design Construction - Cut-Off Walls Under The Arapuni DamDocument19 pages243 Design Construction - Cut-Off Walls Under The Arapuni DamSelah AbdulahiNo ratings yet

- Tech SemDocument18 pagesTech SemSai KumarNo ratings yet

- Well FoundationDocument4 pagesWell FoundationSoundar PachiappanNo ratings yet

- Pin Piles For Building FoundationsDocument15 pagesPin Piles For Building FoundationsAntonio MorenoNo ratings yet

- DSR 12-13Document279 pagesDSR 12-13Chandrashekhar ChopdekarNo ratings yet

- Ground Improvement Techniques by Grouting A.I.T.ChikmagalurDocument20 pagesGround Improvement Techniques by Grouting A.I.T.ChikmagalurJayakumarNo ratings yet

- Improvement of SiteDocument1 pageImprovement of SiteRonit ChariNo ratings yet

- Unit 2BDocument40 pagesUnit 2BNaveen KumarNo ratings yet

- Construction of A Geogrid-And Geocomposite-Faced Soil-Nailed Slope Reinforcement Project in Eastern CanadaDocument9 pagesConstruction of A Geogrid-And Geocomposite-Faced Soil-Nailed Slope Reinforcement Project in Eastern CanadaDilipNo ratings yet

- Shaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Document21 pagesShaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Carlos Arturo Casas HuamánNo ratings yet

- A. What Is Soil Nailing GroutingDocument7 pagesA. What Is Soil Nailing GroutingBENJAMIN III BIDANGNo ratings yet

- Deep Excavation Techniques Deep Excavation Techniques: Presented byDocument31 pagesDeep Excavation Techniques Deep Excavation Techniques: Presented byRizwan Khurram100% (1)

- Remedial Measures Incorporating Jet Grouting and Micropiles For The Construction of A New Back Ow PreventerDocument10 pagesRemedial Measures Incorporating Jet Grouting and Micropiles For The Construction of A New Back Ow Preventerrigaz6366No ratings yet

- Ground Reinforcement MethodsDocument55 pagesGround Reinforcement MethodsVidya SagarNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionFrom EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159From EverandTransactions of the American Society of Civil Engineers, vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The East River Tunnels. Paper No. 1159No ratings yet

- Presentation Unit 1 Introduction To Mining MethodsDocument66 pagesPresentation Unit 1 Introduction To Mining MethodsAsisipho MajaliNo ratings yet

- PurposeDocument2 pagesPurposeAsisipho MajaliNo ratings yet

- Majali Asisipho (2621881) : How You Thinking Learning To Code Can or Can Not Change The Mining Industry?Document2 pagesMajali Asisipho (2621881) : How You Thinking Learning To Code Can or Can Not Change The Mining Industry?Asisipho MajaliNo ratings yet

- UntitledDocument1 pageUntitledAsisipho MajaliNo ratings yet

- Chap - 02r RF and Microwave DesignDocument39 pagesChap - 02r RF and Microwave DesignPrince BoadiNo ratings yet

- PervaporationDocument26 pagesPervaporationWasique KhanNo ratings yet

- 9C Construction Documents Deliverable ListDocument2 pages9C Construction Documents Deliverable ListRashad AbdelhyNo ratings yet

- PDF 417 How ToDocument35 pagesPDF 417 How ToLiloit OsijekNo ratings yet

- Can't Connect To FB Database PDFDocument6 pagesCan't Connect To FB Database PDFElkin Limas RojasNo ratings yet

- June OralsDocument9 pagesJune OralsAditya AryaNo ratings yet

- Bulk - Density and Tap-Density Procedure2 PDFDocument3 pagesBulk - Density and Tap-Density Procedure2 PDFakjeevananthamNo ratings yet

- Rooftop VAV System PDFDocument6 pagesRooftop VAV System PDFMohamed ElarabiNo ratings yet

- Plate GirdersDocument13 pagesPlate GirdersSourabh Negi100% (2)

- Iigm Pvt. LTDDocument5 pagesIigm Pvt. LTDAman DeepNo ratings yet

- Quantum Mechanics. Homework II.: Alfredo Vidal Arias May 6, 2014Document3 pagesQuantum Mechanics. Homework II.: Alfredo Vidal Arias May 6, 2014dajksbeiNo ratings yet

- Property: Duct Bank 600X600Document1 pageProperty: Duct Bank 600X600Byambasuren batbayarNo ratings yet

- Instrument Cluster Warning LightsDocument2 pagesInstrument Cluster Warning Lightsしひち し大100% (1)

- GEELY 2008 Fc-VisionDocument211 pagesGEELY 2008 Fc-VisionКостя ДолинськийNo ratings yet

- Avialite Malaysia Company ProfileDocument22 pagesAvialite Malaysia Company ProfilethangbinhbkNo ratings yet

- Single Aisle Technical Training Manual General Familiarization Course - T4 (Iae V2500) Airframe Level1Document210 pagesSingle Aisle Technical Training Manual General Familiarization Course - T4 (Iae V2500) Airframe Level1chintanNo ratings yet

- BSNL Launches: Summer Training For ENGINEERING StudentsDocument2 pagesBSNL Launches: Summer Training For ENGINEERING StudentsAbhijit TripathyNo ratings yet

- Preparing Tension Test Specimens For Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous CastingsDocument10 pagesPreparing Tension Test Specimens For Copper Alloy Sand, Permanent Mold, Centrifugal, and Continuous Castingspinkan25No ratings yet

- OOABAP Tutorials ExampleDocument2 pagesOOABAP Tutorials ExampleRajiv KumarNo ratings yet

- HAMILTON KETTLES Single Motion, Double Motion & Triple Action AgitatorsDocument4 pagesHAMILTON KETTLES Single Motion, Double Motion & Triple Action Agitatorskevin kurlandNo ratings yet

- OfficeDocument124 pagesOfficeMr. RegistrationNo ratings yet

- XrotorDocument21 pagesXrotorFrancesco ReaNo ratings yet

- Car Loan EMI Calculator - Calculate EMI & Total Interest Due PDFDocument8 pagesCar Loan EMI Calculator - Calculate EMI & Total Interest Due PDFMayur JoshiNo ratings yet

- RC4 and WEP: By: Anthony Gervasi & Adam DickinsonDocument18 pagesRC4 and WEP: By: Anthony Gervasi & Adam DickinsonNeha VermaNo ratings yet

- Department of Metallurgical and Materials Engineering, Nit Rourkela. Spring 2014 15Document1 pageDepartment of Metallurgical and Materials Engineering, Nit Rourkela. Spring 2014 15Sanjeev SahuNo ratings yet

- YIN Company Profile (Yokogawa Indonesia)Document26 pagesYIN Company Profile (Yokogawa Indonesia)Ferio Arsyad0% (1)

- Worksheet # 1Document4 pagesWorksheet # 1riz khanNo ratings yet

- Renewable SourcesDocument27 pagesRenewable SourcesRupesh SingNo ratings yet

- Filter Dropdown Keyboard ShortcutsDocument28 pagesFilter Dropdown Keyboard ShortcutsShara Joy B. ParaynoNo ratings yet

- Propulsion 2 MarksDocument11 pagesPropulsion 2 MarksSasiKumarNo ratings yet