Professional Documents

Culture Documents

Lixio Tec Eng

Lixio Tec Eng

Uploaded by

PedroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lixio Tec Eng

Lixio Tec Eng

Uploaded by

PedroCopyright:

Available Formats

SYSTEM GUIDELINES

lixio®

Rev. 01 dated 03 / 02 / 2022

LIXIO ®

Cement-based Microterrazzo with marble aggregates.

DESCRIPTION

Lixio® is a low thickness (6mm) microterrazzo suitable for application on both new or existing

flatwork. The customer can customise the design by choosing from a selection of colour pigments,

marble aggregates and degree of gloss.

FEATURES

The Lixio® system includes EPOXY-COAT as primer, the coloured pigments COLOUR-PACK C,

selected marble aggregates (LIXIO-BLEND), “LIXIO-FLUID liquid polymer and the cement-based

premix LIXIO-POWDER.

After installation and once the surface has set, it is then ground with diamond abrasive discs using

the same techniques for natural marble. By combining COLOUR-PACK-C and coloured marble

aggregates, the customer can create his desired chromatic effect. By choosing the appropriate level

of polishing, he will be able to obtain the most suitable gloss and level of slip-resistance, from bush

hammered or brushed finishes suitable for exterior surfaces, up to a mirror-polished surface.

The surface can be protected with IDEALPU WB EASY water-based polyurethane sealer or with

PETROTEX-S oil-resistant impregnator. Treatment with IDEAL HARD densifier (or IDEAL HARD PLUS)

will also increase the scratch resistance of the surface.

FIELDS OF USE

Lixio®, in its multiple chromatic finishes, is ideal for use in prestigious environments, perfectly

harmonising both modern architecture and classic restoration schemes.

It is particularly suitable for:

• Commercial areas

• Housing

• Hotels

• Airports and large public spaces

• Museums and galleries

• Offices

APPLICATION

SURFACE PREPARATION

The substrate may consist of sand/cement or concrete screeds and may also have an existing

ceramic or natural stone finish. It must be dry, well levelled, clean and free of oil residues, paints or

other polluting substances. Possible cracks or depressions must be previously repaired with anti-

shrinkage epoxy mortar such as IDEAL MALTA. The surface must be ground with diamond pads to

ensure adhesion. Any existing joints must be mirrored on the surface with suitable profiles.

Thoroughly check the level of the substrate with a straightedge screed. If necessary, grind the higher

areas. Based on the type and condition of the substrate (concrete, sand-cement, ceramic, self-

IDEAL WORK SRL 1/5

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

SYSTEM GUIDELINES

lixio®

leveling…), this must be prepared by sanding, shot blasting etc. and also be clean, rough, free from

contamination, intact and perfectly level.

For floors subject to ordinary pedestrian traffic the substrate must have a compressive strength of

at least 25 Mpa and pull off requirements of at least 1.0 Mpa.

The residual moisture content of the substrate must not exceed 4.0 %.

Respect any control joints that may exist on the substrate.

Repair existing cracks. Firmly place the LIXIO-JOINT profiles before application of Epoxy -coat.

Joints existing in the support must be mirrored on the surface. Profiles will also define the pouring

areas and will be placed to create geometrical crack control joints.

Apply a very thin layer of Epoxy-Coat mixed with 20% quartz sand 0.1-0.5 mm on the pretreated

surface. Broadcast quartz 0,7-1,2 mm (about 2,5 Kg/m2). Limit the work area so that broadcasting can

be completed while the resin is still wet.

The entire surface must be completely covered with quartz.

Always wear spiked shoes or cleats to walk on the surface.

Preparation on a ceramic background

1. First, always sand with a diamond disc.

2. Apply an 80-100 g / m2 fibreglass mesh fixed with IW-BLOCKER

3. On a base with residual grouts, apply 2 coats of Epoxy-coat with quartz broadcast (see above), on

ceramic without or with minimal grouts, just 1 coat is enough.

Preparation on concrete in the absence of rising damp

1. Sand or shotblast

2. Apply a coat of epoxy-coat with quartz broadcast (see above).

Preparation on concrete in the presence of rising damp

1. Sand or shotblast.

2. Apply a coat of BARRIERA CEM as a chemical vapour barrier.

3. Apply a coat of epoxy-coat with quartz broadcast (see above).

Preparation on sand and cement base

1. Sand with paper 24

2. Possible consolidation (if necessary) with IDEAL WATER or alternatively with IW-BLOCKER and

fibreglass mesh.

3. Apply a coat of epoxy-coat with quartz (see above).

Preparation on self-levelling

1. Grind

2. Consolidate with IDEAL WATER

3. Apply a coat of epoxy-coat with quartz broadcast (see above).

Other backgrounds

Contact the Ideal Work technical office.

It will be the care and responsibility of the applicator to evaluate the actual conditions of the

background and the suitability of the indicated solutions on the particular construction site.

IDEAL WORK SRL 2/5

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

SYSTEM GUIDELINES

lixio®

APPLYING THE MATERIAL

The actual application thickness should be made considering that approximately 2mm of the

surface will be ground to expose the aggregates in the final sanding process.

Do not apply at temperatures over 30° or lower than 10°.

MIXING AND COLOURING

Keep LIXIO-FLUID and LIXIO-POWDER cool before and during the use.

Mix the components as follows.

Pour 70% of Lixio® in the mixing-machine and slowly add the whole quantity of LIXIO-BLEND, the

LIXIO-POWDER and then the remaining polymer.

Mix 2-3 minutes to loosen clumps. The quantity of LIXIO-FLUID can vary by +/- 5%.

COLOURPACK -C (see datasheet) is the specific pigment for Lixio®. Mix 28 g /l with the polymer for a

full tone, in a lesser ratio for a lighter shade. It is available in 27 colours.

After 8-12 hours (at 20°, 50% RH) and after having sanded and vacuumed the surface, the Lixio®

mixture should be poured and levelled with a screed and trowel before rolling the surface with

“Stencil-Roller“ to create the perfectly level. Then spray LIXIO-FLUID evenly on the surface as anti-

evaporating product.(about 0,1 Kg/m2).Note, very high temperatures and humidity can delay the

hardening of the primer Lixio® can be walked on from 24 hours after installation.

The previously placed profiles along with suitable steel rods will help to keep the levels (steel rods to

be removed immediately after pouring). Wear spiked shoes or cleats.

GRINDING-POLISHING

Wet (recommended) or dry grinding can begin once the surface has completely set. Whichever is

chosen, this should not be before 3-5 days from the application.

Use stone-polishing machines. The type of discs, number of revolutions and number of passes must

be determined according to the machine used (please contact the manufacturer).

After the first two or three grinding steps, the surface will be filled with a grout composed of 1 part of

LIXIO-FLUID (pigmented) and 2 parts of cement .

After setting of grouting ( 1-2 days) ,subsequent steps will bring Lixio® to the desired degree of gloss.

For example, polishing process 400: G2, G120, G200, G400 (honed)

To mirror polish, additional pass with G800, polishing with salts).

Lixio® can be mirror-polished and treated with PETROTEX-S impregnating water-oil repellent, or

polished with to G 400 grit diamond pad and sealed with the water-based polyurethane sealer

IDEAL PU-WB EASY SL (see the relative technical datasheets). The preventive treatment with IDEAL

HARD or IDEAL HARD PLUS increases the surface resistance to abrasion and scratching.

BACKGROUND PROTECTION

For the protection of the surface, the following products are recommended, please refer to the

relevant technical data sheets and to the Ideal Work technical office for further information.

The previous treatment with IDEAL HARD or IDEAL HARD PLUS densifier increases the scratch

resistance and is recommended for heavy trafficked areas.

IDEAL WORK SRL 3/5

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

SYSTEM GUIDELINES

lixio®

Polyurethane water-based resin

The resin can change the hue of the surface, in some cases significantly.

• IDEALPU WB EASY matt

• IDEALPU WB EASY SL water-based satin (recommended)

• WB-BOOSTER added to the second coat of resins increases the scratch resistance of the

protective film

Protective impregnation

• PETROTEX-S impregnation against oil and water

MAINTENANCE

Use neutral detergents, preferably Ideal Work Perfect. The use of Ideal Care liquid wax combined

with washing water helps maintain the colour over time. See the Ideal Work maintenance manual

https://www.idealwork.it/wp-content/uploads/2019/02/Cat_manutenzione_doppie-1.pdf

TECHNICAL DATA

Technical Data

See data sheet and CE DOP on

https://www.idealwork.it/download/documentazione-tecnica

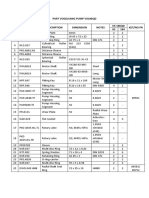

CONSUMPTION AND MIXING RATIOS

The following composition by weight guarantees the achievement of the physical-mechanical

characteristics indicated in the products technical data sheet.

Deviations from the indicated proportions or incorrect mixing can affect the performance of the

product.

CONSUMPTION PER m2

FOR 10 MM THICKNESS *

FOR THE FOR AS AN ANTI-

MIXTURE GROUTING EVAPORANT

LIXIO® POWDER 8,40 Kg -- --

LIXIO® FLUID 3,0 Kg 0,1 Kg 0,1 Kg

LIXIO® MARBLE BLEND 11,6 Kg -- --

COLOUR PACK C 0,08 Kg 0,006 Kg --

WHITE CEMENT 0,2 Kg --

*Please consider initial surface level should be 2 mm more than the final polished thickness

IDEAL WORK SRL 4/5

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

SYSTEM GUIDELINES

lixio®

PACKAGING/STORAGE/DISPOSAL

The system components are packed in the following units:

LIXIO® POWDER 18,75 Kg

LIXIO® FLUID 10,00 Kg

LIXIO® MARBLE BLEND 25,00 Kg

COLOUR PACK C 0,50 Kg in 30 ml minipack.

The products can be stored for 12 months from the date of packaging in a cool and dry place.

CAUTION

Avoid conditions that may encourage different setting times between areas, such as air currents

and solar radiation. In the presence of underfloor heating, complete the ignition cycle beforehand

and do not exceed 12°.

Any shrinkage cracks that formed in the substrate inevitably tend to be transmitted to the Lixio®

finishing layer. If the substrate is characterised by a 28 days shrinkage of more than 300μm / m (UNI

11307 for concrete and UNI 6687 for sand and cement or mortar substrates) it is advisable to wait for

its complete curing and drying and seal any cracks with Epoxy-coat before application.

* Information sur le niveau

d’émission de substances volatiles dans

l’air intérieur, présentant un risque de

toxicité par inhalation, sur une échelle

de classe allant de A+ (très faibles

émissions) à C (fortes émissions).

IMPORTANT:

The manufacturer disclaims any responsibility for the achievement of the services declared for the system and for the success of the work if

it is not used in accord with its instructions. The manufacturer disclaims any responsibility for the achievement of the services declared for

the system and for the success of the work if it is performed even partially in contrast with these guidelines or with products not covered by

them.

The manufacturer also declines any responsibility for the aesthetic aspect of the flooring which depends on the installation methods,

working times and climatic conditions of the site. The applicator must take these into account when scheduling and applying the materials

supplied by the manufacturer.

The applicator notes that Ideal Work is in no way responsible for the suitability of the solution chosen in relation to:

A) Substrate suitability, climatic conditions or any other external parameter which may affect the performance of the Ideal Work products

being used.

B) The stresses to which Ideal Work products may be put under operation.

It also notes that the indications provided by Ideal Work in its technical documentation are to be considered a necessary condition but do

not in any way relieve the contractor of the responsibilities and technical evaluations of the applicator. The data can be changed at any time.

Also note that the products are intended for professional use only.

IDEAL WORK SRL 5/5

Via Kennedy, 52 - Vallà di Riese Pio X – 31030 TV, Italy - P. Iva 03293380261 • www.idealwork.it – T +39 0423 4535

You might also like

- Galvanising and Current TrendsDocument32 pagesGalvanising and Current TrendsMritunjayNo ratings yet

- Fire Triangle, Flash & Fire Point, LEL & UELDocument3 pagesFire Triangle, Flash & Fire Point, LEL & UELviiulm100% (1)

- I Don't Give Two Shits About Revealing Methodology, When It Will Help Teach People To See Hidden Lines of Communication.Document55 pagesI Don't Give Two Shits About Revealing Methodology, When It Will Help Teach People To See Hidden Lines of Communication.Guthrie Douglas PrenticeNo ratings yet

- Process Instruction Heat Treatment (Revised 06.11.2017)Document4 pagesProcess Instruction Heat Treatment (Revised 06.11.2017)Deepak kumarNo ratings yet

- Vc-Api 650 PDFDocument6 pagesVc-Api 650 PDFShinta ShowiantariNo ratings yet

- Dynasand 1Document2 pagesDynasand 1Pandiaraj MkNo ratings yet

- Advances in Gas Turbine Repair TechnologyDocument38 pagesAdvances in Gas Turbine Repair Technologymhdsoleh100% (2)

- Industrial Training Report: Department of Mechanical EngineeringDocument32 pagesIndustrial Training Report: Department of Mechanical EngineeringParul Chhabra67% (3)

- Topfloor Tec EngDocument3 pagesTopfloor Tec EngPedroNo ratings yet

- Betontop Tec EngDocument4 pagesBetontop Tec EngPedroNo ratings yet

- Rasico Tec EngDocument3 pagesRasico Tec EngPedroNo ratings yet

- Colo-Re Tec EngDocument3 pagesColo-Re Tec EngPedroNo ratings yet

- HARD SKY EN STAMPED CONCRETE Installation Instruction5a0e7630f320eDocument3 pagesHARD SKY EN STAMPED CONCRETE Installation Instruction5a0e7630f320eAyça Bayram OzcanlarNo ratings yet

- Ideal Hard Tec EngDocument4 pagesIdeal Hard Tec EngPedroNo ratings yet

- Iw Ec Tec EngDocument2 pagesIw Ec Tec EngPedroNo ratings yet

- Idealbinder Tec EngDocument2 pagesIdealbinder Tec EngPedroNo ratings yet

- Prosolve370e 130304 Ee - Data SheetDocument2 pagesProsolve370e 130304 Ee - Data SheetJorge L. Nieto V.No ratings yet

- Mariseal 270 Version 10Document2 pagesMariseal 270 Version 10Sunny SinghNo ratings yet

- SikaflexPRO TdsDocument6 pagesSikaflexPRO TdsidontlikeebooksNo ratings yet

- Decopol Microtop Cememtetious Polymer Modified MicrotoppingDocument4 pagesDecopol Microtop Cememtetious Polymer Modified Microtoppingtejas_tNo ratings yet

- Ideal Hard Plus Tec EngDocument3 pagesIdeal Hard Plus Tec EngPedroNo ratings yet

- Ds Medapoxy Sol SoupleDocument2 pagesDs Medapoxy Sol SouplefaridNo ratings yet

- Idrostop MasticDocument2 pagesIdrostop MasticPrateek JainNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290shanon33No ratings yet

- Nitotile Fix ProDocument2 pagesNitotile Fix ProtalatzahoorNo ratings yet

- Euco TopDocument2 pagesEuco Toppravi3434No ratings yet

- 2801 Ultracolor Plus GB NoRestrictionDocument6 pages2801 Ultracolor Plus GB NoRestrictionFloorkitNo ratings yet

- S1 NoRestrictionDocument4 pagesS1 NoRestrictionFloorkitNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290Venkata RaoNo ratings yet

- Epoxy Flooring TDSDocument7 pagesEpoxy Flooring TDSMohamed MagdiNo ratings yet

- Euco 700Document2 pagesEuco 700pravi3434No ratings yet

- Idealpu78-Matt Tec EngDocument2 pagesIdealpu78-Matt Tec EngPedroNo ratings yet

- Sikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedDocument6 pagesSikafloor - 161: 2-Part Epoxy Primer, Levelling Mortar, Intermediate Layer and Mortar ScreedhvduylinhNo ratings yet

- The Anydron Manual - Working With PU Waterproof CoatingsDocument5 pagesThe Anydron Manual - Working With PU Waterproof Coatingsakis5375No ratings yet

- ColourDur J701 SC3Document4 pagesColourDur J701 SC3anunand.sNo ratings yet

- Nitoprime 25DSDocument3 pagesNitoprime 25DSSales PPINo ratings yet

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatDocument6 pagesSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal Coatthe pilotNo ratings yet

- SFT Adhesive - Technical InformationDocument2 pagesSFT Adhesive - Technical Informations_omeone4usNo ratings yet

- Dulux Trade Ecosure SilkDocument7 pagesDulux Trade Ecosure SilkEl Bekkari MohamedNo ratings yet

- Acido Tec EngDocument4 pagesAcido Tec EngPedroNo ratings yet

- Ideal Water Tec EngDocument3 pagesIdeal Water Tec EngPedroNo ratings yet

- TDS - en - Tecnotop S-3000Document6 pagesTDS - en - Tecnotop S-3000arhamshafiq.asrNo ratings yet

- Nitotile LM : Constructive SolutionsDocument2 pagesNitotile LM : Constructive SolutionsmilanbrasinaNo ratings yet

- Laticrete Hydro Ban Installation InstructionsDocument5 pagesLaticrete Hydro Ban Installation InstructionsAlex LongNo ratings yet

- Ds Medapoxy SolDocument2 pagesDs Medapoxy SolfaridNo ratings yet

- Gallery 0768498605 Sika Level 100TDocument5 pagesGallery 0768498605 Sika Level 100TRobert EshwerNo ratings yet

- Maricoat 2000: Polyurethane Self-Leveling Floor CoatingDocument2 pagesMaricoat 2000: Polyurethane Self-Leveling Floor CoatingSunny SinghNo ratings yet

- FlotopDocument2 pagesFlotoppravi3434No ratings yet

- Concrete Top SupremeDocument2 pagesConcrete Top Supremepravi3434No ratings yet

- MICROCEMENTDocument2 pagesMICROCEMENTFiorella Margarita Mechato LaraNo ratings yet

- Rapid Set Tds - NoRestrictionDocument4 pagesRapid Set Tds - NoRestrictionFloorkitNo ratings yet

- T010 Rev02 Ad Hoc en PDFDocument2 pagesT010 Rev02 Ad Hoc en PDFMónica AranhNo ratings yet

- TDS en DesmopolDocument9 pagesTDS en Desmopolzana connorNo ratings yet

- TDS - Mastertop 200Document2 pagesTDS - Mastertop 200Venkata RaoNo ratings yet

- Dimetcote 9 Sigmazinc 9Document6 pagesDimetcote 9 Sigmazinc 9kaleshNo ratings yet

- S IKADocument4 pagesS IKAQuevara AntonNo ratings yet

- 82 Ultraflex s2 Quick GB NoRestrictionDocument4 pages82 Ultraflex s2 Quick GB NoRestrictionFloorkitNo ratings yet

- Maritrans Version18Document3 pagesMaritrans Version18Aditya baisNo ratings yet

- Euco 512 EpoxyDocument2 pagesEuco 512 Epoxypravi3434No ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- Zincanode 304 pc142Document3 pagesZincanode 304 pc142kushar_geoNo ratings yet

- Cemtop 250T PDFDocument4 pagesCemtop 250T PDFriverwilliamsNo ratings yet

- Euco WeldDocument2 pagesEuco Weldpravi3434No ratings yet

- Stucco Veneziano: Series 943 DescriptionDocument2 pagesStucco Veneziano: Series 943 DescriptionnaaaNo ratings yet

- Euco 456 BMDocument1 pageEuco 456 BMpravi3434No ratings yet

- Mastertop 1705 TdsDocument3 pagesMastertop 1705 TdsrenandiaNo ratings yet

- Fib Tec EngDocument3 pagesFib Tec EngPedroNo ratings yet

- Adam Q070: Q070005XNA Q070004XNADocument2 pagesAdam Q070: Q070005XNA Q070004XNAPedroNo ratings yet

- Cera Tec EngDocument2 pagesCera Tec EngPedroNo ratings yet

- Repair-Mortar Tec EngDocument2 pagesRepair-Mortar Tec EngPedroNo ratings yet

- Seal Col Tec EngDocument2 pagesSeal Col Tec EngPedroNo ratings yet

- Topfloor Tec EngDocument3 pagesTopfloor Tec EngPedroNo ratings yet

- Acido Tec EngDocument4 pagesAcido Tec EngPedroNo ratings yet

- Idealpu-Wb Primer - Tec - EngDocument2 pagesIdealpu-Wb Primer - Tec - EngPedroNo ratings yet

- Cure Tec EngDocument2 pagesCure Tec EngPedroNo ratings yet

- Ideal Stuck10s Tec EngDocument2 pagesIdeal Stuck10s Tec EngPedroNo ratings yet

- Ideal Malta05 Tec EngDocument3 pagesIdeal Malta05 Tec EngPedroNo ratings yet

- Ideal Hard Tec EngDocument4 pagesIdeal Hard Tec EngPedroNo ratings yet

- Mangiapolvere Tec EngDocument1 pageMangiapolvere Tec EngPedroNo ratings yet

- Ideal Strong Tec EngDocument1 pageIdeal Strong Tec EngPedroNo ratings yet

- Idealpu78-Matt Tec EngDocument2 pagesIdealpu78-Matt Tec EngPedroNo ratings yet

- Iw Ec Tec EngDocument2 pagesIw Ec Tec EngPedroNo ratings yet

- Colour Mix Tec EngDocument2 pagesColour Mix Tec EngPedroNo ratings yet

- Ideal Water Tec EngDocument3 pagesIdeal Water Tec EngPedroNo ratings yet

- Filtene 06 - Tec - EngDocument2 pagesFiltene 06 - Tec - EngPedroNo ratings yet

- Mt-Primer Tec EngDocument2 pagesMt-Primer Tec EngPedroNo ratings yet

- Polyfibra Tec EngDocument2 pagesPolyfibra Tec EngPedroNo ratings yet

- Ideal Floor Tec EngDocument3 pagesIdeal Floor Tec EngPedroNo ratings yet

- Colo-Re Tec EngDocument3 pagesColo-Re Tec EngPedroNo ratings yet

- Idealpu-Wb-Opacizzante Tec EngDocument2 pagesIdealpu-Wb-Opacizzante Tec EngPedroNo ratings yet

- Cement-Scud-Gel Tec EngDocument1 pageCement-Scud-Gel Tec EngPedroNo ratings yet

- Idealbinder Tec EngDocument2 pagesIdealbinder Tec EngPedroNo ratings yet

- Acido Provertical Tec EngDocument2 pagesAcido Provertical Tec EngPedroNo ratings yet

- Ideal Color80 Tec EngDocument2 pagesIdeal Color80 Tec EngPedroNo ratings yet

- Guaina Tec EngDocument1 pageGuaina Tec EngPedroNo ratings yet

- Barriera Cem Tec EngDocument3 pagesBarriera Cem Tec EngPedroNo ratings yet

- CTU Lathe Machine OperationDocument169 pagesCTU Lathe Machine OperationChristopher VergaraNo ratings yet

- Satnam Machine Tools OkDocument17 pagesSatnam Machine Tools OkRupinder SinghNo ratings yet

- Serilux enDocument1 pageSerilux enMagdaGładkowskaNo ratings yet

- Draft Executive Summary of Beekay SteelsDocument6 pagesDraft Executive Summary of Beekay SteelsSuryakanta PradhanNo ratings yet

- Inspection and Test Plan Supply, Fabrication, & Galvanizing of Fence and GatesDocument7 pagesInspection and Test Plan Supply, Fabrication, & Galvanizing of Fence and GatesAzhar ShaikhNo ratings yet

- Which Deoxit® Spray Do I Use?: A) Standard Spray: Provides Flushing ActionDocument2 pagesWhich Deoxit® Spray Do I Use?: A) Standard Spray: Provides Flushing ActionBert VisserNo ratings yet

- Heat Treatment With Salt Bath FurnacesDocument12 pagesHeat Treatment With Salt Bath FurnacesVaikuntam Ramamurthy100% (1)

- Part Vogelsang Pumpvx186qdDocument3 pagesPart Vogelsang Pumpvx186qdvionna wedharinyNo ratings yet

- Wise A600Document2 pagesWise A600naser712No ratings yet

- Jurnal Bastian Dwi Ananta Citizen 2022Document8 pagesJurnal Bastian Dwi Ananta Citizen 2022Muhammad SiddiqNo ratings yet

- SAE52100 VS H13 For Pilger DiesDocument2 pagesSAE52100 VS H13 For Pilger DiesTushar PachlangiaNo ratings yet

- 7120 - 20 Tee VictaulicDocument2 pages7120 - 20 Tee VictaulicmiturraNo ratings yet

- Porca Din 439 BDocument7 pagesPorca Din 439 BFrank NunesNo ratings yet

- TDS Total Ceran-Xm-460 MWK 202112 en IdnDocument2 pagesTDS Total Ceran-Xm-460 MWK 202112 en Idnfalya466No ratings yet

- Back Up Roller Bearing For Sendzimir Rolling Mill Ceo BearingsDocument4 pagesBack Up Roller Bearing For Sendzimir Rolling Mill Ceo Bearings陈林恩No ratings yet

- E2 - Polyflex JB1Document4 pagesE2 - Polyflex JB1vietkhamNo ratings yet

- 10 MM Mini Hitachi PDFDocument4 pages10 MM Mini Hitachi PDFAshish AgrawalNo ratings yet

- Cementing CalcDocument10 pagesCementing CalcAfief Ma'rufNo ratings yet

- Transmission Linkages: Universidad Autónoma Del Estado de México Facultad de IngenieríaDocument19 pagesTransmission Linkages: Universidad Autónoma Del Estado de México Facultad de IngenieríaPanchitou OuuNo ratings yet

- Hydrocerol HKDocument1 pageHydrocerol HKKrzysztof NowakNo ratings yet

- Bending Tools RF-A English - OriginalDocument116 pagesBending Tools RF-A English - OriginalGunnie PandherNo ratings yet

- Ultrasonic MachiningDocument26 pagesUltrasonic MachiningEmanuel Nuñez ClavecillasNo ratings yet