Professional Documents

Culture Documents

A02 - Utilities Requirements - Alk A485-1000 - Nel

A02 - Utilities Requirements - Alk A485-1000 - Nel

Uploaded by

You TubeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A02 - Utilities Requirements - Alk A485-1000 - Nel

A02 - Utilities Requirements - Alk A485-1000 - Nel

Uploaded by

You TubeCopyright:

Available Formats

Confidentiality Level: 2 - Confidential - CONFIDENTIAL

Document Title / N°: Utilities List A485-A1000

Rev. / Author / Approved: 211127 / Linda Larsen / Jon Guldsten

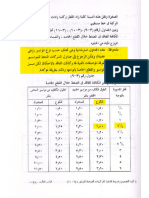

UTILITIES REQUIREMENTS (PRELIMINARY): ALKALINE WATER ELECTROLYSER

A485 (485Nm3/h) A1000 (970Nm3/h) Comments

KOH Initial Fill m3 25 50

Customer Scope INITIAL FILL Pressure Barg atm atm The KOH is not consumed by the process and is internally recycled.

(unless stated otherwise in quote) KOH Mixture Concentration % 15/25 15/25

Specific Water Use L/Nm3 <1 <1

DEMINERALISED WATER

STEADY USE DURING OPERATION

At full flow L/hr < 485 < 970

Customer Scope Demineralised water is applicable when the water purifier is not part of Nel scope

(unless stated otherwise in quote) Water Temp. design C° < 30 < 30

Pressure Barg 3-10 3-10

Specific Water Use L/Nm3/hr 1,4-2,6 1,4-2,6

POTABLE FEED WATER At full flow (485 Nm3/h) L/hr max 1300 max 2600

Potable feed water is needed to feed the RO/DI water purification system

(Potable water quality can affect usage) STEADY USE DURING OPERATION Water Temp. design C° < 20 < 20

(when included in Nel scope)

Customer Scope 6-10

Pressure Barg 6-10

RO/DI System Reject Drain (full load) L/hr Between 150 & 630 Between 300 & 1260

Coolant Load kW 460 920 At BOL, the major part of the heat at stack level will be carried off with the H2, O2, vapor,

Coolant Temperature as well as radiation and convection. This heat loss will remain constant over lifetime. The

C° <45 <45

remaining heat will be removed by the lye heat exchanger and will increase over lifetime

CELL STACKS - Design values (EOL) Coolant Flow at Temperature m3/h 38 76 due to degradation (~1%/year).

Delta T (in/out) C° 10 10

PROCESS COOLING Pressure Barg 2-10 2-10

Customer Scope Coolant Load kW 50-100 100-200

(unless stated otherwise in quote) Coolant Temperature C° <45 <45

CELL STACKS - Beginning of life (BOL) Coolant Flow at Temperature m /h3

5-10 10-20

Delta T (in/out) C° 10 10

Pressure Barg 2-10 2-10

st

1 FILL COOLANT PURITY Solid Particles Size /quantity µm/ mg/litre Max. 50 /100 Max. 50 /100

Coolant Load kW 120 240

GAS COOLING H2 Coolant Temperature C° <30 <30

SCRUBBER

3

Customer Scope Coolant Flow at Temperature m /h 11 22

(unless stated otherwise in quote) Pressure Barg >2 >2

st

1 FILL COOLANT PURITY Solid Particles Size /quantity µm/ mg/litre Max. 50 /100 Max. 50 /100

Coolant Load kW 34 / 28 69 / 57

GAS COOLING H2 Coolant Temperature C° <25 <25

DRYER (at 30 / 200 bar)

3

Customer Scope Coolant Flow at Temperature m /h 3 / 2,5 6/5

(unless stated otherwise in quote) Pressure Barg 2-10 2-10

1st FILL COOLANT PURITY Solid Particles Size /quantity µm/ mg/litre Max. 50 /100 Max. 50 /100

Coolant Load kW 125 / 161 250 / 323

COMPRESSOR COOLING H2 Coolant Temperature C° <30 <30

If compressor is selected COMPRESSOR (at 30 / 200 bar)

3

Coolant Flow at Temperature m /h 11 / 14 22 / 28

Customer Scope

(unless stated otherwise in quote) Pressure Barg 2-10 2-10

1st FILL COOLANT PURITY Solid Particles Size /quantity µm/ mg/litre Max. 50 /100 Max. 50 /100

3

Approx. Consumption Per Purge Nm 250 330

MAINTENANCE (COMPLETE SHUTDOWN ONLY) Min. Pressure Barg 3-10 3-10

RECOMMENDED AFTER SHUTDOWN AND BEFORE RESTART Quality % >99.98 >99.98

NITROGEN

Min. Qty Suggested On Site Nm3 500 660 Nitrogen is used for all purging operations

Customer Scope

Approx. Consumption l/h 200 400

STEADY USE DURING OPERATION (if compressor is selected) Min. Pressure Barg 3-10 3-10

Quality % Free from oil and water Free from oil and water

3

Approx. Consumption Nm /h 1 2

INSTRUMENT AIR

Customer Scope STEADY USE DURING OPERATION Min. Pressure Barg 5-10 5-10

(unless stated otherwise in quote)

Quality % Free from oil and water Free from oil and water

Medium Voltage: 6-32 kV AC, 3 phase, 50Hz/60Hz

ELECTRICAL POWER Ancillary Power: 380-690 VAC, 3 phase 50Hz/60Hz

TYPICAL INSTALLATION:

Customer Scope Control Panel Voltage: 110-230 VAC, 50Hz/60Hz

Voltage & frequency variation: +/- 5%

Nel can offer peripheral equipment as option for some of the utilities mentioned above. Please refer to the quote.

Nel reserves the right to make changes at any time without notice, in materials, equipment, specifications and models shown in this document. These are not necessarily showing the equipment that will be installed in your system.

©2021 Nel Hydrogen | Division: Electrolyser | Nel Confidential and Proprietary. Cannot be distributed without Nel’s approval. Page 1 of 1

You might also like

- Aquarius: Single-Jet MeterDocument3 pagesAquarius: Single-Jet MeterAdyIlieNo ratings yet

- Boiler Water Log Sheet BOILER TREAT ONE SHOT PROGRAMMEDocument1 pageBoiler Water Log Sheet BOILER TREAT ONE SHOT PROGRAMMEAbdi syahputraNo ratings yet

- 104 13479 Mob02918 DSH 420 J 0018 - 1Document3 pages104 13479 Mob02918 DSH 420 J 0018 - 1Roberto Capcha SernaNo ratings yet

- Baylan: KK-2P Single Jet Dry Type Water MeterDocument1 pageBaylan: KK-2P Single Jet Dry Type Water MeterJulian AmayaNo ratings yet

- Eutalloy 1202Document2 pagesEutalloy 1202Siddharth DasNo ratings yet

- 2-Way Flow Control Valve: RE 59032/05.04 Replaces: 04.03 Appendix To RE 28163Document2 pages2-Way Flow Control Valve: RE 59032/05.04 Replaces: 04.03 Appendix To RE 28163Cristian CanteroNo ratings yet

- Check Pilotada RPC12Document1 pageCheck Pilotada RPC12Daniel Sandoval FernándezNo ratings yet

- Vecom Marine Log For Medium-And High-Pressure Boilers Coordinated ProgrammeDocument2 pagesVecom Marine Log For Medium-And High-Pressure Boilers Coordinated ProgrammeAbdi syahputraNo ratings yet

- RBDA Full en Metric LetterDocument3 pagesRBDA Full en Metric LetteressamNo ratings yet

- SOLVOX Reactor Datasheet A4 RZ VIEWDocument2 pagesSOLVOX Reactor Datasheet A4 RZ VIEWsepulterNo ratings yet

- Process Flow Diagram of Ro System: InletDocument1 pageProcess Flow Diagram of Ro System: InletKELVIN TECHNOLOGIESNo ratings yet

- 150HV003-IFT-Data SheetDocument1 page150HV003-IFT-Data SheetgerardoNo ratings yet

- Datasheet For Booster PumpDocument1 pageDatasheet For Booster PumpLe Anh DangNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document5 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- 2PE Salami PDFDocument35 pages2PE Salami PDFMartin MiaNo ratings yet

- 08 - FPS01 Subsea Series (Issue 4 Feb 05)Document4 pages08 - FPS01 Subsea Series (Issue 4 Feb 05)Peter RhoadsNo ratings yet

- Cooling Water Log Sheet COOLTREAT NCLT TREATMENTDocument1 pageCooling Water Log Sheet COOLTREAT NCLT TREATMENTAbdi syahputraNo ratings yet

- BWT 9000 SCDocument1 pageBWT 9000 SCMehdi AcilNo ratings yet

- Belimo CCV Databook V8.6 05.2017 9Document1 pageBelimo CCV Databook V8.6 05.2017 9kautukNo ratings yet

- EGIC - BR - Catalogue 22-2-2022Document1 pageEGIC - BR - Catalogue 22-2-2022Ahmed YousriNo ratings yet

- 90 - 45Document2 pages90 - 45Ahmed YousriNo ratings yet

- Dry Vacuum Pump - LS SeriesDocument4 pagesDry Vacuum Pump - LS SeriesFardhal Virgiawan RamadhanNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- Concrete Mix Design - Grout Mix (SRC) : Cement Ggbs M.Silica Temp (Fresh Conc-) Mix ClassDocument1 pageConcrete Mix Design - Grout Mix (SRC) : Cement Ggbs M.Silica Temp (Fresh Conc-) Mix ClassAlbert NajjarNo ratings yet

- Atos - AdrDocument2 pagesAtos - AdrBillouNo ratings yet

- C10550231 PDFDocument1 pageC10550231 PDFsudhindra_tiwariNo ratings yet

- Electronic CCG: Oil FlowmeterDocument5 pagesElectronic CCG: Oil FlowmeterDimas Agil Roeseno KambunaNo ratings yet

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- 150FV054-IFT-Data SheetDocument1 page150FV054-IFT-Data SheetgerardoNo ratings yet

- 10 Medidor Chorro Multiple TK-4P 31 Al 33Document1 page10 Medidor Chorro Multiple TK-4P 31 Al 33Lester SolanoNo ratings yet

- Operating Manual Sec 12 - Chemical Injection - Rev0Document6 pagesOperating Manual Sec 12 - Chemical Injection - Rev0Anonymous aIuHKoKZjNo ratings yet

- Trimicron Filter Element N1Tm, N3Tm: Description Technical SpecificationsDocument2 pagesTrimicron Filter Element N1Tm, N3Tm: Description Technical SpecificationsSeyedAli TabatabaeeNo ratings yet

- Gear Pumps and Motors "B" Series Group 2,5: Technical CatalogueDocument29 pagesGear Pumps and Motors "B" Series Group 2,5: Technical CatalogueLucyan IonescuNo ratings yet

- Pump - Detail Calculation Sheet (Warman Style)Document2 pagesPump - Detail Calculation Sheet (Warman Style)Sai Krish100% (1)

- FS22-015-PR-DS-001 - Process Datasheet For Xylene PumpDocument1 pageFS22-015-PR-DS-001 - Process Datasheet For Xylene PumpMinh DoNo ratings yet

- Equipment DatasheetDocument9 pagesEquipment DatasheetBimal DeyNo ratings yet

- P110a Data SheetDocument1 pageP110a Data SheetZaw Htet WinNo ratings yet

- Operating ParametersDocument1 pageOperating Parameters陆军No ratings yet

- 2.adcatrol Control Valves - KV GeneralDocument10 pages2.adcatrol Control Valves - KV GenerallemvanNo ratings yet

- Dry Vacuum Pump (LR/HR/UR Series) : FeaturesDocument4 pagesDry Vacuum Pump (LR/HR/UR Series) : FeaturesHảo UlvacNo ratings yet

- D-1309 Sizing Calc Sht1Document1 pageD-1309 Sizing Calc Sht1NKNo ratings yet

- MKI-DS-J-001-A4 - Rev A Data Sheet PCVDocument60 pagesMKI-DS-J-001-A4 - Rev A Data Sheet PCVFIRMANSYAHNo ratings yet

- CSD 82 Vis A Vis Ga 45+Document2 pagesCSD 82 Vis A Vis Ga 45+Santosh ChaudharyNo ratings yet

- Rising MainDocument2 pagesRising MainJitesh KumarNo ratings yet

- Belimo R3..-S.. Datasheet En-GbDocument3 pagesBelimo R3..-S.. Datasheet En-GbLaurentiu LapusescuNo ratings yet

- Liquid Ring Compressor: KLH 47005, KLH 47105Document8 pagesLiquid Ring Compressor: KLH 47005, KLH 47105Jhon Jairo Arango MarquezNo ratings yet

- Baylan: AK-311 ES2 Remote Reading and Prepaid Water MetersDocument1 pageBaylan: AK-311 ES2 Remote Reading and Prepaid Water Metersamr ibrahimNo ratings yet

- Po-03-22-00791 MTCDocument16 pagesPo-03-22-00791 MTCQuincyNo ratings yet

- Skematik Sistem Distribusi Air Bersih: Ruang Pompa UtamaDocument5 pagesSkematik Sistem Distribusi Air Bersih: Ruang Pompa UtamaSinar BiinmafoNo ratings yet

- Z2FS 6 New Series... 40BDocument6 pagesZ2FS 6 New Series... 40Bnemi90No ratings yet

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-012 KNIFE VALVEDocument1 pagePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-012 KNIFE VALVEAnthony InostrozaNo ratings yet

- Aquamet Multi Jet MeterDocument1 pageAquamet Multi Jet MeterkrmchariNo ratings yet

- 34 - Presentation For IAPWS Workshop - Gabriel NicolaidesDocument21 pages34 - Presentation For IAPWS Workshop - Gabriel NicolaidesNoumanIhsanNo ratings yet

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEDocument1 pagePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEAnthony InostrozaNo ratings yet

- R115 TiteflexDocument2 pagesR115 TiteflexFredy OliverosNo ratings yet

- P0100371 SpecsheetDocument12 pagesP0100371 SpecsheetRezeki SimamoraNo ratings yet

- Bc-Irrigation PumpDocument2 pagesBc-Irrigation PumpPrabaKaranNo ratings yet

- Hoja de Datos - Transmisor de Nivel: GeneralDocument1 pageHoja de Datos - Transmisor de Nivel: GeneralPatricio AlarconNo ratings yet

- Buckling Test PresentationDocument11 pagesBuckling Test Presentationarmando nolasco rodriguezNo ratings yet

- Objective: Machine Problem No. 6Document6 pagesObjective: Machine Problem No. 6Cester Avila DucusinNo ratings yet

- Gaas SPDT Switch DC - 3.0 GHZ: Features Functional Schematic Positive Control VoltageDocument3 pagesGaas SPDT Switch DC - 3.0 GHZ: Features Functional Schematic Positive Control Voltageliumt1999No ratings yet

- G9 MATHS P2 (28 Copies)Document9 pagesG9 MATHS P2 (28 Copies)Straight As StudyNo ratings yet

- Oil Gas Flow Metering SystemDocument252 pagesOil Gas Flow Metering Systemsaid250009250No ratings yet

- Topographic Survey SpecificationDocument3 pagesTopographic Survey SpecificationimranNo ratings yet

- Biosensor MIP by Asmaa Abouzaid, TA, Zewail City, EgyptDocument40 pagesBiosensor MIP by Asmaa Abouzaid, TA, Zewail City, Egyptasmaa abouzeidNo ratings yet

- Basic Mathematics of ProjectionDocument63 pagesBasic Mathematics of ProjectionAidan CelesteNo ratings yet

- ANSI B16 5 Bridas y AccesoriosDocument157 pagesANSI B16 5 Bridas y AccesoriosDaniel FloresNo ratings yet

- X-FEM For Abaqus (XFA) Toolkit For Automated Crack Onset and Growth SimulationsDocument1 pageX-FEM For Abaqus (XFA) Toolkit For Automated Crack Onset and Growth SimulationsSIMULIACorpNo ratings yet

- A-Overview of EE3463: Intro To Micro's - Lab 1Document48 pagesA-Overview of EE3463: Intro To Micro's - Lab 1vikasNo ratings yet

- Math in Everyday LifeDocument21 pagesMath in Everyday LifeSumitrabaluNo ratings yet

- Evaluation of Polymer Flooding For Enhanced Oil Recovery in The Norne Field E-SegmentDocument83 pagesEvaluation of Polymer Flooding For Enhanced Oil Recovery in The Norne Field E-Segmentojas82No ratings yet

- GC11 Pipe Thickness CalcDocument1 pageGC11 Pipe Thickness CalcsrinivasanNo ratings yet

- Tests of SignificanceDocument111 pagesTests of SignificanceMeerNo ratings yet

- Contactless Temperature Detector and Entrance Door Opener For Covid SafetyDocument62 pagesContactless Temperature Detector and Entrance Door Opener For Covid Safetypranathi mantravadiNo ratings yet

- M A T H E M A T I C S: Bansal ClassesDocument5 pagesM A T H E M A T I C S: Bansal ClassesRahul Kumar SharmaNo ratings yet

- Associations Between The Royal Arch and Astrology: Ronald Naumowicz IV SRICFDocument29 pagesAssociations Between The Royal Arch and Astrology: Ronald Naumowicz IV SRICFRed Young100% (1)

- Organic+Dpps A1-A14 PDFDocument43 pagesOrganic+Dpps A1-A14 PDFAditya ChakraniNo ratings yet

- Quick Steps To Write A Good Formal ReportDocument6 pagesQuick Steps To Write A Good Formal ReportElie Abou SamraNo ratings yet

- Chapter 9-Verilog Behavioral ModelingDocument55 pagesChapter 9-Verilog Behavioral ModelingThắng Lê NhựtNo ratings yet

- Article by Tomiyama and SakaiDocument6 pagesArticle by Tomiyama and SakaiSukratu BarveNo ratings yet

- Earthscienceforstem q1 Mod8 Energyresources v2Document34 pagesEarthscienceforstem q1 Mod8 Energyresources v2RUTH MIASCONo ratings yet

- Verboncoeur1995CPC PDFDocument13 pagesVerboncoeur1995CPC PDFKavi YaNo ratings yet

- Quantum PhysicsDocument9 pagesQuantum PhysicsLak DavisNo ratings yet

- Mikro PFCR ExplanationDocument31 pagesMikro PFCR Explanationyschan30No ratings yet

- Unit 31Document6 pagesUnit 31GnanendraReddyNo ratings yet

- Cmtcs - Trip Circuit Supervision: 1MRS752363-MUMDocument10 pagesCmtcs - Trip Circuit Supervision: 1MRS752363-MUMhaichau199No ratings yet

- Pharmarocks Pre - Gpat Mock Test-1Document13 pagesPharmarocks Pre - Gpat Mock Test-1Aniket SinghNo ratings yet

- A Comparative Analysis of Deep Learning and Machine LearningDocument14 pagesA Comparative Analysis of Deep Learning and Machine Learningşafak erdoğduNo ratings yet