Professional Documents

Culture Documents

Group 1 Chapter 9

Uploaded by

cecil c0 ratings0% found this document useful (0 votes)

19 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views2 pagesGroup 1 Chapter 9

Uploaded by

cecil cCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Group 1

202150032 – Gerald Galeno

202150044 - Calvin

202150098 – Cecillia Cung

202150116 – Stacia Fortuna Tansri

Production and Operation Management System (POM)

Production and Operations Management (POM) is the management discipline that focuses on

efficiently transforming inputs into desired outputs. It involves planning, organizing,

coordinating, and controlling the activities and resources involved in production or service

delivery.

Functional Business Systems are specific components within an organization that support and

facilitate the overall POM function. These systems enable efficient process execution, data

management, and decision-making in various production and operations areas. Here are some

common types of functional business systems that support POM:

1. Supply Chain Management (SCM) Systems: These systems manage the flow of

goods, information, and services from suppliers to customers. They handle functions

such as procurement, inventory management, logistics, and demand forecasting.

2. Enterprise Resource Planning (ERP) Systems: ERP systems integrate and automate

different business processes, including production planning, inventory management,

order processing, human resources, finance, and accounting.

3. Manufacturing Execution Systems (MES): MES systems monitor and control

manufacturing processes on the shop floor. They collect data to track production

progress, ensure quality control, and optimize resource utilization.

4. Quality Management Systems (QMS): QMS systems ensure products and processes

meet quality standards. They include functions such as quality planning, control,

assurance, inspection, and continuous improvement.

5. Customer Relationship Management (CRM) Systems: CRM systems manage

customer interactions, sales, and service processes. They help capture and analyze

customer data, enhance customer support, and track sales leads.

6. Project Management Systems: These systems facilitate project planning, scheduling,

resource allocation, and tracking. They enable organizations to manage complex

projects, monitor progress, and ensure timely completion.

7. Data Analytics and Business Intelligence (BI) Systems: These systems gather,

analyze, and present data to support decision-making. They provide insights into

production and operational performance, trends, and forecasting.

8. Human Resource Management (HRM) Systems: HRM systems handle aspects like

employee scheduling, performance management, training, recruitment, and payroll.

They optimize workforce management and labor utilization.

These functional business systems collaborate to support POM, ensuring smooth operations,

resource optimization, high-quality output, customer satisfaction, and overall business success.

In general, sales and marketing systems support the following:

- Customer relationships (sales and support)

- Digital advertising

- Social media monitoring and promotions

- Automated ad placement and media buying

- Market research

- Intelligence gathering

- Distributing products and services to customers

- Order tracker

- Online and mobile order processing

- Online and mobile payment methods

Computer-Intergrated Manufacturing is the integration of manufacturing operations by

integrating people, technology, and manufacturing processes

Computer aided manufacturing is the capability of a computer system to process, store, and

display large amounts of data representating part and product specifications

Advantages:

- Reduction in costs

- Improved quality and customer satisfaction

- Greater production control

- Reduced inventory requirements

- Improved product development cycles to enable faster response to market pressures

- Support for manufacturing of small lots

Manufacturing Execution Systems manage, monitor, and synchronize the execution of real-

time, physical process involved in transforming raw materials into intermediate and/or finished

finished goods and execute work orders.

You might also like

- Food Panda ApplicationDocument11 pagesFood Panda ApplicationMaria AlvarezNo ratings yet

- Introduction To Microeconomics, E201Document248 pagesIntroduction To Microeconomics, E201Al Beirão100% (6)

- Articles of IncorporationDocument3 pagesArticles of IncorporationLenard Josh Ingalla100% (1)

- Task 2 System ClassificationDocument10 pagesTask 2 System ClassificationRosemaribel TorresNo ratings yet

- Logistics Management/ Supply Chain Management: DR Aijaz AhmadDocument29 pagesLogistics Management/ Supply Chain Management: DR Aijaz Ahmadsaumya shrivastavNo ratings yet

- Chan - Final Activity 1 - MisDocument3 pagesChan - Final Activity 1 - MisKenn ChanNo ratings yet

- Es Unit 1Document21 pagesEs Unit 1sathvika rathkantiNo ratings yet

- CH-7 (MIS) Introduction To E-Business SystemsDocument7 pagesCH-7 (MIS) Introduction To E-Business SystemsZohaib AhmedNo ratings yet

- 2 Chapter 2 ExplanationDocument9 pages2 Chapter 2 ExplanationMohamedNo ratings yet

- Global Supply Chain Management - NotesDocument10 pagesGlobal Supply Chain Management - NotesShawkat Tanveer RahmanNo ratings yet

- Module - 2Document64 pagesModule - 2JithuHashMiNo ratings yet

- MIS With Functional Areas of BusinessDocument33 pagesMIS With Functional Areas of BusinessShubham Agarwal100% (1)

- Why Are Organisations Trying To Integrate Their Business Process MIS ASSDocument14 pagesWhy Are Organisations Trying To Integrate Their Business Process MIS ASSAyanleke Julius Oluwaseunfunmi0% (1)

- Introduction To Information SYSTEMS (IM 111) : Types of Information Systems Instructor: Augustino Mwogosi Room AB 205Document36 pagesIntroduction To Information SYSTEMS (IM 111) : Types of Information Systems Instructor: Augustino Mwogosi Room AB 205Alfred godsonNo ratings yet

- Point Point of System Information ManagementDocument9 pagesPoint Point of System Information ManagementBoy ZulkarnaenNo ratings yet

- MIS 5TH UINT NotesDocument6 pagesMIS 5TH UINT NotesMala niveNo ratings yet

- Unit-2-Business Application of Information SystemDocument25 pagesUnit-2-Business Application of Information Systemsrinivasa_rcNo ratings yet

- IT in Business: Critical Application in Information Technology Lecture - 05Document30 pagesIT in Business: Critical Application in Information Technology Lecture - 05Aleena AzfarNo ratings yet

- LEAN Manufacturing & ERP: How To Leverage ERP To Get LeanDocument26 pagesLEAN Manufacturing & ERP: How To Leverage ERP To Get LeanDeepak D OjhaNo ratings yet

- Lecture 2 Is in The EnterpriseDocument44 pagesLecture 2 Is in The EnterpriseAludahNo ratings yet

- Chapter 1 - Business Functions and Business ProcessesDocument5 pagesChapter 1 - Business Functions and Business ProcessesKevin GalvezNo ratings yet

- Chapter 9Document5 pagesChapter 9HUSSEIN ABED AL KARIMNo ratings yet

- Unit-I Information System (Is)Document12 pagesUnit-I Information System (Is)SuviNo ratings yet

- Pre Final PPT 4 Lean ERPDocument28 pagesPre Final PPT 4 Lean ERPbinnivenus100% (1)

- Study Guide Enterprise SystemsDocument7 pagesStudy Guide Enterprise Systemsgosaye desalegnNo ratings yet

- 6 - Business Information SystemDocument10 pages6 - Business Information SystemBshwas TeamllcenaNo ratings yet

- LSCM IT & Demand Management in SCMDocument52 pagesLSCM IT & Demand Management in SCMRosemary ScottNo ratings yet

- Enterprise Architecture in Companies:-Operations in Light of Information System: - What Is Management Information SystemDocument20 pagesEnterprise Architecture in Companies:-Operations in Light of Information System: - What Is Management Information SystemSaptarshi Roy ChowdhuryNo ratings yet

- IntroductionDocument34 pagesIntroductionSudani AnkitNo ratings yet

- Essential of E-Business Assignment IIDocument5 pagesEssential of E-Business Assignment IISadikshya PantaNo ratings yet

- Impact of IT On BusinessDocument33 pagesImpact of IT On BusinessSamiksha SainiNo ratings yet

- A Management Information System Restaurant Case StudyDocument2 pagesA Management Information System Restaurant Case StudyGanapati KattigeNo ratings yet

- Chapter 2 Ins RevisionDocument7 pagesChapter 2 Ins Revision--No ratings yet

- MisDocument14 pagesMisRaj Narula100% (1)

- 2008 BreakerDocument3 pages2008 BreakerHzl ZlhNo ratings yet

- Achieving Operational Excellence and Customer Intimacy: Enterprise ApplicationsDocument27 pagesAchieving Operational Excellence and Customer Intimacy: Enterprise ApplicationsAida NatashaNo ratings yet

- Chapter 2 Business Driven Information Systems: ObjectivesDocument23 pagesChapter 2 Business Driven Information Systems: ObjectivesOteng Richard SelasieNo ratings yet

- Mod IIDocument40 pagesMod IIAkshay AkshayNo ratings yet

- Activity 1Document2 pagesActivity 1Kyle AlasaNo ratings yet

- (Networks), and Stored Data (Data Resources)Document8 pages(Networks), and Stored Data (Data Resources)pisabandmutNo ratings yet

- Shilpa - Biz RequirementsDocument13 pagesShilpa - Biz RequirementsShilpa MukeshNo ratings yet

- 12.2 Marketing Information Systems (Figure 12.2 & Figure 12.3)Document7 pages12.2 Marketing Information Systems (Figure 12.2 & Figure 12.3)Premendra SahuNo ratings yet

- Case Study On MIS SolutionDocument36 pagesCase Study On MIS SolutionSubir MitraNo ratings yet

- What Are The Current Information Systems Used Within The OrganizationDocument9 pagesWhat Are The Current Information Systems Used Within The Organizationsharad.karmacharya63No ratings yet

- Functional Business Systems: Foundations of Information SystemsDocument40 pagesFunctional Business Systems: Foundations of Information SystemsSanjay YadavNo ratings yet

- Solution Case Study1Document3 pagesSolution Case Study1vaishalimogha24No ratings yet

- MIS - Lec 1Document22 pagesMIS - Lec 1Abdul Hanan NasirNo ratings yet

- Information Systems: Instructor University of Agriculture, Faisalabad Sub-Campus Burewala/Vehari, PakistanDocument23 pagesInformation Systems: Instructor University of Agriculture, Faisalabad Sub-Campus Burewala/Vehari, PakistantwinklenoorNo ratings yet

- Sales and Marketing Information SystemsDocument2 pagesSales and Marketing Information SystemsJeffry MahiNo ratings yet

- Chapter 2 - Global E-BusinessDocument26 pagesChapter 2 - Global E-BusinessSyeda Nazneen AzadNo ratings yet

- Area of Strategic PlanningDocument6 pagesArea of Strategic PlanningFaryal FatimaNo ratings yet

- Management Information SystemDocument106 pagesManagement Information SystemAbdelrhman AhmedNo ratings yet

- Module 5 MisDocument21 pagesModule 5 Misajay4dudeNo ratings yet

- Lesson 4Document23 pagesLesson 4Ahmed MujtabaNo ratings yet

- Assignment2 1 4Document5 pagesAssignment2 1 4dr. waingNo ratings yet

- Marketing Research MethodDocument25 pagesMarketing Research MethodJeff LacasandileNo ratings yet

- 12.1 Supporting Business Functions in An Enterprise With InformationDocument26 pages12.1 Supporting Business Functions in An Enterprise With InformationCharis ClarindaNo ratings yet

- Mis (Sales and MRKTNG)Document13 pagesMis (Sales and MRKTNG)Amit GuptaNo ratings yet

- Supply Chain Management Systems Supply ChainDocument93 pagesSupply Chain Management Systems Supply Chainbeemajuru87No ratings yet

- Management Information systems - MIS: Business strategy books, #4From EverandManagement Information systems - MIS: Business strategy books, #4No ratings yet

- Selling Success: Mastering CRM for Enhanced Customer Relationships: Boost Sales Success, #4From EverandSelling Success: Mastering CRM for Enhanced Customer Relationships: Boost Sales Success, #4No ratings yet

- Finance Chapter 3Document5 pagesFinance Chapter 3cecil cNo ratings yet

- Finance Chapter 5Document2 pagesFinance Chapter 5cecil cNo ratings yet

- Finance Chapter 2Document4 pagesFinance Chapter 2cecil cNo ratings yet

- Name: Cecillia Cung NIM: 202150098Document1 pageName: Cecillia Cung NIM: 202150098cecil cNo ratings yet

- As MatbisDocument4 pagesAs Matbiscecil cNo ratings yet

- Price List Text 2021aDocument2 pagesPrice List Text 2021acecil cNo ratings yet

- IC4 - T09 Chp7 Final Bank ReconciliationDocument4 pagesIC4 - T09 Chp7 Final Bank Reconciliationcecil cNo ratings yet

- New Regulation Governing AgentsDocument57 pagesNew Regulation Governing AgentsDagobert RugwiroNo ratings yet

- 10 Types of Product Risk - SimplicableDocument8 pages10 Types of Product Risk - SimplicableRicardo SantosNo ratings yet

- Entrep 4THQ ReviewerDocument2 pagesEntrep 4THQ ReviewerJhasse Dela CruzNo ratings yet

- Oracle: 'Marketing Now'Document9 pagesOracle: 'Marketing Now'HugoKondratiukNo ratings yet

- (Student Version) Comparison and Selection Among AlternativeDocument60 pages(Student Version) Comparison and Selection Among AlternativeAyish CehcterNo ratings yet

- What Makes A Children - Reflection Paper.Document1 pageWhat Makes A Children - Reflection Paper.Panis, Mark DaveNo ratings yet

- RecruitmentDocument11 pagesRecruitmentThushara VinayNo ratings yet

- Market Gap Analysis TemplateDocument2 pagesMarket Gap Analysis TemplateZeshanNo ratings yet

- UntitledDocument63 pagesUntitledCesaret EhmedovNo ratings yet

- In Assignment: Submitted byDocument8 pagesIn Assignment: Submitted byrochel100% (1)

- Sales and Distribution of NikeDocument14 pagesSales and Distribution of NikeManideep Nulu67% (3)

- CV LindahDocument5 pagesCV Lindahhozea waswaNo ratings yet

- Turnaround Management Methodology For Fertilizer Plants - Document GuidanceDocument12 pagesTurnaround Management Methodology For Fertilizer Plants - Document Guidancerobertion100% (1)

- Chapter 1 - Introduction To Customer AnalyticsDocument50 pagesChapter 1 - Introduction To Customer AnalyticsKAH' CHISMISSNo ratings yet

- Foundation of Business EthicsDocument4 pagesFoundation of Business EthicslaynonNo ratings yet

- Potential Multibagger 2.0Document4 pagesPotential Multibagger 2.0telegenicsNo ratings yet

- LK-mengelola-buku-jurnal - B. IndoDocument11 pagesLK-mengelola-buku-jurnal - B. IndohussenNo ratings yet

- e-StatementBRImo 714201036008532 Dec2023 20231227 164433Document5 pagese-StatementBRImo 714201036008532 Dec2023 20231227 164433umiyahraditNo ratings yet

- Transportation ProblemDocument52 pagesTransportation ProblemDiv SavaliyaNo ratings yet

- IIPRD Sample Valuation ReportDocument34 pagesIIPRD Sample Valuation ReportAba JifarNo ratings yet

- Make UK Manufacturing Outlook 2023 Q1Document19 pagesMake UK Manufacturing Outlook 2023 Q1Guido FawkesNo ratings yet

- Project Feasibility Study For The Establishment of Footwear and Other AccessoriesDocument12 pagesProject Feasibility Study For The Establishment of Footwear and Other Accessoriesregata4No ratings yet

- Canlas Aniel Jesper C. PlantTourJournalDocument23 pagesCanlas Aniel Jesper C. PlantTourJournalCanlas Aniel Jesper C.No ratings yet

- Ma. Luisa Duarte GVRDocument14 pagesMa. Luisa Duarte GVRXimena JazmínNo ratings yet

- Unilever Case StudyDocument50 pagesUnilever Case StudyGiang DangNo ratings yet

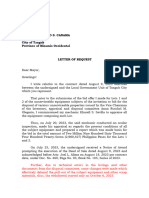

- Letter Mayor Canama ScrapDocument2 pagesLetter Mayor Canama Scrappersantiago.lawofficeNo ratings yet

- Capital Investment AppraisalDocument11 pagesCapital Investment Appraisalrizwan ul hassanNo ratings yet

- Depreciation CVDocument71 pagesDepreciation CVRigine Pobe MorgadezNo ratings yet