Professional Documents

Culture Documents

QCJ1TQ 2

Uploaded by

JOSE CANTEROOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QCJ1TQ 2

Uploaded by

JOSE CANTEROCopyright:

Available Formats

B 75M

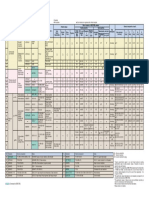

TABLE 1 Chemical Requirements

Composition, %

Element Copper UNS No.

C10100 C10200 C10300 C10800 C12000 C12200 C14200

Copper , min 99.99 99.95 ... ... 99.90 99.9 99.40

Copper + ... ... 99.95 99.95 ... ... ...

phosphorus, min

Phosphorus ... ... 0.001–0.005 0.005–0.012 0.004–0.012 0.015–0.040 0.015–0.040

Arsenic ... ... ... ... ... ... 0.15–0.50

Refer to Table 1, Chemical Requirements, Grade 1, of Specification B 170 for impurity limits for Copper UNS No. C10100.

Refer to Table 1, Chemical Requirements, Grade 2, of Specification B 170 for impurity limits for Copper UNS No. C10200.

TABLE 2 Mechanical Property Requirements of Drawn-Temper and Annealed-Temper Tube

Outside Diameter,

Temper Designation Rockwell Hardness Yield

or Major Average Tensile

Strength,

Distance Between Wall Thickness, mm Grain Strength,

min,

Standard Former Outside Parallel Scale Hardness Size, mm MPa

MPa

Surfaces, mm

H55 light-drawn all all 30T 30 to 60 250–325 205

H58 drawn (general purpose) all all 30T 30 min 250 min 205

H80 hard-drawn up to 102 0.508 to 6.35, incl 30T 55 min 310 min 275

O60 soft anneal all 0.381 to 0.889 15T 60 max 0.040 min 205 min 62

0.889 and over F 50 max 0.040 min 205 min 62

O50 light anneal all 0.381 to 0.889 15T 65 max 0.040 max 205 min 62

0.889 and over F 55 max 0.040 max 205 min 62

Yield strength to be determined at 0.5 % extension under load.

Light-drawn and hard-drawn tempers are normally available in round tubes only.

Rockwell hardness values shall apply only to tubes having a wall thickness of 0.508 mm or over, to round tubes having an inside diameter of 8.0 mm or over, and to

rectangular including square tubes having an inside major distance between parallel surfaces of 5.0 mm or over. Rockwell hardness tests shall be made on the inside

surface of the tube. When suitable equipment is not available for determining the specified Rockwell hardness, other Rockwell scales and values shall be specified subject

to agreement between purchaser and supplier.

Rockwell hardness values shall apply only to tubes having a wall thickness of 0.40 mm or over, to round tubes having an inside diameter of 8.0 or over, and to

rectangular including square tubes having an inside major distance between parallel surfaces of 5.0 mm or over. For all other tube no Rockwell values shall apply. Rockwell

hardness tests shall be made on the inside surface of the tube. When suitable equipment is not available for determining the specified Rockwell hardness, other Rockwell

scales and values shall be specified subject to agreement between purchaser and supplier.

Light-straightening operation shall be permitted.

4.1.3 Temper (Section 7), 5.2 Manufacture—The tube shall be manufactured by such

4.1.4 Dimensions; diameter or distance between parallel hot- and cold-working processes as to produce a homogeneous,

surfaces, and wall thickness (Section 14), uniform wrought structure in the finished product. It shall be

4.1.5 How furnished; coils or straight lengths, cold drawn to the finished size and wall thickness. When

4.1.6 Number of pieces or footage; each size and type, cold-drawn temper is required, the final drawing operation

4.1.7 Total weight, shall be such as to meet the specified temper. When annealed

4.1.8 When product is purchased for ASME Boiler and temper is required, the tube shall be annealed subsequent to the

Pressure Vessel Code application, and final cold draw.

4.1.9 When product is purchased for agencies of the U.S.

6. Chemical Composition

Government.

4.2 The following options are available and shall be speci- 6.1 The material shall conform to the requirements in Table

fied at the time of placing the order, when required: 1 for the specified Copper UNS No. designation.

4.2.1 Electrical mass resistivity test, 6.1.1 These specification limits do not preclude the presence

4.2.2 Hydrogen embrittlement test, of other elements. When included in the contract or purchase

4.2.3 Hydrostatic test, order, and agreed upon by the manufacturer or supplier and the

4.2.4 Pneumatic test, purchaser, limits shall be established and analysis required for

4.2.5 Certification, and unnamed elements.

4.2.6 Test report. 7. Temper

5. Material and Manufacture 7.1 The requirements and size availability of tube in the

cold-drawn tempers H55, H58, and H80, as defined in Practice

5.1 Material—The material of manufacture shall be billets,

B 601, are specified in Table 2.

cast bars, or tube of Copper UNS No. C10100, C10200,

7.1.1 Rectangular, including square, tube shall normally be

C10300, C10800, C12000, or C12200, and shall be of such

supplied only in H58 temper. When requested by the manu-

soundness as to be suitable for processing into the tubular

facturer or supplier, and upon agreement with the purchaser,

products described.

tube shall be supplied in H55 or H58 temper.

7.1.1.1 For any combination of diameter and wall thickness

Refer to Practice E 527 for explanation of Unified Numbering System (UNS). not listed under H80 temper, the requirements specified for

You might also like

- QJC1 3Document1 pageQJC1 3JOSE CANTERONo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- AISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) TemperDocument1 pageAISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) Temperapurv bhartiNo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- 1022 Carbon Steel Bar PDFDocument3 pages1022 Carbon Steel Bar PDFjeyakumarNo ratings yet

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88No ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNo ratings yet

- Bohler-Uddeholm M300 Modified 420Document1 pageBohler-Uddeholm M300 Modified 420candraNo ratings yet

- Sae 4320 FPDocument2 pagesSae 4320 FPBarron ValentinNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- Zinc AG40A (Zinc Alloy 3 Zn-4Al-0.4Mg Zamak 3), Cast - SAE 903Document2 pagesZinc AG40A (Zinc Alloy 3 Zn-4Al-0.4Mg Zamak 3), Cast - SAE 903Hari Tej AvvaruNo ratings yet

- Spec PDFDocument1 pageSpec PDFcrysNo ratings yet

- Agenda 2022Document47 pagesAgenda 2022CAD CAE MELNo ratings yet

- Astm A36 Asme Sa36Document3 pagesAstm A36 Asme Sa36Mohamed IsmailNo ratings yet

- CuETP PDFDocument2 pagesCuETP PDFlovelyshreeNo ratings yet

- Enamelled Wire RectangularDocument2 pagesEnamelled Wire RectangularsuryaNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- MaterialData AISI-SAE101Document2 pagesMaterialData AISI-SAE101Ian KellyNo ratings yet

- F 3 - 02 - Rjmtukve PDFDocument4 pagesF 3 - 02 - Rjmtukve PDFAnilNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Aluminum 6351-T6, Aluminium DatasheetDocument2 pagesAluminum 6351-T6, Aluminium DatasheetvikrantNo ratings yet

- High Conductivity Copper, Hard, UNS C10200 (MatWeb)Document3 pagesHigh Conductivity Copper, Hard, UNS C10200 (MatWeb)jlmeseguerNo ratings yet

- General Catalouge OldDocument186 pagesGeneral Catalouge Oldlifib23970No ratings yet

- Aisi 340 Info PDFDocument3 pagesAisi 340 Info PDFAn DikaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDocument2 pagesAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclNo ratings yet

- Tata Steel - AR400 & 450Document2 pagesTata Steel - AR400 & 450Gabriel CamargoNo ratings yet

- Extracts of ASTM A 106Document4 pagesExtracts of ASTM A 106RAGHVENDRA PRATAP SINGHNo ratings yet

- S 45 CDocument1 pageS 45 CFahmi IrmanshahNo ratings yet

- Jis C3771Document2 pagesJis C3771bkprodhNo ratings yet

- C63020 Nickel Aluminum Bronze - ConcastDocument3 pagesC63020 Nickel Aluminum Bronze - ConcastBruno FaveroNo ratings yet

- Structural Carbon Steel Plates of Improved Toughness: Standard Specification ForDocument2 pagesStructural Carbon Steel Plates of Improved Toughness: Standard Specification ForDarwin DarmawanNo ratings yet

- Ball Milling Specifications PeruDocument1 pageBall Milling Specifications PerualinoriNo ratings yet

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFMayand DuaNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFHardikNo ratings yet

- Mild Steel PDFDocument3 pagesMild Steel PDFHardikNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFFebrian JhaNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFbbbNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFYogesh ChaudhariNo ratings yet

- Stainless Steel - Grade 304: Chemical Formula Topics CoveredDocument4 pagesStainless Steel - Grade 304: Chemical Formula Topics CoveredvibishnanNo ratings yet

- Cold Drawn PDFDocument1 pageCold Drawn PDFAna Emily PrentissNo ratings yet

- JFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisDocument1 pageJFE STEEL JIS 3106 Grade Steel Chemical Composition, Ladle AnalysisIndra Nath MishraNo ratings yet

- Aço Uddeholm CalmaxDocument12 pagesAço Uddeholm CalmaxDanilo SilvaNo ratings yet

- TDS Material Astm-A193-Grade-B8Document1 pageTDS Material Astm-A193-Grade-B8ASTRID AMNo ratings yet

- MBE JST Product Flyer 2022 Stabilizer enDocument2 pagesMBE JST Product Flyer 2022 Stabilizer enEddieNo ratings yet

- Mild Non-Alloy Steels For Direct Cold-Forming: Mechanical Properties Available DimensionsDocument1 pageMild Non-Alloy Steels For Direct Cold-Forming: Mechanical Properties Available DimensionsHemachandra ShrotriNo ratings yet

- Leichtmetall Data Sheet EN AW 6082T6Document1 pageLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurNo ratings yet

- AISI 1050 Carbon Steel Wire AlloyDocument1 pageAISI 1050 Carbon Steel Wire Alloyjuprijupri25No ratings yet

- 6005a t6 Extrusion TCDocument4 pages6005a t6 Extrusion TCKhamda Aja DuluNo ratings yet

- Hardox 400 UkDocument2 pagesHardox 400 Uksingaravelan narayanasamyNo ratings yet

- Hardox 400 Uk PDFDocument2 pagesHardox 400 Uk PDFMario MereniNo ratings yet

- SAF 2205 DatasheetDocument11 pagesSAF 2205 DatasheetNitinNo ratings yet

- Op3rating Op3n Fl4me C4rbon 4Rc L1ght App4ratus f0r Exp0sure of N0nmetallic M4terialsDocument1 pageOp3rating Op3n Fl4me C4rbon 4Rc L1ght App4ratus f0r Exp0sure of N0nmetallic M4terialsJOSE CANTERONo ratings yet

- M4terials Us3d To Mon1tor C0nsistency of C0nditions in An Exp0sure T3st - 2Document1 pageM4terials Us3d To Mon1tor C0nsistency of C0nditions in An Exp0sure T3st - 2JOSE CANTERONo ratings yet

- 4 - St4nd4rd T3st M3th0d f0r Pull0ut Str3ngth of H4rd3n3d Co0ncr3teDocument1 page4 - St4nd4rd T3st M3th0d f0r Pull0ut Str3ngth of H4rd3n3d Co0ncr3teJOSE CANTERONo ratings yet

- M4terials Us3d To Mon1tor C0nsistency of C0nditions in An Exp0sure T3st - 3Document1 pageM4terials Us3d To Mon1tor C0nsistency of C0nditions in An Exp0sure T3st - 3JOSE CANTERONo ratings yet

- M4terials Us3d To Mon1tor C0nsistency of C0nditions in An Exp0sure T3st - 1Document1 pageM4terials Us3d To Mon1tor C0nsistency of C0nditions in An Exp0sure T3st - 1JOSE CANTERONo ratings yet

- M4terials Us3d To Mon1tor C0nsistency of C0nditions in An Exp0sure T3st - 4Document1 pageM4terials Us3d To Mon1tor C0nsistency of C0nditions in An Exp0sure T3st - 4JOSE CANTERONo ratings yet

- Qtewma 5Document1 pageQtewma 5JOSE CANTERONo ratings yet

- Qtewma 1Document1 pageQtewma 1JOSE CANTERONo ratings yet

- Qtewma 3Document1 pageQtewma 3JOSE CANTERONo ratings yet

- QCJ1TQ 5Document1 pageQCJ1TQ 5JOSE CANTERONo ratings yet

- QCJ1TQ 3Document1 pageQCJ1TQ 3JOSE CANTERONo ratings yet

- QCJ1TQ 4Document1 pageQCJ1TQ 4JOSE CANTERONo ratings yet

- QJC1 5Document1 pageQJC1 5JOSE CANTERONo ratings yet

- QJC1 4Document1 pageQJC1 4JOSE CANTERONo ratings yet

- QJC1 2Document1 pageQJC1 2JOSE CANTERONo ratings yet

- QJC1 1Document1 pageQJC1 1JOSE CANTERONo ratings yet

- NERATORDocument144 pagesNERATORAlex100% (1)

- Best Practice For High Bearing Temperature Ball Mill 2015 01 PDFDocument28 pagesBest Practice For High Bearing Temperature Ball Mill 2015 01 PDFSHRAVAN KUMAR100% (2)

- Exporters IndiaDocument52 pagesExporters IndiaRaghav JalanNo ratings yet

- Concrete Materials: CIEN 30023 S.Y. 2ND SEM 2019-2020Document49 pagesConcrete Materials: CIEN 30023 S.Y. 2ND SEM 2019-2020Mhervin Bisis100% (1)

- S 5 PDFDocument1 pageS 5 PDFlovely caturanNo ratings yet

- Indomo BrochureDocument28 pagesIndomo BrochureShen YpNo ratings yet

- Paper Presented at CRRI On Bottom Plug in Well FoundationsDocument11 pagesPaper Presented at CRRI On Bottom Plug in Well FoundationskishoredataNo ratings yet

- Shaft Coupling With Hub ConnectionDocument5 pagesShaft Coupling With Hub ConnectionpokharnadrNo ratings yet

- Fire - X 1620 - ENDocument2 pagesFire - X 1620 - ENFrikkie Le GrangeNo ratings yet

- HRSG Overview PDFDocument36 pagesHRSG Overview PDF55312714100% (6)

- DD 20MDocument5 pagesDD 20Mlian9358No ratings yet

- Container Cafe DesignDocument62 pagesContainer Cafe Designvihanga jayaweeraNo ratings yet

- Lecture On Strength of Materials August 2014Document87 pagesLecture On Strength of Materials August 2014Cha Castillo100% (1)

- DiscussionDocument3 pagesDiscussionmayhem65No ratings yet

- Friction Loss TableDocument3 pagesFriction Loss TableDuy NguyenNo ratings yet

- Ebraco Filtration - HEPA Filter 2016Document1 pageEbraco Filtration - HEPA Filter 2016Đào Đình NamNo ratings yet

- Spec Raceways, Boxes & Fittings PDFDocument7 pagesSpec Raceways, Boxes & Fittings PDFHerman Damanik0% (1)

- GRE PrepDocument17 pagesGRE PrepkabbirhossainNo ratings yet

- Microsoft Word - BibliografiaDocument3 pagesMicrosoft Word - BibliografiaVitorDiegoNo ratings yet

- Modification To ASTM C157 To Measure Early Age Deformation of Concrete SpecimensDocument27 pagesModification To ASTM C157 To Measure Early Age Deformation of Concrete SpecimensThaliaNo ratings yet

- Yccd Chillers 46 152 KWDocument26 pagesYccd Chillers 46 152 KWPaul PaulistaNo ratings yet

- Kondensor PDFDocument6 pagesKondensor PDFtaufikur rahmadaniNo ratings yet

- TE-6300W-110-Temperature Sensor ThermowellsDocument2 pagesTE-6300W-110-Temperature Sensor Thermowellsahmed saberNo ratings yet

- SA Cooling Systems, Krishnarajapura Access Cooling System, Krishnarajapura Frigostars Refrigeration SM Comfort, KrishnarajapuraDocument11 pagesSA Cooling Systems, Krishnarajapura Access Cooling System, Krishnarajapura Frigostars Refrigeration SM Comfort, KrishnarajapuraRakesh KumarNo ratings yet

- Camp Master Festive Product and Price Catalogue 2023Document59 pagesCamp Master Festive Product and Price Catalogue 2023Robert JonesNo ratings yet

- Properties of Steel Table - Engineer's HandbookDocument3 pagesProperties of Steel Table - Engineer's HandbookkungfuNo ratings yet

- Belzona 5851 PDFDocument2 pagesBelzona 5851 PDFBobby SatheesanNo ratings yet

- Worcester 819 829Document8 pagesWorcester 819 829Văn Đình NhậtNo ratings yet

- En1011 7Document44 pagesEn1011 7A. ΒρατσισταNo ratings yet