Professional Documents

Culture Documents

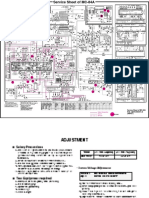

Pattern # Test Pattern Name Purpose: Procedure

Pattern # Test Pattern Name Purpose: Procedure

Uploaded by

Dheeraj Bhandari0 ratings0% found this document useful (0 votes)

6 views1 pageThe document lists 31 test patterns for a printer, including grid patterns to check alignment and slant lines, color registration patterns, tone patterns, and adjustment patterns for inputs, outputs, highlights, and screen rulings. It provides instructions for accessing the test pattern printing function through the user interface diagnostics, entering the pattern number and options, and printing the selected pattern.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document lists 31 test patterns for a printer, including grid patterns to check alignment and slant lines, color registration patterns, tone patterns, and adjustment patterns for inputs, outputs, highlights, and screen rulings. It provides instructions for accessing the test pattern printing function through the user interface diagnostics, entering the pattern number and options, and printing the selected pattern.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pagePattern # Test Pattern Name Purpose: Procedure

Pattern # Test Pattern Name Purpose: Procedure

Uploaded by

Dheeraj BhandariThe document lists 31 test patterns for a printer, including grid patterns to check alignment and slant lines, color registration patterns, tone patterns, and adjustment patterns for inputs, outputs, highlights, and screen rulings. It provides instructions for accessing the test pattern printing function through the user interface diagnostics, entering the pattern number and options, and printing the selected pattern.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Pattern # Test Pattern Name Purpose

1 Grid - 45 degrees To verify slant line reproduction

2 Grid - for adjusting the position to fold To adjust the position to fold

3 Grid (90 degrees) - 102 Alignment measurement

4 Grid (90 degrees) - 204 Alignment measurement

5 Grid (90 degrees) - 208 Alignment measurement

6 Grid (slant) - 101 To verify slant line reproduction

7 Grid (slant) - 102 To verify slant line reproduction

8 Grid (90 degrees) - system registration Registration measurement

9 PH Regi Alignment confirmation

Auto alignment adjustment

10 4 - corners patch CAUTION

Single color print only. Full color print may damage the Fuser.

For measurement using Color RegistrationRegistration Measurement

11 Color Registration

device

12 Banding Banding verification

13 TED/Starvation TED/Statvation verification

14 Auto Tone Correction (for correction) Auto tone correction (for correction)

Auto Tone Correction (for

15 Auto Tone Correction (for confirmation)

confirmation)

16 ProCon Procon, Tone, Defect detection

17 16 Tones Tone, Defect detection

18 ADC check ADC sensor adjustment

Defect Detection

19 Whole Area - Half Tone NOTE:

Adust Cin% for desired haltone density.

20 In - Out adjustment (Primary Color) In - Out adjustment (Primary Color)

In - Out adjustment (Secondary/Triery

21 In - Out adjustment (Secondary/Triery color)

color)

22 In - Out adjustment (Single color) In - Out adjustment (Each color)

23 Highlight adjustment Highlight adjustment, verification of reproduction

24 ATCN24 Tone verification

25 Gradation Tone Jump, verification of reproduction

26 SS direction adjustment (YC) SS direction adjustment (YC)

27 SS direction adjustment (MK) SS direction adjustment (MK)

Tone, Color reproduction

28 IT8 CAUTION

Single color print only. Full color print may damage the Fuser.

29 X’fer Voltage Setup Pattern Second Transfer Output Value, adjustment

30 Custom paper type adjustment Second Transfer Output Value, alignment adjustment

31

Procedure

1. Refer to Table 1 for the pattern you wish to print. NVM location 870-207 specifies which line screen pattern is printed.

2. Enter UI Diagnostics (see Accessing UI Diagnostics).

3. Go to the Maintenance / Diagnostics screen. Select Print Test Pattern.

4. Enter the following information:

3-digit Test Pattern Number from the table

quantity to print

paper supply selection - Save

NOTE:

For the test pattern selected, an incorrect output color (color Vs B/W) selection gives an Invalid Parameter error message.

output color - select the appropriate color for the pattern being printed

density (where applicable)

5. Press the Start button. A status message is displayed after printing. Press the Confirm button.

6. Close the Print Test Pattern screen to return to the Maintenance / Diagnostics screen.

7. Exit Diagnostics. The printer re-boots.

You might also like

- 330 BL ElectricoDocument10 pages330 BL Electricoarmando vara chavezNo ratings yet

- "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer PipeDocument9 pages"Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer PipeRed RedNo ratings yet

- AMS Neve DFC Channel Strip ManualDocument20 pagesAMS Neve DFC Channel Strip Manual55barNo ratings yet

- ECT Inspection Technique: Setup and CalibrationDocument19 pagesECT Inspection Technique: Setup and CalibrationAbhishek DevarajNo ratings yet

- As400 CommandsDocument48 pagesAs400 Commandsprejish100% (1)

- AWM TrianglesDocument196 pagesAWM TrianglesSamwell ZukNo ratings yet

- 3D Metrology and Automation Platform: Revision Date: March 2013Document161 pages3D Metrology and Automation Platform: Revision Date: March 2013Nilton Luis Porras GabrielNo ratings yet

- Colorimetry: Understanding the CIE SystemFrom EverandColorimetry: Understanding the CIE SystemJanos SchandaNo ratings yet

- January 2021 (Partial) Statement: Contact Tel +44 (0) 207 930 4450Document6 pagesJanuary 2021 (Partial) Statement: Contact Tel +44 (0) 207 930 4450RanaNo ratings yet

- R7 230 Beam Moving Head Light ManualDocument11 pagesR7 230 Beam Moving Head Light ManualjuanzzzNo ratings yet

- Kemper Profiler Reference Manual 3.1Document149 pagesKemper Profiler Reference Manual 3.1Wellington Leandro ConstantinoNo ratings yet

- Sansui Sv21e25s m28l g2 Slimline SMDocument25 pagesSansui Sv21e25s m28l g2 Slimline SMPrasanna kumarNo ratings yet

- Diatonic Harmonic Quantiser: Harmonàig User ManualDocument40 pagesDiatonic Harmonic Quantiser: Harmonàig User ManualscribidisshitNo ratings yet

- Features: CG100 Corrosion Thickness GaugesDocument6 pagesFeatures: CG100 Corrosion Thickness GaugesJawwad AhmedNo ratings yet

- Ak37 Chassis Manual Adjustment ProcedureDocument6 pagesAk37 Chassis Manual Adjustment ProcedureneneanaieNo ratings yet

- General Electric Ge2910st Chassis - m34Document34 pagesGeneral Electric Ge2910st Chassis - m34adriancho66No ratings yet

- схема и сервис мануал на английском Toshiba 32HV10G Ver. 1.00Document50 pagesсхема и сервис мануал на английском Toshiba 32HV10G Ver. 1.00Владислав РусинNo ratings yet

- Dth-29ms Service Manual Cm012m (S-M)Document34 pagesDth-29ms Service Manual Cm012m (S-M)carlosgassmann786No ratings yet

- Service Sheet of MC-84A P/N: 3854VA0037A-S (980427) : Video (Composite) Sound ChromaDocument5 pagesService Sheet of MC-84A P/N: 3854VA0037A-S (980427) : Video (Composite) Sound Chromamahmuod mohamadNo ratings yet

- Scientech 2670Document1 pageScientech 2670Tushar PatilNo ratings yet

- Aoc f22sDocument43 pagesAoc f22sJoao Jose Santos NetoNo ratings yet

- Sony ST SB920Document23 pagesSony ST SB920Dave HuntNo ratings yet

- Vestax Vestax: HDR-V8 Operational ManualDocument36 pagesVestax Vestax: HDR-V8 Operational ManualShilloKattos0% (1)

- LG mc-84 Chassis Service-Mode AdjustmentDocument4 pagesLG mc-84 Chassis Service-Mode AdjustmentVadakkevalappilNo ratings yet

- Service Manual: LCD TVDocument97 pagesService Manual: LCD TVAbdulraouf DefnanyNo ratings yet

- MC 84A ChassisDocument19 pagesMC 84A ChassisKapila Gunawardena100% (1)

- Part 2Document9 pagesPart 2M Salman RyanNo ratings yet

- Service Manual Chasis TK 2080Document21 pagesService Manual Chasis TK 2080jotita73No ratings yet

- Haier - BH2404DDocument42 pagesHaier - BH2404DTecnico GenioNo ratings yet

- Anel Overview: Front Panel Overview Display ControlsDocument6 pagesAnel Overview: Front Panel Overview Display ControlsLois Louie Follosco ArcellanaNo ratings yet

- 8893CRCNG7D65Document18 pages8893CRCNG7D65Lakhan SahuNo ratings yet

- Alignment AdjustmentDocument16 pagesAlignment AdjustmentIsaac Ramirez GarciaNo ratings yet

- L42H961 Spec SheetDocument1 pageL42H961 Spec SheetOlga SotoNo ratings yet

- 05 Dial GaugesDocument103 pages05 Dial GaugesZélia OrnelasNo ratings yet

- Haier HL42BG-B LCD TV SM PDFDocument43 pagesHaier HL42BG-B LCD TV SM PDFPedro BancayanNo ratings yet

- RCA E13344 Chasis TX808H - DiagramaDocument7 pagesRCA E13344 Chasis TX808H - DiagramaVictor Antonio Rojas RojasNo ratings yet

- 4 IN 1 Coaxial Control Manual - ENDocument2 pages4 IN 1 Coaxial Control Manual - ENBagwisNo ratings yet

- Ap-300 enDocument2 pagesAp-300 enD FrNo ratings yet

- Printnet: Quality Management & PressmanagementDocument36 pagesPrintnet: Quality Management & Pressmanagementapi-19584611No ratings yet

- HD Monitor Calibration - White Balance and Color Bars: Color Bar Test SignalsDocument17 pagesHD Monitor Calibration - White Balance and Color Bars: Color Bar Test SignalsAdlon BarcellosNo ratings yet

- PAL Encoder and DecoderDocument32 pagesPAL Encoder and Decodertejaswini0% (1)

- Slate Digital Infinity EQ - User GuideDocument38 pagesSlate Digital Infinity EQ - User GuideHo Cheung LaiNo ratings yet

- Rs-232 Protocol Commands: Recordex SimplicitytouchDocument5 pagesRs-232 Protocol Commands: Recordex SimplicitytouchLapfu NgNo ratings yet

- Elp ManualDocument15 pagesElp ManualWilliamBradley PittNo ratings yet

- 21pt5438 94 Dfu EngDocument26 pages21pt5438 94 Dfu EngQuick SolutionNo ratings yet

- Tedelex Ec2109 Chassis m5 SMDocument66 pagesTedelex Ec2109 Chassis m5 SMAndrei Constantin0% (1)

- Manual Harman-Kardon AVR 235Document44 pagesManual Harman-Kardon AVR 235Rafa NacherNo ratings yet

- FP93GX C501 Service Manual 99.L2E72.XBC 99.L2E72.XBC-C501-001 99.L2E72.001 NA Q9T5Document48 pagesFP93GX C501 Service Manual 99.L2E72.XBC 99.L2E72.XBC-C501-001 99.L2E72.001 NA Q9T5Anton PopaNo ratings yet

- RCA Color TV Service Handbook Vol 2 1968Document178 pagesRCA Color TV Service Handbook Vol 2 1968Norgen QuinteroNo ratings yet

- Hitachi L42a403 LCD TV Service ManualDocument84 pagesHitachi L42a403 LCD TV Service ManualIon IoneteNo ratings yet

- PAL Encoder and DecoderDocument22 pagesPAL Encoder and Decoderjutex0% (1)

- BEKO L6B LCD Service ManualDocument59 pagesBEKO L6B LCD Service ManualAdelina Elena EhimovNo ratings yet

- 752BD/CXU Blu-Ray Disc Player RS-232 Control ProtocolDocument14 pages752BD/CXU Blu-Ray Disc Player RS-232 Control ProtocolJustin WilliamsNo ratings yet

- Mainstage Effects User GuideDocument337 pagesMainstage Effects User GuidePaul D. PatronNo ratings yet

- Service Manual VR01BDocument43 pagesService Manual VR01BLindomar ChavesNo ratings yet

- Harman Kardon Avr 255, Avr 355 Receiver User ManualDocument58 pagesHarman Kardon Avr 255, Avr 355 Receiver User ManualDavid NicolasNo ratings yet

- Ervice Manual: MonitoareDocument55 pagesErvice Manual: MonitoarePercy BernuyNo ratings yet

- Model Vm-5N Ramp Differential Expansion Monitor Page 1 of 2Document2 pagesModel Vm-5N Ramp Differential Expansion Monitor Page 1 of 2Rendy PreviantoNo ratings yet

- Harmony Engine User GuideDocument25 pagesHarmony Engine User Guide릴황No ratings yet

- Auto Tune VocodistDocument42 pagesAuto Tune VocodistAll 99No ratings yet

- Ajuste Del CB775CDocument2 pagesAjuste Del CB775CAdalbertoRoqueNo ratings yet

- Cambridge-Audio 540r Ver-2.0 SM PDFDocument41 pagesCambridge-Audio 540r Ver-2.0 SM PDFTomasz MinsterNo ratings yet

- ModeDocument1 pageModeferozahmedkhanNo ratings yet

- Partisipasi Masyarakat Dalam Pembangunan Di Kota BDocument17 pagesPartisipasi Masyarakat Dalam Pembangunan Di Kota BSayyid AliNo ratings yet

- Sample Test: Page 1 - 4Document4 pagesSample Test: Page 1 - 4Nguyễn Quốc Phương UyênNo ratings yet

- Tender Document: M.P. Industrial Development Corporation LTD., Regional Office, IndoreDocument69 pagesTender Document: M.P. Industrial Development Corporation LTD., Regional Office, IndoreSoniyaSinghNo ratings yet

- Vitalina Malakar: ObjectiveDocument2 pagesVitalina Malakar: Objectiveapi-560642428No ratings yet

- Lenntech: 18 Frame Block-Style Stainless Steel Plunger PumpDocument4 pagesLenntech: 18 Frame Block-Style Stainless Steel Plunger Pumpdiv02No ratings yet

- Radio Broadcasting Research PaperDocument5 pagesRadio Broadcasting Research Papergvzph2vh100% (1)

- International Conference On Automation, Control Engineering & Computer ScienceDocument107 pagesInternational Conference On Automation, Control Engineering & Computer ScienceIPCO AssistanteNo ratings yet

- Cube-A User Manual ENG V4.2Document174 pagesCube-A User Manual ENG V4.2Cristina PadrónNo ratings yet

- Community Radio Research PaperDocument4 pagesCommunity Radio Research Paperznsgjgvnd100% (1)

- EngineDocument4 pagesEnginesacomani_123No ratings yet

- Msrit BrochureDocument72 pagesMsrit BrochurerkNo ratings yet

- (November-2019) Braindump2go New PCNSE VCE Dumps Free ShareDocument6 pages(November-2019) Braindump2go New PCNSE VCE Dumps Free Shareshinde_jayesh2005No ratings yet

- Canon Duty CycleDocument4 pagesCanon Duty CycleQetty BerishaNo ratings yet

- Cse III Logic Design 10cs33 Notes PDFDocument80 pagesCse III Logic Design 10cs33 Notes PDFtrupti.kodinariya98100% (1)

- 04 150 211 DTR.L Mat Fa10Document1 page04 150 211 DTR.L Mat Fa10ClarkFedele27No ratings yet

- Excel Dashboard WidgetsDocument50 pagesExcel Dashboard WidgetslewgneNo ratings yet

- SDG - Auto Cad Day 3Document19 pagesSDG - Auto Cad Day 3Kadu Than NaingNo ratings yet

- Covid Impact On IT and BPM Sector PPT FinalDocument10 pagesCovid Impact On IT and BPM Sector PPT FinalMaheshNo ratings yet

- "Mahindra Aerostructure PVT Limited": Internship Report atDocument5 pages"Mahindra Aerostructure PVT Limited": Internship Report atUday GowdaNo ratings yet

- Technische Manual CSRN XHE2 FFA 12.2 44.4Document52 pagesTechnische Manual CSRN XHE2 FFA 12.2 44.4SolarNo ratings yet

- BeltsDocument89 pagesBeltszul100% (2)

- Set 1 QuestionDocument8 pagesSet 1 Question2023485572No ratings yet

- AndFound Case StudyDocument2 pagesAndFound Case StudyEden De GuzmanNo ratings yet

- Rci 4100 System Configuration SheetDocument7 pagesRci 4100 System Configuration SheetEpuAmerNo ratings yet