Professional Documents

Culture Documents

EP 520 EPC 520 Rev. 3

Uploaded by

yoniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EP 520 EPC 520 Rev. 3

Uploaded by

yoniCopyright:

Available Formats

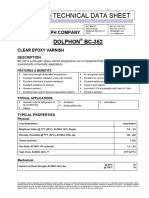

Technical Data:

Issued: Nov. 2007 EP 520/EPC 520

Revision 3: April 2021, Page: 1 Low Viscosity Room Temperature Curing Epoxy

Product Description EP 520/EPC 520 is a clear, low viscosity, two component epoxy compound

designated for composite materials used in aviation and aerospace, and

industrial composites. EP 520 exhibits high temperature resistance,

excellent mechanical properties and high chemical resistance.

Features & Benefits ● Low viscosity ● Long pot life at RT

● Excellent mechanical properties ● High temperature resistance

● Rapid cure at high temperature

Applications Manufacturing of Glass/Epoxy or Carbon/Epoxy composite parts using

Resin Transfer Molding, wet lay-up and infusion processes at low to

moderate temperature.

Typical Uncured Note: The following technical information and data should be considered representative or

typical only and should not be used for specification purposes.

Properties

Base Resins Base (A) Epoxy Resins

Hardener (B) Amines

Appearance/Color Base (A) Clear

Hardener (B) Clear

Viscosity @25°C, mPa*s Base (A) 1400-1800

ASTM-D-2393 Hardener (B) 40-50

Density @ 25°C, g/cm3 Base (A) 1.17 ± 0.03

Hardener (B) 0.94 ± 0.02

Mix Ratio A:B, (w/w) 100:30

Mix Viscosity @25°C, mPa*s 500-700

ASTM-D-2393

Work life, @ 25°C, min 60-90

Gel-time, 100g @ 25°C, min 120-150

Polymer Gvulot Ltd. Mail: info@polymer-g.com

Kibbutz Gvulot, 85525 ISRAEL Tel.: +972 (0)8 9987931, Fax.: +972 (0)8 9965286 http://www.polymer-g.com

Technical Data:

Issued: Nov. 2007 EP 520/EPC 520

Revision 3: April 2021, Page: 2 Low Viscosity Room Temperature Curing Epoxy

Typical Cured Note: The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

Properties

Curing Schedule 24hr/23°C + 8hr/60°C or

24hr/23°C + 4hr/100°C

Hardness, ASTM-D-2240, Shore D 80-85

Tensile Strength, ASTM-D-638, MPa 60-80

Tensile Elongation, ASTM-D-638,% 2.0-6.0

Flexural Strength, ASTM-D-790, MPa 100-140

Flexural Modulus, ASTM-D-790, MPa 2000-3000

Compressive Strength, ASTM-D-695, MPa 1100-1200

HDT, (0.455MPa), ASTM D-648, °C 114

Glass Temperature, ASTM-3418, °C 119

Service Temperature, °C -40 to 150

Storage and handling The shelf life of the EP 520 is 12 months at 16-35°C.

For the best results, store in tightly closed original containers.

Certain resins and hardeners are susceptible to crystallization. If

crystallization occurs, warm the container to 50-60°C until the crystals

have dissolved.

Stir and allow content to cool to room temperature before use.

Packaging Packaging sizes are available from 1L to 25L containers

Limitation of Liability Except where prohibited by law, Polymer-G and seller will not be liable for

any loss or damage arising from the Polymer-G product, whether direct,

indirect, special, incidental or consequential, regardless of the legal theory

asserted, including warranty, contract, negligence or strict liability.

Polymer Gvulot Ltd. Mail: info@polymer-g.com

Kibbutz Gvulot, 85525 ISRAEL Tel.: +972 (0)8 9987931, Fax.: +972 (0)8 9965286 http://www.polymer-g.com

You might also like

- Belex Wireline LubricantDocument2 pagesBelex Wireline LubricantdhowardjNo ratings yet

- Technical Data Sheet: Heavy Duty GreaseDocument1 pageTechnical Data Sheet: Heavy Duty GreaseDon HowardNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Dol_BC352Document2 pagesDol_BC352Jerry Mar LucenaNo ratings yet

- Equate EMDA 6200Document2 pagesEquate EMDA 6200HichamSalamaNo ratings yet

- Renolin Therm 300Document1 pageRenolin Therm 300Mohamed SalemNo ratings yet

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- Sabic BM 1052Document2 pagesSabic BM 1052ifahNo ratings yet

- Hoja Tecnica Sabic 5707NDocument2 pagesHoja Tecnica Sabic 5707NJaimito Ramirez RodasNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- Ultrapaste Cu 12 SF - 2017 (E)Document1 pageUltrapaste Cu 12 SF - 2017 (E)HANIF AKBARNo ratings yet

- BR-352-TDSDocument2 pagesBR-352-TDSJerry Mar LucenaNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- HD6200B/HD6600B High Density Polyethylene Resin Product DescriptionDocument1 pageHD6200B/HD6600B High Density Polyethylene Resin Product DescriptionRizaldi Nur Imani100% (1)

- Adeco Lithium Grease 2: Technical Data SheetDocument1 pageAdeco Lithium Grease 2: Technical Data SheetVelibor KaranovicNo ratings yet

- TDS Dromide 9443Document1 pageTDS Dromide 9443Kim MarNo ratings yet

- Zylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Document3 pagesZylar 631: Methyl Methacrylate Butadiene Styrene (MBS)Fernando Garcia HiguitaNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Westlake Epolene® E-10 Emulsifiable - Oxidized Low Molecular Weight Polyethylene PolymerDocument1 pageWestlake Epolene® E-10 Emulsifiable - Oxidized Low Molecular Weight Polyethylene PolymerKarenNo ratings yet

- Colpoly 7167 8A TDSDocument2 pagesColpoly 7167 8A TDSKristjan PosavecNo ratings yet

- Molykote D-321R DowCorning DatasheetDocument2 pagesMolykote D-321R DowCorning DatasheetalbertoNo ratings yet

- Styrolution PS 1290/1291: General Purpose Polystyrene (GPPS)Document2 pagesStyrolution PS 1290/1291: General Purpose Polystyrene (GPPS)DiegoTierradentroNo ratings yet

- Technical Data Sheet: Hi-Therm BC-346-ADocument16 pagesTechnical Data Sheet: Hi-Therm BC-346-Avignesh vikkyNo ratings yet

- Technical Data Sheet: Hi - Therm BC-346-ADocument2 pagesTechnical Data Sheet: Hi - Therm BC-346-AAjay AbrahamNo ratings yet

- Dow CorningDocument2 pagesDow Corningwardoyoclp75No ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- Cardolite NX-2007: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite NX-2007: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- BC346ADocument2 pagesBC346AJerry Mar LucenaNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Sabic Lldpe MG200024: PolymersDocument2 pagesSabic Lldpe MG200024: PolymersYoshie IwaiNo ratings yet

- SCG H5480SDocument2 pagesSCG H5480Sakankshas06No ratings yet

- Belex Wireline LubricantDocument2 pagesBelex Wireline LubricantdhowardjNo ratings yet

- Loctite EA 907™: Technical Data SheetDocument2 pagesLoctite EA 907™: Technical Data Sheetuzzy2No ratings yet

- GlassRock Wire Mesh BlanketsDocument2 pagesGlassRock Wire Mesh BlanketsMohamedNo ratings yet

- MolykoteDocument2 pagesMolykoteRafael FrançaNo ratings yet

- Colpoly 7167 TDSDocument2 pagesColpoly 7167 TDSKristjan PosavecNo ratings yet

- Sikalastic®-8800: Product Data SheetDocument4 pagesSikalastic®-8800: Product Data SheetshahoorhussainNo ratings yet

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregDocument5 pagesEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuNo ratings yet

- CoolThermTC 2002Document2 pagesCoolThermTC 2002pranavNo ratings yet

- Sikalastic - 8800Document4 pagesSikalastic - 8800Michael A FarinNo ratings yet

- Epofine 184-Finehard 907 - Acc 062Document4 pagesEpofine 184-Finehard 907 - Acc 062Karishma PrabhuNo ratings yet

- 1200G 150 TDSDocument2 pages1200G 150 TDSRamy Abd Elkhalek ShahinNo ratings yet

- Technical Data Sheet for Bergquist Sil Pad TSP 1600S Thermal InsulatorDocument2 pagesTechnical Data Sheet for Bergquist Sil Pad TSP 1600S Thermal InsulatorKim WayneNo ratings yet

- TDS Pe 100 Ub5206h 02 PDFDocument2 pagesTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraNo ratings yet

- Indorama - Copo NGC700I PP Copolymer Grade For Injection MouldingDocument2 pagesIndorama - Copo NGC700I PP Copolymer Grade For Injection MouldingAnonymous pQ3FRKTNo ratings yet

- Alathon®: ApplicationsDocument2 pagesAlathon®: ApplicationsCarlos Revilla FloresNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- Colpoly 736 WAT TDSDocument2 pagesColpoly 736 WAT TDSKristjan PosavecNo ratings yet

- Dolphon CC-1095 CLEAR EPOXY RESIN KITDocument2 pagesDolphon CC-1095 CLEAR EPOXY RESIN KITJerry Mar LucenaNo ratings yet

- High rigidity HDPE grade for 20L lubricant containersDocument1 pageHigh rigidity HDPE grade for 20L lubricant containersStella KazanciNo ratings yet

- Almasol 2002 LEDocument2 pagesAlmasol 2002 LEUdit JainNo ratings yet

- TDS LF-371 - Dec22Document2 pagesTDS LF-371 - Dec22ofershochetNo ratings yet

- 1125 (Eng)Document1 page1125 (Eng)Sarthak AggarwalNo ratings yet

- Opal - Hdpe - 4Document2 pagesOpal - Hdpe - 4Piyush A JoshiNo ratings yet

- Bergquist Sil Pad TSP 3500 enDocument2 pagesBergquist Sil Pad TSP 3500 enmariela baigorriaNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- InnoPlus HD8100MDocument1 pageInnoPlus HD8100MLe Minh TuanNo ratings yet

- Indorama - PP HPIG250 PP Homopolymer Grade For Injection MouldingDocument2 pagesIndorama - PP HPIG250 PP Homopolymer Grade For Injection MouldingAnonymous pQ3FRKTNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Metric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDocument5 pagesMetric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDHEERAJ413No ratings yet

- P-520 EPOXY RESIN Data SheetDocument4 pagesP-520 EPOXY RESIN Data SheetyoniNo ratings yet

- IR12.P04F-F50.PO1Z.7BO: Inductive Proximity SwitchDocument2 pagesIR12.P04F-F50.PO1Z.7BO: Inductive Proximity SwitchyoniNo ratings yet

- Standard Dimensions for Various Steel SectionsDocument2 pagesStandard Dimensions for Various Steel SectionsyoniNo ratings yet

- SDS AkzoNobel Hardener S6622RDocument14 pagesSDS AkzoNobel Hardener S6622RyoniNo ratings yet

- Polymer-G EP520Document2 pagesPolymer-G EP520yoniNo ratings yet

- MSDSDocument4 pagesMSDSyoniNo ratings yet

- Slotted Spring Pins: Spring Steel, 2.5 MM Diameter, 18 MM Long, For 2.5 MM HoleDocument1 pageSlotted Spring Pins: Spring Steel, 2.5 MM Diameter, 18 MM Long, For 2.5 MM HoleyoniNo ratings yet

- Walbro In-Tank Filter PS ENDocument1 pageWalbro In-Tank Filter PS ENyoniNo ratings yet

- Compression Spring: 0.375" Long, 0.300" OD, 0.244" IDDocument1 pageCompression Spring: 0.375" Long, 0.300" OD, 0.244" IDyoniNo ratings yet

- Threaded-Stud Bumper for M6 Threads, 3/4" OD, 3/8Document1 pageThreaded-Stud Bumper for M6 Threads, 3/4" OD, 3/8yoniNo ratings yet

- Omnetics DistributorsDocument1 pageOmnetics DistributorsyoniNo ratings yet

- ComboSD Silver Series ENDocument4 pagesComboSD Silver Series ENyoniNo ratings yet

- BK Precision 01062022 8600B Series-2891758Document11 pagesBK Precision 01062022 8600B Series-2891758GILSON ROSANo ratings yet

- Programmable DC Electronic Loads: Programming ManualDocument83 pagesProgrammable DC Electronic Loads: Programming ManualyoniNo ratings yet

- Data Sheet - SanDisk Extreme Go USB 3.2 Flash DriveDocument2 pagesData Sheet - SanDisk Extreme Go USB 3.2 Flash DriveyoniNo ratings yet

- Dominion KX User Station V1270Document2 pagesDominion KX User Station V1270yoniNo ratings yet

- Loctite Shelf LifeDocument1 pageLoctite Shelf LifeyoniNo ratings yet

- Dell Latitude 14 Rugged Extreme Spec HeetDocument2 pagesDell Latitude 14 Rugged Extreme Spec HeetyoniNo ratings yet

- Lean Six Sigma and Innovation PDFDocument19 pagesLean Six Sigma and Innovation PDFFrancis ParedesNo ratings yet

- Majed Abdeen - PMBOK Processes 6thDocument1 pageMajed Abdeen - PMBOK Processes 6thHassan Mody TotaNo ratings yet

- JHA - Lifting ACUs With 60 Ton CraneDocument2 pagesJHA - Lifting ACUs With 60 Ton Cranescottie MailauNo ratings yet

- Closing Cockpit: 1.find The Functions Under Following Menu PathDocument9 pagesClosing Cockpit: 1.find The Functions Under Following Menu PathSPNo ratings yet

- SPC 3629799 0101Document41 pagesSPC 3629799 0101vladoNo ratings yet

- ACC vs DJC: Comparing Manufacturing StrategiesDocument11 pagesACC vs DJC: Comparing Manufacturing StrategiesVedant MundadaNo ratings yet

- NAP Shipdesign ProcessDocument4 pagesNAP Shipdesign ProcessFerdy Fer DNo ratings yet

- Facilities at Cranfield 2018Document7 pagesFacilities at Cranfield 2018Jay SanghrajkaNo ratings yet

- Die Maintenance Supervisor ResponsibilitiesDocument2 pagesDie Maintenance Supervisor ResponsibilitiesSarah ChaudharyNo ratings yet

- Tech Brief Wind PowerDocument28 pagesTech Brief Wind PowerTuğberkDayanNo ratings yet

- 3512 12in Manual103007Document28 pages3512 12in Manual103007Joe HartNo ratings yet

- Gireesh Jagannath Sahassrabudhe Resume-MalaysiaDocument13 pagesGireesh Jagannath Sahassrabudhe Resume-MalaysiaGirish SahasrabudheNo ratings yet

- HP-CurrentPriceListZero Normal PDFDocument49 pagesHP-CurrentPriceListZero Normal PDFZohan Haider100% (1)

- Interior Fluid Resistant Epoxy Primer: Technical Data SheetDocument5 pagesInterior Fluid Resistant Epoxy Primer: Technical Data SheetLeonard Ngiam YkNo ratings yet

- Tigerpaw Implementation GuideDocument117 pagesTigerpaw Implementation Guidescboley100% (1)

- Integrated Business ProcessDocument6 pagesIntegrated Business ProcessMuhamad Al GamalNo ratings yet

- Excavation and TrenchingDocument12 pagesExcavation and TrenchingWahyu Endra PurwantoNo ratings yet

- Bill 06242018Document5 pagesBill 06242018Sukrit Ghorai50% (2)

- OpenScape DECT Phone S5 On OpenScape Cordless Enterprise User GuideDocument85 pagesOpenScape DECT Phone S5 On OpenScape Cordless Enterprise User GuideDaniel LuisNo ratings yet

- Procedure System of Site Quality Record ControlDocument5 pagesProcedure System of Site Quality Record ControlImtiyaz AkhtarNo ratings yet

- Railway Ticket Reservation System AbstractDocument2 pagesRailway Ticket Reservation System Abstractb2uty77_593619754100% (1)

- X 105 DL 18 4WD-PDocument1 pageX 105 DL 18 4WD-PRalf MaurerNo ratings yet

- BCOM 314 Final Recommendations Presentation SlidesDocument15 pagesBCOM 314 Final Recommendations Presentation SlidesMadison C BarnettNo ratings yet

- Vehicle Body EngineeringDocument186 pagesVehicle Body EngineeringAthamNadYousuff100% (1)

- Value Engineering Technique and Its Role On Reducing of Manufacturing Costs (Case Study: Giad Industrial Group-Sudan)Document12 pagesValue Engineering Technique and Its Role On Reducing of Manufacturing Costs (Case Study: Giad Industrial Group-Sudan)Ali MohamedNo ratings yet

- WWW Stanhope-Seta Co UkDocument4 pagesWWW Stanhope-Seta Co UkGISELLENo ratings yet

- Construction Basics: Staying Safe On SiteDocument23 pagesConstruction Basics: Staying Safe On Siteshailesh goral100% (1)

- Woodwork Joints 1917Document53 pagesWoodwork Joints 1917cornel_bursucel7099100% (4)

- How Do I Calculate Plastic PartsDocument15 pagesHow Do I Calculate Plastic Partsmohamed sabryNo ratings yet

- SEERS Medical ST3566 ManualDocument24 pagesSEERS Medical ST3566 ManualAlexandra JanicNo ratings yet