Professional Documents

Culture Documents

Section 01 General PDF

Uploaded by

lakmalperera1986Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 01 General PDF

Uploaded by

lakmalperera1986Copyright:

Available Formats

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

SYMBOLS, ABBREVIATIONS AND DEFINITIONS

Symbols and abbreviations used are generally in accordance with the following list.

Units of Measurement

Length, Area and Volume

°‘“ degree, minute, second (of angle)

µm micron (m x10-6)

ha Hectare

km kilometre(s)

2

km square kilometre

l (lt) Litre

m metre (s)

2

m square metre

m3 Cubic metre

mm millimetre (s)

2

mm square millimetre

nm nautical mile

rad Radian

Time and Time Derived Units

d Day

dB Decibel

H (hr) Hour

Hz Hertz (cycles per second)

kHz kilohertz (Hz x 103 )

km/h Kilometres per hour

m/s Metres per second

2

m /s Square metres per second

m3/s Cubic metres per second

MHz megahertz (Hz x 106)

min Minute

mm/s millimetres per second

mth Month

s (sec) Second

wk Week

yr Year

Section –1 Page 1 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

Mass, Force and Derived Units

°C degree Celsius

Atm standard atmosphere (101,325 Pa)

g Gramme (kg x 10-3)

kg kilogramme

3

kg/m kilogrammes per cubic metre

kN kilo Newton

2

kN/m kilo Newton per square metre

kNm kilo Newton metre

kPa kilo Pascal

kW kilo Watt (W x 103)

mg milligramme (kg x 10-6)

mg/l Milligrammes per litre

MN Mega Newton

MPa Mega Pascal

MW Mega Watt (W x 106)

N Newton

Nm Newton metre

Pa Pascal

T(t) Tonne (kg x 103)

T/m3 Tonnes per cubic metre

W Watt (J/s)

Electrical Units

A Ampere

Cd Candela

kVA kilo Volt Ampere

kWh kilo Watt hour

Lx Lux

V Volt

Proper Names / Organisations – International

AASHTO American Association of State Highways and Transportation Officials

ACE Association of Consulting Engineers (UK)

ACI American Concrete Institute

ADB Asian Development Bank

AISC American Institute of Steel Construction

API American Petroleum Institute

ASTM American Society for Testing and Materials

BA British Admiralty

BS British Standard

Section –1 Page 2 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

BSI British Standards Institution

CIRIA/CUR UK Construction Industry Research and Information Association/

Civieltechnisch Centrum Uitvoering Research en Regelgeving

DIN Deutches Institut fur Normung ev (German Standards Organisation)

EIA Environmental Impact Assessment

EN European Standard

HSE Health and Safety Executive (UK)

IALA International Association of Lighthouse Authorities

ICE Institution of Civil Engineers (UK)

IEE Institution of Electrical Engineers (UK)

IMO International Maritime Organisation

ISO International Organisation for Standardisation

ISPS International Ship and Port Facility Security

LPC Loss Prevention Council

NEA National Environmental Act

PIANC International Navigation Association (formerly Permanent International Association of

Navigation Congresses)

SI Systeme Internationale d’Unites (International System of Units)

SIS Sveriges Standardiseringskommisionen (Swedish Standards

Commission)

SLMG Sri Lankan Metric Grid

TRL Transport Research Laboratory (UK)

UTM Universal Transverse Mercator

WGS World Geodetic System

Proper Names / Organisations – Sri Lanka

BOI Board of Investment of Sri Lanka

BQ Bandaranaike Quay

CCD Coast Conservation Department

CEA Central Environmental Authority

CEB Ceylon Electricity Board

CPC Ceylon Petroleum Cooperation

CMC Colombo Municipal Council

CSH Colombo South Harbour

DASL Department of Archaeology Sri Lanka

DMSL Department of Meteorology Sri Lanka

DPSL Department of Police Sri Lanka

GOSL Government of Sri Lanka

GSMB Geological Survey & Mines Bureau

HM Harbour Master

JCT Jaya Container Terminal

LHI Lanka Hydraulic Institute

MOC Marine Operations Centre

Section –1 Page 3 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

MPPA Marine Pollution Prevention Authority

NARA National Aquatic Resources Research and Development Agency

NWSDB National Water Supply & Drainage Board

PCT Port Control Tower

PS Pilot Station

PVQ Prince Vijaya Quay

RDA Roads Development Authority

SAGT South Asia Gateway Terminal

SBH Small Boat Harbour

SDHM Senior Deputy Harbour Master

SDSL Survey Department Sri Lanka

SLC Sri Lanka Customs

SLMG Sri Lanka Metric Grid

SLN Sri Lanka Navy

SLPA Sri Lanka Ports Authority

SLR Sri Lanka Railways

SLT Sri Lanka Telecom Ltd.

UCT Unity Container Terminal

Section –1 Page 4 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

Other Abbreviations

% per cent

ACM Asbestos Containing Material

AMP Asbestos Management Plan

approx Approximately

BM Bench Mark

CD Chart Datum

dia Diameter

DRCM Direct Reading Current Meter

eg for example

etc and so on/etcetera

Fig Figure

GMS Galvanised Mild Steel

GRP Glass Reinforced Plastic

HAT Highest Astronomical Tide

horiz Horizontal

Hs Significant Wave Height

HSFG High Strength Friction Grip (bolt)

Ie that is

LAT Lowest Astronomical Tide

LWOST Low Water Ordinary Spring Tide

max Maximum

min Minimum

MHWNT Mean High Water Neap Tide

MHWST Mean High Water Spring Tide

MLWNT Mean Low Water Neap Tide

MLWST Mean Low Water Spring Tide

MSL Mean Sea Level

MOF Materials Off-Loading Facility

No Number (order) as in No 6

no/nr Number (units) as in 6 no

PVC Poly Vinyl Chloride

PVC u/-u Poly Vinyl Chloride (unplasticised)

RCM Recording Current Meter

SD Sounding Datum

SSS Side Scan Sonar

Temp Temperature

Tp Peak Wave Period

vert Vertical

vol Volume

WBP Water and Boil Proof

(Plywood)

w/c Water/Cement (ratio)

wt Weight

Section –1 Page 5 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

SECTION 1 – GENERAL

Table of Contents

Description of the Works

1.001 Location of the Works

1.002 General Description of the Works

Site Information

1.003 Site Investigations

Site Conditions

1.004 Temperature

1.005 Humidity

1.006 Rainfall

1.007 Winds

1.008 Waves

1.009 Tides

1.010 Currents

Surveys

1.011 Setting-out Grid

1.012 Level Datum

1.013 Topographic Survey

1.014 Condition Survey

1.015 Bathymetric Survey

1.016 Movement Monitoring

Conduct of the Works

1.017 Access to Site

1.018 Interference with Other Operations

1.019 Working within a Port Security and Customs Area

1.020 Agreement of Engineer to Significant Operations

1.021 Notice for Checking by Engineer

1.022 Loads on Existing Structures

1.023 Sequence of Construction and Programme

Control of Programme

1.024 Progress Meetings

1.025 Attendance upon Trades

1.026 Setting-out of Works

1.027 Existing Services

1.028 Existing Obstructions

On-Land Works

1.029 Silting of Works during Construction

1.030 Project Signboards

1.031 Fencing, Hoardings, Watching & Lighting

1.032 Traffic Safety & Control on Site

1.033 Port Entry Passes

1.034 Visitors

1.035 Cleaning and Clearing of Roadways and Footpaths

1.036 Noise Control

1.037 Debris

1.038 Health and Safety, Generally

1.039 First Aid Facilities

1.040 Life Saving Apparatus and Rescue Boat

1.041 Diving

1.042 Use of Explosives

1.043 Quarries, Borrow Pits and Haul Roads

Section –1 Page 6 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

Marine Operations

1.044 Port Limits and Approvals

1.045 Floating Equipment and Craft

1.046 Navigation

1.047 Reconfirmation of Marine Operations

1.048 Mooring, Buoys, Lights etc

1.049 Night time Markings and Lights

1.050 Radio Link with Port Authority, Contractor's Radio Equipment

1.051 Pilotage

1.052 Tide Gauges

Facilities and Equipment for Engineer's Site Staff

1.053 Office Accommodation

1.054 Equipment

1.054 Materials Testing Laboratory

1.055 Motor Vehicles

1.056 Boat for the Use of the Engineer

1.057 Survey Craft

1.058 Diving Pontoon

Attendance upon the Engineer

1.059 General

1.060 Setting-out and Survey Staff and Small Equipment

1.061 Materials Testing Staff and Transport

1.062 Vehicle Drivers

1.063 Boat Crew

1.064 Diving Assistance

Accommodation and Facilities for Contractor

1.065 Contractor’s Compound Area and MOF

1.066 Contractor's Office, Stores, Workshops, etc

1.067 Staff Quarters and Labour Camp

Services for Contractor

1.068 Services for Contractor's Use

Records

1.069 Records

1.070 Progress Photographs

1.071 Progress Reports

1.072 Returns of Labour and Equipment

1.073 Submission of Information and Records

1.074 ‘As-Constructed Drawings’

Drawings, Designs and Standards

1.075 Additional or Notified Drawings

1.076 Interpretation of Drawings

1.077 Contractor's Designs

1.078 Contractor's Working Drawings

1.079 Alternative Design Proposals

1.080 Provision of Standards, Codes of Practice

1.081 Applicable Standards and Codes of Practice

Environmental Considerations During Construction

1.082 General

1.083 Environmental Management Plan

1.084 Mitigation Measures for Water Quality

1.085 Dredging and Reclamation

1.086 Disposal of Sewage and Wastewater from Land-Based Sources

1.087 Disposal of Sewage and Wastewater from Construction Vessels

1.088 Control of Surface Water Runoff from Reclamation Areas

1.089 Control of Spillages

Section –1 Page 7 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.090 Mitigation Measures for Control of Solid Wastes

1.091 Mitigation Measures for Air Quality

1.092 Mitigation Measures for Noise and Vibration

1.093 Mitigation Measures for Ecology & Fisheries

1.094 Mitigation Measures for Cultural Heritage

1.095 Measures for Employment

1.096 Health and Safety

1.097 Monitoring General

1.098 Types of Monitoring

1.099 Impact Monitoring

1.100 Compliance Monitoring

Section –1 Page 8 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

SECTION 1 – GENERAL

Description of the Works

1.001 Location of the Works

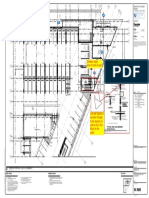

Colombo is situated on the west coast of Sri Lanka. The Permanent Works to be constructed

under this Contract are located within the marine area outside the western breakwater of the

existing Port of Colombo.

The location of Colombo, the existing port and the Permanent Works are indicated on

drawings number D105234 / GE – W / 0010 to 0012.

1.002 General Description of the Works

The Works to be executed under the Contract comprise the Harbour Infrastructure Works

associated with the Colombo South Harbour (CSH) expansion of the Port of Colombo. These

works include:

• Rerouting of a submarine oil pipeline. A new 36” pipeline of approximately 6km

length is to be laid in trench with one shore connection and one underwater

connection to the existing pipeline.

• Construction of a main breakwater. The breakwater is approximately 5 km in length

with the core formed using sand arising from the dredging operations. It is armoured

with rock and concrete armour units and capped with a concrete wave wall. It is

backed by partial reclamation and a beach.

• Construction of a secondary breakwater with Small Boat Harbour. The breakwater is

approximately 1 km long and encloses a small boat harbour with 400m of precast

concrete block quay wall. Onshore buildings include a Marine Operations Centre,

Control Tower and accommodation for pilots and crew.

• Dredging of a new access channel to CSH with a realigned channel to the existing

harbour.

• Construction of road access, drainage and utility services to the newly constructed

facilities.

• Dredging is mostly in sands and silty sands and the dredged material is to be used in

reclamation. Estimated volume of reclamation is 13.6 million cu m.

• Onshore Works including a number of small buildings and other facilities.

Site Information

1.003 Site Investigations

A schedule of the information available for the Site and the investigations carried out is

contained in Appendix 1.6 of this Section.

The site investigation data is available to the Contractor on a without prejudice basis and

solely for the purpose of assisting the Contractor to make his own interpretation of the ground

conditions. The accuracy or reliability of the information given and other information supplied,

prepared or commissioned at any time by the Employer in connection with the Contract is not

therefore warranted and the Employer shall not be held responsible in any manner for such

information.

Copies of the scheduled reports are available for inspection at the offices of the Sri Lanka

Ports Authority, Colombo.

Site Conditions

1.004 Temperature

The maximum temperature during the day is 2 or 3 hours after mid day. The minimum

temperature is generally in the night 1 or 2 hours before dawn. The higher monthly average

temperatures are in April, May or June, the low values are in December, January or

Section –1 Page 9 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

February, however the differences are relatively small (6° seasonal variation). The average

monthly temperature at Colombo varies from 26°C to 28°C.The average maximum and

minimum monthly temperatures being 31°C and 23°C.

1.005 Humidity

Humidity is relatively high at most times. Generally variation is between 70% and 90% on

average.

1.006 Rainfall

The annual West Coast rainfall has considerable seasonal variation. The total annual rainfall

is generally between 2000 mm and of 2500 mm.

Typically the rainfall on the West Coast may be divided seasonally as follows:

• 250 – 500 mm in the first inter-monsoon period March – May

• 1000-1500 mm during the SW monsoon

• 500-1000 mm during the second inter-monsoon period October November and

• 250 – 500 mm during the NE monsoon.

Average monthly rainfall varies between 70 mm and 320 mm. The maximum recorded

rainfall figures for the past 15 years are as follows:

Annual 2888 mm

Monthly 683 mm

Daily 494 mm.

1.007 Winds

Wind at the south-west and west coast of Sri Lanka is governed by the monsoon conditions.

The summer monsoon or Southwest Monsoon is reckoned from May to September. The

winter monsoon or the Northeast Monsoon lasts from December to February. The period

between February and May is the first inter-monsoon period and the period between

September and December the second inter-monsoon period.

This regional wind system is locally influenced by the daily variation of sea to land and land to

sea winds. The breeze affects the strength of the SW monsoonal winds without significantly

affecting the wind direction. During the NE monsoon period, with weak average winds at the

West Coast, a daily pattern of a sea to land wind (during the day) and land to sea wind (at

night) can be established. An annual wind rose based on measurements in the Port between

1979 – 1984 is reproduced below.

C al m

0 .00 %

% 10%

S peed

B and s

m /s

Palett

10% A b ove 20

15 -20

10 -15

5 - 10

0- 5

B elow 0

Wind Rose – Annual Climate

Section –1 Page 10 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.008 Waves

Wave Climate

The wave climate at the southwest and west coast of Sri Lanka is characterised by the

combination of two simultaneous wave systems:

•Sea waves, waves generated under the influence of the wind within the wind field,

and

• Swell waves, waves which have moved out of the area of generation and are no

longer subjected significantly to wind action.

Sea waves are characterised by having relatively short periods (3-8 seconds), whereas swell

waves are characterised by having relatively long periods (8-20 seconds).

Swell waves originate predominantly from the southern oceans. As the waves reach Sri

Lanka they are refracted towards the coast and the angle of approach measured at Colombo

ranges from 200° to 270°. Swell waves have their greatest intensity during the Southwest

monsoon.

In contrast, sea waves have a direction determined by the prevailing wind at the time of

generation, which varies much more widely. In the period May to September (the Southwest

monsoon), winds are predominantly from the southwest and sea waves are predominantly

from this direction. In the period December to February (the Northeast monsoon), wind

directions reverse and waves are predominantly from the North. However, the effect of the

orientation of the coastline is such that waves arrive at Colombo from a generally north-

westerly direction.

During the inter-monsoon periods, depression weather systems can lead to high sea waves

from directions between Southwest and Northwest. As a consequence of these mechanisms,

the sea state may consist of sea and swell with similar or different directions. In addition to

these permanent features, cyclones occur infrequently but may generate some of the highest

waves. Hence sea states are complex.

Wave roses for the annual swell wave climate and annual sea wave climate are reproduced

below. The data was compiled from directional wave measurements in the vicinity of

Colombo Port for periods in 1998 – 1999 and 2002 - 2003.

Section –1 Page 11 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

Annual Swell Wave Rose

N

N

Calm

Calm

0.00 %

0.00 %

Hs (m)

Above 2.8

2.4 - 2.8

2 - 2.4

1.6

Legend

H (m) s

- 2

1.2Above

- 1.62.8

0.8 2.4 – 2.8

-2 1.2

– 2.4

1.6 – 2

0.4 1.2

- 0.8

– 1.6

0.8 – 1.2

0 0.4

- 0.4

– 0.8

55 %

% Below 00

0 – 0.4

Legend

Calm Hs (m)

0.00 % Above 2.8

2.4 - 2.8

2 - 2.4

1.6 - 2

1.2 - 1.6

0.8 - 1.2

0.4 - 0.8

0 - 0.4

5% 0

Annual Sea Wave Rose

The figures below show the variation in sea wave and swell wave height through the year

based on an annual composite of the most recent wave data. The increase in wave height

during the months of the Southwest monsoon can be clearly seen. The figures give a

representation of seasonal variation and are not to be considered as definitive values.

Section –1 Page 12 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

Composite Directional Wave Data - Colombo

Sea Waves

2.5

1.5

Hs

0.5

0

D J F M A M J J A S O N D

Month

Variation of Sea Wave Height during the Year

Composite Directional Wave Data - Colombo

Swell Waves

3

2.5

2

Hs

1.5

0.5

0

D J F M A M J J A S O N D

Month

Variation of Swell Wave Height during the Year

1.009 Tides

LWOST is 0.42m below Mean Sea Level (MSL) Ref. National Hydrographic Office (NHO)

Sea Chart NO. 101.

Mean High Water Springs +0.7m

Mean High Water Neaps +0.5m

Mean Sea Level +0.4m

Mean Low Water Neaps +0.3m

Mean Low Water Springs +0.1m

The extreme mean water levels recommended for the planning of the construction works are

between +0.1m and +1.2m. All tide levels are quoted relative to LWOST datum.

Section –1 Page 13 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.010 Currents

Due to the small tidal range in the Colombo area, tidal currents are relatively weak and are

influenced by the prevailing wind conditions.

Historical data indicates that currents speeds of up to 0.25 m/s have been recorded offshore

(JICA, 1996). Within the port area the maximum recorded speed is 0.39 m/s, but currents are

more typically between 0.05 and 0.25 m/s (Jayaweera, 1999).

Recent analysis of currents offshore of Colombo Port has confirmed that, in general, current

speeds are weak and are not dominated by a single driving force e.g. tides, winds. The

current regime varies from day to day and across the sea area adjacent to the existing Port.

This light and variable regime is driven by the complex interaction of environmental

conditions (tide, wind, oceanic currents, temperature/salinity) and the local bathymetry.

On average current speeds are less than 0.1 m/s; higher speeds of between 0.2-0.30 m/s

occur regularly but for short periods.

In extreme cases, depth averaged currents of greater than 0.4 m/s have been found to occur

and surface currents can exceed 0.8 m/s. These phenomena are common for the west coast

of Sri Lanka and are typified by currents which travel from south to north and have a duration

of a few days, generally in November.

Surveys

1.011 Setting-out Grid

The setting-out grid for the Works shall be the Sri Lankan Metric Grid. The grid co-ordinates

of existing points are as follows:

SRI LANKAN METRIC GRID:

DATUM Name : Kandawala

Ellipsoid : Everest 1830

Semi-major axis : 6377276.345

Flattening : 300.8017

PROJECTION Name : Sri Lanka TM

Type : Transverse Mercator

Latitude origin : 07-00-01.729 N

Longitude origin : 80-46-18.160 E

False easting : 200,000

False northing : 200,000

Scale Factor Org : 0.99992384189

The Sri Lankan metric grid is in a period of transition as at 2004/2005. The original 200,000 /

200,000 False Easting and Northing are being replaced by 500,000 / 500,000 values. Scale

Factor for these coordinates is as above.

Control Stations for the setting out of the Works and Contractor’s Bench Marks are indicated

on Drawing D105234/GE - S / 0013. Control station parameters shall be jointly surveyed and

confirmed by the Contractor and Engineer prior to commencement of the Works.

The Contractor shall at the commencement of the Works establish additional fixed survey

stations which will be used for setting out the Works. He shall construct the survey stations in

suitable positions and in such a manner that they are not disturbed during the execution of

the Works.

The Contractor shall protect the survey stations from damage throughout the execution of the

Works, and shall repair or replace at his own cost any that are damaged or destroyed.

Section –1 Page 14 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.012 Level Datum

The level datum adopted for the Contract is LWOST Datum (0.0m). This datum shall be used

during the execution of the Works.

Drawing number D105234/ GE-S/ 0013 indicates the location of the control bench mark. The

Contractor shall be responsible for the establishment of such additional bench marks as he

deems necessary for the construction of the Works.

Should the Contractor consider there to be any discrepancy between the survey and design

information, at any point, he shall notify the Engineer accordingly, in writing, stating the basis

for his concern. The Engineer will instruct mitigating measures to be adopted to resolve any

proven discrepancy.

1.013 Topographic Survey

Prior to commencing the Works the Contractor shall carry out a topographic survey of the

land area of the Site, in which the position and level of all existing features shall be accurately

measured. The area of this survey shall be extended to include the areas where the Works

will tie into the existing topography and structures.

The Contractor shall prepare survey drawings plotted to a scale of 1:500, indicating the local

grid and the location of all existing infrastructure, earthworks and other installations and

features. The survey drawings shall be signed off as a true agreed record by the Contractor

and the Engineer prior to the commencement of Works. The Contractor shall supply the

Engineer with two hard copies of the signed plots and a ‘soft’ electronic copy in an agreed

format.

1.014 Condition Survey

Prior to commencement of the Works the Contractor shall undertake jointly with the Engineer

a condition survey of the existing structures, highways and installations which are likely to be

affected by the Works or operations associated with the execution of the Works.

The Contractor shall prepare a report as a written and photographic record of the condition of

these structures, highways and installations. This report shall be signed by the Contractor

and the Engineer as an agreed record and two copies provided to the Engineer by the

Contractor.

1.015 Bathymetric Survey

Before commencing marine construction, dredging or reclamation works in any area, the

Contractor shall undertake a bathymetric survey jointly with the Engineer. The survey shall be

carried out in accordance with Section 5 of this Specification relating to Dredging and

Reclamation works. Post dredge and post reclamation surveys shall be carried out in

accordance with Section 5 and other applicable Sections of this Specification.

The survey shall be plotted to a scale of 1:500 and shall show the local grid. The survey

plot(s) shall be jointly signed by the Contractor the Engineer as an agreed record. A hard

copy of the survey plot(s) shall be given to the Engineer together with an electronic copy of

the plot and original survey data in approved formats.

1.016 Movement Monitoring

The Contractor shall monitor the movement of structures and elements of the Works during

construction as required by the relevant sections of this Specification.

The frequency of monitoring surveys shall be agreed with the Engineer following receipt of

the Contractor’s programme for the Works. For the purposes of planning, monitoring for

movements shall be carried out at a minimum of once weekly.

Section –1 Page 15 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

Measurements shall be taken at survey points and settlement stations to be established by

the Contractor at locations agreed with the Engineer.

The results of all monitoring surveys shall be recorded and plotted in an agreed format. Hard

and electronic copies of all data and plots shall be submitted to the Engineer by the

Contractor for his records.

Where the results of any movement survey have a bearing on the design, performance or

programming of the Works the Contractor shall not proceed without the prior agreement in

writing of the Engineer. Such agreement or otherwise will be provided within seven days of

receipt, by the Engineer, of the appropriate records.

Conduct of the Works

1.017 Access to Site

The CSH Works are to be constructed adjacent to and connected to the existing Port of

Colombo. Vehicular access to the Site shall be through the operational port areas using the

present highways network and associated highway structures.

Access to the Contractor’s working area and materials offloading facility (MOF) shall be

generally as indicated on Drawings No. D105234/GE-S/0012 & 0016. The Contractor shall

consider the available depth of water in the area and determine the optimum method of

transporting reclamation materials to provide adequate land area and water depth for the

establishment of the site compound and working areas. The Contractor shall at all times

conduct construction activities, both on land and at sea, in compliance with Clause 1.018.

The Contractor shall satisfy himself that the existing height and width clearances to bridge

structures are adequate for the passage of his proposed vehicles.

In addition the gross weight of his vehicles shall not cause damage to the carriageway and

bridges on the access route.

1.018 Interference with Other Operations

The Works are to be constructed, in part, adjacent to operational container terminals and

other operational Port facilities.

The Contractor shall execute the Works throughout the period of construction so as not to

interfere with third party traffic or the use of the existing facilities in the vicinity of the Site and

shall co-ordinate his activities with the Port authorities, and comply fully with their

requirements.

In particular the Contractor shall not interfere with the movement of marine traffic to and from

the Port of Colombo.

The Contractor shall programme the Works so as to cause minimum interference and

disruption to other parties with approved access to Contractor’s working areas, or rights of

way on the Site or in its approaches, and shall make due allowance for the work of other

contractors working on or near the Site.

The Contractor shall construct temporary diversions where Works activities are likely to

interfere with the existing foot and/or vehicular traffic. Diversions shall be to the approval of

the Engineer and concerned authorities, and shall have a capacity not less than that of the

routes which they replace. They shall be constructed in advance of likely interference and

shall be maintained throughout the required period and removed when no longer required.

1.019 Working within a Port Security and Customs Area

The site of the Works is within a Port Security area and is adjacent to or partially within a

Customs Bonded area. Colombo Port is a signatory to the International Ship and Port Facility

Section –1 Page 16 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

Security Code (ISPS) and the Sri Lankan Navy is the ISPS authority. The Contractor shall be

bound by any security requirements imposed by the Navy.

The Contractor shall be responsible for liaison with the appropriate Authorities and for

obtaining all necessary permits and approvals for working within and entering / leaving the

designated areas.

1.020 Agreement of Engineer to Significant Operations

Notwithstanding the submission by the Contractor and agreement by the Engineer of any

programme, no significant operation shall commence without the written consent of the

Engineer.

1.021 Notice for Checking by Engineer

The Contractor shall give the Engineer a minimum of 48 hours notice of any proposed

operation to enable the Engineer to make such necessary arrangements for checking and

supervision. The Contractor shall only request inspections when works have been

completed in accordance with the Contract and the Contractor is satisfied that those works

are satisfactory and ready for inspection.

1.022 Loads on Existing Structures

The Contractor shall be responsible for liaison with the owners and occupiers of all existing

structures, either within the Site boundary on its boundary or likely to be affected in any way

by the proposed methods of construction.

Further to the provisions of Clause 1.017 the Contractor shall be responsible for assessing

the strength of the existing structures and their capacity to carry any loads imposed by

Contractor’s Equipment or Vehicles delivering Goods. Any damage to these structures due to

the use or passage of the Contractor’s Equipment or other vehicles shall be rectified by the

Contractor at his expense.

1.023 Sequence of Construction and Programme

The Contractor shall prepare and submit detailed method statements to accompany the

programme of Works. Particular consideration shall be given to the following sequence of

construction requirements:

• Use of dredged material in the Works

• Monsoon period working

• Breakwater construction Stages

• Surcharge and consolidation periods.

A programme, in accordance with Clause 8.3 of the Conditions of Contract, shall be prepared

by the Contractor using the latest version of Primavera, Microsoft Project or similar software,

clearly indicating the critical path.

The work headings to be shown in the programme shall be the main elements of the Works

and the structure shall be aligned with the work breakdown structure established and agreed

with the Engineer.

The programme shall clearly show the inter-relationship between the elements of the Works

and any dependencies between them. It shall also show the Monsoon periods and assign as

necessary alternative production rates for those activities affected by the seasonal weather

and sea states.

Each work heading shall be split into detailed activities including design (where required),

approvals, delivery of Materials, temporary works, fabrication, precasting, construction,

testing and commissioning. Long lead-in items and their lead-in times shall also be identified.

Section –1 Page 17 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

Work to be undertaken by third parties shall be shown as separate activities. The duration of

activities to be undertaken by the Contractor shall be broken down into periods not exceeding

4 weeks.

Each activity shall be uniquely referenced. Bar charts, logic diagrams/tables and any other

necessary tabular and graphical reports shall be submitted to show the following information

for each activity on the network:

(a) Reference

(b) Description

(c) Duration

(d) Relationship with other activities

(e) Early and Late Start and Finish Dates

(f) Resources or Unit Production Time.

The Contractor shall provide all network details in electronic format.

Control of Programme

Progress against the programme shall be updated by the Contractor at monthly intervals so

that the progress of the Works can be adequately monitored by the Engineer and the

Employer.

The Contractor shall assess and report progress on each activity and all other input data not

more than 2 days after the scheduled time for an update. Changes in the network logic may

only be made after consultation with the Engineer.

The Contractor shall submit to the Engineer updated programming data (bar charts, tables

and disk), showing actual progress and comparison with the programme.

Where slippage has occurred, the Contractor shall give explanations together with his

proposals for recovery of critical activities.

1.024 Progress Meetings

Progress meetings will be convened by the Engineer at both weekly and monthly intervals

and at other times as appropriate. The purpose of the meetings will be to review the

progress of the Works, to discuss the Contractor's programme and to cover such other

matters under the Contract as may be specified or notified by either the Engineer or the

Contractor. Such meetings shall be attended by an authorised senior representative of the

Contractor. A senior representative of the Employer and the funding agency may also attend

monthly meetings.

The agenda and minutes of each meeting will be prepared by the Engineer with a copy to the

Contractor. The Contractor shall record agreement of the minutes, either by signing them or

by minuted oral agreement at the following meeting.

1.025 Attendance upon Trades

Each trade shall provide for, and make good as necessary, all other trades so that each

section of the work is carried out in its correct sequence and completed in accordance with

the Specification.

1.026 Setting-out of Works

The Contractor shall give the Engineer not less than 24 hours’ notice of any intention to set

out or take levels for any part of the Works so that arrangements may be made, if required,

for monitoring the work. The accuracy of setting out and levelling shall be as called for in the

Specification, or as agreed with the Engineer; in the absence of other information, the

tolerances specified in BS 5606 shall be taken as the minimum requirement.

Section –1 Page 18 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.027 Existing Services

The Contractor shall be responsible for locating and identifying existing services within the

Works and for protecting them during the progress of the Works.

Where appropriate, the Contractor shall with prior approval open up the ground in advance of

the main work, by hand digging if necessary, to locate precisely the position and details of the

services which are likely to affect its operations.

The Contractor shall be responsible for arranging any necessary temporary diversion,

supports and protection from interruptions of services. The Contractor shall carry out these

temporary diversions as directed by, and to the satisfaction of, the appropriate authority and

the Engineer.

The existing storm water drainage outfalls are indicated on Drawing No D105234/GE - D/

6200. The Contractor shall take all necessary measures to ensure the flow from these

outfalls is maintained throughout the construction of the Works, until such time as the flow

from these outfalls is diverted into the permanent drainage Works.

The Contractor shall remove all temporary diversions and re-instate the Site upon completion

of the final permanent diversions to the satisfaction of the appropriate authority and the

Engineer.

1.028 Existing Obstructions

General

The Contractor shall satisfy himself as to the nature and extent of any obstructions and shall

be responsible for taking any necessary measures to deal with any obstructions which may

affect the Works. Such measures shall, for obstructions encountered under water, include the

provision of buoys and lights and all things necessary for the safety of navigation while the

obstruction remains. The Contractor shall remove any such obstruction as is necessary for

the proper completion of the Works.

Marine Works

The Marine Works are generally to be carried out in an offshore area not previously

developed. Obstructions are anticipated to be of the form of wrecks and debris deposited at

sea.

The Contractor is advised to review the Site Investigation documents available including the

Side Scan Sonar (SSS) result plots and subsequent diving inspection reports, available for

inspection on request. The SSS results and the subsequent diving inspection have identified

the nature of the targets found and, where practicable, have quantified the magnitude of the

obstruction.

Wrecks and other targets to be removed by the Contractor are scheduled on Drawing No.

D105234 / DE – W / 0015.

It is anticipated that the remaining targets will be undisturbed by the Works or buried by

subsequent reclamation work.

On-Land Works

The Contractor shall note that a proportion of the on-land Works are in an area where

structures may have been constructed in the past and remnants of these and other

obstructions may be present.

1.029 Silting of Works during Construction

The Contractor shall ascertain the propensity of the Site for inundation by silt or debris of any

sort during construction, whether from the Contractor's activities, the activities of others or as

a result of natural conditions. The Contractor will be responsible for removing silt and debris

Section –1 Page 19 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

from the Works to meet the requirements of the Contract and the Engineer, and to enable the

completed Works to fulfil their required function(s).

1.030 Project Signboards

The Contractor may provide a sign or signs on Site stating the project and the names of

Contractor, Employer, Engineer and the Bank. The sign(s) shall be subject to approval by the

Engineer and Employer.

1.031 Fencing, Hoardings, Watching & Lighting

The Contractor shall provide and maintain continuous fencing or hoardings around the areas

of work, storage, offices, etc., and all necessary watching and lighting. The Contractor shall

have at least one watchman at each main area of work at all times when work is not in

progress.

For work at night the Contractor shall arrange adequate lighting at each area of operation

with adequate standby in case of failure. The Contractor shall satisfy the relevant authorities

that such lighting will not constitute a hazard to traffic by land, sea or air in the areas adjacent

to the Site.

1.032 Traffic Safety & Control on Site

The Contractor shall provide, erect and maintain such traffic signs, lights, barriers and other

measures as may be necessitated on Site by the execution of the Works. The measures

shall be to the approval of the Engineer and of the relevant authorities.

1.033 Port Entry Passes

The Contractor shall, where necessary, arrange for all employees and subcontractors and

any of his visitors to have valid port entry passes and identification cards required for access

the Site.

Port entry passes may be applied for by providing the necessary information to the following

contact: SLPA Port Permit office tel. 2421201 or 2421231.

1.034 Visitors

The Contractor shall not allow any unauthorised visitors on the Site. Authorised visitors shall

sign a Contractor's visitors book. The Contractor shall provide safety equipment and

appropriate protective clothing for such visitors.

1.035 Cleaning and Clearing of Roadways and Footpaths

The Contractor shall ensure that existing roadways and footpaths used by vehicles or

Equipment of the Contractor, his suppliers or subcontractors are kept clean and clear of all

materials, dirt, soil or debris.

1.036 Noise Control

The Contractor shall follow the general recommendations of BS 5228 to minimise noise and

vibration arising from construction activities, noting the existence of important buildings in the

vicinity including the President’s House and offices of the Ministry, SLPA and Government

Departments.

1.037 Debris

The Contractor shall not discharge any oil or noxious materials within the Site or into drains,

ditches, watercourses or the sea adjoining the Site. The Contractor shall remove from the

Site and the adjacent areas any debris arising out of the construction of the Works.

Section –1 Page 20 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.038 Health and Safety, Generally

The Contractor shall comply with the health and safety requirements of the Specification and

with the health and safety recommendations for building and civil engineering work published

by the International Labour Organisation and the Ministry of Employment and Labour, Sri

Lanka (Ref – Labour Code of Sri Lanka (2004)) and (Understanding Labour Law (2002)).

1.039 First Aid Facilities

The Contractor shall provide and maintain at each main area of the Works, including floating

Equipment, first aid medical facilities for the use of the Contractor's personnel and also those

of the Employer and the Engineer.

1.040 Life Saving Apparatus and Rescue Boat

Life saving apparatus on floating Contractor’s Equipment shall comply with current maritime

regulations appropriate for the type of equipment.

In addition, for land based works the Contractor shall provide and maintain at each active

marine area of the Works a minimum of three lifebelts, with buoyant lifelines at least 30m

long, in easily accessible positions, together with a boat suitable for rescue work fully

equipped and ready for immediate use.

The rescue boat shall be deployed whenever operations are taking place on, over or

adjacent to water.

1.041 Diving

All diving operations shall be carried out in accordance with accepted international standards

of safety (eg "Diving Operations at Work Regulations 1981" (SI 1981 No. 399) issued under

the Health and Safety at Work Act of the United Kingdom) and to the satisfaction of the

Engineer.

Prior to the start of any proposed diving operations the Contractor shall submit to the

Engineer a copy of the diving rules intended for use generally, and also to any hazards

peculiar to specific aspects of the Works and to shipping. The Contractor shall also submit to

the Engineer a general method statement for diving operations.

The Contractor's diving team shall have, as a minimum requirement, a competent diving

supervisor, two qualified divers and a linesman in attendance at all times when underwater

works requiring diving are being carried out.

The diving equipment used by the Contractor shall conform to international diving standards.

1.042 Use of Explosives

The storage, handling, transport and use of all explosives for use in connection with the

Works shall be the responsibility of the Contractor, and shall be in accordance with the

requirements of Specification Section 20 “Use of Explosives", relevant authorities, the

Employer, and with the applicable recommendations in BS5607.

Before using explosives, the Contractor shall submit to the Engineer written details of

proposed warning and safety precautions for the protection of all persons, works, property

and shipping from injury or damage.

Generally, blasting will not be permitted within 30 metres of any completed Permanent Works

under water or 20 metres on land, and shall be carried out only during the hours of daylight.

These limits shall be subject to confirmation following receipt of details of the Contractor’s

proposals and any trials deemed necessary by the Engineer or other authority.

Section –1 Page 21 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.043 Quarries, Borrow Pits and Haul Roads

The Contractor shall be entirely responsible for making arrangements for the supply of

quarried stone and for ensuring that the materials obtained meet the Specification and are

available in sufficient quantities to enable the programme to be met. All quarried rock shall be

brought to the Site by sea.

A report on “Sources of Materials for Breakwaters Construction” is available for review. This

report includes a survey of a number of operating and potential quarry sites within a short

haul distance from the coast.

The Contractor’s attention is drawn to the environmental legislation in Sri Lanka. It will be

necessary to apply for a Mining Licence for expansion of any existing quarry or development

of new quarries. A significant part of any such application is submission of an Environmental

Impact Assessment.

The Contractor shall be wholly responsible for the transport of rock from quarries to the Site.

Arrangements for a haul road from the quarry to a load-out facility shall be made with the

local Divisional Secretariat, Roads Development Authority or other duly authorised body. Use

of an existing harbour facility for load-out to barge shall be agreed with the relevant Authority.

Construction of temporary load-out facilities at the coast will require the approval of the Coast

Conservation Department, in addition to local Authorities.

The Contractor may wish to develop the rock resource at Piyiangala in the Ampara Region.

This is on Government land and the Employer holds an EIA permit for the extraction of

material for the construction of a port at Oluvil. Information on this and other potential

services of rock is given in Appendix 1.7.

Marine Operations

1.044 Port Limits and Approvals

The Operational Limits of the Port of Colombo, for which the Sri Lanka Port Authority (SLPA)

has responsibility for vessel control, falls within the area contained by the following:

i. LAT 07° 2’ N LONG 079° 43’ E

ii. An Eastery line 90° from position (i) to the Coast

iii. LAT 06° 52’ N LONG 079° 43’ E

iv. An Eastery line 90° from position (iii) to the Coast

v. A North / South line connecting Positions (i) and (iii).

These limits are shown on drawing D105234 / GE – D / 0010.

The Contractor shall make all arrangements and obtain all necessary approvals and

consents for any temporary marine traffic arrangements and controls within this area.

Not less than 14 days before marine works commence, the Contractor shall submit the

following to the Engineer:

a) Evidence that SLPA and Naval authorities have been notified of the intention to

commence the Works.

b) Licences, permits etc to undertake the Works and any related conditions or restrictions.

c) Approval of temporary marine traffic control arrangements.

1.045 Floating Equipment and Craft

The Contractor shall comply with the regulations and shall obey the orders of relevant

authorities in respect of navigation or mooring of floating Contractor’s Equipment and craft in

the adjacent waterway/harbour and in the vicinity of the Site, and shall conduct operations in

such a manner that they do not interfere with the use of the waterways, anchorages or

wharves, jetties, causeways, dolphins etc.

Restrictions are imposed by the Naval Authorities on the speed and engine characteristics of

all craft operated within the Port Limits. The Contractor shall ensure that all craft and crew

Section –1 Page 22 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

intended for use during the execution of the Works are duly authorised and approved by the

Port and Naval authorities prior to their operation.

Only classified vessels, fully registered and recently surveyed to IMO standards, shall be

used on the Works, including for the transport or handling of rock. The Contractor shall

maintain all floating Equipment in good working order and in a seaworthy condition, and shall

provide copies of current seaworthiness certificates if required by the Engineer.

All craft and floating Contractor’s Equipment shall be manned at all times with adequate crew

and safety measures to be able to effectively deal with normal emergencies.

All floating Equipment shall be equipped with a comprehensive set of safety and first aid

equipment which shall be regularly checked and serviced, all in accordance with IMO

standards. This shall include, but not be limited to, sufficient lifejackets and lifebuoys for the

personnel on board, safety railing, fire extinguishers, lighting and navigation lights and signals,

a rescue boat with outboard engine maintained in a state of readiness at all times, and means

for the rapid evacuation of all personnel in the event of an emergency.

1.046 Navigation

The Contractor shall conform to any bye-laws and regulations concerning navigation and

shall obey the orders of any authorised officer in reference thereto. The Contractor shall

obtain all necessary approvals and permits from the appropriate authorities for any

operations that may affect the operations of the Port, and submit them to the Engineer at

least 7 days prior to commencing work.

Normal movement of craft within the harbour shall be notified to the authorised authorities.

All craft shall be fitted with VHF radios and sufficient safety equipment for the number of

persons permitted to be on the craft.

1.047 Reconfirmation of Marine Operations

Any marine operations to be carried out by the Contractor which involve the suspension of

ship movement and which have been agreed with the relevant authorities shall be

reconfirmed by the Contractor with both the Engineer and those authorities seven days

before the agreed date.

When the Contractor does not carry out any operation reconfirmed with the Engineer and the

relevant authorities, requiring the authorities to suspend shipping movement for the duration

of the operation, then the Contractor shall reschedule the operation to the convenience of the

authorities.

Any delays arising from rescheduling the operations to the authorities' convenience shall be

deemed to be the Contractor's responsibility and the Contractor shall not be entitled to any

extension of the Time for Completion of the Works, unless the Engineer is satisfied that the

rescheduling is due to circumstances outside the Contractor's control.

1.048 Mooring, Buoys, Lights etc

The Contractor shall provide such buoys, moorings and fastenings as may be required for

securing the floating Contractor’s Equipment and craft and also such buoys, warning lights,

signs and signals (if any) arising as a consequence of undertaking the Works as the

appropriate authorities may direct or as the Engineer may deem necessary to meet the

requirements of the authorities.

All mooring arrangements, locations and periods of use shall be agreed by the relevant

authorities, and all anchors shall be marked by lit buoys. The Contractor shall submit for

approval by the Engineer an emergency plan for rapid removal from shipping channels of the

moorings required for floating Equipment.

Section –1 Page 23 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.049 Night time Markings and Lights

The Contractor shall during the execution of the Works provide and maintain every night from

sunset to sunrise such light or lights on or near the Works as the appropriate authorities or

the Engineer may require.

1.050 Radio Link with Port Authority, Contractor's Radio Equipment

The Contractor shall carry VHF radio-telephones on all self-propelled marine Equipment so

that communication can be made at all times with the Port Authorities. The radios shall be

manned at all times during working hours and all radio messages shall be logged.

The radios shall operate on agreed channels and the Contractor shall maintain a listening

watch on one of them during the periods that the marine Equipment is within the port limits.

Radio frequencies used by the Contractor, including those relating to on-board

communication equipment, shall be to the approval of the duly constituted authority having

jurisdiction. The Contractor shall be responsible for obtaining the necessary licences and

permits.

1.051 Pilotage

The extent of the Colombo Port Limits are as set out in Specification Clause 1.044 and

shown on Drawing No. D105234/GE-D/0010.

Generally Contractor’s floating Equipment operating within these limits, outside the existing

breakwaters, shall be exempt from pilotage.

The requirement for pilotage on vessels wishing to enter the port may be waived at the

discretion of the Port Authority but shall be subject to negotiation.

1.052 Tide Gauges

The Contractor shall establish a master tide board and a pressure operated radio tide gauge

on a firm foundation at an easily accessible sheltered location to be approved by the

Engineer. A piled foundation and/or artificial shelter shall be constructed if it is necessary, in

the opinion of the Engineer, to provide the necessary support and/or shelter. On completion

of the Works the master tide board and its foundations/shelter, if any, shall become the

property of the Employer.

The master tide board shall be levelled directly from the main survey control datum and the

radio tide gauge subsequently calibrated from the master tide board. The reading of the

radio tide gauge shall be checked daily against the master tide board. The tide board shall be

checked against an approved benchmark when requested by the Engineer and in any case

at intervals not exceeding 1 month.

Facilities and Equipment for Engineer's Site Staff

1.053 Office Accommodation

The Contractor shall provide on Site for the sole use of the Engineer the following office

accommodation within temporary buildings. Areas given are the minimum required and are

exclusive of circulation areas.

Offices 10 no. total area 180 m2

Meeting Room 2 no. area 40 m2

Canteen 1 no. area 30 m2

2

Store/Filing Area 2 no. total area 20 m

Server Room 1 no area 4 m2

Welfare facilities , shower and w/c facilities 25 m2

The design, construction, location and layout of building(s) and surroundings shall be agreed

with the Engineer.

Section –1 Page 24 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

The Contractor shall, not more than 7 days after the Commencement Date, submit full details

to the Engineer, including floor plans, elevations, construction principles, materials, fittings

and finishes, before commencing erection. Both the building and the facilities shall be

suitable for the environmental conditions prevailing at the Site. The Contractor shall provide

all additional incidentals necessary, so that the facilities will be completely adequate and

satisfactory in every respect for their intended use.

The Contractor shall be responsible for raising the ground (if necessary), grading and

drainage in the vicinity of the buildings, with suitable access and walkways. The Contractor

shall construct a covered hard-standing, for the exclusive use of the Engineer and his visitors,

of sufficient size to accommodate 15 vehicles adjacent to the office, and an access road to

the parking area. The access road shall be high enough in order not to be inundated during

heavy rain. Outside lighting shall be installed around the buildings and the parking area, and

appropriate signs shall be erected to indicate the purpose of the facilities.

Buildings shall be complete with all services connected including potable water, electricity

and sewerage. Each room shall be provided with least four 13 amp sockets. All power shall

be 220-240V, 50Hz, except where otherwise agreed by the Engineer. All rooms shall be

illuminated by fluorescent lighting.

Facsimile and PABX telephone services, including international direct dialling, shall be

provided in the main office by the Contractor. These shall be in the name of the Contractor

who shall pay all user charges, including installation, maintenance and removal. Each office

shall be equipped with a telephone connected to the PABX.

Offices and meeting rooms shall be air conditioned. The air conditioning may be either

individual units or a central ducted system and shall be adequate to maintain a temperature

of not more than 24oC (dry bulb) at a relative humidity of 50% during the hottest season of the

year. The noise level of the air conditioning while working should be sufficiently low to allow

normal voice level discussions to take place.

The Server room shall be air-conditioned to provide environmental conditions suitable for the

operation of electronic computer office equipment on a continuous 24hr basis.

Buildings shall be weatherproof, fire protected, heat-insulated and secure. Windows shall

give adequate light and ventilation and be protected with metal mosquito-proof gauze and

have security bars and venetian, or other approved, sun blinds. Ceiling height above the

floor level shall be at least 2.75m. All internal partition walls shall be sound insulated. Floors

shall be PVC tile covered. In toilets and other washing areas the floors shall have drains to

assist cleaning.

All doors shall be fitted with locks, with two keys provided for each lock. Two master keys

shall be provided, appropriate to all locks.

The Contractor shall provide, to the approval of the Engineer, the office furniture and fittings

as scheduled in Appendices 1.1 and 1.2 to this Section.

Full office accommodation, furniture and fittings shall be provided complete within 28 days

after the Commencement Date and shall be equipped and maintained by the Contractor to

the satisfaction of the Engineer until 3 months after the issue of the Taking-Over Certificate

for the Works or such earlier time as instructed by the Engineer, whereupon the buildings and

furniture shall be removed from the Site. Reduced office accommodation facilities, to be

agreed with the Engineer, shall be provided throughout the Defects Notification Period until

the issue of the Performance Certificate.

The Contractor shall provide all labour, materials and equipment for maintaining and cleaning

offices, furniture and fittings. The Contractor shall replace and/or restore, as directed, any

facilities or parts thereof that become damaged, worn out, lost or stolen. The Contractor shall

provide an adequate stock of all expendable items and shall ensure proper and continuing

functioning of all components and parts of the facilities.

Section –1 Page 25 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

The Contractor shall provide a full time cleaner to ensure that the offices of the Engineer are

cleaned daily. Containers shall be provided for waste disposal in each office and these shall

be emptied and disposed of daily by the Contractor.

1.054 Equipment

The Contractor shall provide, to the approval of and for the sole use of the Engineer, the

equipment as scheduled in Appendices 1.3 and 1.4 of this Section.

The equipment shall be provided and be fully operational within 28 days after the

Commencement Date or at such other time as agreed by the Engineer. It shall be maintained

by the Contractor to the satisfaction of the Engineer until 3 months after the issue of the

Taking-Over Certificate for the Works or such earlier time as instructed by the Engineer,

whereupon the items shall be removed from the Site. The equipment, other than personal

protection equipment, shall remain the property of the Contractor and shall revert to the

Contractor upon the authorised removal of the office, or at such prior time as instructed by

the Engineer. Reduced equipment, to be agreed with the Engineer, shall be provided

throughout the Defects Notification Period until the issue of the Performance Certificate.

The Contractor shall be responsible for maintaining the equipment in full working order and

shall repair or replace at his own expense any equipment which is damaged or defective for

any reason.

The Contractor shall be responsible for filling as required the air bottles provided for diving

use by the Engineer, using approved equipment. The Contractor shall have sufficient

reserve bottles to ensure that two charged bottles are always available.

1.054 Materials Testing Laboratory

The Contractor shall provide a laboratory for the use of both the Contractor and the Engineer,

for the testing of materials on Site in accordance with the Specification, including such

additional tests as may be required. It shall be operated by staff provided by the Contractor

working under the direction of the Engineer.

The laboratory shall be in a self-contained temporary building at a location agreed with the

Engineer. It shall have a plan area sufficient to accommodate all the equipment, materials,

functions and test programmes laid down in the Specification and any further testing required

by the Contractor to ensure the quality of the Works.

The laboratory shall include, for the exclusive use of the Engineer, an enclosed, air

conditioned office of at least 6m2 area with soundproof partition walls and an internal lockable

door. The office shall be equipped with a telephone and electrical sockets with furnishings

and fittings similar to those for the Engineer's office.

The store area shall be not less than 10 m2 and the laboratory plant / testing area a minimum

of 24 m2.

The laboratory building shall be to the standards specified for Engineer's offices and to the

approval of the Engineer.

The Contractor shall equip the laboratory with sufficient new equipment of the best quality to

carry out the laboratory tests as required in the Specification. The Contractor shall refer to the

Specification for the minimum of tests required.

The laboratory, furnishings and test equipment shall be provided and be fully operational

within 28 days after the Commencement Date and shall be maintained by the Contractor to

the satisfaction of the Engineer until 3 months after the issue of the Taking-Over Certificate

for the Works or such earlier time as instructed by the Engineer, whereupon the laboratory

shall be removed from the Site. The test equipment shall remain the property of the

Contractor and shall revert to the Contractor upon the authorised removal of the laboratory,

or at such prior time as instructed by the Engineer.

Section –1 Page 26 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

The Contractor shall provide all labour, materials and equipment for the maintenance and

cleanliness of the laboratory. Containers shall be provided for waste disposal and these shall

be emptied daily by the Contractor.

The Contractor shall be responsible for ensuring that all test equipment is correctly calibrated

before it is used for testing. The Contractor shall in addition arrange periodic calibration

checks in accordance with the manufacturer's recommendations, or as stated in the relevant

standard or directed by the Engineer. The Contractor shall provide evidence of calibration

checks whenever required by the Engineer.

The laboratory shall incorporate space and facilities for storing and curing of concrete test

cubes and other test samples in accordance with the Specification.

The laboratory shall be provided with sufficient work benches to accommodate the

equipment provided.

A schedule of typical testing equipment in contained in Appendix 1.5 to this Section.

1.055 Motor Vehicles

The Contractor shall provide, within 14 days after the Commencement Date, or at such later

time as approved by the Engineer, the following new vehicles for exclusive use by the

Engineer.

No Type Description

2 A 4×4 Station Wagon 2.8 Turbo Diesel (Toyota Landcruiser or similar)

2 B 4×4 Twin cab utility vehicle (pick-up) 2.8 Turbo Diesel (Toyota Hi-Lux or

similar)

2 C 1.8 Lt Saloon (Nissan Primera or similar)

2 d 10 seat minibus

Detailed specifications of the vehicles, associated equipment, spare parts and manuals shall

be submitted to the Engineer for approval.

If any vehicle is unavailable for use for whatever reason the Contractor shall replace it with a

similar vehicle for the whole period of unavailability.

The vehicles shall be registered in the Contractor's name and shall remain the property of the

Contractor for the duration of the Contract. The Contractor shall be responsible for all

Customs clearance and licensing of vehicles for the duration of the Contract.

During the Contract the vehicles shall remain within the custody of the Engineer but they shall

be insured, fuelled, cleaned, repaired, serviced and maintained by the Contractor. Each

vehicle shall be provided with a qualified and experienced driver. The Contractor shall be

responsible for providing all spare parts to keep the vehicles in full safe working order.

Vehicles provided by the Contractor may be used by the Engineer in connection with other

works for the Employer. The Contractor shall ensure that insurance cover to this ‘extra-

curricular’ use is in place for the duration of the Contract.

The Contractor shall obtain all permits to allow the vehicles to enter and leave the port or

other restricted areas for the purpose of the Works.

Upon completion of the Contract all vehicles purchased under the Contract shall be fully

serviced and handed over to the Employer and the registration transferred to the Employer’s

name.

Section –1 Page 27 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.056 Boat for the Use of the Engineer

The Contractor shall provide a crewed launch of at least 8m length powered by an inboard

engine for the exclusive use of the Engineer in the waters adjacent to the Works during hours

when the Contractor is working. It shall be of robust construction and suitable for use in open

sea conditions. It shall be licensed (where appropriate), and maintained in good seaworthy

condition. It shall have a maximum speed of at least 5 knots and good slow speed

characteristics.

The forward part of the boat should have an enclosed area with a chart table and lockable

compartment. The aft part of the boaft shall be open with a canvas awning and be provided

with seats along the gunwales for at least 6 passengers, excluding crew.

The crewed launch shall be equipped with sufficient safety equipment for all crew and

Engineer’s staff.

1.057 Survey Craft

The Contractor shall provide a craft with crew suitable for carrying out hydrographic surveys

which shall be made available to the Engineer as required, but will not be for the Engineer's

exclusive use. The survey craft shall be equipped with a maintained echo sounder and

supply of paper as specified in Section 5 of this Specification.

1.058 Diving Pontoon

For the purpose of diving inspections, as required by the Engineer, the Contractor shall

provide a suitable equipped diving pontoon with crew for the use of the Engineer. The

pontoon shall be suitably sized to carry an enclosed weatherproof and insulated office cabin

for the diving inspector of minimum area 10m2 and a deck area of at least 10m2 for

accommodating diving equipment and operations.

The diving pontoon shall be seaworthy, sufficiently stable to be fully usable by divers at all

times when marine works are being undertaken, and adequate for the security and safety of

equipment and personnel.

The Contractor shall provide the pontoon with means of access agreed with the Engineer.

The open deck space shall be covered with a canvas awning to an extent agreed with the

Engineer.

The Contractor shall submit to the Engineer full details of the diving pontoon for approval in

sufficient time to mobilise before diving works commence.

The Contractor shall move the pontoon between positions as and when required by the

Engineer, to suit the progress of the Works, and shall ensure that the pontoon is adequately

moored in safe and convenient locations.

Attendance upon the Engineer

1.059 General

The Contractor shall provide such assistance and supply such labour, materials and

equipment as may be required by the Engineer to support the Engineer and his staff in

carrying out his Site duties under the Contract.

1.060 Setting-out and Survey Staff and Small Equipment

The Contractor shall provide the services of competent chainmen, staffmen and labourers

and shall supply materials and small tools such as pegs, poles, lines, spirit levels and other

items required by the Engineer for checking the setting out of the Works or carrying out

surveys.

Section –1 Page 28 of 57 December 06

© Scott Wilson Group Plc 2006

Colombo Port Expansion Project

Harbour Infrastructure Works

Specification

1.061 Materials Testing Staff and Transport

The Contractor shall provide suitably experienced, qualified laboratory technicians and

assistants to carry out, under the direction of the Engineer, the testing of materials. The

Contractor shall also provide transport, as required, for sampling and testing.

1.062 Vehicle Drivers

The Contractor shall provide, as required by the Engineer, competent and licensed drivers for

all of the vehicles provided for the use of the Engineer. Drivers shall be able to speak English

and shall be made available during normal working hours and at such other times as may be

required by the Engineer to undertake duties under the Contract or in connection with other

works for the Employer.

1.063 Boat Crew

The Contractor shall provide experienced crew to operate all boats and craft to be made

available for the use by the Engineer in a safe manner. They shall be made available during

normal working hours and at such other times as may be required by the Engineer to

undertake duties under the Contract. At least one crew member on each boat or craft shall be

proficient in English.

1.064 Diving Assistance

The Contractor shall provide a diving team to attend the Engineer when undertaking diving

work in connection with the Works. The team shall comprise at least the following:

• a competent supervisor

• a stand-by diver

• a competent linesman.

Accommodation and Facilities for Contractor

1.065 Contractor’s Compound Area and MOF

An area just outside the port on the southern boundary shall be made available to the

Contractor for his initial working area and compound. This is shown on Drawing D 105234 /

GE-TW/0016. Only cars and light vehicles may access this area from the South (Galle Face).

All other vehicles will be required to use the Port Access Road, transit through the Port and

then exit through Gate 1.

A further area as designated on Drawing D 105234 / GE –TW / 0016 has been allocated for

the Contractor’s longer term working area compound and Materials Offloading Facility

(MOF).

As no land area exists in the area indicated at present, the facility requires reclamation prior

to occupation.

The reclaimed area will become part of the Permanent Works and the southern edge of the