0% found this document useful (0 votes)

426 views5 pagesTorispherical Head

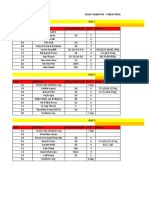

The document summarizes the design analysis of a torispherical head component with an inside diameter of 24 inches and minimum thickness of 0.3 inches. The required thickness due to internal pressure is 0.2945 inches. The maximum allowable working pressure is 101.92 psig and maximum allowable pressure when new and cold is 345.75 psig. Hydrostatic test pressures are calculated to be between 367.59 psig and 449.47 psig depending on the test method. The allowable external pressure is 125.61 psig and required thickness for the external pressure is 0.0811 inches.

Uploaded by

Liaquat AliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as TXT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

426 views5 pagesTorispherical Head

The document summarizes the design analysis of a torispherical head component with an inside diameter of 24 inches and minimum thickness of 0.3 inches. The required thickness due to internal pressure is 0.2945 inches. The maximum allowable working pressure is 101.92 psig and maximum allowable pressure when new and cold is 345.75 psig. Hydrostatic test pressures are calculated to be between 367.59 psig and 449.47 psig depending on the test method. The allowable external pressure is 125.61 psig and required thickness for the external pressure is 0.0811 inches.

Uploaded by

Liaquat AliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as TXT, PDF, TXT or read online on Scribd