Professional Documents

Culture Documents

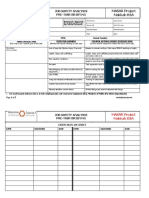

General Inspection Checklist For Safety Representatives

Uploaded by

Doaa Gamal0 ratings0% found this document useful (0 votes)

46 views2 pagesOriginal Title

general-inspection-checklist-for-safety-representatives

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views2 pagesGeneral Inspection Checklist For Safety Representatives

Uploaded by

Doaa GamalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

General Inspection Checklist

for Safety Representatives

This checklist can be used as a guide to help inspect a workplace for common problems. It is not an exhaustive list of items

and will not cover all hazards in all workplaces. It can be completed in a single inspection or over a series of shorter

inspections. The template can be adapted to suit your workplace or you can use the blank boxes to add in additional items

that you want checked or items that you come across.

Area or Location Inspected:

Date:

Inspected By:

No. Item Yes No Comments

1 Is the workplace clean and tidy?

2 Is there adequate lighting?

3 Is there excessive noise?

4 Is the temperature reasonable?

5 Are welfare facilities, e.g. toilets and canteen,

clean and tidy?

6 Are walkways kept clear of trip hazards?

7 Are there trailing leads?

8 Is there clear access to exit doors and do fire exits

open outwards?

9 Are floors and walkways slippery?

10 Are floors wet at the entrance?

11 Are secure handrails in place on stairways and

raised walkways?

12 Are steps hard to see, damaged or slippery?

13 Is wet cleaning of floors carried out at a time when

there is little or no pedestrian traffic?

14 Are fire extinguishers in their marked locations?

15 Have fire extinguishers been serviced and checked

and are they in date?

16 Has the fire alarm recently been tested?

17 Are employees aware of the location of the

assembly point?

18 Has an evacuation drill been carried out in the past

6 months?

19 Are employees aware of the location of the first aid

kit?

20 Is the first aid kit fully stocked and has it recently

been checked?

21 Are employees aware of the location of emergency

power cut offs e.g. for electricity and gas?

22 Have employees using machines and equipment

been trained?

General Inspection Checklist

for Safety Representatives

No. Item Yes No Comments

23 Are machine guards in place to prevent access to

dangerous parts?

24 Are employees aware of the location of machine

emergency stop(s) and are they within easy reach

and working?

25 Are machine operator manuals / instructions

available?

26 Is PPE (Personal Protective Equipment) provided

and being worn?

27 Do electrical cables and plugs show signs of

over-heating, damage or wear and tear?

28 Has the RCD (Residual Current Device) recently

been tripped / tested?

29 If asbestos is present in the building is its

condition being monitored and are there

procedures and signs in place to prevent its

disturbance?

30 Are chemicals stored safely?

31 Are systems for removing dust or fumes in good

working order and used as needed?

32 Do the wheels of trolleys and manual handling

aids move freely?

33 Are signs or information provided to direct visitors

to reception?

34 Are vehicles and pedestrians kept safely apart?

35 Are vehicles loaded or unloaded in a suitable area?

36 Are mirrors and other visibility aids on workplace

vehicles in good working order?

37 Are there edges and openings where people

could fall?

38 Is suitable equipment used for getting to work

areas at height?

39 Is there an in-date certificate of thorough exam-

ination for lifting equipment e.g. lift, crane, hoist,

forklift, MEWP?

40 Is there an in-date certificate of thorough exam-

ination for pressure systems e.g. pressurised steam

boiler, compressed air?

Have employees been made aware of the

41 contents of the safety statement and the risk

assessments relevant to their work?

42 Are employees aware where the safety statement

is available?

Additional items / hazards in your

workplace: Yes No Comments

43

44

45

You might also like

- Practical Guide to Occupational Health and SafetyFrom EverandPractical Guide to Occupational Health and SafetyRating: 4 out of 5 stars4/5 (13)

- 22 Safety ChecklistsDocument30 pages22 Safety ChecklistsIrvys G. Juarez Dordi100% (2)

- Workers Accommodation ChecklistDocument2 pagesWorkers Accommodation ChecklistRaza Muhammad Soomro100% (1)

- Health & Safety Audit ChecklistDocument4 pagesHealth & Safety Audit Checklistfinbar iluobeNo ratings yet

- Facility Inspection ChecklistDocument9 pagesFacility Inspection ChecklistdesignselvaNo ratings yet

- Environmental, Health, and Safety (Ehs) Audit ChecklistDocument8 pagesEnvironmental, Health, and Safety (Ehs) Audit ChecklistGbenga100% (2)

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Is 14489 2018Document21 pagesIs 14489 2018Rohit100% (3)

- Checklist For Evaluation of Security: R R R R R RDocument7 pagesChecklist For Evaluation of Security: R R R R R Rjaideep_bhwNo ratings yet

- Inspection ChecklistsDocument6 pagesInspection Checklistsmegaspice0% (1)

- Daily Site Inspection ChecklistDocument2 pagesDaily Site Inspection ChecklistRavi thokalNo ratings yet

- Safety Audit ChecklistDocument5 pagesSafety Audit ChecklistAbhishekNo ratings yet

- Office Safety ChecklistDocument3 pagesOffice Safety ChecklistJaijeev Pali100% (1)

- Security Officer's Handbook: Standard Operating ProcedureFrom EverandSecurity Officer's Handbook: Standard Operating ProcedureRating: 2 out of 5 stars2/5 (3)

- Contractor SHE Plan-HANNESDocument16 pagesContractor SHE Plan-HANNESMominé Ve100% (1)

- Digest Cawad Vs ABadDocument2 pagesDigest Cawad Vs ABadCherry Bepitel100% (1)

- EHS Audit ChecklistDocument6 pagesEHS Audit ChecklistVIJAY BHARATENo ratings yet

- ANSI ISEA Z89 1 2014 American National PDFDocument41 pagesANSI ISEA Z89 1 2014 American National PDFTeam SHEQMS100% (3)

- Manufacturing Plant Audit ChecklistDocument6 pagesManufacturing Plant Audit ChecklistAnurag SrivastavaNo ratings yet

- FMS - EOC ChecklistDocument6 pagesFMS - EOC Checklisthany winihastutiNo ratings yet

- Factory compliance documents checklistDocument5 pagesFactory compliance documents checklistvermaamanvermaNo ratings yet

- Storage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsDocument1 pageStorage Area Inspection Form: NO. Items To Be Checked YES NO N/A Observations / CommentsArshad MahmoodNo ratings yet

- Protocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesFrom EverandProtocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesNo ratings yet

- General Industrial Safety ChecklistDocument9 pagesGeneral Industrial Safety Checklistابو محمدNo ratings yet

- 22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentDocument30 pages22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentMohammed Hasnain Saleem/KSA/EMD100% (1)

- Site Inspection ChecklistDocument21 pagesSite Inspection ChecklistVictor BiacoloNo ratings yet

- Construction Safety Audit ChecklistDocument7 pagesConstruction Safety Audit Checklistamit sikkaNo ratings yet

- Lab Audit FormDocument6 pagesLab Audit Formmahesh90600No ratings yet

- Safety Induction TrainingDocument43 pagesSafety Induction Trainingboss baskarNo ratings yet

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- All Safety Inspection ChecklistsDocument30 pagesAll Safety Inspection ChecklistsSagar Sharma50% (2)

- Inspection Checklists - Sample Checklist For Manufacturing Facilities - OSH AnswersDocument6 pagesInspection Checklists - Sample Checklist For Manufacturing Facilities - OSH Answersshahira100% (1)

- H S ChecklistDocument17 pagesH S ChecklistkhajaimadNo ratings yet

- What Is An Example of An Inspection Checklist For A Manufacturing FacilityDocument7 pagesWhat Is An Example of An Inspection Checklist For A Manufacturing FacilityaKureishi100% (1)

- HSE Audit Checklist: Emergency Equipment Safety Inspection Checklist ItemDocument3 pagesHSE Audit Checklist: Emergency Equipment Safety Inspection Checklist Itemramod100% (2)

- Is 14489 2018 Audit Check ListDocument34 pagesIs 14489 2018 Audit Check ListRajesh Dhake100% (2)

- Final - Hazard - Identification - Checklist - Gas & Oil - Mysha - 0419022037 - M.SC PDFDocument5 pagesFinal - Hazard - Identification - Checklist - Gas & Oil - Mysha - 0419022037 - M.SC PDFMysha Momtaz100% (1)

- FireRiskAssessmentDocument3 pagesFireRiskAssessmentوأكثرهم كارهونNo ratings yet

- Food Defence ChecklistDocument3 pagesFood Defence ChecklistRevanth100% (1)

- Accident PreventionDocument46 pagesAccident PreventionRajneesh PatelNo ratings yet

- AHB Hong KongDocument46 pagesAHB Hong KongPraveen SankaranNo ratings yet

- Safety Inspection ChecklistDocument3 pagesSafety Inspection ChecklistVivienne IrvingNo ratings yet

- Booklet For Assignment CHC30113 Subject 1 LG F 2.2Document337 pagesBooklet For Assignment CHC30113 Subject 1 LG F 2.2Kanza Amir100% (2)

- Chemical Case Studies Safety LessonsDocument76 pagesChemical Case Studies Safety LessonsSanthosh Kumar50% (2)

- SIMSA Fire Safety Audit ChecklistDocument8 pagesSIMSA Fire Safety Audit ChecklistAshish MendirattaNo ratings yet

- Certificado Pilz e TurvDocument12 pagesCertificado Pilz e TurvSantiago.No ratings yet

- Demolition ChecklistDocument1 pageDemolition ChecklistAhmed El-sherpiniNo ratings yet

- Inspection Checklist Template Word FileDocument2 pagesInspection Checklist Template Word Filebaaaa100% (2)

- He - Household Services CGDocument4 pagesHe - Household Services CGDaisy Anne Bilbao PatriarcaNo ratings yet

- Civil Construction Risk Assessment ChecklistDocument3 pagesCivil Construction Risk Assessment ChecklistJeduardo Ch-mezaNo ratings yet

- Construction Site Inspection Checklist For Safety RepresentativesDocument2 pagesConstruction Site Inspection Checklist For Safety RepresentativesMORRIS MWONGELANo ratings yet

- Construction Site Inspection Checklist For Safety Representatives 19 DecDocument2 pagesConstruction Site Inspection Checklist For Safety Representatives 19 DecKazeneza BMNo ratings yet

- Lab Audit FormDocument6 pagesLab Audit FormJohnyLampNo ratings yet

- Checklist Analysis Ensures LPG Plant SafetyDocument25 pagesChecklist Analysis Ensures LPG Plant SafetyShree CetNo ratings yet

- Inspection ReportDocument2 pagesInspection ReportArul PrasaadNo ratings yet

- Contractor ConstructionDocument6 pagesContractor ConstructionAshwinSiddaramaiahNo ratings yet

- Safety Inspection Checklist: NAME OF OFFICEDocument3 pagesSafety Inspection Checklist: NAME OF OFFICEMuhammad ShafiqueNo ratings yet

- Hazard Identification ChecklistDocument2 pagesHazard Identification Checklistansarmulla711No ratings yet

- Office Inspection Safety ChecklistDocument3 pagesOffice Inspection Safety ChecklistDon McleanNo ratings yet

- LpinspecDocument3 pagesLpinspecRaju BiswasNo ratings yet

- SoBo - Site Inspection ChecklistDocument5 pagesSoBo - Site Inspection ChecklistAndrada Roxana IonescuNo ratings yet

- Fire Risk Assessment ChecklistDocument5 pagesFire Risk Assessment ChecklisthanloveNo ratings yet

- Safety Inspection Checklist NTCCDocument3 pagesSafety Inspection Checklist NTCCBarri FebriandiNo ratings yet

- Fire Risk Assessment Safety Checklist HSEDocument5 pagesFire Risk Assessment Safety Checklist HSEMuhammad Zohaib AliNo ratings yet

- Contractor Camp Inspection Check List Rev9Document14 pagesContractor Camp Inspection Check List Rev9Brazilemio RoswithaNo ratings yet

- Ohs Audit Check ListDocument4 pagesOhs Audit Check ListVenkata SattiRajuNo ratings yet

- Internal Chemical Overal AuditDocument28 pagesInternal Chemical Overal AuditLabonno NaajNo ratings yet

- Inspectors: DateDocument7 pagesInspectors: DateMuruganNo ratings yet

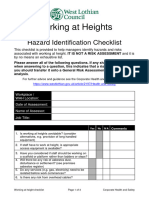

- Hazard Identification Checklist - Working at HeightDocument3 pagesHazard Identification Checklist - Working at HeightkamranNo ratings yet

- Fire Safety Audit ChecklistDocument4 pagesFire Safety Audit Checklistsiswoyoazqih83No ratings yet

- Checklist009 WorkhealthandsafetyinspectionsDocument13 pagesChecklist009 WorkhealthandsafetyinspectionsDoaa GamalNo ratings yet

- Tool 2 Inspection ChecklistDocument5 pagesTool 2 Inspection ChecklistAxmarya ZulfiqarNo ratings yet

- Workplace Inspection Checklist WorkshopDocument3 pagesWorkplace Inspection Checklist WorkshopDoaa GamalNo ratings yet

- Sample Workplace Inspection ChecklistDocument5 pagesSample Workplace Inspection ChecklistDoaa GamalNo ratings yet

- SSSP Form 5 Site Inspection ChecklistDocument5 pagesSSSP Form 5 Site Inspection ChecklistDoaa GamalNo ratings yet

- IMF - Request For Extended Arrangement Under The E - 230110 - 192944 - 1Document39 pagesIMF - Request For Extended Arrangement Under The E - 230110 - 192944 - 1Doaa GamalNo ratings yet

- ATTENDocument1 pageATTENDoaa GamalNo ratings yet

- Element 1: Why We Should Manage Workplace Health and SafetyDocument45 pagesElement 1: Why We Should Manage Workplace Health and SafetyIjas ahmedNo ratings yet

- The Civil Engineer and His Duties: Scope of Civil EngineeringDocument8 pagesThe Civil Engineer and His Duties: Scope of Civil EngineeringCian ChanNo ratings yet

- CBLM Maintain and Repair Cellular PhoneDocument166 pagesCBLM Maintain and Repair Cellular PhonesorcererpcNo ratings yet

- ASE's Integrated Management System for Static Equipment InspectionsDocument5 pagesASE's Integrated Management System for Static Equipment InspectionsEnahs RamirezNo ratings yet

- Attachment 1 - 20200310 - COC Business Partners (COCBP)Document10 pagesAttachment 1 - 20200310 - COC Business Partners (COCBP)Tengku JohNo ratings yet

- 4600 Plum Eye Wash 112015 UKDocument7 pages4600 Plum Eye Wash 112015 UKArdXkillerNo ratings yet

- Abdul Wahab - CV & DocumentsDocument34 pagesAbdul Wahab - CV & DocumentsSaif Ur RehmanNo ratings yet

- QuestionsDocument45 pagesQuestionsA.A M.A.RNo ratings yet

- Risk AssessmentDocument26 pagesRisk AssessmentsolomonbegNo ratings yet

- BSBMGT517 Student Assessment v3.0Document16 pagesBSBMGT517 Student Assessment v3.0nirajan sapkotaNo ratings yet

- Law of Labour Safty and Hygiene in MongoliaDocument14 pagesLaw of Labour Safty and Hygiene in MongoliaDejidmaa GalbadrakhNo ratings yet

- MSDS Sulzer Metco 4198Document10 pagesMSDS Sulzer Metco 4198candraNo ratings yet

- BMI As of June 2019Document16 pagesBMI As of June 2019jeffordillasNo ratings yet

- 1100-P-001 Rev. 0 Quality Manual ValarbiDocument20 pages1100-P-001 Rev. 0 Quality Manual ValarbiRahmad DesmanNo ratings yet

- GSCP Reference Code V2 April 2010Document8 pagesGSCP Reference Code V2 April 2010Sara MarianiNo ratings yet

- Professional Diploma in Management Human Resource Management Class Test (15Document10 pagesProfessional Diploma in Management Human Resource Management Class Test (15Arfreden DenNo ratings yet

- Nitrogen Gas FillingDocument21 pagesNitrogen Gas Fillingsanjeev kumarNo ratings yet

- Module 5 Safety and Health at WorkDocument46 pagesModule 5 Safety and Health at WorkYhan Brotamonte BoneoNo ratings yet

- Code of Practice For Health and Safety in Dock Work PDFDocument84 pagesCode of Practice For Health and Safety in Dock Work PDFmanuelNo ratings yet