Professional Documents

Culture Documents

Documento PAG2

Uploaded by

André Kolenyak0 ratings0% found this document useful (0 votes)

18 views1 pageBusway Eaton

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBusway Eaton

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pageDocumento PAG2

Uploaded by

André KolenyakBusway Eaton

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

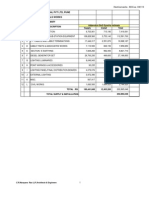

Low-Voltage Busway Design Guide DG017003EN

Pow-R-Flex Effective February 2020

General Description 24.2-3

Ground Options Pow-R-Bridge For a Pow-R-Flex type plug-in busway,

Integral ground—uses the extruded Pow-R-Flex joint connections are made a plug-in/tap-off provision cover is used.

aluminum housing as the ground/earth with the Pow-R-Bridge joint package, This cover hinges into the housing in

path. It has been designed, manufactured which is installed on each section of the same manner as the extruded front

and UL listed as a 50% integral ground/ busway prior to shipment. A double- covers and is made from the same

earth path and is fully fault rated. The headed, torque-indicating bolt is provided durable, high-strength polycarbonate

system ground continuity is maintained to ensure that the proper installation material as the support blocks, which are

through each joint by the aluminum joint torque is achieved. Fall-away instruction rated as Class B 130 °C insulation. The

covers. The joint covers are furnished with tags are furnished on the torque-indicating plug-in provision cover incorporates a

ground/earth path contact surfaces on the bolt heads to allow for visual inspection shutter design that prevents incidental

inside of each cover. When installed, the from a distance. When the proper torque contact with the conductors inside the

contact surfaces are bolted directly to value is achieved, the top bolt head will busway. The shutter has a positive screw

the busway ground/earth path. A highly shear off and allow the tag to fall to the close feature that prohibits the shutter

visible label is furnished on each joint floor. Any joint that is improperly torqued from being operated and opened without

cover to alert the installer that the covers will retain the highly visible (caution the use of a tool. Once the screw is

must be properly installed to maintain yellow) tag at the bolt head. removed, it is mechanically operated by

the ground/earth path. The result is a the plug-in unit when a plug-in unit is

50% ground/earth path with very low The Pow-R-Bridge can provide an being inserted onto the busway. This

resistance characteristics. adjustment of ±0.50-inch (12.7 mm) at shutter design puts safety first and is IP2X

each joint. Overadjustment is prevented finger safe. One plug-in/tap-off provision

Internal ground—uses a copper ground/ by the joint covers, which will only allow cover is provided every 12.00 inches

earth conductor that is internal to the a 0.50-inch (12.0 mm) adjustment to be (304.8 mm) along a plug-in busway

busway and is UL listed as a 50% ground/ made. The nonrotating design of the section. Each feeder section will include

earth path. The internal ground/earth Pow-R-Bridge maintains its configuration one factory-installed Pow-R-Bridge on the

continuity is maintained through the integrity when it has been removed from left end of the busway when viewing the

Pow-R-Bridge joint in the same fashion a section of busway. The conductors, front of the busway.

as each phase conductor. insulator plates, and insulators will not

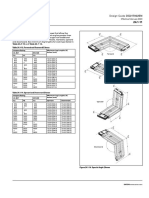

displace or swivel, making reinstallation Table 24.2-1. Number of Plug-In Openings

Isolated internal ground—uses the of the Pow-R-Bridge quick and easy. Duct Length Number of

50% internal ground/earth conductor; Inches (mm) Plug-In Provisions

however, it has been isolated from the

busway housing throughout the busway 24.00 (609.6) 1

Pow-R-Flex Feeder Busway 48.00 (1219.2) 3

system and is UL listed as a 50% isolated ■ 150–400 A aluminum 72.00 (1828.8) 5

ground/earth path. 96.00 (2438.4) 7

■ 225–600 A copper 120.00 (3048.0) 9

Straight sections of feeder busway can

Housing Details be supplied in any length, at 0.50-inch

The Pow-R-Flex low-ampere busway (12.7 mm) increments, from 24.00 inches

is constructed with a heavy-duty (609.6 mm) minimum to 120.00 inches

“U”-shaped aluminum extruded base (3048.0 mm) maximum. Each feeder

housing. The front covers are also section will include one factory-installed

made from extruded aluminum. The Pow-R-Bridge on the left end of the

“U”-shaped base and front cover busway when viewing the front of

incorporate a unique hinge design to the busway. For added safety and

lock in the front covers on the top side. reliability, there are no openings or

The bottom sides are fastened in place. access covers along the entire length

This maintains short-circuit strength, of each feeder section.

provides clean lines, and adds to the

aesthetic look and feel of the product.

The non-magnetic, all-aluminum housing

Pow-R-Flex Plug-In Busway

provides for excellent heat dissipation and ■ 150–400 A aluminum Figure 24.2-2. Feeder Busway

a significant reduction in reactance and ■ 225–600 A copper

magnetic flux leakage, as compared to

steel, or steel and aluminum combination Straight sections of plug-in busway can

housings.The integrity and strength of the be supplied in only 24.00-inch (609.6 mm)

housing ensures specifiers and users of a increments from 24.00 inches (609.6 mm)

safe and durable installation over a broad minimum, with a maximum of

spectrum of applications. 120.00 inches (3048.0 mm).

A protective finish is applied by an

electrostatic process. There are two

color options: ANSI 61 gray or black.

Figure 24.2-3. Plug-In Busway

EATON www.eaton.com

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Cutler Hammer Bus DuctsDocument28 pagesCutler Hammer Bus DuctsOliver HermosaNo ratings yet

- Ad 30560Document28 pagesAd 30560venjaytabagoNo ratings yet

- Henikwon S Line Al Cu BBT CatalogueDocument93 pagesHenikwon S Line Al Cu BBT CatalogueArunava BasakNo ratings yet

- GET7005J Busway Pub 9-12-10Document44 pagesGET7005J Busway Pub 9-12-10Man MadhanNo ratings yet

- Electrical Service - Subpanel ChecklistDocument3 pagesElectrical Service - Subpanel ChecklistTommyCasillas-GerenaNo ratings yet

- ABB Spectra GET-7005 20210811 10 DigitalDocument60 pagesABB Spectra GET-7005 20210811 10 DigitalDodongNo ratings yet

- POGLIANO Company Profile and Product Range202101210310356298300Document33 pagesPOGLIANO Company Profile and Product Range202101210310356298300ARSAL 22231No ratings yet

- Eaton - B-Line - Flextray Fittings Support & Channel Tray Expansion Splice Installation - r0Document3 pagesEaton - B-Line - Flextray Fittings Support & Channel Tray Expansion Splice Installation - r0gali vidyasagarNo ratings yet

- Busbar Trunking System (Busways)Document6 pagesBusbar Trunking System (Busways)saravana3kumar3ravic100% (1)

- Model: 1. General DescriptionDocument4 pagesModel: 1. General DescriptionWalterHuNo ratings yet

- Documento PAG1Document2 pagesDocumento PAG1André KolenyakNo ratings yet

- Busway Ge PDFDocument44 pagesBusway Ge PDFHotaruSanNo ratings yet

- 200 A Loadbreak Connectors: 25 KV Posi-Break Elbow and CapDocument19 pages200 A Loadbreak Connectors: 25 KV Posi-Break Elbow and CapCARHUAMACA PASCUAL mhNo ratings yet

- Cathodic Protection ReportDocument13 pagesCathodic Protection Reportjeedan78% (9)

- Isophase Technical Sheet PDFDocument2 pagesIsophase Technical Sheet PDFanirudhalcNo ratings yet

- Sandwich Type Bus DuctDocument2 pagesSandwich Type Bus DuctPankaj KumarNo ratings yet

- Sub Station DesignDocument43 pagesSub Station DesignZIPDASH86% (7)

- Nesco Catalogo de Poleas para Lineas AereasDocument70 pagesNesco Catalogo de Poleas para Lineas AereasAntonio LantiguaNo ratings yet

- Component FM200 2Document8 pagesComponent FM200 2awuawu86100% (1)

- Loadbreak Apparatus Connectors: 200 A 25 KV Class Loadbreak Bushing InsertDocument2 pagesLoadbreak Apparatus Connectors: 200 A 25 KV Class Loadbreak Bushing InsertkarimakkiNo ratings yet

- Overhead Busbar SystemsDocument4 pagesOverhead Busbar Systemsgianfutol1No ratings yet

- 5.section-Lt Switchgear, Rev 05Document28 pages5.section-Lt Switchgear, Rev 05Uday Sankar YadavNo ratings yet

- Ari SB SWG Cat en 0722Document4 pagesAri SB SWG Cat en 0722Marco DeunaNo ratings yet

- SECTION 26 05 39 Underfloor Raceways For Electrical SystemsDocument5 pagesSECTION 26 05 39 Underfloor Raceways For Electrical SystemsEzana EzanaNo ratings yet

- Controllogix Chassis-Series B: Installation InstructionsDocument16 pagesControllogix Chassis-Series B: Installation InstructionsneoflashNo ratings yet

- 10A - Cutouts AB CHANCEDocument16 pages10A - Cutouts AB CHANCELuis MartinezNo ratings yet

- Insulator: PackingDocument8 pagesInsulator: PackingZeeshan SubhaniNo ratings yet

- Insulator: PackingDocument8 pagesInsulator: PackingZeeshan SubhaniNo ratings yet

- Get 7005Document52 pagesGet 7005Leonardo Andrés Aznate TeheranNo ratings yet

- Maintenance Handbook On DC Track Circuit Ver2Document51 pagesMaintenance Handbook On DC Track Circuit Ver2Vsrisai ChaitanyaNo ratings yet

- Electrical Works - Package 2B Addendum BoQ Synefra EstimateDocument46 pagesElectrical Works - Package 2B Addendum BoQ Synefra Estimatemsdixit2006100% (4)

- Earthing and Bonding For Electrical SystemDocument2 pagesEarthing and Bonding For Electrical SystemvaraNo ratings yet

- CatalogDocument48 pagesCatalogAhmad AshrafNo ratings yet

- 10A CutoutsDocument16 pages10A Cutoutsbuaran2023No ratings yet

- 02.06.05 3-Way Valve 1240 6519 - enDocument6 pages02.06.05 3-Way Valve 1240 6519 - enabuya3kubmNo ratings yet

- Type C-Polymer: Cutouts and Cutout-Arrester CombinationsDocument16 pagesType C-Polymer: Cutouts and Cutout-Arrester CombinationsPratiktaArdianataNugrahaNo ratings yet

- Earthing and Bonding For 2 X25 KVDocument2 pagesEarthing and Bonding For 2 X25 KVNagi Reddy ChintakuntaNo ratings yet

- Major ProjectDocument30 pagesMajor ProjectRakesh YadavNo ratings yet

- Va 26 24 16Document6 pagesVa 26 24 16adrian karl bonaNo ratings yet

- Specification ADWEADocument2 pagesSpecification ADWEASaad AkramNo ratings yet

- Technical Specification of 11Kv 630A VCB Panel With 5 Nos 11Kv Lbs O/GDocument9 pagesTechnical Specification of 11Kv 630A VCB Panel With 5 Nos 11Kv Lbs O/GShayarrn KhatiwodaNo ratings yet

- CPV10 enDocument68 pagesCPV10 enThomas HaböckNo ratings yet

- EMT 140 With ADocument30 pagesEMT 140 With AJoe KaplowitzNo ratings yet

- Bus Bar ProtectionDocument9 pagesBus Bar ProtectionparameshvkrNo ratings yet

- JCI Curb InstallationDocument2 pagesJCI Curb InstallationJoe YoungNo ratings yet

- Spec For 33kv SystemDocument27 pagesSpec For 33kv SystemkjfenNo ratings yet

- Pages From 3. 22kV Kiosk Distribution Substation - Scope of WorksDocument8 pagesPages From 3. 22kV Kiosk Distribution Substation - Scope of WorksMauricio SaulNo ratings yet

- Switchboards, Distribution Boards and Control PanelsDocument45 pagesSwitchboards, Distribution Boards and Control PanelsRachel IngramNo ratings yet

- Submersible PumpDocument15 pagesSubmersible Pumpnwright_besterNo ratings yet

- ACO Civil Engineering: Bridge DrainageDocument34 pagesACO Civil Engineering: Bridge DrainageSanja RadovicNo ratings yet

- HVAC Specs - ComplianceDocument32 pagesHVAC Specs - ComplianceArchanaShenoyNo ratings yet

- Trunking Busbar E-Line - KBDocument33 pagesTrunking Busbar E-Line - KBJosé LopesNo ratings yet

- Instruction Manual Il-Obct-R1: Slip-Over Current Transformer ObctDocument2 pagesInstruction Manual Il-Obct-R1: Slip-Over Current Transformer Obctبوحميدة كمالNo ratings yet

- Festo Szelepsziget TYP10-G - ENDocument64 pagesFesto Szelepsziget TYP10-G - ENEde HeimNo ratings yet

- Item 683.03105008 - 50 Foot Camera Pole With 1 Lowering DeviceDocument8 pagesItem 683.03105008 - 50 Foot Camera Pole With 1 Lowering DeviceWaheed AhmadNo ratings yet

- Stinger Technical SpecificationDocument8 pagesStinger Technical Specificationrickbushido100% (1)

- Bridge GulliesDocument34 pagesBridge GulliesJpolyPolyNo ratings yet

- Eaton Busway Pow R Way Design Guide Dg017002enDocument1 pageEaton Busway Pow R Way Design Guide Dg017002enAndré KolenyakNo ratings yet

- Eaton Busway Pow R Way Design Guide Dg017002enDocument1 pageEaton Busway Pow R Way Design Guide Dg017002enAndré KolenyakNo ratings yet

- Eaton Busway Pow R Way Design Guide Dg017002enDocument1 pageEaton Busway Pow R Way Design Guide Dg017002enAndré KolenyakNo ratings yet

- Documento PAG7Document1 pageDocumento PAG7André KolenyakNo ratings yet

- Documento PAG5Document1 pageDocumento PAG5André KolenyakNo ratings yet

- Documento PAG6Document1 pageDocumento PAG6André KolenyakNo ratings yet

- Documento PAG1Document2 pagesDocumento PAG1André KolenyakNo ratings yet

- SIPROTEC 5 CatalogDocument90 pagesSIPROTEC 5 CatalogAndré KolenyakNo ratings yet

- Documento PAG3Document1 pageDocumento PAG3André KolenyakNo ratings yet

- Big Fat Lies - How The Diet Industry Is Making You Sick, Fat & PoorDocument212 pagesBig Fat Lies - How The Diet Industry Is Making You Sick, Fat & PoorangelobuffaloNo ratings yet

- Time Series - Practical ExercisesDocument9 pagesTime Series - Practical ExercisesJobayer Islam TunanNo ratings yet

- Eurolite Led TMH 7 PDFDocument2 pagesEurolite Led TMH 7 PDFSarahNo ratings yet

- 06ESL37 Analog Electronics Lab MANUALDocument70 pages06ESL37 Analog Electronics Lab MANUALSan AngadiNo ratings yet

- Pahlavi PoemDocument9 pagesPahlavi PoemBatsuren BarangasNo ratings yet

- Safety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationDocument10 pagesSafety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationEscobar ValderramaNo ratings yet

- Fill in The Table by Determining The Functions of The Following ItemsDocument6 pagesFill in The Table by Determining The Functions of The Following ItemsJessabel CandidatoNo ratings yet

- Reservoir Rock PropertiesDocument148 pagesReservoir Rock Propertiesiscribdusername100% (7)

- Squares and Square Roots Chapter Class ViiiDocument24 pagesSquares and Square Roots Chapter Class ViiiManas Hooda100% (1)

- Circle Theorems, Class 10Document7 pagesCircle Theorems, Class 10Susan MathewNo ratings yet

- One - Touch Fittings: Series: WP2Document12 pagesOne - Touch Fittings: Series: WP2PrashantNo ratings yet

- The Redesigning of Junction: Tatya Tope Square BhopalDocument15 pagesThe Redesigning of Junction: Tatya Tope Square BhopalAr Raj YamgarNo ratings yet

- Grand Vitara 2005Document35 pagesGrand Vitara 2005PattyaaNo ratings yet

- Dyson - Environmental AssesmentDocument16 pagesDyson - Environmental AssesmentShaneWilson100% (5)

- The Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateDocument22 pagesThe Russian Review - 2020 - ROTH EY - Listening Out Listening For Listening in Cold War Radio Broadcasting and The LateOkawa TakeshiNo ratings yet

- Regulatory Framework For Water Dams in QuebecDocument2 pagesRegulatory Framework For Water Dams in QuebecRaveeNo ratings yet

- Lesson 24 - Laminate Modeling - Rev C PDFDocument20 pagesLesson 24 - Laminate Modeling - Rev C PDFraduga_fbNo ratings yet

- Silo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserDocument2 pagesSilo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserTahir Güçlü100% (1)

- (Studies in American Popular History and Culture) Gail Fowler Mohanty - Labor and Laborers of The Loom - Mechanization and Handloom Weavers, 1780-1840 - Routledge (2006)Document292 pages(Studies in American Popular History and Culture) Gail Fowler Mohanty - Labor and Laborers of The Loom - Mechanization and Handloom Weavers, 1780-1840 - Routledge (2006)Милош Станојловић100% (1)

- 2014 Catbalogan Landslide: September, 17, 2014Document6 pages2014 Catbalogan Landslide: September, 17, 2014Jennifer Gapuz GalletaNo ratings yet

- RestrictedDocument51 pagesRestrictedsridharpalledaNo ratings yet

- SC4860-48120 (-MPV) User Manual EN 202107Document23 pagesSC4860-48120 (-MPV) User Manual EN 202107Nattachai BoonchooNo ratings yet

- Method Statement For Painting WorksDocument2 pagesMethod Statement For Painting Worksmustafa100% (3)

- Oertel - Extracts From The Jāiminīya-Brāhma A and Upanishad-Brāhma A, Parallel To Passages of TheDocument20 pagesOertel - Extracts From The Jāiminīya-Brāhma A and Upanishad-Brāhma A, Parallel To Passages of Thespongebob2812No ratings yet

- Laboratory Experiment 3 Test For CarbohydratesDocument9 pagesLaboratory Experiment 3 Test For CarbohydratesRenee Dwi Permata MessakaraengNo ratings yet

- (Js-Umum) Daftar Harga 01 Maret '23Document1 page(Js-Umum) Daftar Harga 01 Maret '23Kristin NataliaNo ratings yet

- UntitledDocument300 pagesUntitledUnbox itNo ratings yet

- Chemical Resistance TableDocument6 pagesChemical Resistance TableEdgarDavidDiazCamposNo ratings yet

- Mits Chocolates: Let The Life Be More Sweet'Document30 pagesMits Chocolates: Let The Life Be More Sweet'Azaz NathaniNo ratings yet

- 1753-Article Text-39640-3-10-20220815Document9 pages1753-Article Text-39640-3-10-20220815Inah SaritaNo ratings yet