Professional Documents

Culture Documents

5 Tbo

Uploaded by

Pratap ThakurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 Tbo

Uploaded by

Pratap ThakurCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

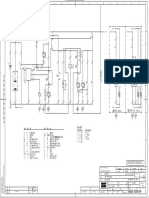

REV ECN DESCRIPTION BY DATE

5 ECN249582 (A) ADD SUPERSEDE NOTE PARROTJ 2018-03-01

A A

B B

C C

288.0

3.2

125 11.339

257.52

10.139

4 X R 2.5 91.19 -91.40 60.0 46.0

.098 3.591 -3.598 2.362 1.811

D MIN FULL D

1.5 DEPTH OF

86.4 28.5 SPLINES

.06 3.402 1.122

3.2

125 23.0

CENTERS 3.8

2.5 .906

PERMISSIBLE 2 X R 25.0 .150

BOTH ENDS .098 30 $

.984

B

E E

1.6 15 $

63

38.138 -38.151 44.20 -44.45 MAJOR

1.5015 -1.5020 1.741 -1.750

GRIND

F F

1.517-1.516 1

TURN A SCALE 1:1

10.49

.413

48.05

51.50 1.892

2.028 1.5 X 45 $ 62.0

.059 2.441 TURN

G G

76.52 -76.72 50.025 -50.038

3.013 -3.020 1.9695 -1.9700 47.55 -47.70

GRIND 1.6 1.873 -1.877 CROWN CENTER TO BE

63

GRIND 0.4

WITHIN THIS LENGTH

16

1.984-1.980 0.038-0.013 10.0 10.0

TURN .0015-.0005 .394 .394

H H

EXTERNAL INVOLUTE SPLINE DATA

FILLET ROOT SIDE FIT

0.038-0.013

NUMBER OF TEETH 27 .0015-.0005 TOOTH q

MODULE (DIA.PITCH=16/32) 1.5875/0.79375 NOTES:

1. HEAT TREATMENT: CASE CARBURIZE

J PRESSURE ANGLE 37.5 SURFACE HARDNESS: 56-63 HRC J

SECTION OF GEAR TOOTH

PITCH DIAMETER 42.8625/1.68750 EFFECTIVE CASE DEPTH: 1.02-1.40 / .040-.055 AT PITCH LINE

BASE CIRCLE DIAMETER 34.0051/1.33878 AS MEASURED AT MID-FACE OF GEAR TOOTH (CROWN IS SHOWN

40.800-40.437 EXAGERATED--VIEW

MINOR DIAMETER 2. FOR GEAR DATA SEE DRAWING 71389648.

1.6063-1.592 NOT TO SCALE)

T.I.F DIAMETER (MAX) 41.48 / 1.633 SC 2 GEAR MEASUREMENT OVER PINS IS

SIGNIFICANT CHARACTERISTIC

FILLET RADIUS (APPROX.) 0.41 / .016

MAX EFFECTIVE 2.652 / .1044 3. THIS GEAR IS CROWNED

K

CIRCULAR MIN EFFECTIVE (2.606) / (.1026) K

TOOTH VERIFY USING ANY METHOD SC 1 4. OPT. MATERIAL: BAR STOCK, DIN EN 10084 18CrNiMo 7-6

THICKNESS MAX ACTUAL (2.593) / (.1021)

MIN ACTUAL 2.548 / .1003

MEASURING PIN DIA. 3.048/.1200 1 LOCATION FOR MANUFACTURERS

DIM. OVER PINS BASED

MAX 47.661/1.8764

ID/TRACKING NUMBER

5

ON ACTUAL CIRCULAR TOOTH

MIN 47.605/1.8742 A SUPERSEDED BY ACW3224430

SPACE (MIN IS REFERENCE)

+0.010 -0.018

INVOLUTE PROFILE ERROR

+.0004 -0.0007

L KC 1 57600284 1 FORGING-PINION L

TOTAL INDEX ERROR (MAX.) 0.056 / 0.0022 REQU SYMBOL I

IR DE

ALIGNMENT/LEAD ERROR (MAX.) 0.018 / 0.0007 AGCO ING PROC NTIFIES DESCRIPTION

HESS E F

FINISH ON SPLINE TEETH Ra 3.2 / 125 FOR TON' SS CAPAB EATURES ITEM PART NO QTY

DESCRIÇÃO

KEY S QU I L IT

ALIT

CONFORMS TO ANSI B92.1 1996 CLASS 6

CHAR

ACTE Y PR Y PER NO. MILLIMETER

RIST O CEDU OF CC AND SC DIMENSIONS: MILLIMETER OR

CAT NO FIRST ANGLE DESCRIPTION:

ICS. RE

KC'S SYMBOLS IDENTIFY INCH 5145 PROJECTION

ISO 5456 PINION-14 T FINAL DRIVE,SHORT

FEATURES REQUIRING

PROCESS CAPABILITY TOLERANCES NOT SPECIFIED ORIG NEXT ASM

DESIGNED BY: DESIGN CONTROL: TRANSLATED DESCRIPTION:

S ```

2

PER AGCO'S QUALITY

PROCEDURE FOR

P

NOMINAL OVER 120 400 1000 S-B HE1 PINION-14 T FINAL DRIVE,SHORT

KEY CHARACTERISTICS METRIC DRAWN DATE

E DIMENSION TO 120 400 1000 2006-06-13 LIFECYCLE STATE: DRAWING NUMBER: VERSION:

GOP0010007

M C

S 0 OR 1 DECIMAL ORIG PROD

To be Obsolete 71400418 5.2 M

NO. OF

KC's ``` SCALE: SIMILAR: WEIGHT: SHEET:

KEY CHARACTERISTIC LEVEL 2 DECIMALS

MULTI-LANGUAGE

1:1 71389619 0.000 KG / 0.000 LBS 1/1

KCL 0

PROPRIETARY STATEMENT THE REPRODUCTION, DISTRIBUTION AND UTILIZATION OF THIS DOCUMENT AS WELL AS THE COMMUNICATION OF ITS CONTENTS TO OTHERS WITHOUT EXPRESS AUTHORIZATION IS

PROCESS SPEC. EP.A01 ANGULAR FORMED # 1 $ OTHER # 0.5 $ 705100871 PROHIBITED. OFFENDERS WILL BE HELD LIABLE FOR THE PAYMENT OF DAMAGES. ALL RIGHTS RESERVED IN THE EVENT OF THE GRANT OF A PATENT, UTILITY MODEL OR DESIGN.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 A1 CreoParametric

You might also like

- Diagram Punya NovalDocument1 pageDiagram Punya NovalcaktotNo ratings yet

- 001 00 PDFDocument1 page001 00 PDFGerman GomezNo ratings yet

- AUD600 Power Supply Rev 3.0.1 Simulation: Circuit Designer: Manoj T.MDocument1 pageAUD600 Power Supply Rev 3.0.1 Simulation: Circuit Designer: Manoj T.MSaurabh VaidyaNo ratings yet

- Note:: Scaleplate DescriptionDocument1 pageNote:: Scaleplate DescriptionAlbet MulyonoNo ratings yet

- Audio 600Document3 pagesAudio 600rea sonerNo ratings yet

- 02C-1 Lin Xlraem4100g211062Document1 page02C-1 Lin Xlraem4100g211062Daniel PricopNo ratings yet

- Amb-Agcc02-Tun Ce 1002 - P0Document1 pageAmb-Agcc02-Tun Ce 1002 - P0Sugam JainNo ratings yet

- MTT Hva DWG 02 000 Ef 4016393Document1 pageMTT Hva DWG 02 000 Ef 4016393wangruiNo ratings yet

- Limita Zona Protectie Autostrada 50m Fata de Axul Drumului (Conf. OG43/1997-Anexa1, Lit. B)Document1 pageLimita Zona Protectie Autostrada 50m Fata de Axul Drumului (Conf. OG43/1997-Anexa1, Lit. B)ciciNo ratings yet

- Data Extraction and Multileaders Sample-Layout2Document1 pageData Extraction and Multileaders Sample-Layout2Sunem Rios YañacNo ratings yet

- 0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelDocument1 page0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelVivek VinayakumarNo ratings yet

- Earthing & Lightning Protection Layout - Ground Floor Plan - Part GDocument1 pageEarthing & Lightning Protection Layout - Ground Floor Plan - Part GAwais NaeemNo ratings yet

- Upc6gx RC11 B0600 DD030 - 001 - 00Document1 pageUpc6gx RC11 B0600 DD030 - 001 - 00Viet NguyenNo ratings yet

- (RFC) PE-V1-417-165-N023A R2P0 Stircase ReinforcementDocument3 pages(RFC) PE-V1-417-165-N023A R2P0 Stircase ReinforcementParshuram ManjareNo ratings yet

- Workplot: Not For ProductionDocument1 pageWorkplot: Not For ProductionOmkar TodkarNo ratings yet

- EC BA715 - Part1Document1 pageEC BA715 - Part1botas georgianaNo ratings yet

- DDRG-LH41-C11-G00-DE-0001 - 1 - TAILRACE CIVIL DETAIL & SECTION - Pak Fadli - 2021.01.20Document1 pageDDRG-LH41-C11-G00-DE-0001 - 1 - TAILRACE CIVIL DETAIL & SECTION - Pak Fadli - 2021.01.20FadliNo ratings yet

- Atlas Copco Wiring A38Document2 pagesAtlas Copco Wiring A38Mochamad fandi Dharmawan100% (1)

- FP-04 Upper Ground Floor Sprinkler LayoutDocument1 pageFP-04 Upper Ground Floor Sprinkler LayoutBerlin Andrew SionNo ratings yet

- Terrace Floor Plan: Scale 1:100Document1 pageTerrace Floor Plan: Scale 1:100Manish MishraNo ratings yet

- Kitchen SpecDocument1 pageKitchen SpecabebaNo ratings yet

- 1 Ton Hurricane IGRDocument1 page1 Ton Hurricane IGRVitor OlivettiNo ratings yet

- X0231 PDW Ecb DG 20004 AaDocument1 pageX0231 PDW Ecb DG 20004 AajianranrenNo ratings yet

- Isometric View: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetDocument1 pageIsometric View: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetParikh DhavalNo ratings yet

- Control Board - Schematic v626Document1 pageControl Board - Schematic v626XuNo ratings yet

- P&id For Bed& Fly Ah SystemDocument3 pagesP&id For Bed& Fly Ah Systemraaj bharathNo ratings yet

- 6M33 Series CAD English Version Drawing UNLCKD-ModelDocument1 page6M33 Series CAD English Version Drawing UNLCKD-ModelMukulNo ratings yet

- Diagram - XAS 57-97 DD WUXDocument1 pageDiagram - XAS 57-97 DD WUXCovid 55100% (1)

- M10 Class H Power Amp.Document10 pagesM10 Class H Power Amp.alanbermeo058No ratings yet

- Schematic - Design Mock Up - Main PCB Copy - 20200327153258Document1 pageSchematic - Design Mock Up - Main PCB Copy - 20200327153258Yoshua M FANo ratings yet

- Fire Alarm Lantai 3Document1 pageFire Alarm Lantai 3Ilham AdiNo ratings yet

- Documento Certificado: COMPRESSOR ZT315VSD-8,6FF380/220V-60HZ TAG UC-6500A / UC-6500B PESO TOTAL: 7150 KGFDocument1 pageDocumento Certificado: COMPRESSOR ZT315VSD-8,6FF380/220V-60HZ TAG UC-6500A / UC-6500B PESO TOTAL: 7150 KGFAndré Andrade RamosNo ratings yet

- А3Document1 pageА3Radostin GeorgievNo ratings yet

- For Discussion: SpectrumDocument1 pageFor Discussion: Spectrumshubhamoffice007No ratings yet

- De 22 36 DWG HV CH PL0B 400 01Document1 pageDe 22 36 DWG HV CH PL0B 400 01Mahmoud A. HafeezNo ratings yet

- Ab-By Bang RonieDocument1 pageAb-By Bang Ronieronie lastriNo ratings yet

- DNP DNP DNP: Proto - Area Proto - AreaDocument14 pagesDNP DNP DNP: Proto - Area Proto - AreaAinis ŠtelemėkasNo ratings yet

- CP 332 Me DDD 0001 - 0Document1 pageCP 332 Me DDD 0001 - 0Percy HurtadoNo ratings yet

- De 22 36 DWG PF CH PL 01 FF 120 00Document1 pageDe 22 36 DWG PF CH PL 01 FF 120 00Mahmoud A. HafeezNo ratings yet

- Samb108 sch0.8 - de - EfrcomDocument8 pagesSamb108 sch0.8 - de - EfrcomHotel WijayaNo ratings yet

- DW85 of Cut & Cover.Document1 pageDW85 of Cut & Cover.kallupahalawan3No ratings yet

- Ab-H-16 - Level 4 WestDocument1 pageAb-H-16 - Level 4 Westicas2017secaNo ratings yet

- M BD3 1F8000 Cutl Edr 000202Document1 pageM BD3 1F8000 Cutl Edr 000202ahmed.abdelmegeed78No ratings yet

- DR-CST-800-0014 - Rev ADocument1 pageDR-CST-800-0014 - Rev APinak ProjectsNo ratings yet

- De 22 36 DWG PF CH PL 00 FF 110 00Document1 pageDe 22 36 DWG PF CH PL 00 FF 110 00Mahmoud A. HafeezNo ratings yet

- (RFC) PE-V1-417-165-N023 R2P0 StaircaseDocument6 pages(RFC) PE-V1-417-165-N023 R2P0 StaircaseParshuram ManjareNo ratings yet

- Quy Trinh 2Document1 pageQuy Trinh 2HOÀNG LÊ PHẠMNo ratings yet

- Electrical 2528C.fmDocument1 pageElectrical 2528C.fmmayobanex moyaNo ratings yet

- Schematic - ODM-3 Overdrive Master - 2020-11-11 - 06-14-24Document1 pageSchematic - ODM-3 Overdrive Master - 2020-11-11 - 06-14-24Marcus FeilNo ratings yet

- Single Line Diagram For Sunrays: Orient Energy Systems (PVT.) LTDDocument1 pageSingle Line Diagram For Sunrays: Orient Energy Systems (PVT.) LTDjhon smithNo ratings yet

- Fire Alarm Lantai 3 MezzanineDocument1 pageFire Alarm Lantai 3 MezzanineIlham AdiNo ratings yet

- SEL SN-1 POINT - 1 Reference DrawingsDocument2 pagesSEL SN-1 POINT - 1 Reference DrawingsKs MuraliNo ratings yet

- Pergola Design 2Document1 pagePergola Design 2raheemNo ratings yet

- Vezalna Shema Wiring Diagram: No. Yy-Mm-DdDocument2 pagesVezalna Shema Wiring Diagram: No. Yy-Mm-Ddenermac projetosNo ratings yet

- AUD600 Power Supply Rev 3.0.1 SimulationDocument1 pageAUD600 Power Supply Rev 3.0.1 SimulationGianmarco ScarabelloNo ratings yet

- Hassan Allam: Refer Comments Made On Isometric Drawing at 693186-V-5001-0345-01 and Update This Isometric AccordinglyDocument1 pageHassan Allam: Refer Comments Made On Isometric Drawing at 693186-V-5001-0345-01 and Update This Isometric AccordinglymohsinqcqaNo ratings yet

- KC Me Eer 031 Rev. 1Document9 pagesKC Me Eer 031 Rev. 1danielNo ratings yet

- p165 NI Main Control Panel PartsDocument1 pagep165 NI Main Control Panel PartsFRANCISCO JAVIER RUEDA LOPEZNo ratings yet

- Iso 20lae05aa101Document1 pageIso 20lae05aa101Mohd Effiezool YaserNo ratings yet

- FFC Nts FinalDocument10 pagesFFC Nts FinalSullahuddin Salu100% (1)

- Motor Selection Guide PDFDocument56 pagesMotor Selection Guide PDFUdit AgrawalNo ratings yet

- DX210WA Spec SheetDocument59 pagesDX210WA Spec SheetAbdelrahman100% (1)

- Operador Siemens Intercam PDFDocument32 pagesOperador Siemens Intercam PDFCristian Orosco ValverdeNo ratings yet

- 01j Audi MultitronicDocument7 pages01j Audi MultitronicLUIS ALEJANDRONo ratings yet

- Hibon DisplacmentBlower Iom D898Document55 pagesHibon DisplacmentBlower Iom D898Ricardo RGNo ratings yet

- Agma 920 A01 Materials For Plastic GearsDocument46 pagesAgma 920 A01 Materials For Plastic GearsNursena SEVİNÇNo ratings yet

- ERROR: Shigley's Mechanical Engineering Design 10th EdDocument1 pageERROR: Shigley's Mechanical Engineering Design 10th EdTimNo ratings yet

- A Study On Power Assists For Bicycle Rickshaws in IndiaDocument47 pagesA Study On Power Assists For Bicycle Rickshaws in Indianadeemq_0786No ratings yet

- HMT Machine Tools Ltd. - Internship ReportDocument51 pagesHMT Machine Tools Ltd. - Internship ReportSwaroop Somanna33% (3)

- DD15 Engine Torque SpecificationsDocument5 pagesDD15 Engine Torque SpecificationsJoser Roberto Magana67% (3)

- Engine - TD4 2.2L Diesel - EngineDocument48 pagesEngine - TD4 2.2L Diesel - EngineNhật Anh Trần100% (1)

- Bomba Nemo FloculanteDocument4 pagesBomba Nemo FloculanteJosaphat Avila RodriguezNo ratings yet

- Seite 32-33 Dyna Bus Rollover Aus IP 1-05Document2 pagesSeite 32-33 Dyna Bus Rollover Aus IP 1-05Jorge LuisNo ratings yet

- Acoplamento de Tambor TCB-TCB-HDDocument32 pagesAcoplamento de Tambor TCB-TCB-HDClaudio de PaulaNo ratings yet

- Ingenious Mechanisms Vol.3 Jones 1930Document272 pagesIngenious Mechanisms Vol.3 Jones 1930RobertoDlCruzLaraNo ratings yet

- Oriental Motor Electromagnetic Brake MotorsDocument44 pagesOriental Motor Electromagnetic Brake MotorsMauro H. S. WencelewskiNo ratings yet

- Manual de Servicio FUSO FE, FG, FH, FK, FM, 1996-2001 - Parte1 - 1Document232 pagesManual de Servicio FUSO FE, FG, FH, FK, FM, 1996-2001 - Parte1 - 1Brian VilchisNo ratings yet

- Screw Conveyor DesignDocument8 pagesScrew Conveyor DesignRamsai ChigurupatiNo ratings yet

- Chapter 1 IntroductionDocument172 pagesChapter 1 IntroductionVincoy JohnlloydNo ratings yet

- KO Lee A600 BrochureDocument6 pagesKO Lee A600 BrochureRobert W. Lamparter100% (1)

- 227 e Cr269 en Voith Geared Variable Speed CouplingsDocument14 pages227 e Cr269 en Voith Geared Variable Speed Couplings050678No ratings yet

- Basic of GearsDocument35 pagesBasic of Gearskcshieh100% (1)

- Rotating Equipment Codes and StandardsDocument2 pagesRotating Equipment Codes and StandardsWong Da100% (6)

- CAPE Building and Mechanical Engineering Syllabus With Specimen PapersDocument187 pagesCAPE Building and Mechanical Engineering Syllabus With Specimen PapersJonoyJetticsZêrcõnSmith57% (7)

- Rui Zhan and Xieeryazidan AdayiDocument9 pagesRui Zhan and Xieeryazidan AdayiBhaskar NandiNo ratings yet

- Marley Geareducer: Model 3600 and 4000Document16 pagesMarley Geareducer: Model 3600 and 4000rashm006ranjanNo ratings yet

- Subject - Machine Design - : Topic - Worm GearsDocument28 pagesSubject - Machine Design - : Topic - Worm GearsRohit GhulanavarNo ratings yet

- Approximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingDocument11 pagesApproximate Equation For The Addendum Modification Factors For Tooth Gears With Balanced Specific SlidingCan CemreNo ratings yet

- Catalogo SewDocument608 pagesCatalogo Sewmtto cgNo ratings yet