Professional Documents

Culture Documents

Check Cant Slab PDF

Uploaded by

peter wongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check Cant Slab PDF

Uploaded by

peter wongCopyright:

Available Formats

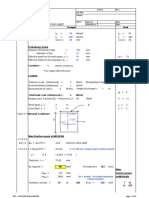

Page 1

Date: 22-Apr-23

Time: 3:39 pm

w= 24.5x0.35x1.4+2x1.6=15.2kN/m

Project: Check Cantilever Slab V=15.2x1.2=18.2kN

Member: M=15.2x1.2^2/2 = 10.9kN

1. Design Data:

Span length, L = 1.2 m

Width, b = 1000 mm Eff. depth, d = 314 mm (Sagging)

Depth, h = 350 mm d' = 36 mm

Cover, c = 30 mm

fcu = 30 MPa Eff. depth, d = 314 mm (Hogging)

fy = 460 MPa d' = 36 mm

fyv = 460 MPa

2. Ultimate Design Load

Bending Moment (Sagging) Mx = 0.0 kNm Bending Moment (Hogging) Mx = 11.0 kNm

Shear Force Vx = 19.0 kN Torsional Moment T = 0.0 kNm

3. Design Resistance Moment of Beam ….. Clause 6.1.2.4

Sagging moment

K = M / bd2 fcu = 0.000 K' = 0.156

< K' for fcu<=45N/mm2

Therefore, Compression Reinforcement is not Required

z = d { 0.5 + √(0.25-K/0.9)}

= 314 mm but not greater than 0.95d = 298 mm

z = 298 mm

(K-K')fcubcd2 Minimum Steel Area = 0%

As' = = 0 mm2

0.87fy(d-d') = 0 mm2

M Minimum Steel Area = 0.13%

As =

0.87fyz

+ As' = 0 mm2

= 455 mm2

Hogging moment

K = M / bd2 fcu = 0.004 K' = 0.156

< K' for fcu<=45N/mm2

Therefore, Compression Reinforcement is not Required

z = d { 0.5 + √(0.25-K/0.9)}

= 313 mm but not greater than 0.95d = 298 mm

z = 298 mm

(K-K')fcubcd2 Minimum Steel Area = 0%

As' = = 0 mm2

0.87fy(d-d') = 0 mm2

M Minimum Steel Area = 0.13%

As =

0.87fyz

+ As' = 92 mm2

= 455 mm2

Total Top Bar Required, Atop = 455 mm2

Total Bottom Bar Required, Abot = 455 mm2

Provide Top Bar 7 T 12 + 0 T 0 As, provided = 792 mm² O.K.

( 0.23 %)

Provide Bottom Bar 7 T 12 + 0 T 0 As, provided = 792 mm² O.K.

( 0.23 %)

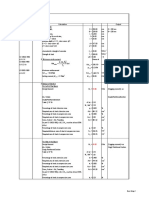

Page 2

Date: 22-Apr-23

Time: 3:39 pm

Project: Check Cantilever Slab

Member:

4. Design Resistance Shear of Beam (Major Axis) ….. Clause 6.1.2.5

2 2

Shear Stress, v = V / bv d = 0.06 N/mm < 0.8√fcu = 4.4 N/mm and 7.0 N/mm2 O.K.

Shear Resistance of Concrete, vc = 0.45 N/mm2 ….. Table 6.3

Design Shear Resist. for Min. Links, vr = 0.40 N/mm2 ….. Table 6.2

v < 0.5vc

Therefore, No Links is required.

0

Required Ratio for Links, Asv / sv = = 0.00 mm2/mm

0.87 fyv

Provide Shear Reinforcement T0 - 2 legs - 200 Asv / sv, provided = 0.00 mm2/mm O.K.

5. Design Reinforcement for Torsion ….. Clause 6.3.3

Direct Shear Stress, v = 0.06 N/mm2

2T ….. eq. 6.65

Torsion Shear Stress, vt = = 0.000 N/mm2

hmin2 ( hmax - hmin/3)

Minimum Torsion Shear Stress, vt min = 0.067√fcu but not more than 0.6 N/mm2 = 0.37 N/mm2 ….. Table 6.17

Maximum Combined Shear Stress, vtu = 0.8√fcu but not more than 7.0 N/mm2 = 4.38 N/mm2

Smaller c/c Dimension of Link, x1 = 290 mm

Larger c/c Dimension of Link, y1 = 940 mm

( v + vt ) < vtu & y1 > 550 mm , vt < vtu y1 / 550 O.K.

Since, v < vc + vr & vt < vt min ….. Table 6.18

Therefore, Minimum shear reinforcement; no torsion reinforcement

Additional Reinforcement for Torsion

Asv T ….. eq. 6.67

= = 0.00 mm2/mm

sv 0.8 x1 y1 ( 0.87 fyv )

Asv fyv ( x1 +y1 ) ….. eq. 6.68

As = = 0 mm2

sv fy

Provide Additional Torsion Links T0 - 2 legs - 150 Asv / sv, provided = 0.00 mm2/mm O.K.

Total Required Longitudinal Steel Area = 910 mm²

Total Provided Longitudinal Steel Area = 1583 mm² > 910 mm² O.K.

6. Checking for Deflection (Span to Effective Depth Ratio) ….. Clause 7.3.4

Support Condition is Cantilever

Basic Span to Effective depth Ratio, Br = 7 ….. Table 7.3

2 fy Ast,req ….. Table 7.4

Design Service Stress in Tension Steel, fs = = 0 N/mm2

3 Ast,prov b b

( 477 - fs )

M. Factor for Tension Steel, Ft = + 0.55 but not greater than 2.0

120 ( 0.9 + M / bd2)

= 2.00

100 A's,prov / bd

M. Factor for Compression Steel, Fc = +1 but not greater than 1.5

3 + 100 A's,prov / bd

= 1.08

Allowable Span to Effective depth Ratio = Br Ft Fc = 15.09

Actual Span to Effective depth Ratio = L / d = 3.82 < 15.09 O.K.

You might also like

- Beam DesignDocument9 pagesBeam Designujaval shah100% (1)

- BS 8110 Data Given: Calculation SheetDocument10 pagesBS 8110 Data Given: Calculation SheetLee See VoonNo ratings yet

- New SlabDocument1 pageNew SlabParthiban ArivazhaganNo ratings yet

- 2018 DSE ECON Paper 2 PDFDocument23 pages2018 DSE ECON Paper 2 PDFpeter wongNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- Slab-Design-2 Way - ISDocument5 pagesSlab-Design-2 Way - ISKamran AliNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Design of Beam BS 8110 (May 2019)Document3 pagesDesign of Beam BS 8110 (May 2019)thanigai veluNo ratings yet

- WALL DESIGN-400mm THK.Document2 pagesWALL DESIGN-400mm THK.voilNo ratings yet

- DSEpp - Money and BankingDocument11 pagesDSEpp - Money and Bankingpeter wongNo ratings yet

- PROJECT:punggol CC SUBJECT - Major AxisDocument36 pagesPROJECT:punggol CC SUBJECT - Major Axisshamen amarasekaraNo ratings yet

- Beam DesignDocument9 pagesBeam Designمحمد شاويNo ratings yet

- Design CalculationsDocument8 pagesDesign CalculationsJIBEESH01No ratings yet

- Transfer BeamDocument150 pagesTransfer Beamshamen amarasekaraNo ratings yet

- Calculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK DataDocument3 pagesCalculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK Dataasif billalNo ratings yet

- 2018 DSE ECON Paper 2 Answers PDFDocument13 pages2018 DSE ECON Paper 2 Answers PDFpeter wong100% (1)

- DSEpp - Market and PriceDocument21 pagesDSEpp - Market and Pricepeter wongNo ratings yet

- Isolated Footing BumaatDocument6 pagesIsolated Footing BumaatJaphet BumaatNo ratings yet

- 4.substructure PH 2Document16 pages4.substructure PH 2snehaNo ratings yet

- Quality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodeDocument7 pagesQuality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodejunarkoNo ratings yet

- Undr DR CalcDocument292 pagesUndr DR Calcpeter wongNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Title: Slab Design PDI Block-Hetauda Input ParametersDocument13 pagesTitle: Slab Design PDI Block-Hetauda Input ParametersAnimras TamrakarNo ratings yet

- FFB2Document8 pagesFFB2prajjwal patidarNo ratings yet

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- Slab Design 2 Way IsDocument5 pagesSlab Design 2 Way IsPirpasha UjedeNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- Design of Double Pilecap: Design For Axial Load and MomentDocument16 pagesDesign of Double Pilecap: Design For Axial Load and MomentMidhun BabuNo ratings yet

- RCC Slab DesignDocument4 pagesRCC Slab DesignarghyadeepNo ratings yet

- Isolated Footing - MomentsDocument1 pageIsolated Footing - MomentsKaushlendra KumarNo ratings yet

- Design of Beam: Effective Depth, D D' D'/D Mu/bd2 Me1 Mu, LimDocument8 pagesDesign of Beam: Effective Depth, D D' D'/D Mu/bd2 Me1 Mu, LimVhârÆt Ķħâptäđi KhàdkâNo ratings yet

- Desingn of U.G TANK WALLDocument5 pagesDesingn of U.G TANK WALLnileshNo ratings yet

- Grade Beam (GB) For All Axis: M F F M F FDocument2 pagesGrade Beam (GB) For All Axis: M F F M F FMustefa Mohammed AdemNo ratings yet

- Plinth Floor Beams - REvisedDocument23 pagesPlinth Floor Beams - REvisedask.kulkarni KulkarniNo ratings yet

- Grade Beam (GB) For All Axis: M F F M F FDocument2 pagesGrade Beam (GB) For All Axis: M F F M F Fpawar praveenNo ratings yet

- Y CK Min: Beam Design-1Document4 pagesY CK Min: Beam Design-1PraYush RajbhandariNo ratings yet

- Slab DesignDocument9 pagesSlab Designarif_rubinNo ratings yet

- Return WallDocument4 pagesReturn WallAshish GNo ratings yet

- Worksheet: Reinforced Concrete Design Calculation By: Projek: Check: CCYDocument2 pagesWorksheet: Reinforced Concrete Design Calculation By: Projek: Check: CCYAinil SharirNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation DesignNaison StanleyNo ratings yet

- Beam Design SheetDocument10 pagesBeam Design SheetmudithaNo ratings yet

- 5.7 Pile CapDocument2 pages5.7 Pile CapPhilip ChanNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- Design Calculation of Typical Cantilever RC Slab 1m Span 125mm THKDocument14 pagesDesign Calculation of Typical Cantilever RC Slab 1m Span 125mm THKAgus CnsNo ratings yet

- GHBJBJNMDocument6 pagesGHBJBJNMMiguel Prabowo Dos SantosNo ratings yet

- Design of Motor Floor Slab: 1. Calculation of Loads:: Ref: IS 456:2000, Table - 26, Four Edges DiscontinuousDocument4 pagesDesign of Motor Floor Slab: 1. Calculation of Loads:: Ref: IS 456:2000, Table - 26, Four Edges Discontinuousp_ignatiusNo ratings yet

- Design of Cantilever Slab: Change 180 167.4667Document2 pagesDesign of Cantilever Slab: Change 180 167.4667madasamya20No ratings yet

- Flat Slab Design (SK)Document5 pagesFlat Slab Design (SK)Mohd Said Mohd ZakariaNo ratings yet

- Rectangular Beam Torsion LinkDocument3 pagesRectangular Beam Torsion LinkTan Choon LengNo ratings yet

- Doubly Reinforced BeamDocument3 pagesDoubly Reinforced BeamriverieNo ratings yet

- Deflection Due To Creep and ShrinkageDocument3 pagesDeflection Due To Creep and ShrinkagekarthiNo ratings yet

- Beam DesignDocument4 pagesBeam DesignPrayush RajbhandariNo ratings yet

- Project:-Date: - Description: - By:-: Dimension MaterialDocument2 pagesProject:-Date: - Description: - By:-: Dimension MaterialMustefa Mohammed AdemNo ratings yet

- Design of Slab SDocument25 pagesDesign of Slab Sapi-19754583No ratings yet

- Plinth Beam Design For Pb1: Safe Extra TopDocument2 pagesPlinth Beam Design For Pb1: Safe Extra TopNAYAN RANPURANo ratings yet

- CSE519 - Beam Design - 2 - TrialDocument2 pagesCSE519 - Beam Design - 2 - TrialTik HonNo ratings yet

- Working StressDocument17 pagesWorking StressSandy KavitakeNo ratings yet

- Beam DesignDocument4 pagesBeam DesignPraYush RajbhandariNo ratings yet

- Example 6.1 - Slab-Simply Supported (One-Way) PDFDocument5 pagesExample 6.1 - Slab-Simply Supported (One-Way) PDFnur100% (1)

- SLAB DESIGN-300mm THK. CENTER SLABDocument2 pagesSLAB DESIGN-300mm THK. CENTER SLABvoilNo ratings yet

- Beam DesignDocument54 pagesBeam DesignLagnajit DasNo ratings yet

- 6 R Design 13.88 Section A-ADocument4 pages6 R Design 13.88 Section A-AsudipNo ratings yet

- 7 R Design 13.88 Section B-BDocument4 pages7 R Design 13.88 Section B-BsudipNo ratings yet

- Armare Radierxls PDF FreeDocument5 pagesArmare Radierxls PDF FreeBarbu-Sebastian SofronNo ratings yet

- Slab 1Document20 pagesSlab 1Bikesh ManandharNo ratings yet

- UntitledDocument6 pagesUntitledpeter wongNo ratings yet

- 心淡Document5 pages心淡peter wongNo ratings yet

- DSEpp - Competition and Market StructureDocument4 pagesDSEpp - Competition and Market Structurepeter wongNo ratings yet

- 1990 Bookmatter StructuralMechanicsDocument11 pages1990 Bookmatter StructuralMechanicspeter wongNo ratings yet

- Paper 2 With Marking Scheme PDFDocument17 pagesPaper 2 With Marking Scheme PDFpeter wongNo ratings yet

- DSEpp - Firms and ProductionDocument12 pagesDSEpp - Firms and Productionpeter wongNo ratings yet

- DSE Past Paper: Basic ConceptsDocument6 pagesDSE Past Paper: Basic Conceptspeter wongNo ratings yet

- DSE Past Paper - Equity, Efficiency and Role of GovernmentDocument3 pagesDSE Past Paper - Equity, Efficiency and Role of Governmentpeter wongNo ratings yet

- 2018 DSE ECON Paper 1 (With Answers) PDFDocument16 pages2018 DSE ECON Paper 1 (With Answers) PDFpeter wongNo ratings yet

- DSE Past Paper ADAS and Monetary and Fiscal PolicyDocument13 pagesDSE Past Paper ADAS and Monetary and Fiscal Policypeter wongNo ratings yet

- Hkcee Economics - 3.5 Unit Subsidy - P.1Document3 pagesHkcee Economics - 3.5 Unit Subsidy - P.1peter wongNo ratings yet

- Hkcee Economics - 4.1 Types of Production - P.1Document3 pagesHkcee Economics - 4.1 Types of Production - P.1peter wongNo ratings yet

- Hkcee Economics - 4.2 Division of Labour - P.1Document2 pagesHkcee Economics - 4.2 Division of Labour - P.1peter wongNo ratings yet

- Econ 10.1 PDFDocument3 pagesEcon 10.1 PDFpeter wongNo ratings yet

- Hkcee Economics - 4.3 Factors of Production - P.1Document14 pagesHkcee Economics - 4.3 Factors of Production - P.1peter wongNo ratings yet

- Econ 10.5 PDFDocument3 pagesEcon 10.5 PDFpeter wongNo ratings yet

- Econ 11.2 PDFDocument3 pagesEcon 11.2 PDFpeter wongNo ratings yet

- Econ 10.6 PDFDocument6 pagesEcon 10.6 PDFpeter wongNo ratings yet

- Econ 12.2 PDFDocument5 pagesEcon 12.2 PDFpeter wongNo ratings yet

- Hkcee Economics - 9.1 Business Cycle - P.1Document1 pageHkcee Economics - 9.1 Business Cycle - P.1peter wongNo ratings yet