Professional Documents

Culture Documents

Engineers Hand Book M25 PDF

Uploaded by

Rahul SawantOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineers Hand Book M25 PDF

Uploaded by

Rahul SawantCopyright:

Available Formats

m

c

M25

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Table of Contents

Table of Contents .......................................................................... 2

Engine Data .................................................................................... 6

Engine Operating Data .................................................................. 6

Engine Block .................................................................................. 7

- Tightening torques for screw plugs ............................................................................. 7

- Crank case cover ................................................................................................................ 7

Cylinder Head ................................................................................. 8

- Tie bolts engine block ....................................................................................................... 8

- Tightening torques ............................................................................................................. 8

- Tightening torques for screw plugs at cylinder head ............................................... 8

- Valve rocker bracket .......................................................................................................... 9

- Valve rocker ......................................................................................................................... 9

- Radial clearance ................................................................................................................... 9

- Setting of valve bridges and valve clearances .......................................................... 10

- Valve clearance .................................................................................................................. 10

- Valve guide ......................................................................................................................... 10

- Guiding bolts for the valve bridges ............................................................................... 11

- Indicating and safety valve ............................................................................................... 11

- Starting valve ...................................................................................................................... 11

- Sleeve for the fuel injection valve ................................................................................ 12

- Fuel injection valve ........................................................................................................... 12

- Fuel pressure pipe dismounting .................................................................................. 14

- Fuel pressure pipe mounting ........................................................................................ 14

- Pressure piece .................................................................................................................. 15

- Grinding of inlet and exhaust valves ............................................................................ 16

- Fitted valve stems: ........................................................................................................... 17

- Fitting of inlet and exhaust valve seats ....................................................................... 18

- Valve seat ring ................................................................................................................... 18

Piston ............................................................................................ 19

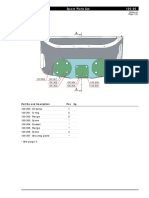

- Built-up piston 2500.7-26.70.00-01 / -02 / -03 ................................................................ 19

- Fitting ................................................................................................................................... 19

- Wear and clearance limits ............................................................................................... 20

- Dismounting of fire ring .................................................................................................. 20

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 2

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Table of Contents

Connecting Rod ........................................................................... 21

- Big end bearing ................................................................................................................. 21

- Piston pin bush - piston pin ........................................................................................... 21

Liner .............................................................................................. 22

- Wear limits .......................................................................................................................... 22

- Assembly ............................................................................................................................ 23

Crankshaft .................................................................................... 24

- Tightening torque bearing caps .................................................................................... 24

- Measurement of gap ....................................................................................................... 24

- Marking ............................................................................................................................... 25

- Located main bearing ...................................................................................................... 25

- Counterweight mounting ............................................................................................... 26

- Crank web deflection ...................................................................................................... 26

Gear Train ..................................................................................... 27

- Gear wheel on crankshaft .............................................................................................. 27

- Intermediate gear wheel mounting ............................................................................. 28

- Camshaft gear wheel assembly ................................................................................... 29

- Backlash .............................................................................................................................. 30

- Lub. oil injectors for the gear drive .............................................................................. 30

Governor Drive ............................................................................ 31

- Governor drive .................................................................................................................. 31

- Bushes in the crankshaft housing ............................................................................... 32

Camshaft ....................................................................................... 33

- Camshaft mounting ......................................................................................................... 33

- Vibration damper mounting ........................................................................................... 34

- Camshaft bearings ........................................................................................................... 34

Lower Valve Drive ....................................................................... 35

- Lower valve drive mounting .......................................................................................... 35

Fuel Injection Pump ..................................................................... 36

- Dismounting - mounting ................................................................................................. 37

- Fuel distributing and collecting pipe ............................................................................ 37

- Starting process ............................................................................................................... 38

- Check of commencement of fuel delivery ................................................................. 39

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 3

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Table of Contents

IMO Adjustment ............................................................................ 40

- Engine adjustment IMO ................................................................................................... 40

- IMO - adjustment, check ................................................................................................. 41

Sundries ....................................................................................... 42

- Regulating shaft ................................................................................................................ 42

- Cooling water distributing pipe .................................................................................... 42

- Barring gear ....................................................................................................................... 43

- Starting fuel limiter ........................................................................................................... 44

- Fuel rack sensor ............................................................................................................... 45

- Governor arrangement ................................................................................................... 45

Opposite Side of Coupling (Free End) ...................................... 46

- Mounting without power take-off ................................................................................. 46

- Mounting pump carrier ................................................................................................... 46

- Mounting with power take-off ....................................................................................... 47

- Mounting PTO coupling hub ........................................................................................... 48

Pump Carrier with Attached Pumps ........................................... 49

- Pump carrier ...................................................................................................................... 49

- Gear wheel mounting ...................................................................................................... 49

Flywheel Mounting ...................................................................... 50

- Dismounting of flywheel ................................................................................................. 52

Flexible Flange Connection ....................................................... 53

Charge Air Cooler ........................................................................ 54

- Installation .......................................................................................................................... 54

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 4

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Table of Contents

Turbocharger Mounting .............................................................. 57

- Mounting turbocharger KBB R4-3 to 6-cylinder engines ......................................... 57

- Mounting turbocharger KBB R5-3 to 8- and 9- cylinder engines ........................... 58

- Mounting turbocharger KBB HPR6000 to 6-, 8- and 9- cylinder engines .............. 59

- Mounting turbocharger ABB TPS61D to 9- cylinder engines ................................. 60

- Oil drain ............................................................................................................................... 61

Exhaust Gas Manifold ................................................................. 62

- Exhaust gas manifold ....................................................................................................... 62

- Gaskets between cylinder head and exhaust gas manifold .................................. 62

Generator GP-Engine ................................................................. 63

- Attachment engine and generator ............................................................................... 63

- Sealing surfaces ............................................................................................................... 63

Flexible Mounting ........................................................................ 64

- Locking device in case of average ............................................................................... 67

Firing Sequences - Valve Timing ............................................... 68

Dimensions and Weights ............................................................ 69

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 5

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Engine Data Engine Operating Data

Stroke = 400 mm Temperatures

Bore = 255 mm Lub. oil

Speed, rpm = 720 - 750 Engine inlet 60 - 65° C

Main bearing Temperature rise 10 - 14° C

Inside Ø = 240 mm Fresh water circulation cooling

Outside Ø = 252 mm Engine outlet 80 - 90° C

Big end bearing Temperature rise 7 - 10° C

Inside Ø = 193 mm Charge air

Outside Ø = 204 mm Engine inlet 45 - 60° C

Valves, inlet and exhaust Pressures

Length = 446 mm Lub. oil 4.0 - 5.0 bar

Valve disk Ø = 84 mm Fresh water circulation cooling

With min. 4 mWc 2.5 - 6.0 bar

Valve guide

Length = 235 mm Fuel pressure before injection pumps

Inside Ø = 19.10 mm MDO-operation 3.0 - 5.0 bar

HFO-operation 4.0 - 10.0 bar

Details for rated engine output and

nominal engine speed.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 6

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Engine Block

- Tightening torques for screw plugs

Tighten screw plugs M33x2 with → M = 200 Nm

Tighten screw plugs M18x1,5 with → M = 140 Nm

Tighten screw plugs M12x1,5 with → M = 70 Nm

Tighten screw plugs G1/2A with → M = 160 Nm

Tighten screw plugs G3/4A with → M = 70 Nm

- Crank case cover 1

Mount flat gaskets slightly greased.

Use Dirko, Nr.610.020 (Dirko, grey) for coverings

without any gasket.

Tighten the screws - 1 - for the cover with blow-off valve

(new variation 2500.7-16.33.00-02)

with → M = 24.5 Nm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 7

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Tie bolts engine block

The tightening torque for inserting the

tie bolts into engine block is → M = 450 Nm

Molykote

- Tightening torques

1. Tighten round nuts with pin by hand.

2. Lengthen bolts with → P = 820 bar

and tighten round nuts with pin taking

care of easy motion.

Check: Reduce pressure to → P = 770 bar

Loosening the nuts must not be possible any more.

The pressure must remain constant, when the pump is not operated, otherwise faulty

tightening.

Dismounting: If the cylinder head nuts cannot be loosened with P = 820 bar, an increase by 50

bar is possible. Further pressure increase involves the risk that the thread will expand and the

nuts will jam.

At the control bore 1 - leakages between

cylinder head, flame ring and cooling water

distributing housing can be detected.

(e.g. black, sooty film = gas leakage)

1

- Tightening torques for screw plugs at cylinder head

The tightening torque for screw plugs with thread

G1/2A with high-temperature paste is → M = 60 Nm

The tightening torque for screw plugs with thread

M10x1 with Loctite 270 is → M = 15 Nm

The tightening torque for screw plugs with thread

M10x1 with Molykote is → M = 30 Nm

The tightening torque for screw plugs with thread

M36x2 with Hylomar is → M = 250 Nm

The tightening torque for screw plugs with thread

M42x2 with Hylomar is → M = 300 Nm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 8

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Valve rocker bracket

The tightening torque for inserting

the studs - 1 - is → M = 100 Nm

Oil

Tighten nuts - 2 - with → M = 160 Nm

Molykote

- Valve rocker

Reference size for the bush after

pressing-in → Ø 59.99 + 0.12 mm

The bush shall recede after

pressing-in by → 0.20 + 0.10 mm

0.20+0.10

Ø 59.99 + 0.12

Before pressing-in slightly coat the bushes with oil, Molykote must not be used.

- Radial clearance

Original size → 0.02 - 0.159 mm

Limit clearance → 0.359 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 9

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Setting of valve bridges and valve clearances 1

1. Turn out adjusting screws - 1 - of the valve

rockers to obtain a sufficient clearance.

2. Turn out adjusting screws - 2 - of the valve

bridges to obtain a clearance when

valve bridge „X“ touches „Y“.

3. Screw in adjusting screws - 2 - until the

valve bridges rest on the valves without

clearance.

4. Hold adjusting screws - 2 - fast and lock

them. 2

5. Adjust valve clearance. Y X

- Valve clearance

Inlet → 0.50 + 0.10

mm

Exhaust → 0.90 + 0.10

mm

- Valve guide

(Inlet - Exhaust)

The valve guides are inserted into the cylinder head

undercooled to -195°C (liquid nitrogen)

Nominal clearance → 0.10 - 0.15 mm

Limit clearance → 0.35 mm

Measure diameter of the valve shaft in the guide area.

Measure guide in cross direction of engine.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 10

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Guiding bolts for the valve bridges

with thread

The tightening torque for the guiding bolts is → M = 180 Nm

Insert guiding bolts with Loctite 243

and provide the contact faces with Molykote.

without thread

The guiding bolts are inserted into the cylinder head for newer engines undercooled to

-195°C (liquid nitrogen)

- Indicating and safety valve

The tightening torque for inserting the

studs (M12) - 1 - is → M = 50 Nm

Oil

Tighten nuts (M12) - 2 - with → M = 50 Nm

Molykote

Joint ring

- Starting valve

Tighten locking screw - 1 - with → M = 250 Nm

Tighten safety nut - 2 - with 1 → M = 35 Nm

Molykote 2

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 11

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Sleeve for the fuel injection valve

Tighten the sleeve for the fuel injection valve with → M = 140 Nm

Loctite 510 (thread+sealing surface)

Use special wrench!

Reference dimension

307,5

O-ring Viton, green

O-ring Perbunan

- Fuel injection valve

The tightening torque for inserting

the studs - 1 - is → M = 50 Nm

Oil

Tighten nuts - 2 - within 2 steps with → M = 50 Nm

Molykote paste G.

Tighten nozzle nut with

2

→ M = 750 Nm

Oil

dimension 29.5

1

Reference

Ensure flush

contact of flange

to nozzle holder.

Nozzle cooling return

Coat o-rings

slightly with Nozzle cooling supply

Molykote. Fuel pressure pipe connection

Nozzle leak fuel

Attention !

Insert the injection Insert nozzle element with

valve into the cylinder high-temperature paste

head without joint

ring !

Nozzle nut

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 12

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Fuel injection valve

Tighten counternut - 1 - for adjusting screw - 2 - with → M = 70 - 90 Nm

With intermediate plate

Tighten counternut - 1 - for adjusting screw - 2 - with → M = 60 ± 10 Nm

Without intermediate plate

The injection valve has proven optimum reliability in both operation

modes, MDO and HFO. This injection valve, however, must be 4

3

carefully completed. During assembly of the locking

screw deformations to the joint ring might occur. This could lead to Joint

leak fuel with following contamination of the lubricating oil. When ring

completing an injection valve, attention must be paid to the following:

with intermediate plate without intermediate plate

1

1. The joint ring must be centered.

2. The nut - 3 - with the locking

screw - 4 - is to be tightened with a M = 90 - 130 Nm

torque of →

With intermediate plate

1. The joint ring must be centered.

2. The nut - 3 - with the locking

screw - 4 - is to be tightened with a M = 90 + 30 Nm

torque of →

Without intermediate plate

3. The joint ring must be checked visually once more for correct fitting.

Otherwise, the before-mentioned procedure is to be repeated with a new joint ring.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 13

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Fuel pressure pipe dismounting

First loosen screwing - 4 - of transverse pressure piece - 3 -, then screwing - 6 -.

- Fuel pressure pipe mounting

1. Tighten nuts of the fuel injection valve with the prescribed torque, loosen them by one

turn and tighten with M = 10 Nm.

2. Put the parts together and care for the correct position of cover - 1 -.

Sleeve - 2 - is in a pushed back position inside the cylinder head.

3. Tighten screwing - 4 - of transverse pressure piece - 3 - and thrust bolt - 6 - of radial

pressure piece - 5 - (without spanner).

4. Tighten thrust bolt - 6 - and screwing - 4 - of transverse

pressure piece - 3 - with → M = 10 Nm

5. Tighten screwing - 4 - of transverse pressure

piece - 3 - with → M = 150 ± 5 Nm

Tighten thrust bolt - 6 - with → M = 130 ± 5 Nm

Warning ! Keep transverse pressure piece - 3 - in position

using a spanner (avoidance of damages to the individual connections)

6. Push sleeve - 2 - into the fuel injection pump for locking. Tighten nuts of the fuel

injection valve with prescribed torque.

Coat thread and contact surfaces of screwing - 4 -, transverse pressure piece - 3 -, radial

pressure piece - 5 - and thrust bolt - 6 - with Molykote paste G.

4 Coat thread and

2

contact surfaces

3 with Molykote.

6

1

5

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 14

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Pressure piece

The projection dimension - 1 - must not be less than 4.7 mm (e. g. when reworking the

sealing surface), because otherwise the first thread pitch may abut against the pump

casing. As a result of this the pre-tension moment may drop below the required limit. This

may cause a leakage.

Injection pumps from March 2000 are not affected by this problem, because an undercut

has been introduced on the pump casing.

1 5 ± 0.3

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 15

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Grinding of inlet and exhaust valves

Apply small dots of the diamond paste Dp 30/10-15 my with a syringe to the new or

remachined valve cone and distribute the paste equally. Thereafter the seat ring surface

is to be sprayed with a thinner (F25) belonging to the diamond paste, for dilution and in

order to increase the grip. Insert the oiled valve stem into the

guide bush. Fasten the device at the valve disk and grind the

valve face and seat by hand applying a moderate pressure,

rotating the device. The contact reflection „a“ which is visible by

the smooth grinding process shall not exceed 30 % of the seat

width starting from the outside diameter. If the bearing

characteristics described above are not reached, remachining of

both sealing surfaces is necessary. After machining both seats

have to be checked with a luminous magnifier. The fillet must not

be refinished.

After machining round off the outside edge with a stone.

The dimensions specified in the sketch are to be observed.

Exhaust valve HFO operation Exhaust valve MDO operation

29° 59’ - 2’

29° 87’ + 2’

min. 1.5 mm

min. 1.5 mm

Inlet valve

29° 52’ + 2’

min. 0.2 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 16

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

Deviations from true running

The deviation from true running on the valve stem must not exceed 0.05 mm on the

measuring distance "S" of 264 mm.

The deviation from true running on the valve cone must not exceed 0.025 mm.

For both measurements the valve stem must touch at points A and B in the measuring

device.

0.05 mm

20 20

s

0.025 mm

Reuse of a valve stem is not possible, if:

1. there is severe pitting on the bottom side of the valve head (formation of so-called

„paving stones"),

2. there are corrosion pits and

mechanical damages in the area of

the valve, stem, stem transition, and

valve head,

3. the limit for refinishing is exceeded or

4. in case of corrosive material wear

of 2 % from the valve disk diameter. In

case of high-temperature corrosion

„S“ of 1.50 mm.

S

- Fitted valve stems:

MDO operation 2500.7-22.10.01-01 Inlet valve

2500.7-22.10.01-02 Exhaust valve

HFO operation 2500.7-22.10.01-01 Inlet valve

2500.7-22.10.01-03 Exhaust valve

2500.7-22.10.01-05 Exhaust valve

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 17

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Cylinder Head

- Fitting of inlet and exhaust valve seats

1. Cool valve seat rings down to - 195° C (liquid

nitrogen). To cool down the valve seat ring to -20°C

and heat up the cylinder head to 130°C is also

possible (if necessary).

Y1

2. Insert the inlet and exhaust valve seat rings.

Y2

3. When the valve seat rings are tight, press them

on with the pressure device.

Tightening torque for the pressure device is → M = 50 Nm

4. Check the bearing surface „Y 2 "; between inlet valve seat ring and cylinder head no

air gap is admissible.

5. Check the air gap „Y 1" between exhaust valve seat ring and cylinder head.

Admissible air gap 0.40 + 0.30 mm

Pressure test: Cooling water spaces 10 bar for 8 min.

- Valve seat ring

+ 0.20

Maximum admissible dimension Ø X for refinishing the exhaust valve seat rings 92.00

mm and on the inlet valve seat rings 85.00 + 0.20 mm

At „a“ no material may be taken off.

Exhaust valve seat ring Inlet valve seat ring

’

’

5’+5

5’+5

a a

30°+

ØX

30°+

ØX

Refinishing is possible with MaK valve seat ring turning machine or with MaK valve seat

milling fixture. After grinding the bearing portion shall be 30- 50 %, beginning from the

outer diameter.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 18

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Piston

- Built-up piston 2500.7-26.70.00-01 / -02 / -03

Coat thread and contact surface with Molykote paste G-n-plus.

Tighten screws crosswise with → M = 60 Nm

Loosen screws again.

Pretighten screws crosswise with → M = 25 Nm

and tighten with → Dw = 60°

Check:

At → M = 45 Nm

the nuts must not turn further.

Gap size

2500.7-26.70.00-01 / -02 → 0.06 - 0.10 mm

2500.7-26.70.00-03 → 0.07 - 0.11 mm

Measure gap here,

screws not

tightened.

68+0,4

- Fitting

Arrange the ring butts in longitudinal direction of engine alternately opposed, then oil

pistons and piston rings well.

Fit piston rings with marking upwards.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 19

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Piston

- Wear and clearance limits

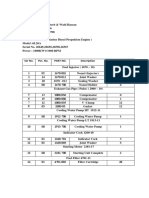

Grooves Groove height Ring height Wear limit Clearance limit

1 6.15 +0.03 6.00 -0.010 - 0.025 6.60 0.50

+0.03

2 6.13 6.00 -0.010 - 0.025 6.60 0.50

+0.03

3 8.06 8.00 -0.013 - 0.035 8.60 0.50

Pistons 2500.7-26.70.00-01 / 02 / 03 for gas oil and heavy fuel operation

Grooves Rings

1 Rectangular ring 2500.7-26.17.01-01

2 Compression ring 2500.7-26.17.01-02

3 Oil scraper ring 2500.7-26.17.01-03

Minimum Maximum Limit

clearance clearance clearance

Piston bosses -

Piston pin 0.050 0.078 0.100

Piston boss distance -

Piston pin

bush width 0.500 1.100 1.300

- Dismounting of fire ring

7

1. Turn piston top edge below the fire ring.

2. Place dismounting device on the piston so that the recess lies inside

the fire ring.

3. Slightly tighten the dismounting device by turning spindle nut - 1 -.

4. Press fire ring out by turning the piston up.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 20

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Connecting Rod

- Big end bearing

1. Tighten upper big end bearing bolts successively

with → M = 150 Nm

2. Tighten upper big end bearing bolts successively

up to → M = 300 Nm

3. Tighten lower big end bearing bolts successively

with →

M = 150 Nm

4. Tighten lower big end bearing bolts successively

up to → M = 300 Nm

5. Tighten upper big end bearing bolts successively

up to → M = 600 Nm

6. Tighten lower big end bearing bolts successively

up to → M = 600 Nm

7. Tighten upper big end bearing bolts once more

successively up to →

M = 600 Nm

Coat threads and contact surfaces with a thick layer of Molykote G Rapid Plus.

Reference size B

Reference size A

Here cylinder No.

Here cylinder No.

Lower screws

Upper screws

Reference dimension of the big end bearings after correct tightening.

Size „A“ → 193.16 + 0.05 mm

Size „B“ → A + 0.04 + 0.01 mm

The reference dimension of the piston pin bush

after shrinking-in into cooled state is Ø → 120.11 + 0.08 mm

- Piston pin bush - piston pin

Minimum clearance → 0.113 mm

Maximum clearance → 0.199 mm

Limit clearance → 0.210 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 21

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Liner

- Wear limits

Nominal size Ø (original size) → 255.00 + 0.052 mm

Wear and tear value → TDC 1st ring 0.90 mm

Max. ovality → 0.25 mm

Wedge shape Height → 6.00 mm

Depth * → 0.03 mm

Wedge-shaped indentation across the entire circumference, beginning at TDC 1st piston ring.

Canyon Max. number → 3

Length → 150.00 mm

Total width → 0.03 mm

Individual deep blow-through ducts in the area of the 1st piston ring (TDC)

Score Number → 3

Length → 150.00 mm

Depth → 0.03 mm

Hard vertical, linear friction marks.

Pocket Number → 3

Length → 60.00 mm

Width ** → 20.00 mm

Depth * → 0.02 mm

Areal, irregular indentations.

* Radius r ≥ 3 mm

** In circumferential direction

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 22

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Liner

Wedge shape Pocket Sore TDC 1st ring Canyon

- Assembly

During installation take care that 2

marking - 1 - of the liner coincides

with marking - 2 - of the cooling

water distributor casing.

The liner must slide into the cylinder

crankcase by its own weight.

Attention! Incorrectly inserted liners

may cause considerable damages.

1

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 23

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Crankshaft

- Tightening torque bearing caps

The tightening torque for inserting the studs - 1 - is → M = 450 Nm

Molykote

Tighten crankshaft bearing

nuts - 2 - steadily by hand.

Insert hexagon screws - 3 - 3 3

with Molykote and tighten

alternately in 3 steps.

2 1 2

Tighten 1st step up to → M = 140 Nm

Tighten 2nd step up to → M = 420 Nm

Tighten 3rd step up to → M = 670 Nm

Lengthen studs - 1 - with → P = 980 bar

and tighten crankshaft bearing nuts - 2 - .

Check: Reduce pressure to → P = 930 bar

Loosening the nuts must not be possible any more.

Tighten both crankshaft bearing nuts of one bearing pocket in one operation.

- Measurement of gap

1. Remove hexagon screws - 3 - of the crankshaft bearing. Loosen hexagon screws

- 3 - of the adjacent crankshaft bearing.

2. Loosen both crankshaft bearing nuts - 2 - of one bearing pocket in one operation.

3. Tighten crankshaft bearing nuts with a pin alternately and steadily until the joint faces

of the bearing shells are just touching each other.

4. Check the projecting length of the bearing shell by measuring the gap between

cylinder crankcase and bearing cap on camshaft and exhaust gas side.

Sum of gap → 0.75 - 1.00 mm

After longer operation the sum of gap

shall not be less than → 0.60 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 24

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Crankshaft

- Marking

Bearing caps and bearing shells are marked on camshaft side with relative cylinder

numbers counted from flywheel side. The parts must not be mixed up.

Bearing No.

stamped here The protection against

torsion is on camshaft

side

X

X

Located and normal main bearings are

identical, for axial fixing on bearing 1 (located

main bearing) thrust washers - 1 - with

clamping pins - 2 - are mounted on bearing

cap - 3 -.

3 2

- Located main bearing

End clearance → 0.30 - 0.60 mm

Limit clearance → 0.80 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 25

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Crankshaft

- Counterweight mounting

Pretighten screws with → M = 100 Nm

and tighten

with → Dw = 120°

Lubricant Molykote (G-Rapid) on thread and screw contact surface.

6 cyl. engine 12 counterweights

8 cyl. engine 12 counterweights

Crankpin 1 2 pcs.

Crankpin 2 1 pc. left side *

Crankpin3 1 pc. right side *

Crankpin 4 2 pcs.

Crankpin 5 2 pcs.

Crankpin 6 1 pc. left side *

Crankpin 7 1 pc. right side *

Crankpin 8 2 pcs.

9 cyl. engine 12 counterweights

Crankpin 1 2 pcs.

Crankpin 2 1 pc. left side *

Crankpin 3 without counterweight

Crankpin 4 2 pcs.

Crankpin 5 2 pcs.

Crankpin 6 2 pcs.

Crankpin 7 without counterweight

Crankpin 8 1 pc.. right side *

Crankpin 9 2 pcs.

* = seen from camshaft side.

- Crank web deflection

Limit values

Cylinder without external load (generelly valid for all cylinders,

also for cylinder 1 if flywheel hub and flywheel are not yet

mounted, as well as for the last cylinder if the auxiliary PTO

with bearing in pump mounting plate is not connected.) → 0.05 to - 0.08 mm

Cylinder with additional load (normally cylinder 1

by means of flywheel and last cylinder if power is

actually taken of at the free end.) → 0.05 to - 0.11 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 26

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Gear Train

- Gear wheel on crankshaft

Press gear wheel with device and oil hydraulic mounting

-

connection Z - → M = 500 Nm

on the crankshaft cone into its final position.

The final position is reached when the gear wheel touches the spacer. The spacer simulates the

located bearing, it must be adjusted so that with the gear wheel in final position a dimension

of 126 + 0.1 mm results between gear wheel and crank web cyl.1.

The slide-on distance is 12 -3,5

mm.

The device must remain fitted 20 minutes after pressure relief.

Engine start 2 hours after pressure relief at the earliest.

Spacer

126 + 0.01

Connection„Z“ 1/4 ‘’

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 27

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Gear Train

- Intermediate gear wheel mounting

Tighten screws - 1 - with → M = 130 Nm

Molykote

X

X

1

S

O-ring

End clearance S min. → 0.30 mm

max. → 0.60 mm

Gap size

Gap size between axle and locking sheet see - Y -

Min. → 0.30 mm

Max. → 1.40 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 28

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Gear Train

- Camshaft gear wheel assembly

gear wheel mounting new design

Journal - 1 - must not extend into the

gear box.

Turn the camshaft gear wheel - 2 - with

the device into the gear box. Push the

journal until it touches the camshaft gear 2

wheel cone. Prefit helical gear - 3 - until

it touches the camshaft gear wheel. 3

Mount the camshaft gear wheel

hydraulically on the bearing journal cone

by tightening screws - 4 - up to the end 1

of the cone.

Attention!

4

Tighten screws - 4 - steadily.

Final position: Draw helical wheel - 3 -

against bearing journal - 1 -.

Slide-on distance: 10.5 - 2.9 mm

Pressing liquid: hydraulic oil

Tighten screws - 4 - with → M = 130 Nm

Molykote G Rapid Plus

ISO4014-M16x80-8.8

See chapter

Tighten screws - 5 - with → camshaft - camshaft

Molykote G Rapid Plus mounting

End clearance at - 6 - → 0.30 - 0.70 mm

Hydraulic oil pressure with hand pump → P = approx. 1200 bar

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 29

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Gear Train

- Backlash

Crankshaft gear wheel - intermediate gear wheel → 0.23 - 0.35 mm

Intermediate gear wheel - camshaft gear wheel → 0.23 - 0.35 mm

- Lub. oil injectors for the gear drive

Tighten screws with → M = 160 Nm

Attention !

During assembly of the helical gear wheel

attention must be paid to bore - 1 -, that means

cylinder 1 and injection cam ramp must be in 1

TDC position.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 30

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Governor Drive

- Governor drive

Pretighten castle nut - 1 - M = 30 Nm

with →

further tightening up to the

next split pin hole.

Molykote 3

End clearance - 2 - → 2 0.30 - 0.60 mm

Mount governor bracket - 3 - with

liquid sealing compound.

1

Backlash - 4 - → 0.15 - 0.50 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 31

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Governor Drive

- Bushes in the crankshaft

32

housing

8

If the bushes - 1 - and - 2 - in

the cylinder crankcase must be

exchanged, take care that the 1

dimensions stated in the sketch

are observed.

Slightly oil the bushes before

pressing them in, do not use

Molykote.

302

335

2

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 32

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Camshaft

- Camshaft mounting

Tighten screws - 1 - (DIN931-M14 x 60-10.9)

with → M = 140 Nm

Molykote G Rapid Plus

Tighten screws - 2 - See chapter gear

with → train - camshaft gear

Molykote G Rapid Plus wheel assembly

Note: Upon assembly of the helical gear wheel correct position of the IMO bore is

observed! (cylinder 1 and rising curve for delivery of the injection cam in TDC)

Helical gear wheel

Flange code number

Exhaust

cam Position of parallel pin

Inlet Injection (see table below)

cam cam

1

2

1

Flange code number

Position of parallel pin

(see table below)

Flange Code Num bers

6 cyl. engine 8 cyl. engine 9 cyl. engine

Before assembly of the flange flange flange

camshaft provide each cylinder cylinder cylinder

code code code

camshaft flanges with one section section section

number number number

parallel pin according to

the table. 1 5 1 1 1 5

2 1 2 2 2 8

3 6 3 3 3 2

4 5 4 4 4 6

5 3 5 5 5 4

6 7 6 6 6 4

7 7 7 6

8 8 8 2

9 8

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 33

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Camshaft

- Vibration damper mounting

Tighten screws - 1 - with → M = 85 Nm

1

Molykote

Screws DIN931-M14x60-8.8

Tighten screws - 2 - with → M = 50 Nm

Molykote

Screws DIN931-M12x70-8.8

Bore arrangement for Bore arrangement for 8 M25

6 / 9 M25

- Camshaft bearings

Tighten fixing screws - 1 - for the camshaft bearings

with → M = 130 Nm

Molykote

Allen screws ISO4762-M16x100-8.8

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 34

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Lower Valve Drive

- Lower valve drive mounting

Tighten screws - 1 - for the bearing

brackets with → M = 130 Nm

Molykote

End clearances (not for first bearing bracket at cyl.1) →

0,20 mm

End clearance (only for first bearing bracket at cyl.1) → 0,30 mm

1

0.3 min. 0.2 min. 0.2

Determine the end

x clearance by shifting the

bearing brackets.

At the contact points of the rocking lever shafts no gap

is admissible.

Loosen the bearing caps and push rocking lever shaft

flush together from both sides.

Attention!

Take care of the

chamfer. Valid for cy.

2 to cyl. 5/ 7/ 8l

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 35

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Fuel Injection Pump

The tightening torque for inserting the

studs is → // 0,3 1 2 M = 120 Nm

Molykote

Type: PF1WX230V-C

Tighten fastening nuts

with → M = 200 Nm

Molykote

Pretighten screws - 1 -with → M = 10 Nm

and tighten

3

with → 5 M = 90 ± 3 Nm

Tighten screws - 2 -with → M = 53 ± 2 Nm

Tighten screws - 3 -with → M = 14 ± 1 Nm

Tighten screws - 4 -with → M = 22 ± 2 Nm

X

Tighten screws - 5 -with → M = 85 ± 5 Nm

Tighten counter-sunk

screws for

the indicator at

the fuel rack with →

4 M = 3.50 + 0.50 Nm

leak fuel outlet X

tightening torque

max. 30 Nm

Pay

attention

to the

mounting

screws for

direction!

leak oil outlet

torque

max. 50 Nm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 36

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Fuel Injection Pump

- Mounting

Before mounting the injection pump take care that the roller of the rocking lever rests on

the cam base circle and that the air passage sleeves are correctly positioned in the

cooling water distributor casing.

- Dismounting - mounting

During dismounting / mounting attention must be paid that the appertaining distance steel

plates are not removed.

If for any reason removal of the distance steel plates is necessary, they have to be

marked with the relevant cylinder number.

The thickness of the distance steel plates for each cylinder is stated in the acceptance test

record.

- Fuel distributing and collecting pipe

Tighten screws - 1 - DIN933-M10x35-8.8 and - 2 - DIN933-M10x20-8.8

with → M = 20 + 5 Nm

1 2

1 loose

flange 2 loose

installation flange

installation

Attention! For screws DIN933-M10x30-8.8 the standard torques are valid!

Tighten screw - 3 - with → M = 80 Nm

Insert screw with Loctite 542.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 37

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Fuel Injection Pump

- Starting process

The engine starting process is controlled via the injection pumps.

Roller of rocking lever on

cam base circle Starting process is released

Plunger in BDC-position

Start

Control air inlet

Plunger in TDC-position Venting is released

Starting

process Start of venting

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 38

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Fuel Injection Pump

- Check of commencement of fuel delivery

1. Dismount the injection pump delivery valve.

Commencement of Firing TDC

2. Mount dial gauge with extension. delivery

3. Turn engine so that the roller rests on the Position of

cam base and the TDC mark is abt. 45° commencement

before the dead centre indicator. of delivery

4. Set dial gauge to „0“, turn engine in

direction of rotation until the indication on

the gauge is 5 mm (5 mm on the gauge

correspond to 11° crank angle on the

flywheel).

24.6

5. Check the dimension on the flywheel from

TDC mark to dead centre indicator.

- Setting

1. Place the gauge with measuring device on

a level support by means of the adjusting

bush (dimension = 24.6 mm) and set gauge

to „0“.

2. Insert measuring device into the injection

pump bore in the engine housing and read

value on the dial gauge.

roller on the cam base

(For versions with eccentric cam follower

the eccentric position has to be vertically

upwards.)

3. Indicated value = thickness of the distance

steel plates.

The distance steel plates are used for setting the pre-stroke.

Available sizes:

2,10 mm 2,20 mm 2,40 mm 2,50 mm 2,60 mm 2,70 mm

2,80 mm 2,90 mm 3,00 mm 3,20 mm 3,40 mm 3,60 mm

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 39

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

IMO Adjustment

- Engine adjustment IMO

290, 300, 330 kW/cyl. 720/750 min-1

1. Commencement of injection

Needle bouncing as arithmetic mean value over all cylinders

Nominal value: 3,5° (+0,5° -1,5°) before TDC

Measured with MaK-EB-Tester

2. Commencement of fuel delivery

Commencement of fuel delivery as arithmetic mean value over all cylinders

Nominal value: 10,5° (+0,5° -1,5°) before TDC

Measured according to the overflow method; control travel >38mm

or pre stroke dimension 4,2mm at the auxiliary device

3. Cooling water temperature NT

NT- water inlet temperature

Nominal value: 30°C (±2°C) with PI control valve

Working range: 20°C - 30°C with P control valve

4. Cooling water temperature HT

HT- water outlet temperature

Nominal value: 90°C (±2°C) with PI control valve

Working range: 82°C to 92°C with P control valve

5. Charge air temperature

Nominal value: 45°C (±5°C)

6. Piston distance

Distance: piston - cylinder liner:

Nominal value: 18,6 mm (+0,55

-1,55

mm)

Measured from border of bowl to liner support

Adjustment of TDC mark and adjustment of commencement of fuel delivery of the injection

pumps as well as the appropriate working sheets.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 40

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

IMO Adjustment

- IMO - adjustment, check

1. Remove screw plug - 1 -.

2. Turn the engine until the bore Ø 4 mm in 1

the helical gear wheel is centrically with

regard to the bore - 2 - M10 x 1 in the

cover (see sketch).

3. Check at the flywheel whether the IMO

marking matches the dead center

indication.

2

- IMO - adjustment, marking of flywheel

1. Marking is only permitted when changing

the flywheel.

2. Adjust the engine in accordance with the

engine test bed record. Especially the IMO-valve

timing has to be observed.

3. Turn the engine until the bore Ø 4 mm in the helical

gear wheel is centrically with regard to the bore -

2 - M10 x 1 in the cover.

4. Stamp the IMO notch directly at the dead center

indicator on the flywheel.

Marking on

I flywheel

M

O

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 41

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Sundries

- Regulating shaft

Tighten screws - 1 - with → 1 M = 130 Nm

Molykote

Clearance at - 2 - → 0.20 mm

Before inserting the regulating shaft

lubricate the bearing areas.

Do not use Molykote nor oil.

2

Tighten screw - 3 - for the articulated lever with → M = 20 Nm

Molykote

- Cooling water distributing pipe

Tighten screws - 1 - with → M = 130 Nm

Molykote

ISO4014-M16x110-8.8-A3C

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 42

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Sundries

- Barring gear

Tighten screws - 1 - and - 2 - with → M = 130 Nm

Insert screws - 1 - with Loctite 243 .

Screws - 2 - Molykote

Actuate barring gear with torque

wrench up to 800 Nm, reversible

ratchet and socket wrench insert.

Engine operation is

1 only possible with

screwed on cover - 2 -.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 43

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Sundries

- Starting fuel limiter

Fitting instruction

1. For basic adjustment of lever - 1 - pull the piston of cylinder - 2 - by 30 mm.

2. Set the fuel rack of the injection pumps to position 16.

3. Lever - 1 - must by stopped by mechanical limit at piston - 3 -.

4. Push piston of cylinder - 2 - back.

At full load lever - 1 - must not fit closely piston - 3 -.

5. Lever - 1 - must be bored through with 6 mm and be pinned and leaded by a clamping

sleeve.

ad

2

l lo

Ful

16

n

tio

1

si

Po

30 op

St

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 44

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Sundries

- Fuel rack sensor

Adjust cam -1- so that center punch mark aligns with axis of sensor -2- in stop position.

Sketch: variation -03 variation -04

1 2

1

3 3

Exception: For applications with the UG8 D MAS (designation: 8527-151) governor the

fuel rack sensor need not to be adjusted, because for this type of governor a fuel rack

sensor is integrated.

- Governor arrangement

Always follow the adjustment data of the governor data sheets. Only in exceptional

cases and only after consulting the technical service VT5 the setting of the governor may

be changed.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 45

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Opposite Side of Coupling (Free End)

- Mounting without power take-off

Pretighten screws - 1 - with → M = 250 Nm

and tighten with → Dw = 90°

Molykote

6 cyl. engines - 10 tie bolts

8 cyl. engines - 12 tie bolts 1

9 cyl. engines - 14 tie bolts

Screw arrangement 6 Screw arrangement 8 Screw arrangement

cyl. engine cyl. engine 6 cyl. engine

Tightening torque for M16 screws → M = 130 Nm

Molykote

Sealing compound in the

hatched area only

- Mounting pump carrier

Degrease all flange facings. Provide

pump carrier with sealing compound and

position it at the cylinder crankcase

using a device.

Screw the carrier on and pin it.

Apply a thin layer of the sealing

compound only in the double-hatched

area. Take care that no sealing

compound clogs the oil ducts.

For mounting the pumps and

tightening torque see chapter:

Pump carrier with attached pumps

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 46

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Opposite Side of Coupling (Free End)

- Mounting with power take-off

Pretighten screws - 1 - with → M = 250 Nm

and tighten with → Dw = 90°

Molykote

Attention: For flywheel sided power take-off pay attention to the crank web deflection

of the last cylinder.

Ø 157

Subsequent unit

from 1000 kW power

Ø 100

Subsequent unit

up to1000 kW power

170

Screw arrangement Screw arrangement

6 cyl. engine 6, 8 and 9 cyl. engine

with 10 tie bolts with16 tie bolts

Tighten screws M 12 with → M = 60 Nm

Molykote

Tighten screws M 16 with → M = 130 Nm

Molykote

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 47

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Opposite Side of Coupling (Free End)

- Mounting PTO coupling hub

The hub mounting is carried with an oil-hydraulic pressure unit. The oil-hydraulic pressure

unit is designed different for each application. For this reason a general statement about

push-up distances and hydraulic oil pressures is not possible.

Generally valid information:

- Hub has to be slid onto the shaft without pressure until the contact surfaces are fitting

closely.

- In standard cases hydraulic oil SAE10 is used as compression liquid.

- The hydraulic oil pressure, the push-up force and the push-up distance are varying in

according to the application.

(For that different devices can be used.)

- The push-up force may only be released after one hour at the earliest.

- After removal of the oil hydraulic pressure unit stress on the hub is not allowed for

at least 24 hours.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 48

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Pump Carrier with Attached Pumps

- Pump carrier

Tighten screws M16 with → M = 130 Nm

For further information for pump carrier mounting see chapter:

Opposite Side of Coupling (Free End)

- Mounting pump carrier

- Lub. oil pumps, suction and pressure pump, cooling water circulation pumps

- Gear wheel mounting

Cover gear wheel cone with blue paste and check contact reflection on the appertaining

pump shaft cone with gear wheel cone, covered with blue paste.

Contact reflection ≥ 80°. Heat gear wheel up to 90°C-100°C (100°C-110°C for pump CLG

water) above temperature of the pump shaft and mount it firmly on the pump cone up to

stop position. The cone faces must be grease-free and dry.

Example: 20° C shaft temperature → 110 ° to 120 ° C gear wheel temperature.

The slide-on distance is 0,40 - 0,44 mm(0,29mm-0,32mm for pump CLG water).

M = 60 Nm

Tighten screw for the gear wheel with →

Lubricant: Molykote

0.20 - 0.45 mm

Backlash →

- Drive - Fuel feed pump

- Gear wheel assembly

Test contact reflection on the related pump shaft cone by means of gear cone covered

with blue paste. Only a contact reflection displaced to the thick end is admissible.

Heat gear wheel up to 30°-40°C above temperature of the pump shaft and mount it firmly

on the related pump cone up to stop position. The cone faces must be grease-free and

dry.

Example: 20° C shaft temperature → 50 ° to 60 ° C gear wheel temperature.

The slide-on distance is 0.14 - 0.18 mm.

M = 60 Nm

Tighten screw for the gear wheel with →

Lubricant: Molykote

0.20 - 0.45 mm

Backlash →

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 49

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Flywheel Mounting

Insert studs - 1 - with Loctite 243 into the flywheel. Grind clamping pins - 2 - at the sharp-

edged end (chamfer abt. 2 x 15ø) and insert them with this end into the gear wheel on

the crankshaft. Turn crankshaft into TDC cyl. 1 position. Guide splash ring - 3 - over the

crankshaft cone. Align end cover - 4 - centered to the crankshaft and flush with the

bottom edge of the cylinder crankcase before fitting it. Oil crankshaft cone with hydraulic

oil. Hang flywheel in the transfer port and slide it on the crankshaft cone until contact is

reached. Fit tightening device. Take care that the flywheel is fixed on the locating pin of

the device. In this position the projecting clamping pins at the gear wheel on the

crankshaft are aligned to the relative receiving bores at the flywheel.

Press flywheel with tightening device and oil hydraulic mounting into its final position (fit

closely to crankshaft gear wheel).

5 3

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 50

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Flywheel Mounting

Tighten nut on the device with → M = 1600 Nm

Oil pressure (with hand pump) → P = 1200 bar

The slide-on distance is → 23 - 3.5

mm

End clearance -7- → 0.30 + 0.30 mm

The device must not be loosened earlier than 24 hours after pressure relief. Engine start

not before 72 hours after removal of the device. Mount the splash ring on flywheel.

Tighten screws -5- (13xISO4017-M16x45-8.8-A3C) with → M = 130 Nm

Molykote

Mount nuts -6- (10xDIN934-M10) with

clamping disk (DIN6796-16-FST-A3C)

and tighten them with → M = 75 Nm

Loctite 243.

Hydraulic connection in the crankshaft → 1/4 ‘’

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 51

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Flywheel Mounting

- Dismounting of flywheel

While installed the device is 510 mm long. The length of the thread of the „threaded rod“ is

80 mm. For mounting the device at least 590 mm are required!

Loosen the oil slinger on the crankshaft.

Secure the flywheel by appropriate means.

Remove the plug of the hydraulic connection „S“ in the crankshaft.

Mount the device according to picture 1 („threaded rod“ and guide plate).

Screw the hydraulic pipe into the connection „S“ and tighten it.

Mount the pressure disk and the hydraulic jack.

Unscrew the nut until there is a distance of approximately 25 mm to the hydraulic jack.

Connect the hand pump to the hydraulic jack and the hydraulic pump to the flywheel.

Extend the hydraulic jack to approximately 25 mm using the hand pump. Then loosen the

nut half a pitch so that there is a gap of approximately 1-2 mm between the hydraulic jack

and the nut.

Pump the flywheel up using the hydraulic pump (pressure approximately 1300 bar)

until the flywheel loosens.

Lower the pressure of the hydraulic jack (flywheel is moving) and then dismount the

device completely.

Remove the flywheel.

Mounting proceeds in reverse order. The slide-on distance is 23 mm. When sliding on

take care that the oil slinger is placed upon the studs.

Hydraulic connection 1/4’’

M39 for the

threaded rod Connection „S“

Connection „Z“

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 52

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Flexible Flange Connection

- Flexible flange connection for generator gp engine

Tighten screws - 1 - (DIN931-M22x200-10.9) with → M = 495 Nm

Oil

or

Tighten screws - 1 - (ISO4014-M20x200-10.9) with → M = 490 Nm

Oil

or

Tighten screws - 1 - (DIN6912-M22x160-8.8) with → M = 500 Nm

Oil

Tighten screws - 2 - (ISO4017-M24x60-10.9) with → M = 675+75 Nm

Oil

or

Tighten screws - 2 - (ISO4017-M30x90-10.9) with → M = 1300+75 Nm

Oil

For further information for 2

generator mounting see chapter:

Generator GP Engine

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 53

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Charge Air Cooler

- Installation

2500.7-72.40.00-01 coupling side

1. Fix L-strap - 1 - with screws - 2 - at the charge air cooler without water separator.

2. Loosen landing surfaces - 3 - at the charge air cooler and press them against the

cooler.

3. Push the charge air cooler into the casing.

4. Before screwing the charge air cooler together with the casing, tighten screws - 4 -.

5. Fix the charge air cooler with screws - 5 - and washers at the casing.

6. Push the landing surfaces against the casing and fix them with screws - 6 -.

1 2

X

Tighten screws - 2 - M = 20 Nm

with →

Molykote

Fixing screws

Tighten charge air cooler casing - M = 130 Nm

cylinder crankcase with →

Molykote

X = Mount charge air cooler casing with sealing compound

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 54

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Charge Air Cooler

Y

5

3

6

Installation 2500.7-72.40.00-03 / 2500.7-72.40.00-04 / -05 coupling side

2500.7-72.80.00-03 / 2500.7-72.80.00-05 opposite side of coupling

1. Fix L-strap - 1 - with screws - 2 - at the charge air cooler.

2. Push the charge air cooler into the casing.

3. Draw the charge air cooler with screws - 3 - against the sealing surface.

Loosen screws a little again.

4. Fix the charge air cooler with screws - 4 - und - 5 - at the casing.

5. Now draw the charge air cooler with screws - 3 - finally against the sealing

surface at the air inlet of the casing.

Y = Mount this holder at the charge air cooler, contrary to its delivered condition, turned by 180°.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 55

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Charge Air Cooler

Tighten screws - 2 - with → M = 20 Nm

Molykote

Fixing screws

Tighten charge air cooler casing -

cylinder crankcase with → M = 130 Nm

Molykote

1 2

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 56

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Turbocharger Mounting

- Mounting turbocharger KBB R4-3 to 6-cylinder engines

2500.7-72.50.00-01 / -03 / -04 flywheel side / 2500.7-72.55.00-01 / -03 free end

Tighten screws e.g. for turbocharger foot - 1 - with → M = 60 Nm

Molykote

2500.7-72.50.00-01:

1a: 10x DIN931-M12x55-8.8, 1b: 1x DIN933-M12x35-8.8

2500.7-72.50.00-03:

1a: 10x DIN931-M12x55-8.8, 1b: 1x DIN933-M12x35-8.8

2500.7-72.50.00-04:

1a: 10x DIN931-M12x55-8.8, 1b: 1x DIN933-M12x35-8.8, 1c: 9x DIN931-M12x65-8.8

2500.7-72.55.00-01:

1a: 11x DIN931-M12x55-8.8

2500.7-72.55.00-03:

1a: 11x DIN931-M12x55-8.8

No gaskets

here!

1c

1a 1b

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 57

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Turbocharger Mounting

- Mounting turbocharger KBB R5-3 to 8- and 9- cylinder engines

2500.7-72.50.00 -02 / -05 / -07 flywheel side, 2500.7-72.55.00 -04 / -07 free end

Tighten screws - 1 - with →

Molykote M = 130 Nm

Tighten screws - 2 - with →

Molykote M = 60 Nm

2500.7-72.50.00-02:

1: 8x ISO4014-M16x60-8.8

2500.7-72.50.00-05:

1: 8x ISO4014-M16x60-8.8, 2: 11x DIN 931-M12x65-8.8

2500.7-72.50.00-07:

1: 8x ISO4014-M16x60-8.8, 2: 11x DIN 931-M12x65-8.8

2500.7-72.55.00-04:

1: 8x ISO4014-M16x60-8.8, 2: 11x DIN 931-M12x65-8.8

2500.7-72.50.00-07:

1: 8x ISO4014-M16x60-8.8, 2: 11x DIN 931-M12x65-8.8

No gaskets here!

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 58

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Turbocharger Mounting

- Mounting turbocharger KBB HPR6000 to 6-, 8- and 9- cylinder engines

2500.7-72.50.00-08 / -09 / -10 flywheel side, 2500.7-72.55.00-08 / -09 / -10 free end

Tighten screws - 1 - (2x ISO4014-M24x320-10.9) with → M = 640 Nm

Molykote

Tighten screws - 2 -

(flywheel s.:21x / free e.:24x ISO4014-M16x60-8.8) with → M = 130 Nm

Molykote

Tighten screws - 3 - (11x DIN933-M12x65-8.8) with → M = 60 Nm

Molykote

1

Compensator

mounting:

No gasket between

flange surfaces!

2 3

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 59

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Turbocharger Mounting

- Mounting turbocharger ABB TPS61D to 9- cylinder engines

2500.7-72.55.00-05 free end

Tighten screws - 1 - (2x ISO4014-M24x320-10.9) with → M = 640 Nm

Molykote

Tighten screws - 2 - (24x ISO4014-M16x60-8.8) with → M = 130 Nm

Molykote

Tighten screws - 3 - (11x DIN933-M12x65-8.8) with → M = 60 Nm

Molykote

No gaskets

here!

2

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 60

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Turbocharger Mounting

- Oil drain

Oil drain turbocharger

Oil drain cylinder crankcase

Item 1 = O-ring 1

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 61

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Exhaust Gas Manifold

- Exhaust gas manifold

Tighten screws to cyl. head generally alternately in 2 steps.

Tighten screws ISO4014-M20x120 (marking VW)

for 1. step with → M = 150 Nm

and for 2. step with →

M = 250 Nm

Rivolta G.W.F.

Tighten screws ISO4014-M20x130 (marking V or VH)

for 1. step with → M = 180 Nm

and for 2. step with →

M = 330 Nm

Rivolta G.W.F.

Tighten screws (M16) from connecting links

to engine block with → M = 130 Nm

Molykote

Tighten screws (M16) of the exhaust gas manifold → M = 140 Nm

Rivolta G.W.F.

Spray all connecting links with graphite or molybdaen spray before mounting.

Mount compensators in direction of arrow.

Between the exhaust gas pipes and the expansion joints no gaskets are fitted.

The expansion joints are installed in the direction of arrow.

Take care of the correct screw length. No projection is admissible.

Recession max. 5 mm

Gasket

- Gaskets between cylinder head and

exhaust gas manifold

When fitting the gasket take care that the bead in

the gasket shows to the exhaust gas pipe flange.

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 62

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Generator GP-Engine

- Attachment engine and generator

Tighten the torques for the fixing screws step by step.

step 1 → 20 %

step 2 → 60 %

step 3 → 100 %

Tighten bolts class of strength 8.8 - M10 - with → M = 40 Nm

oil

Tighten bolts class of strength 8.8 - M12 - with → M = 70 Nm

oil

Tighten bolts class of strength 8.8 - M20 - with → M = 150 Nm

oil

Tighten bolts class of strength 8.8 - M24 - with → M = 600 Nm

(engine) oil

Tighten bolts class of strength 8.8 - M30 - with → Ask VT5 for value!

(generator) oil

- Sealing surfaces

Daub sealing surfaces of engine and base frame with sealing material Hylomar. Lay

GORETEX - sealing towards the engine inside; overlap cutting points.

- Alignment instruction diesel gensets

only valid for: 6M25 on base frame with Vulkan RATO-DS 3311A, series 2100

8/9M25 on base frame with Vulkan RATO-DS 3411A, series 2100

Consultation of VT5 is necessary for all other combinations.

The generators are to be aligned as follows in cold condition.

Axial alignment: The generators are to be shifted in direction of the engine until the

mounting reference dimension of the coupling is 260± ±0.5mm.

Radial alignment: The generators are to be lifted by means of the jacking screws so that

they are on a level 1.00mm higher than the engine. In this a settlement of about 0.1mm of

the vibracon elements has to be taken into account.

Angular alignment: Angular clearance ± 0,2mm measured at coupling outside diameter

1070mm → 8/9M25 on base frame with Vulkan RATO-DS 3411A, series 2100 and

995mm → 6M25 on base frame with Vulkan RATO-DS 3311A, series 2100.

In this position place the vibracon elements onto the topp plate, put through the foundation

bolts and fasten finger tight (about 20Nm). Centre the vibracon elements with regard to the

bolt and raise by turning until the spherical cap fits closely without any clearance (about

20Nm). Slacken the jacking screws and tighten the foundation bolts to the prescribed

torque.

After a test run of the gensets the crank web deflection is to be measured at operating

temperature (10 minutes after shut down from full load), checked and recorded.

For information for coupling tightening torques see chapter:

Flexible Flange Connection

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 63

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Flexible Mounting

Assembly

Casting resin: Clean unmachined top plates.

Steel chocks: Top plates must be machined by milling or planing.

1. Align engine with jacking screws:

Vertically approx. 2.00 mm above the gear shaft (gearbox with vertical shaft

offset) and horizontally approx. 2.20 mm above the gear shaft (gearbox with

horizontal shaft offset).

In true alignment diagonally to the gearbox.

Axial coupling axially relieved.

2. Bore top plates for bonded rubber rail fixation - 1 - and - 2 -.

3. Screw bonded rubber rails - 1 - and - 2 - with screws - 3 - and washers - 4 -

below the engine.

Tighten screws - 3 - with → M = 350 Nm

Oil

The contact surfaces of the bonded rubber rails must be absolutely clean.

Contaminations by scale, rust or suchlike are to be mechanically removed before

screwing.

1

2

3

Secure with 4

Loctite 242

max. 13

≥ 17

6

5

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 64

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Flexible Mounting

4.1 Pourable resin: Pour the resin around the bonded rubber rails according to the

instructions of the resin manufacturer (resin must not touch the rubber). Lower the

engine after curing of the resin. That means relieve jacking screws completely.

After relieving/disassembly of the jacking screws, the jacking screws are to be

inserted again with spacer sleeves

and tightened with → M = 150 Nm

Statical spring deflection approx. 1.50 mm.

4.2 Steel chocks: Measure distance between plate and bonded rubber rails. Manu-

facture steel chocks and insert them. Lower engine according to 4.1.

5. Further settlement (lowering of the engine after 24 h approx. 0.40 mm). The engine

is then in line with the gear shaft.

6 Fix bonded rubber rails with screws - 5 - and washers - 6 - on top plate.

Tighten screws - 5 - with → M = 350 Nm

Oil

7. Before fitting stoppers - 7 - in the stopper area machine a chamfer of 1 x 45°on a

length of 350 mm at the engine mount.

Adjust 2.0 mm during assembly 15

16

18 14

12

11

9

R

H

10

8

13 17

Edition Service document of Page

15.04.2005 Caterpillar Motoren GmbH & Co. KG 65

Caterpillar confidential: yellow

Engineer ´s Handbook

m M25 c

Flexible Mounting

8. Mount lateral stoppers - 7 - and holders - 8 -. Fasten screws finger tight. Before

screwing on the locking ring on the stopper pipe insert screws - 9 - and

washers - 10 -.

9. Measure the distance top plate – bottom edge locking ring. Dimension - H -.

Add 7 mm to the measured dimension - H -. The calculated dimension is the

pipe length - R

10. Remove lateral stoppers -7 -and holders - 8 -.

11. Mount lateral stoppers - 7 - and holders - 8 - above the pipe.

Fasten screws finger-tight.

12. The pipe is centered by screwing down the locking ring -11-. The conical surfaces

must come to rest with a positive fit. Level any unevenness of the top plates, tack

the pipe and weld it.

13. Remove lateral stoppers - 7 - and holders - 8 -

14. Bore top plates for the tie rods - 12 -.

15. Insert rubber cladding - 13 - into the welded pipe. Mount lateral stoppers - 7 -

and holders - 8 -.

16. Screw the locking ring upward up to the limit stop and secure it with 2 grub

screws.

17. At normal operating temperature the engine stands by about 1.00 mm higher than

the gear shaft (due to growth of bonded rubber rail, engine, gearbox and

foundation). The flexible coupling is designed accordingly. Re-alignment is not