Professional Documents

Culture Documents

Idea 31 Ce (En)

Uploaded by

Milos StevanovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Idea 31 Ce (En)

Uploaded by

Milos StevanovicCopyright:

Available Formats

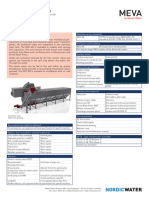

TECHNICAL DATA SHEET IDEA 31

VACUUM PACKAGING MACHINES

FEATURES

- Oil lubricated rotary vane vacuum pump, nominal speed 12 m³/h; Busch

pump 10 m³/h on request;

- Vacuum level control through high precision absolute-type vacuum

sensor, which does not require calibration;

- Maximum vacuum 99,8% (2 millibar);

- 310 mm sealing bar, easily removable for cleaning;

- Brilliant stainless steel vacuum chamber with constant thickness, easy to

clean being free of edges and receptacles;

- Standard inert gas injection with 2 injection nozzles with "Gasplus"

system, which allows to reach values up to 90% of inert gas for products

extremely sensitive to crushing

VACUUM PACKAGING MACHINES IDEA 31

DESCRIPTION - Waterproof control panel, resistant to liquids, humidity, dirt and dust;

- 10 editable user programs;

The "31" model of the Idea line

- 1 cycle for vacuum containers;

catches the eye for cutting-edge

- 1 deaeration "chef" cycle (Degas);

design. Ease of use and versatility

- "H2Out" pump oil dehumidification cycle,

make it an ideal work tool in every

- Resettable oil change alarm;

professional kitchen. Made entirely

- Menu accessible to technical assistance for parameter adjustment and

of AISI304 stainless steel, it stands

reading of cycles carried out;

out for its digital control panel with

absolute vacuum sensor, inert gas - High-thickness blued PMMA (Plexiglass) lid with polished and rounded

injection and a "Degas" series edges; opens automatically at the end of the cycle;

cycle. Easy maintenance and - Lowering system of the lid at the end of the work in the rest position by

cleaning are facilitated by the front releasing the rear gas spring, which allows to release the tension on the

opening of the machine body and gas spring and on the lid;

the brilliant, rounded surfaces of - Access for easy maintenance through front opening of the casing;

the vacuum chamber. - Standard "Easy" accessory for external vacuum in embossed bags;

- 2 PE-filling plates for product adjustment and cycle speed up.

SEALING BAR 310mm

VACUUM PUMP 12 m³/h ACCESSORIES (NOT INCLUDED)

ABSOLUTE SENSOR - Bags for storage, cooking and "cook & chill"; embossed bags;

CONTROL - Stainless steel cart with castors and shelf;

- Inclined stainless steel plate for liquid packing;

- Stainless steel vacuum containers; suction device.

28/07/2021

UPDATED:

PROJECT DATE APPROVED

ITEM QTY

ORVED S.P.A.

1/2

Via dell' Artigianato, 30

Service: assistenza@orved.it

30024 Musile di Piave (VE) - ITALY - www.orved.it Sales support: orved@orved.it

TECHNICAL DATA SHEET IDEA 31

VACUUM PACKAGING MACHINES

SPECIFICATIONS

Length of seal L1 mm 310

Nominal pump speed m³/h 12 (DVP) / 10 (BUSCH)

Final pressure mbar 2

Chamber Size (FxGxH) mm 434x343x195

Useful space Chamber (N) mm 380

Chamber depth (L) mm 135

Chamber volume Lt 19

Power W 700 (DVP) / 600 (BUSCH)

Electrical voltage/Frequency/Phases V/Hz 220-240V / 50-60Hz / 1Ph+N+PE

Power cord and plug 2m + IEC / Schuko

Current A 3,04 (DVP) / 2,6 (BUSCH)

Housing materials Stainless steel (AISI304)

Vacuum chamber material Hydroformed stainless steel (AISI304)

Lid material PMMA (plexiglas)

Overall dimensions (AxBxC) mm 415x603x460

Maximum height with open lid (C1) mm 789

Distance between supports (DxE) mm 356x425

Weight (with shelves) kg 46,3

Noise level dB(A) 62

Environmental operating temperature (min-max) °C 12-40

ORVED S.P.A.

2/2

Via dell' Artigianato, 30

Service: assistenza@orved.it

30024 Musile di Piave (VE) - ITALY - www.orved.it Sales support: orved@orved.it

You might also like

- Idea 41 Ce (En)Document2 pagesIdea 41 Ce (En)Milos StevanovicNo ratings yet

- Idea 30Document2 pagesIdea 30Milos StevanovicNo ratings yet

- Idea 40Document2 pagesIdea 40Milos StevanovicNo ratings yet

- Idea 32 Ce (En)Document2 pagesIdea 32 Ce (En)Milos StevanovicNo ratings yet

- TC 1000 BrochureDocument2 pagesTC 1000 BrochureerniewatersNo ratings yet

- PB C Deko 260Document2 pagesPB C Deko 260muhamadripansopian93No ratings yet

- Procontrol Technical Description - 3!9!21Document6 pagesProcontrol Technical Description - 3!9!21samim_khNo ratings yet

- Maallgem-024 1TDocument24 pagesMaallgem-024 1TAngeles Sendon GonzalezNo ratings yet

- Service Manual: Mod.: F400-SAEV-TS F400 SAEW TS F400 SAEC TSCDocument18 pagesService Manual: Mod.: F400-SAEV-TS F400 SAEW TS F400 SAEC TSCCông ty CP Công nghệ An PhúcNo ratings yet

- Sauermann Si82 Pack2Document2 pagesSauermann Si82 Pack2Farhaan SajjadNo ratings yet

- TP22 0400Document27 pagesTP22 0400KagetenkeNo ratings yet

- GWC 300 - Technical Specifications - SmukDocument5 pagesGWC 300 - Technical Specifications - Smuknguyen kienNo ratings yet

- Valve Insertion Assemblies For The Model 228 SensorDocument2 pagesValve Insertion Assemblies For The Model 228 SensorOmar AlmonteNo ratings yet

- Mini Vitaq - 022858Document4 pagesMini Vitaq - 022858Ahmed SalemNo ratings yet

- Voith Servo Punch UnitDocument5 pagesVoith Servo Punch Unittammam shamiNo ratings yet

- New Items - StalgastDocument14 pagesNew Items - StalgastDanut DorofteiNo ratings yet

- Meva MCU AG Technical Specification ENDocument3 pagesMeva MCU AG Technical Specification ENDavid Hernandez GonzalezNo ratings yet

- T8730 Depliant ENG PDFDocument2 pagesT8730 Depliant ENG PDFForTestNo ratings yet

- Karcher HD Mid Class Cage Web-AmcsngDocument4 pagesKarcher HD Mid Class Cage Web-Amcsng王小冬No ratings yet

- 84-93-001 Avk002ax Eni 432477Document3 pages84-93-001 Avk002ax Eni 432477Gotica ManagementNo ratings yet

- IVC 60/30 Ap M Z22: EquipmentDocument7 pagesIVC 60/30 Ap M Z22: EquipmentPulse XNo ratings yet

- C2248pe SumoiiDocument4 pagesC2248pe SumoiiAhmed Mohamed HassanNo ratings yet

- GR BluePro Brochure enDocument4 pagesGR BluePro Brochure enabdu taliaNo ratings yet

- SP210.M 23 03Document32 pagesSP210.M 23 03tranvietphi0710No ratings yet

- Ficha Tecnica D12000Document1 pageFicha Tecnica D12000Nguyễn Hữu ĐồngNo ratings yet

- Multi-Cycle Shut-In Tool: Reservoir MonitoringDocument2 pagesMulti-Cycle Shut-In Tool: Reservoir MonitoringTheNourEldenNo ratings yet

- Tuttnauer - Intl - 3870HSG - Technical Specification - Ver 1.0Document2 pagesTuttnauer - Intl - 3870HSG - Technical Specification - Ver 1.0Fabian GoyenagaNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- Dmix International: Vacuum 22-kDocument2 pagesDmix International: Vacuum 22-kMateus GuilhermeNo ratings yet

- Dynamelt PUR Series Adhesive Bag MelterDocument2 pagesDynamelt PUR Series Adhesive Bag MelterITWDynatecNo ratings yet

- Grundfos - SEG 40 12 E 2 50BDocument14 pagesGrundfos - SEG 40 12 E 2 50BYashwanth ReddyNo ratings yet

- Top Guide Control ValveDocument32 pagesTop Guide Control Valveachari_swapnilNo ratings yet

- CATDO4Document2 pagesCATDO4DHRUBAJYOTI GUPTANo ratings yet

- VD SV Ka 5 GBDocument3 pagesVD SV Ka 5 GBbahadorNo ratings yet

- Nautilus v10 enDocument6 pagesNautilus v10 enntorrescNo ratings yet

- Altecnic Tagus Class D Volumetric Cold Water Meter 1-2inch MBSPDocument1 pageAltecnic Tagus Class D Volumetric Cold Water Meter 1-2inch MBSPAdvancedWaterCoNo ratings yet

- Vacuum SystemsDocument1 pageVacuum SystemsshrinkfilmNo ratings yet

- VAL Team Adca: Condensate Drain Valves CDV 32Document2 pagesVAL Team Adca: Condensate Drain Valves CDV 32constantin.iacomi3837No ratings yet

- Technical & Service ManualDocument60 pagesTechnical & Service ManualDavid Lemos SanchezNo ratings yet

- Liv Arv BS 001Document1 pageLiv Arv BS 001romel tilakNo ratings yet

- Purgeur UFM-D130Document4 pagesPurgeur UFM-D130youcef alimNo ratings yet

- Rundfos - SEG 40 12 E EX 2 1 502Document13 pagesRundfos - SEG 40 12 E EX 2 1 502Mohamed OudaNo ratings yet

- Technical Proposal For Olympic Pool PDFDocument10 pagesTechnical Proposal For Olympic Pool PDFAlma DerajNo ratings yet

- P720 Brochure ENDocument2 pagesP720 Brochure ENVictor GalarzaNo ratings yet

- 02122020-Gen - Cat - EuropeDocument32 pages02122020-Gen - Cat - EuropeABDULSALAMNo ratings yet

- CXHAXAN - Full - en - Metric - Letter BorbetDocument2 pagesCXHAXAN - Full - en - Metric - Letter BorbetRonaldNo ratings yet

- SPEC Pulsatron E PLUS SeriesDocument2 pagesSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethNo ratings yet

- 2.VD SV Ka 5 GBDocument3 pages2.VD SV Ka 5 GBshanmugamNo ratings yet

- AWH Catalogue Product Revovery Technology 12.2 PDFDocument38 pagesAWH Catalogue Product Revovery Technology 12.2 PDFGeorge_Wabag_2014No ratings yet

- ÉSECÈ Group - Steam Boiler - Mar12 ENGDocument4 pagesÉSECÈ Group - Steam Boiler - Mar12 ENGDiego Otero RodríguezNo ratings yet

- Motor Multi v210Document20 pagesMotor Multi v210huayra85No ratings yet

- Grundfos - SL1 50 65 22 2 50D CDocument13 pagesGrundfos - SL1 50 65 22 2 50D CThilina Lakmal Edirisingha100% (1)

- DTS 400 PDM VesDocument5 pagesDTS 400 PDM Vesalvaro.gimenez.colegioNo ratings yet

- Dunham Bush Package UnitsDocument8 pagesDunham Bush Package UnitsStephanie StewartNo ratings yet

- Datasheet - Ultrasonic Heat Meter RC12Document4 pagesDatasheet - Ultrasonic Heat Meter RC12MostafaHeshmatNo ratings yet

- Divertron TS EngDocument2 pagesDivertron TS Engbaracuss323iNo ratings yet

- Trident CTD - 11 B LeafletDocument2 pagesTrident CTD - 11 B LeafletBOOBALANNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Pompe Clu3 E1001 Carte TehnicaDocument2 pagesPompe Clu3 E1001 Carte TehnicaAnonymous RCPxaonfvNo ratings yet

- APC200 ECM-ECI Error Codes Ver1.3Document10 pagesAPC200 ECM-ECI Error Codes Ver1.3Amel Abbas Abbas AbbakerNo ratings yet

- Physics Form 5 - 8.2 Force Acting On A Current Carrying Conductor in A Magnetic FieldsDocument20 pagesPhysics Form 5 - 8.2 Force Acting On A Current Carrying Conductor in A Magnetic FieldsNoorNo ratings yet

- Diode 1NDocument57 pagesDiode 1Nalexandru255No ratings yet

- M250-C20 Ceb-1165Document7 pagesM250-C20 Ceb-1165turboshaftNo ratings yet

- Skema Rangkaian Long Range ..Document3 pagesSkema Rangkaian Long Range ..dedy kurniawanNo ratings yet

- Rain DetectorDocument5 pagesRain Detectorsurya suryaNo ratings yet

- Motion PRO Technical Manual Rev 1 - 14Document64 pagesMotion PRO Technical Manual Rev 1 - 14camohunter710% (1)

- Digix-1 Programmable Logic Controller: FeaturesDocument2 pagesDigix-1 Programmable Logic Controller: FeaturesBala SundaramNo ratings yet

- Sha, SHB, SHC &PS1260Document9 pagesSha, SHB, SHC &PS1260LAUTHUSNo ratings yet

- Technology and Livelihood Education: Home EconomicsDocument9 pagesTechnology and Livelihood Education: Home EconomicsJacquilyn Dela Cruz100% (1)

- Model ExamDocument2 pagesModel ExamexcitekarthikNo ratings yet

- Cardans PDFDocument108 pagesCardans PDFmarianoNo ratings yet

- 3508B 1000kVAPrimeDocument6 pages3508B 1000kVAPrimearturo2992No ratings yet

- Instalation Manual FratelliDocument25 pagesInstalation Manual FratelliIon Aniel Barbu100% (1)

- Fassi Crane: Use and MaintenanceDocument42 pagesFassi Crane: Use and MaintenanceДенис ЧерныйNo ratings yet

- Repair and Service Manual TXT 48V: Electric Powered Golf CarDocument192 pagesRepair and Service Manual TXT 48V: Electric Powered Golf Carmg victorNo ratings yet

- Cable GlandsDocument14 pagesCable GlandsSACHINNo ratings yet

- Reliablegatevalveswitch 2Document3 pagesReliablegatevalveswitch 2jajakaNo ratings yet

- Om615 616 617 PDFDocument221 pagesOm615 616 617 PDFAnonymous wpUyixsj100% (1)

- Quincy QGD 30 HPDocument80 pagesQuincy QGD 30 HPLuis Fernando Bravo100% (1)

- ZEBRA ZMx00 Series Parts Catalog-EnDocument10 pagesZEBRA ZMx00 Series Parts Catalog-Enmanubis26No ratings yet

- Analysis of The Indian Maintenance Center For WAG-9 Electric Locomotives and Improve For New Railways ServiceDocument45 pagesAnalysis of The Indian Maintenance Center For WAG-9 Electric Locomotives and Improve For New Railways Service2251 EE MANMAT BIRADARNo ratings yet

- 160,000 Lbs (72,574 KGS) 53 Yd (40.52 M) Standard Operating CapacityDocument6 pages160,000 Lbs (72,574 KGS) 53 Yd (40.52 M) Standard Operating CapacitycoutoNo ratings yet

- Manual FCD 302 InglesDocument77 pagesManual FCD 302 InglesCamila E. DavidNo ratings yet

- Backhoe Operator AssessmentDocument27 pagesBackhoe Operator AssessmentGermain DgermainNo ratings yet

- Piping Class: PROJ: 2963 REV: 2 DOC: PPAG-100-ET-C-012Document7 pagesPiping Class: PROJ: 2963 REV: 2 DOC: PPAG-100-ET-C-012Santiago GarciaNo ratings yet

- Barramento PCI: PDF Generated At: Mon, 29 Apr 2013 11:40:35 UTCDocument50 pagesBarramento PCI: PDF Generated At: Mon, 29 Apr 2013 11:40:35 UTCKay SmithNo ratings yet

- PM 7 002883 en 01Document60 pagesPM 7 002883 en 01Mundial Elevadores AdministrativoNo ratings yet

- Intermediate Maintenance 911 Carrera S (991), 911 Carrera 4 4S (991) (As of 2012 Model)Document2 pagesIntermediate Maintenance 911 Carrera S (991), 911 Carrera 4 4S (991) (As of 2012 Model)Dale Joseph KiehlNo ratings yet