Professional Documents

Culture Documents

Understanding The Role of NB in Hot-Rolled Rebars: Influence of Final Geometry and Process Parameters

Uploaded by

JJOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Understanding The Role of NB in Hot-Rolled Rebars: Influence of Final Geometry and Process Parameters

Uploaded by

JJCopyright:

Available Formats

AISTech 2019 — Proceedings of the Iron & Steel Technology Conference

6–9 May 2019, Pittsburgh, Pa., USA

DOI 10.1000.377.206

Understanding the Role of Nb in Hot-Rolled Rebars: Influence of Final Geometry and Process

Parameters

Felipe Bastos2,3, Beatriz Pereda1,2, Beatriz Lopez1,2, Jose M. Rodriguez-Ibabe1,2, Marcelo Rebellato

1

Ceit

P. M. Lardizabal 15, 20018 San Sebastian, Spain

Phone: +34 943 212 800

Email: jmribabe@ceit.es

2

Universidad de Navarra, Tecnun

P. M. Lardizabal 13, 20018 San Sebastian, Spain.

3

CBMM

Av. Brigadeiro Faria Lima, 4285, 9th, 04538-133 São Paulo / SP, Brazil.

4

RMS

Rua Doutor Diogo de Faria, 1202, cj. 53, 04037-004 São Paulo / SP, Brazil.

Keywords: Nb microalloyed steels, Bar hot rolling, Dynamic recrystallization, Phase transformation

INTRODUCTION

Microalloying has been widely studied in flat products but not so much in medium carbon long products. In flat steel

production, Nb microalloying is mainly used due to the large retarding effect that it exerts on recrystallization kinetics

during hot deformation, which can be due to solute drag or to strain-induced precipitation effects [1]. This results in pancaked

austenite microstructures before phase transformation, and therefore, in refined room temperature microstructures. As well

as during thermomechanical processing (TMCP), Nb can also exert some effect during phase transformation, due to

enhanced hardenability or to the formation of nanometer sized precipitates [2]. However, the role of Nb in hot rolled bars is

not so well known. In bar rolling, much higher strain and strain-rates, and lower interpass times are applied compared to flat

product rolling. This can modify the role of Nb on the austenite microstructural evolution. To investigate this, in this work,

multipass torsion tests were performed simulating hot rolling of 8 mm and 20 mm rebars. The tests were performed with

two medium carbon steels (0.24%C), one of them microalloyed with 0.03% Nb. Two different reheating temperatures, 1100ºC

and 1220ºC, were considered, and both the austenite and the room temperature microstructures obtained after phase

transformation were analyzed.

A model for the prediction of the austenite microstructural evolution during hot deformation (MicroSim-Bars©) which takes

into account the singularities of these processes has been developed. In addition, the continuous cooling transformation curves

(CCT) were determined for the Nb microalloyed steel by dilatometry at different previous austenite grain size and Nb

dissolution conditions.

MATERIALS AND EXPERIMENTAL PROCEDURE

The composition of the medium carbon steels (0.25%C) investigated is shown in Table 1. As it can be observed from the

table, one of them is a reference CMn steel, while the other one is microalloyed with 0.03%Nb.

C Table 1.

Mn Chemical

Si composition

Nb ofCr

the steels

Cuinvestigated

Ni (weightNpercent). P S

CMn 0.25 0.55 0.23 - 0.2 0.2 0.15 0.010 0.018 0.017

CMnNb 0.24 1.25 0.50 0.03 - - - 0.006 0.030 0.027

© 2019 by the Association for Iron & Steel Technology. 2001

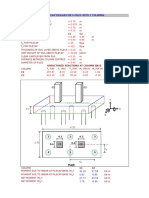

In the multipass torsion tests, the specimens consisted of a gauge geometry of 16.5 mm in length and 7.5 mm in diameter. In

the tests, the samples were first reheated for 20 min at soaking temperatures of 1100ºC or 1220ºC. Next, deformation sequences

representative of hot rolling of rebars of 8 and 20 mm diameter were applied, based on industrial data from several producers.

The deformation temperatures, cooling rates and interpass times (tip) corresponding to the 1100ºC reheating condition are

summarized in Figure 1. In the 1220ºC sequences, all these parameters were kept constant, except for the temperatures which

were in all cases 50ºC higher. A schematic representation of the cycle is also included in the figure. As it can be observed, after

reheating, 24 and 16 deformation passes were applied for the 8 and 20 mm sequences, respectively. In the tests, for simplicity,

the deformation per pass (H=0.45) and the strain rate (ߝሶ=5 s-1) were kept constant. As the figure shows, during the first

deformation passes, the temperature decreased, first at 5ºC/s (pass 1 to 7) and next at 2ºC/s (pass 8 to 11). On the other hand,

during the last passes, the specimens were heated at 2ºC/s (pass 12 to 15) or 10ºC/s (9 last deformation passes of the 8 mm

sequence) to simulate the adiabatic heating that takes place during the last passes of industrial bar hot rolling. Decreasing

interpass times of 5, 2 and 0.5 s were applied during the different cooling and heating stages. After the tests, specimens were

water quenched to analyze the austenite microstructure after deformation and holding time to rolling exit, or cooled down at

different rates to simulate air-cooling.

Cooling 8 mm 20 mm Pass Cooling 8 mm 20 mm

Pass rate T tip T tip rate T tip T tip

(ºC/s) (ºC) (s) (ºC) (s) (ºC/s) (ºC) (s) (ºC) (s)

1 5 1080 5 1080 5 12 -2 889 2 889 2

2 5 1055 5 1055 5 13 -2 893 2 893 2

3 5 1030 5 1030 5 14 -2 897 2 897 2

4 5 1005 5 1005 5 15 -2 901 2 901 2

5 5 980 5 980 5 16 -10 905 0.5 905 5.5

6 5 955 5 955 5 17 -10 910 0.5

7 5 930 5 930 5 18 -10 915 0.5

8 2 905 2 905 2 19 -10 920 0.5

9 2 901 2 901 2 20 -10 925 0.5

10 2 897 2 897 2 21 -10 930 0.5

11 2 893 2 893 2 22 -10 935 0.5

23 -10 940 0.5

24 -10 945 3.5

Texit 980 960

Reheating temperatures: 1100ºC and 1220ºC

Specimens

Reheating, 20 min quenched after last

T start

deformation: deformation pass +

1130/1080ºC holding time to exit

Temperature

7 passes

tip=5 s Air cooling

(cooling rate of 5 ºC/s) simulations

4 passes 9 passes

tip=2 s 4 passes tip=0.5 s

(cooling rate of 2 ºC/s) tip=2 s (heating rate of

. (heating rate of 2 10 ºC/s)

H=5s-1

H per pass=0.45 ºC/s) HEATING HEATING

Time

Figure 1. Temperature and interpass times (tip) employed in the tests carried out with a reheating temperature of 1100ºC and

schematic representation of the cycle.

2002 © 2019 by the Association for Iron & Steel Technology.

A scheme of the thermal cycle applied in the dilatometry tests to construct the continuous cooling transformation (CCT) curves

for the CMnNb steel is shown in Figure 2. First, a reheating treatment was applied at 1050ºC or 1250ºC followed by water

quenching, with the aim of obtaining different amounts of Nb in solid solution. Next, the specimens were again reheated at two

temperature ranges to obtain austenite grain sizes of #6-7 μm (T conditioning 820ºC-860ºC), or of #20 μm (T conditioning

975ºC). After this, the specimens were cooled at different rates from 0.1ºC/s to 20ºC/s to room temperature. The phase fractions

were determined using the lever rule.

Reheating:

1050ºC-1250ºC,

2 hours

Temperature Austenite

conditioning: 820ºC-

860ºC, 975ºC

Cooling

Quenching rates: 0.1, 1,

2, 5, 10,

20ºC/s

Time

Figure 2. Thermal cycles applied in the dilatometry tests

Metallographic measurements of the torsion specimens were carried out in a section corresponding to 0.9 of the outer radius of

the torsion specimen, also known as the sub-surface section [3]. In the of dilatometry specimens, a region corresponding to a

maximum area fraction of nominal strain and reduced strain gradient was selected [4]. Bechet-Beaujard etching [5] was applied

for revealing the previous austenite grain boundaries in the quenched samples, while 2%Nital was used in the transformed

microstructures. The etched samples were examined via optical microscopy, and in some cases, carbon extraction replicas were

prepared and analyzed by transmission electron microscopy (TEM) to characterize their precipitation state.

RESULTS AND DISCUSSION

Stress-Strain behavior

Figure 3 shows examples of the stress-strain curves determined for both steels in the 8 mm rebar simulations at 1220ºC

reheating condition. The different cooling rate/interpass time ranges have also been marked in the figures. During the first

seven deformation passes, for both steels, the stress increases due to temperature decrease. However, for the Nb steel, after

approximately pass four, (T#1050ºC) a higher stress increase rate is appreciated. This is in accordance with the behavior usually

reported for Nb microalloyed steels in decreasing temperature deformation schedules. It is well known that Nb leads to

softening kinetics retardation, due to solute drag or strain-induced precipitation effect [6]. As a result, below a temperature

known as non-recrystallization temperature (Tnr) [7], softening between deformation passes is suppressed, leading to strain

accumulation and higher stress levels, as observed in stage 1 for the CMnNb steel. However, it is interesting to note that when

the interpass time decreases to 2 s (stage 2), although the temperature continues decreasing, some stress stabilization or even

decrease is observed for both steels. This indicates that some interpass softening takes place during this period. In stage 3 (finish

rolling stage for 20 mm simulation), the temperature increases and this makes difficult the interpretation of the stress-strain

behavior. On the other hand, for both steels, during the second pass of stage 4 (last rolling passes of the 8 mm simulation,

tip=0.5 s) the stress slightly increases with respect to the previous pass, but then decreases during the subsequent deformation

passes. This indicates that strain accumulation takes place during the first deformation pass while some softening takes place

during subsequent deformation passes. This shape is characteristic of dynamic recrystallization activation [8].

The mean flow stress (MFS), defined as the area under the stress-strain curve divided by the pass strain, was determined and it

has been represented in Figure 4 for all the conditions investigated. During the first deformation passes, similar MFS are

calculated for the CMn and CMnNb steels. However, for both reheating temperatures, after pass #4 larger increase in the MFS

is observed for the CMnNb steel. This difference remains approximately constant or slightly increases during the rest of the

tests. Based on the standard method [7], from the change of MFS increase rate the Tnr values can be estimated. As shown in the

© 2019 by the Association for Iron & Steel Technology. 2003

figure for the CMnNb steel, Tnr values of #1005ºC and of 1055ºC for 1100ºC and 1220ºC reheating temperatures were

determined, respectively. However, when the interpass time decreases to 2 s (stage 2), some stress decrease or stabilization is

observed for all steels and reheating conditions investigated. As mentioned above, since the temperature is increasing in this

stage, the behavior is indicative of some softening during the interpass time. It is also interesting to note that, in stage 4 (tip=0.5

s), although higher stress was determined for the Nb steel, the mean flow stress (MFS) follows the same trends for both steels

and reheating conditions analyzed: it increases during the second pass and then it decreases during the last deformation passes.

250

CMn, 8 mm, 1220ºC

a)

1: tip = 5 s, 'T/'t=-5ºC/s

200 3 2: tip = 2 s, 'T/'t=-2ºC/s

2 3: tip = 2 s, 'T/'t=2ºC/s

1 4: tip= 0.5 s, 'T/'t=10ºC/s

150 4

Stress (MPa)

100

50

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Strain

250

b) CMnNb, 8 mm, 1220ºC

2 3

200

1 4

Stress (MPa)

150

100

50

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Strain

Figure 3. Stress-strain curves obtained in the 8 mm – 1220ºC reheating temperature tests.

The austenite microstructures, characterized from specimens quenched after the deformation sequences, are presented in Figure

5. It can be observed that for both steels, fine and equiaxed microstructures are obtained at all the conditions analyzed. As

above mentioned, in other rolling configurations Nb is added mainly to promote austenite pancaking during hot deformation.

However, the austenite microstructures obtained in these sequences indicate that this role is not applicable for the current rolling

schedules, and that regardless reheating temperature or rolling sequence, recrystallization takes place during the last

deformation passes of the torsion tests. Therefore, this indicates that these routes does not necessarily need the application of

classical TMCP. Nevertheless, some effect of Nb microalloying is observed. For both sequences at 1220ºC reheating

temperature, and at 1100ºC for the 20 mm sequence, significant austenite grain refinement is observed for the CMnNb steel

compared to the CMn one. In addition, it can be observed that for the CMn steel, increasing reheating temperature leads to

coarser microstructures. This can be attributed to the higher deformation temperatures applied in this sequence. On the other

2004 © 2019 by the Association for Iron & Steel Technology.

hand, for the Nb steel this is not observed, showing that for this steel the microstructure is less dependent on process parameter

modification.

200 200

a) Reheating 1100ºC 1: tip = 5 s, 'T/'t=-5ºC/s b) Reheating 1220ºC

180 2: tip = 2 s, 'T/'t=-2ºC/s 180 2

3: tip = 2 s, 'T/'t=2ºC/s 3

1 4: tip= 0.5 s, 'T/'t=10ºC/s

160 160 1 4

140 140

MFS (MPa)

MFS (MPa)

Tnr#1000ºC

Tnr#1050ºC

120 2 3 4 120

100 CMn, 8 mm 100 CMn, 8 mm

CMn, 20 mm CMn, 20 mm

80 CMnNb, 8 mm 80 CMnNb, 8 mm

CMnNb, 20 mm CMnNb, 20 mm

60 60

0 5 10 15 20 25 3 0 5 10 15 20 25 3

Pass number Pass number

Figure 4. MFS determined for both steels at: (a) 1100ºC and (b) 1220ºC reheating temperatures.

Reheating at 1100ºC:

8 mm 20 mm

50 μm 50 μm 50 μm 50 μm

CMn, D=15.2±0.5 μm CMnNb, D=15.8±0.5 μm CMn, D=17.4±0.7 μm CMnNb, D=13.4±0.7 μm

Reheating at 1220ºC:

8 mm 20 mm

50 μm 50 μm 50 μm 50 μm

CMn, D=21.2±1 μm CMnNb, D=14.4±0.5 μm CMn, D=22.3±0.6 μm CMnNb, D=12.1±0.3 μm

Figure 5. Austenite microstructures obtained from quenched specimens.

Carbon extraction replicas were prepared from the 8 mm CMnNb quenched samples to investigate their precipitation state.

Figure 6 shows some examples of the precipitates observed for both reheating conditions. In the micrograph from the 1220ºC

condition, some coarse particles that could be precipitates that remain undissolved during reheating can be observed. However,

more abundantly, particles smaller than 15 nm can be detected, which indicates that some strain-induced precipitation has taken

place during the sequence. In the 1100ºC sample, the amount of undissolved precipitates was larger and their size coarser. As

shown in Figure 6, some small Nb particles could also be detected in this sample although much less frequently than at 1220ºC.

© 2019 by the Association for Iron & Steel Technology. 2005

It is well known that Nb strain-induced precipitation can stop or greatly retard static recrystallization [6, 9]. This is in good

agreement with the detection of a Tnr temperature during stage 1 of the deformation schedule, where an interpass time of 5 s

was applied. However, when the interpass time decreases to 2 s or 0.5 s, the stress-strain behavior and the microstructures

obtained after the cycles indicate that during these stages precipitates are not able to stop recrystallization and, independently

of the reheating temperature considered, equiaxed microstructures are obtained for both steels. It is also worth noting the small

size of some of these precipitates (<10 nm). This means that if precipitate growth rate is not high during phase transformation,

they could provide some contribution to mechanical strength due to precipitation hardening.

Nb

Nb

Ni

Ni

Ni

Ni

Nb

0 2 4 6 8 10

(a) Reheating 1220ºC

O

Ni Ni

Ni

Cu

Nb

Nb

Cu

Cu

Ni

Nb Cu

0 2 4 6 8 10

(b) Reheating 1100ºC

Figure 6. Precipitates detected in the carbon replicas extracted from 8 mm quenched specimens.

In the frame of this work, a microstructural evolution model, MicroSim-Bars© based on the approaches described in references

[6] and [10], with improved equations to consider the singularities observed in these processes, has been developed. Examples

of the predictions of the model for the 8 mm – 1220ºC sequences for both steels are shown in Figure 7. It can be observed

that for the CMn steel, the predicted final austenite grain size agrees well with the measured values (23 μm model vs. 21.2 μm

experimental). For the CMnNb steel, this is slightly overestimated (18.3 μm model vs. 14.4 μm experimental), although the

austenite refining effect that it is observed experimentally with Nb addition is well captured.

It can be observed that during the first passes, for both steels static recrystallization is predicted to occur and 100% recrystallized

fractions are predicted between passes. However, for the CMnNb steel, after 4th pass, where the Tnr is detected, the recrystallized

fraction starts to decrease, first due to solute drag effect, and next due to the occurrence of strain-induced precipitation. This is

in good agreement with the experimental TEM results, which show the presence of some precipitation at the end of the sequence

(Figure 6(a)). However, for both steels, during the last passes, when the interpass time decreases, the model predicts the

activation of dynamic recrystallization during deformation and within the interpass times, metadynamic recrystallization is the

main softening process. This agrees well with the equiaxed microstructures observed for both steels at the end of the sequences.

2006 © 2019 by the Association for Iron & Steel Technology.

(a) CMnNb steel

(b) CMn Steel

Figure 7. Predictions of MicroSim-Bars© program for the austenite microstructural evolution during the 1220ºC-8 mm hot

rolling sequences.

Torsion tests were also performed simulating final air cooling conditions. The cooling rates were calculated for the different

bar diameters using a temperature model. The model predicted two approximately linear cooling ranges: the first one from exit

temperature to 800ºC (#14ºC/s and 5ºC/s for 8 and 20 mm respectively), and a final slower one to 500ºC (#5ºC/s and 2ºC/s

for 8 and 20 mm, respectively). It can be observed from Table 1 that for the CMn steel, the Mn content (0.55%) is significantly

lower than for the CMnNb steel (1.25%). While this difference is not expected to affect significantly the microstructural

evolution during hot deformation, it can have large effect on the microstructure that it is obtained after phase transformation.

Therefore, due to the lack of comparability, simulations were only performed with the CMnNb steel. Figure 8 shows optical

micrographs of the microstructures obtained, together with phase fraction and hardness measurements. For the 20 mm

© 2019 by the Association for Iron & Steel Technology. 2007

simulation samples, ferritic-pearlitic microstructures that are slightly coarser than for 8 mm can be observed. At this

condition, slightly higher hardness and ferrite fraction is determined for the 1220ºC reheating temperature. As well as the ferrite

fraction, the ferrite grain size is also slightly larger in this sample. Therefore, this suggests some contribution of precipitation

hardening to the mechanical strength for this specimen. For the 8 mm sequences, the microstructures are more acicular and in

addition, in the case of the 1220ºC sample, a small amount of bainite is detected (#4%). The highest hardness value was also

determined for this sample.

Reheating at 1100ºC: Reheating at 1220ºC:

8mm 20mm 8mm 20mm

20 μm 20 μm 20 μm 20 μm

73.6%α + 26.4%p ; dα = 7.4 μm; 68.3%α + 31.7%p; dα = 8.6 μm; 71.5%α + 24.5%p + 77.9%α + 22.1%p; dα = 9.1 μm;

182 HV 187 HV 4.1%bainite; dα = 8.0 μm; 199 HV

203 HV

Figure 8. Transformed microstructures obtained from the specimens after air cooling simulation.

CCT Curves

To further study the phase transformation behavior, CCT diagrams were constructed for the CMnNb steel. Different conditions

were applied (Figure 2) to produce three initial austenite microstructures before phase transformation: reheating at 1200ºC and

low conditioning temperature to produce a fine initial austenite grain size (6.3 μm) or reheating at 1050ºC and low and high

austenite conditioning temperatures (austenite grain sizes of 6.8 μm and 20.2 μm, respectively). Trials were also performed

using higher conditioning temperatures after 1200ºC reheating to produce a coarser grain size. However, abnormal austenite

grain growth took place, and due to this, it was not possible to produce comparable homogeneous austenite microstructures

with #20 Pm grain size. In Figure 9, the CCT diagrams determined for the three conditions are compared. It can be observed

that increasing reheating temperature and, therefore, the amount of Nb in solid solution, does not lead to large differences in

the transformation start temperatures. On the other hand, except for 0.1ºC/s, increasing the initial grain size results in a decrease

of the temperature of approximately 20º to 70ºC. Some decrease of the transformation finish temperature is also observed,

although mainly for the highest cooling rates.

1000

1200ºC, 860ºC, 6 microns

900 1050ºC, 820ºC, 7 microns

1050ºC, 975ºC, 20 microns

800

F

700

Temperature (⁰C)

P

600 B

500

400 Ms = 375ºC

300

200

⁰C/s 20 10 5 2 1 0.1

100

0

1 10 100 1000 10000

Time (s)

Figure 9. CCT (continuous cooling transformation) curves determined for the CMnNb steel at different reheating and initial

grain size conditions.

2008 © 2019 by the Association for Iron & Steel Technology.

Several examples of the transformed microstructures obtained at constant reheating conditions (1050ºC) and different initial

austenite grain sizes are included in Figure 10. The transition from ferritic-pearlitic microstructures to more acicular phases can

be observed in both cases. However, it is evident from the figure that for the coarse austenite grain size, the appearance of

bainite is significantly enhanced. For this condition, some bainite is observed even at the relatively low 2ºC/s cooling rate and

it clearly increases with increasing cooling rate. On the other hand, for the small initial grain size condition, a significant ferrite

fraction is maintained on the microstructure even for 10ºC/s cooling rate.

Reheating 1050ºC, 20 Pm initial austenite grain size:

1ºC/s 2ºC/s 5ºC/s 10ºC/s

50 P m 50 Pm 50 Pm 50 Pm

Reheating 1050ºC, 7 Pm initial austenite grain size:

1ºC/s 2ºC/s 5ºC/s 10ºC/s

50 Pm 50 Pm 50 Pm 50 Pm

Figure 10. Transformed microstructures observed for the CMnNb steel after 1050ºC reheating and different initial austenite

grain sizes of #7 and 20 Pm.

The phase volume fractions measured by quantitative metallography from the different microstructures are summarized in

Figure 11. It can be observed that for the lowest cooling rates (0.1ºC/s – 1ºC/s) ferritic-pearlitic microstructures are obtained in

all the cases. However, as shown above, at 2ºC/s, for the low reheating temperature and coarse initial austenite grain size

condition, some bainite appeared. In addition, for 5ºC/s this increases drastically to 66%. On the other hand, at these cooling

rates, for the small austenite grain size samples bainite is not detected or the fraction is much more limited. Within the low

initial grain size specimens, large bainite fractions can only be detected at 20ºC/s cooling rate, and more abundantly for the

1200ºC reheating condition. It can be noted that at 20ºC/s, some martensite was also present in the 20 μm initial austenite grain

size sample.

The ferrite grain sizes and hardness values measured from the transformed specimens are summarized in Figure 12. Figure 12

(a) shows that decreasing the initial austenite grain size leads to significant ferrite grain size refinement, as usually reported

[11]. For the fine initial grain size samples, similar ferrite grain sizes were determined for cooling rates from 1 to 10ºC/s (3.0

Pm to 4.5 Pm), although for 2ºC/s and 1ºC/s they tend to be slightly coarser for the high reheating temperature condition. A

slight grain size increase with decreasing cooling rate to 0.1ºC/s is observed (5.2 Pm). On the other hand, for the 20 μm austenite

grain size, the ferrite grain size increase at 0.1ºC/s is much more marked (from 7.2 Pm to 12.8 Pm). Regarding hardness, for

the lowest cooling rates of 0.1ºC/s and 1ºC/s, these tend to be higher for the samples reheated at 1200ºC. At intermediate cooling

rates of 2ºC/s and 5ºC/s the differences are not large. Finally, for the highest cooling rates (10ºC/s-20ºC/s) hardness increases

significantly for the coarse initial austenite grain size condition. This can be attributed to the presence of more acicular phases

(note that some martensite was detected at 20ºC/s).

© 2019 by the Association for Iron & Steel Technology. 2009

100 0

90 10

Pearlite volume fraction (%)

Acicular ferrite/Bainite

Bainite volume fraction (%)

80 20

70 30

60 40

50 50

40 Pearlite 60

30 70

20 Martensite 80

10 90

0 100

0.1 1 2 5 10 20

Cooling rate (ºC/s)

1200ºC, 6 microns 1050ºC, 7 microns 1050ºC, 20 microns

Figure 11. Phase volume fraction as a function of cooling rate for the different initial conditions investigated.

16 350

a) 1200ºC, 6 microns b) 1200ºC, 6 microns

14 1050ºC 7 microns 1050ºC, 7 microns

300

1050ºC, 20 microns 1050ºC, 20 microns

Ferrite grain size (μm)

12

10 250

HV1

8

200

6

4 150

2

100

0 0.1 1 10

0.1 1 10 Cooling rate (⁰C/s)

Cooling rate (ºC/s)

Figure 12. (a) Ferrite grain size and (b) hardness measured from the different specimens.

SUMMARY AND CONCLUSIONS

-Multipass torsion tests simulating hot rolling of 8 mm and 20 mm rebars have been performed at two different reheating

conditions (1100ºC and 1220ºC) with two 0.24%C steels, one of them microalloyed with 0.03%Nb. For the Nb microalloyed

steel, during the first deformation passes, the behavior is similar to that observed conventionally for flat products and some

strain accumulation is observed. As a result, Tnr values of #1000ºC and 1050ºC can be determined for reheating temperatures

of 1100ºC and 1220ºC, respectively. However, during the last deformation passes, decreasing interpass time leads to strain

accumulation and to the activation of dynamic recrystallization.

-As a result of this, after the deformation sequences, fine and recrystallized austenite grain sizes were determined for both steels

and all reheating and rolling conditions investigated. However, higher austenite grain size refinement was observed for the

CMnNb steel compared to the CMn one, especially at high reheating temperature and high diameter conditions. Lower

dependence of austenite grain size with processing conditions was also observed for the CMnNb steel.

-In good agreement with the detection of a T nr during the first deformation passes, the occurrence of Nb(C,N) strain-induced

precipitation was detected via TEM analysis. However, these precipitates were not able to stop recrystallization during the last

deformation passes, where the interpass time decreased.

-These trends are well predicted by an austenite microstructural evolution model, MicroSim-Bars©, developed to take into

account the singularities of bar hot rolling.

2010 © 2019 by the Association for Iron & Steel Technology.

-The phase transformation behavior of the CMnNb steel was also investigated as a function of reheating temperature and initial

grain size conditions. Modifying the initial reheating temperature did not affect much the transformation temperatures or the

size or the morphology of the phases developed. However, increasing initial austenite grain size lead to the development of

more bainitic microstructures in the range of cooling rates that can be considered representative of rebar air-cooling conditions.

ACKNOWLEDGEMENTS

The authors would like to gratefully acknowledge Companhia Brasileira de Metalurgia e Mineração (CBMM) for funding this

project.

REFERENCES

1. H.L. Andrade, M.G. Akben, J.J. Jonas, “Effect of Molybdenum, Niobium, and Vanadium on Static Recovery and

Recrystallization and on Solute Strengthening in Microalloyed Steels”, Metall. Trans. A, Vol. 14, 1983, pp. 1967-1977.

2. M.A. Altuna, A. Iza-Mendia, I. Gutierrez, “Precipitation in Nb in Ferrite after Austenite Conditioning. Part II:

Strengthening Contribution in High-Strength Low-Allow (HSLA) Steels, Metall. Mater. Trans. A., Vol. 43, 2012, pp.

4571-4586.

3. G. Glover, C.M. Sellars, “Recovery and Recrystallization during High Temperature Deformation of D-iron”, Met.

Trans., Vol. 4, 1973, pp. 765-775.

4. M. Olasolo, P. Uranga, J.M. Rodriguez-Ibabe, B. Lopez, “Effect of Microstructure and Cooling Rate on Transformation

Characteristics in a Low Carbon Nb-V Microalloyed Steel”, Mater. Sci. Eng. A, Vol. 528, 2011, pp. 2559-2569.

5. S. Bechet, L. Beaujard, “New Reagent for the Micrographical Demonstration of the Austenite Grain of Hardened or

Hardened-Tempered Steels”, Rev. Met., Vol. 52, 1995, pp. 830-836

6. B. Pereda, J.M. Rodriguez-Ibabe, B. Lopez, “Improved Model of Kinetics of Strain Induced Precipitation and

Microstructure Evolution of Nb Microalloyed Steels during Multipass Rolling”, ISIJ Int., Vol. 48, 2008, pp. 1457-1466.

7. D.Q. Bai, S. Yue, W.P. Sun, J.J. Jonas, “Effect of Deformation Parameters on the No-recrystallization Temperature in

Nb Bearing Steels”, Metall. Trans. A, Vol. 24, 1993, pp. 2151-2159.

8. B. Lopez, J.M. Rodriguez-Ibabe, "Recrystallisation and Grain Growth in Hot Working of Steels", in Microstructure

Evolution in Metal Forming Processes, 2012, pp. 67-113.

9. S.S. Hansen, J.B. Vander Sande, M. Cohen, “Niobium Carbonitride Precipitation and Austenite Recrystallisation in

Hot-Rolled Microalloyed Steels”, Metall. Trans. A, 1980, pp. 387-402.

10. P. Uranga, J. Rodriguez-Ibabe, D.G. Stalheim, R. Barbosa, M. Rebellato, “Application of Practical Modeling of

Microalloyed Steels for Improved Metallurgy, Productivity and Cost Reduction in Hot Strip Mill Applications”,

Proceedings of AISTech 2016 Conference, 16-19 May 2016, Pittsburgh, PA, pp. 1769-1778.

11. P.D. Hodgson, R.K. Gibbs, “A Mathematical Model to Predict the Mechanical Properties of Hot Rolled C-Mn and

Microalloyed Steels”, ISIJ Int., Vol. 32, 1992, pp. 1329-1338.

© 2019 by the Association for Iron & Steel Technology. 2011

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Hot RollingDocument10 pagesHot Rollingpoom2007No ratings yet

- COMET 2018 Presentation - S K ShuklaDocument22 pagesCOMET 2018 Presentation - S K ShuklaskshuklaNo ratings yet

- Artigo 4Document7 pagesArtigo 4Kawan BartrasNo ratings yet

- The TEMPCORE ProcessDocument15 pagesThe TEMPCORE ProcessShanna Lee100% (1)

- Chalcogenide Letters Vol. 6, No. 8, September 2009, P. 403Document12 pagesChalcogenide Letters Vol. 6, No. 8, September 2009, P. 403Brandon StoneNo ratings yet

- Metallurgical and Micostructural Effect On CVN Impact Toughness in 2,25Cr1Mo Weld MetalDocument16 pagesMetallurgical and Micostructural Effect On CVN Impact Toughness in 2,25Cr1Mo Weld MetalMubeenNo ratings yet

- Tech Rep 4-2011 Copper Zirkonium AlloysDocument14 pagesTech Rep 4-2011 Copper Zirkonium AlloysBahadır UysalNo ratings yet

- Homework06-Fig and TablesDocument4 pagesHomework06-Fig and TablesapiratzNo ratings yet

- Unit-I Heat Treatment of SuperalloysDocument15 pagesUnit-I Heat Treatment of SuperalloysJ JhansibaiNo ratings yet

- Thermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B MicroadditionsDocument4 pagesThermo-Mechanical Treatment of The C-MN Steel With NB, Ti, V and B MicroadditionsGaurav TripathiNo ratings yet

- Low Temperature Embrittlement Studies On Stainless Steel 304 LN TIG WeldsDocument10 pagesLow Temperature Embrittlement Studies On Stainless Steel 304 LN TIG WeldsRajmchzNo ratings yet

- High Temperature Corrosion of Ni Based Alloy Inconel 740H in Simulated Coal-Ash and Flue-Gas EnvironmentsDocument7 pagesHigh Temperature Corrosion of Ni Based Alloy Inconel 740H in Simulated Coal-Ash and Flue-Gas EnvironmentsAnonymous lmCR3SkPrKNo ratings yet

- Realization of ITS-90 From 273.15 K Through 1234.93 K, One Company's ApproachDocument11 pagesRealization of ITS-90 From 273.15 K Through 1234.93 K, One Company's ApproachAndres LarrahonaNo ratings yet

- Detremination of CCT Diagrams by Thermal Anal of HSLA Bainitic Submitet To Thermomech TreatDocument5 pagesDetremination of CCT Diagrams by Thermal Anal of HSLA Bainitic Submitet To Thermomech TreatLjubica MilovicNo ratings yet

- Metals: Influence of Hot Forging Parameters On A Low Carbon Continuous Cooling Bainitic Steel MicrostructureDocument11 pagesMetals: Influence of Hot Forging Parameters On A Low Carbon Continuous Cooling Bainitic Steel Microstructureth34560No ratings yet

- Very Strong Low Temp BainiteDocument6 pagesVery Strong Low Temp BainiteS RamakrishnaNo ratings yet

- Evolution of Microstructural Banding During The Manufacturing Process of Dual Phase SteelsDocument3 pagesEvolution of Microstructural Banding During The Manufacturing Process of Dual Phase SteelsWazir Shah KazmiNo ratings yet

- Datasheet PDFDocument3 pagesDatasheet PDFShady MohamedNo ratings yet

- P91TPDocument37 pagesP91TPPhong ĐỗNo ratings yet

- Effect of Austempering Time On Microstructure and Properties of A Low-Carbon Bainite SteelDocument7 pagesEffect of Austempering Time On Microstructure and Properties of A Low-Carbon Bainite Steelمسعود بوزويرNo ratings yet

- Property Improvement of Subzero/Cryogenic Heat Treated Camshafts Made of 8620H, 16Mncr5 and 100Cr6 SteelsDocument4 pagesProperty Improvement of Subzero/Cryogenic Heat Treated Camshafts Made of 8620H, 16Mncr5 and 100Cr6 SteelsSama UmateNo ratings yet

- 1.3343 HS6-5-2CDocument3 pages1.3343 HS6-5-2CmustafabodurNo ratings yet

- Elimination of Crystallinity in Fractured Surface of Medium Carbon Low Alloy Steel Plates Through Process ImprovementDocument9 pagesElimination of Crystallinity in Fractured Surface of Medium Carbon Low Alloy Steel Plates Through Process ImprovementCris CristyNo ratings yet

- Y-A350 GearDocument7 pagesY-A350 Gearshaotao guoNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- Material Inconel 600Document16 pagesMaterial Inconel 600arvindgupta_2005100% (1)

- Magnetic NDE Characterization of Tempered 2.25Cr-1Mo SteelDocument19 pagesMagnetic NDE Characterization of Tempered 2.25Cr-1Mo SteelApoorv KrishnaNo ratings yet

- CA 6NM CastingsDocument11 pagesCA 6NM CastingsvasanthiNo ratings yet

- P92 Paper IIW Conference GrazDocument13 pagesP92 Paper IIW Conference GrazzhangxingzydNo ratings yet

- Riopipeline2019 1197 201906020505paper Ibp1197 19 RDocument10 pagesRiopipeline2019 1197 201906020505paper Ibp1197 19 Rbarraocos emailsNo ratings yet

- Faria AISTech 2019Document9 pagesFaria AISTech 2019Mada TetoNo ratings yet

- 10 0000@www Onepetro org@conference-paper@NACE-2019-12783Document13 pages10 0000@www Onepetro org@conference-paper@NACE-2019-12783rajiv_quantumNo ratings yet

- Material IDocument30 pagesMaterial IgabrieleNo ratings yet

- 02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocument12 pages02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical Applicationsivanmatijevic100% (1)

- Nitriding Problems On Rolled Rings Made of 42crmo4: MemorieDocument6 pagesNitriding Problems On Rolled Rings Made of 42crmo4: MemoriebcachNo ratings yet

- Alloy Steel p22 PlatesDocument3 pagesAlloy Steel p22 PlatesMiguel PulidoNo ratings yet

- Asanovic, 2004Document7 pagesAsanovic, 2004Muhammad Falqi YusufNo ratings yet

- Sciencedi Rect: Effect of Heat Treatment Process On Properties of 1000 Mpa Ultra-High Strength SteelDocument6 pagesSciencedi Rect: Effect of Heat Treatment Process On Properties of 1000 Mpa Ultra-High Strength SteelDodiFitriyadiNo ratings yet

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgNo ratings yet

- 94 PDFDocument8 pages94 PDFNancy Carolina Prieto MartinezNo ratings yet

- Incoloy Alloy 825Document4 pagesIncoloy Alloy 825Roman PaduaNo ratings yet

- Influence of The Normalizing Rolling Parameters On The Toughness of A NB, V and Ti Microalloyed Steel Processed in The Gerdau Plate MillDocument8 pagesInfluence of The Normalizing Rolling Parameters On The Toughness of A NB, V and Ti Microalloyed Steel Processed in The Gerdau Plate MillJJNo ratings yet

- Metals: Design of A Nickel-Based Bond-Coat Alloy For Thermal Barrier Coatings On Copper SubstratesDocument16 pagesMetals: Design of A Nickel-Based Bond-Coat Alloy For Thermal Barrier Coatings On Copper SubstratesDean DatthaNo ratings yet

- CM247LCDocument29 pagesCM247LCMathi LoguNo ratings yet

- PhysicsDocument5 pagesPhysicsAditya Budi FauziNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- C Media:-Open Air CoolingDocument2 pagesC Media:-Open Air Coolingsachin2712No ratings yet

- Basic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660Document1 pageBasic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660mohamed AdelNo ratings yet

- Research Article: Mandana Zebarjadi Sar, Silvia Barella, Andrea Gruttadauria, Davide Mombelli, and Carlo MapelliDocument8 pagesResearch Article: Mandana Zebarjadi Sar, Silvia Barella, Andrea Gruttadauria, Davide Mombelli, and Carlo MapelliAnisur RahamanNo ratings yet

- Bio-Functionalization of Silicon Nitride-Based Piezo-Resistive MicrocantileversDocument7 pagesBio-Functionalization of Silicon Nitride-Based Piezo-Resistive MicrocantileversNitin KaleNo ratings yet

- Structural SteelsDocument5 pagesStructural SteelsijazNo ratings yet

- Metals 07 00040 v2Document11 pagesMetals 07 00040 v2Hany KhalifaNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFtiele_barcelosNo ratings yet

- $RYMI2T7Document24 pages$RYMI2T7sid mebarekNo ratings yet

- VDM Data Sheet Nicrofer 6025 HT - e PDFDocument0 pagesVDM Data Sheet Nicrofer 6025 HT - e PDFeugenio.gutenbertNo ratings yet

- Characterization of The Superalloy Inconel 718 After Double Aging Heat TreatmentDocument8 pagesCharacterization of The Superalloy Inconel 718 After Double Aging Heat TreatmentanshuNo ratings yet

- Heat Treatment of Steel: Assessment Performance CriteriaDocument6 pagesHeat Treatment of Steel: Assessment Performance CriteriaMahmoud AlwasifNo ratings yet

- InvarDocument5 pagesInvardusan.papez9216No ratings yet

- Development of Basic Gunning Mixes: Comparison of Laboratory Trials, Thermochemical Calculations and Steel Plant TrialsDocument10 pagesDevelopment of Basic Gunning Mixes: Comparison of Laboratory Trials, Thermochemical Calculations and Steel Plant TrialsJJNo ratings yet

- Optimized Heating of Steel Slabs With Radar MeasurementsDocument14 pagesOptimized Heating of Steel Slabs With Radar MeasurementsJJNo ratings yet

- Controlling Equipment Failures Caused by Petroleum-Based Fluid DegradationDocument6 pagesControlling Equipment Failures Caused by Petroleum-Based Fluid DegradationJJNo ratings yet

- The Causes and Effects of The Keys Missed in The Main Hoist Gear Reducer On The Ladle CranesDocument20 pagesThe Causes and Effects of The Keys Missed in The Main Hoist Gear Reducer On The Ladle CranesJJNo ratings yet

- Advanced Profile Control: Model - Optimization - ContourDocument8 pagesAdvanced Profile Control: Model - Optimization - ContourJJNo ratings yet

- Analysis of The Effects of Oxygen Enrichment in A Reheating FurnaceDocument12 pagesAnalysis of The Effects of Oxygen Enrichment in A Reheating FurnaceJJNo ratings yet

- Inhibition Effect of CaO-ZrO2-C Nozzles On Alumina Deposition in Continuous Casting of Al-Killed SteelDocument8 pagesInhibition Effect of CaO-ZrO2-C Nozzles On Alumina Deposition in Continuous Casting of Al-Killed SteelJJNo ratings yet

- Advanced Cold Isostatic Press MgO-C BrickDocument10 pagesAdvanced Cold Isostatic Press MgO-C BrickJJNo ratings yet

- Reheat Furnace Efficiency at Laverton Rod MillDocument12 pagesReheat Furnace Efficiency at Laverton Rod MillJJNo ratings yet

- Mathematical Model of Static and Dynamic Recrystallization, Roll Force and Mean Flow Stress of The Nb-Microalloyed Steels For Plain Steel Hot Roughing MillDocument10 pagesMathematical Model of Static and Dynamic Recrystallization, Roll Force and Mean Flow Stress of The Nb-Microalloyed Steels For Plain Steel Hot Roughing MillJJNo ratings yet

- Non-Destructive Magnetic Measurements and Thermodynamics Calculations For Evaluation of Carburization of Tubes During PyrolysisDocument8 pagesNon-Destructive Magnetic Measurements and Thermodynamics Calculations For Evaluation of Carburization of Tubes During PyrolysisJJNo ratings yet

- How Furnace Model Predictive Control Forecasts Transitions To Enhance Strip Quality and ProductivityDocument12 pagesHow Furnace Model Predictive Control Forecasts Transitions To Enhance Strip Quality and ProductivityJJNo ratings yet

- Carburization Degree, Pyrolysis, Non-Destructive Techniques, Thermodynamics Calculation, Diffusion CalculationDocument10 pagesCarburization Degree, Pyrolysis, Non-Destructive Techniques, Thermodynamics Calculation, Diffusion CalculationJJNo ratings yet

- Development of Ti-Nb Microalloyed HSLA and UHSS On A Thin-Slab Casting and Rolling MillDocument8 pagesDevelopment of Ti-Nb Microalloyed HSLA and UHSS On A Thin-Slab Casting and Rolling MillJJNo ratings yet

- Effect of Allotriomorphic Ferrite Thickness On Advanced High-Strength Steel ToughnessDocument12 pagesEffect of Allotriomorphic Ferrite Thickness On Advanced High-Strength Steel ToughnessJJNo ratings yet

- Evolution of Oxide Inclusions in 304 Stainless Steel Treated by Rare Earth During Isothermal Heating at 1,473 K (1,200°C)Document6 pagesEvolution of Oxide Inclusions in 304 Stainless Steel Treated by Rare Earth During Isothermal Heating at 1,473 K (1,200°C)JJNo ratings yet

- Systematic Optimization Creates Higher CompetitivenessDocument6 pagesSystematic Optimization Creates Higher CompetitivenessJJNo ratings yet

- Achieving Optimal Energy Savings in Hot Strip Mills With Predictive SolutionDocument8 pagesAchieving Optimal Energy Savings in Hot Strip Mills With Predictive SolutionJJNo ratings yet

- Process Optimization and Product Metallurgy in Long ProductsDocument12 pagesProcess Optimization and Product Metallurgy in Long ProductsJJNo ratings yet

- Modernization of Continuous Casting Machine in The Era of Intelligent ManufacturingDocument12 pagesModernization of Continuous Casting Machine in The Era of Intelligent ManufacturingJJNo ratings yet

- Texture and Mechanical Behavior of UNS S32205 Duplex Stainless Steel Processed by Warm, Cold Rolling and AnnealingDocument8 pagesTexture and Mechanical Behavior of UNS S32205 Duplex Stainless Steel Processed by Warm, Cold Rolling and AnnealingJJNo ratings yet

- The Effect of Heat Treatment On The HAZ Microhardness and Fracture Resistance of Weld Joints of ABS EH36 150-mm Heavy Plates For Monopiles of Offshore Wind GeneratorsDocument10 pagesThe Effect of Heat Treatment On The HAZ Microhardness and Fracture Resistance of Weld Joints of ABS EH36 150-mm Heavy Plates For Monopiles of Offshore Wind GeneratorsJJNo ratings yet

- Effect of Solution Treatment On Grain Size and Toughness of Lightweight Fe-Mn-Al-C SteelDocument10 pagesEffect of Solution Treatment On Grain Size and Toughness of Lightweight Fe-Mn-Al-C SteelJJNo ratings yet

- Practical Mitigation Procedures To Control Hydrogen-Related Damage During Production of Structural SteelsDocument12 pagesPractical Mitigation Procedures To Control Hydrogen-Related Damage During Production of Structural SteelsJJNo ratings yet

- Effect of M-EMS On Steel Solidification Behavior of A Round Billet CastingDocument12 pagesEffect of M-EMS On Steel Solidification Behavior of A Round Billet CastingJJNo ratings yet

- Advanced Continuous Annealing Technology and Application For High-Strength SteelDocument10 pagesAdvanced Continuous Annealing Technology and Application For High-Strength SteelJJNo ratings yet

- Development of A Predictive Tundish Open Eye Model Using Artificial Neural Network (ANN)Document12 pagesDevelopment of A Predictive Tundish Open Eye Model Using Artificial Neural Network (ANN)JJNo ratings yet

- Modeling of Multiphase Flow and Argon Bubble Entrapment in Continuous Slab Casting of SteelDocument14 pagesModeling of Multiphase Flow and Argon Bubble Entrapment in Continuous Slab Casting of SteelJJNo ratings yet

- 3D Thermal-Mechanical Model of Solidifying Steel StrandDocument12 pages3D Thermal-Mechanical Model of Solidifying Steel StrandJJNo ratings yet

- Development of A Predictive Model For Minimizing Ladle Desulfurization Cycle Time and Associated CostsDocument14 pagesDevelopment of A Predictive Model For Minimizing Ladle Desulfurization Cycle Time and Associated CostsJJNo ratings yet

- Pile Cap For 6 PilesDocument4 pagesPile Cap For 6 PilesHemant Sonawadekar100% (2)

- TUT-Photoelectric EffectDocument30 pagesTUT-Photoelectric EffectThabelo NgwenyaNo ratings yet

- The Physical Dimension of God's VoiceDocument11 pagesThe Physical Dimension of God's VoiceRodger JonesNo ratings yet

- User Manual: EM Clamp For Immunity Tests Acc. EN 61000-4-6Document7 pagesUser Manual: EM Clamp For Immunity Tests Acc. EN 61000-4-6spohanNo ratings yet

- Mixology Mixing EbookDocument227 pagesMixology Mixing EbookChloe JimzNo ratings yet

- Ieee Paper 1Document5 pagesIeee Paper 1Chandan LawrenceNo ratings yet

- First Law of ThermodynamicsDocument5 pagesFirst Law of Thermodynamicssanket dashNo ratings yet

- Fire WaterDocument7 pagesFire WaterMohammad MohseniNo ratings yet

- Conical Water TankDocument64 pagesConical Water TankRiyaz Siddique100% (1)

- Plasma: Plasma (from Greek πλάσμα, "anything formed"Document7 pagesPlasma: Plasma (from Greek πλάσμα, "anything formed"Maitri ShahNo ratings yet

- Physics Full PDF EMDocument125 pagesPhysics Full PDF EMhirankaNo ratings yet

- ISO+556-2020 Coke (Greater Than 20 MM in Size) - Determination of Mechan...Document17 pagesISO+556-2020 Coke (Greater Than 20 MM in Size) - Determination of Mechan...Julio PadillaNo ratings yet

- GT2007 27064 PDFDocument10 pagesGT2007 27064 PDFEfrain ValleNo ratings yet

- Physics Laws of MotionDocument9 pagesPhysics Laws of MotionLux SilverNo ratings yet

- Cree Plcc8 4 in 1 SMD Led Clr6A-Tkw: Product Family Data SheetDocument17 pagesCree Plcc8 4 in 1 SMD Led Clr6A-Tkw: Product Family Data SheetguciNo ratings yet

- FEA Simulation of Metal CuttingDocument6 pagesFEA Simulation of Metal CuttingAnonymous p8bHAAxNo ratings yet

- Lasers in Additive Manufacturing: A ReviewDocument16 pagesLasers in Additive Manufacturing: A ReviewluisNo ratings yet

- Waves and Sound TestbankDocument9 pagesWaves and Sound TestbankЕлнур ИкимбаевNo ratings yet

- SIEMENS Price List2009Document60 pagesSIEMENS Price List2009Goutam MandalNo ratings yet

- Conventional Zone Module With Sci Eva-Zmu-Sci: FeaturesDocument3 pagesConventional Zone Module With Sci Eva-Zmu-Sci: FeaturesPrima Fitra SaputraNo ratings yet

- Manual Deron 1Document15 pagesManual Deron 1Cristian OrtuzarNo ratings yet

- Manual de Instrucciones Compresores Tecumseh en Ingles 0000359Document17 pagesManual de Instrucciones Compresores Tecumseh en Ingles 0000359williams vega moscoteNo ratings yet

- Equivalent Broadband Electrical Circuit of Synchronous Machine Winding For Frequency Response Analysis Based On Gray Box ModelDocument10 pagesEquivalent Broadband Electrical Circuit of Synchronous Machine Winding For Frequency Response Analysis Based On Gray Box ModelrodineicarraroNo ratings yet

- Type Equation Here.Document3 pagesType Equation Here.HKVMVPVPV021511No ratings yet

- Force and Laws of MotionDocument3 pagesForce and Laws of MotionPranchalNo ratings yet

- D11 - Power Manager UA Regulation Functionalities-GD180267 R2Document20 pagesD11 - Power Manager UA Regulation Functionalities-GD180267 R2Mạc DavidNo ratings yet

- Faraday Point FormDocument3 pagesFaraday Point Form10SHARMA SUMIT RAMADHINNo ratings yet

- MCQ MicrosDocument5 pagesMCQ Microsamitrameshwardayal50% (2)

- 3.2 Electric Currentvoltage Lesson ProperDocument15 pages3.2 Electric Currentvoltage Lesson ProperShia FuevoNo ratings yet

- Monoslope Wind NSCP - PDF - Windward and Leeward - WoundDocument13 pagesMonoslope Wind NSCP - PDF - Windward and Leeward - WoundAicel RegenciaNo ratings yet