Professional Documents

Culture Documents

V2I803018

Uploaded by

Salvador Reyes0 ratings0% found this document useful (0 votes)

16 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views2 pagesV2I803018

Uploaded by

Salvador ReyesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

Alternators & Regulators

MOTORCRAFT ALTERNATORS

Fiesta

DESCRIPTION

Alternotor is belt driven from engine, An external regulator

controls charging rate by switching rotor field current in. ond

‘out os required through brushes contacting slip rings. Alter

nating current is produced and converted to direct current by

the diode rectifier casembly,

IDENTIFICATION & SPECIFICATIONS

Alternator is stomped with "Motorcraft" trademerk in either

orange oF green

APPLICATION

Color Rating

Orange

Green

40 Amps.@15V

60 Ampsa15V

TESTING

FUSE LINK

Fuse links ore provided in the charging system to prevent

domage to the harness and alternator in cose the harness

becomes grounded or a booster battery is connected with

reverse polarity, Insulation which is rippled or bubbled i

dicotes that the link is blown ond must be eeplaced. In case of

vehicles with two fuse links, check the accessories link by turn

ing headlomps or an accessory an, If fuses are not blown and

they sil foil to function, the link is prabably blown and must

be replaced.

INDICATOR UGHT

Wersing light should come an when starting engine and go

off atter engine is idling. If no light, check bulb ond replace it

burned our. Irbulb is not burned out check for open circuit bet

ween switch ond regulator. If light does not go out until engine

reaches high RPM, check 15 ohm resistor connected in parallel

‘with light

VOLTAGE OUTPUT TEST

1) Attach voltmeter to battery ond record voltage. Stort

fengine and increase engine speed to 1500 RPM when normal

‘operating temperature is reached, With NO electrical load on

system, voltage should increase to at least} volt but not more

than 2 volts above original reading

2) Turn on heater blower motor to high speed and headlights

to high beam. Increase engine speed to 2000 RPM ond note

bottery voltage ot least 0.5 volt above original reading with

engine off

3) If noload voltage in step 1) exceeds 2 volts, ossure that

‘ground connections between regulator, alternator and engine

fre fight. Disconnect wiring plug from egulator and recheck

novload voltage. If voltmeter now indicotes battery voltage

throughout the fest, replace voltage regulotor and recheck

4) tf voltage increase is excessive with regulatar disconnected,

repoir shorted wiring horness between allernator ond

regulator.

= It harness is shorted, regulator will hove been

damaged ond must be replaced.

5) I lood voltage in step 2) did not increase or increase was

less than 0.5 volt, check battery voltage at alternator “BAT”

terminal. Disconnect regulator plug ond check battery voltage

of "A" terminal. IF no voltage present at these terminals, repair

wicing ond repeat output tes.

6) Il bottery voltage is present at both "BAT" ond "A" ter-

minals, connect jumper across "A" ond "F" terminals of

Fegulator plug. I field circuit is grounded, jumper will spark

fond heot, Check field cirevit for ground ‘end regulator for

open belore continuing

7) To check field circuit, measure resistance between °F” ter:

‘minal on regulator plug ond negative battery cable clamp.

COhmmeter should read between 4 ohms ond 250 ohms. NO

resistance indicotes that the field circut is grounded and re.

quires alternator removal and repair

8) Check resistance between "I" and "F” terminals with plug

removed. Ohmmeter should indicate zero resistance, A reading

‘of 10 or more ohms indicotes an open connection in the

Fegulator. Replace requlator and repair alternatar field circuit

9) It load voltage is sill less thon specified, remove jumper

from regulator wiring plug and installa jumper between olter

notor "BAT" ond "FLD" terminals. Repeat output tet. IF results

are sotistactory, witing harness is at foult_ ond must be

repaired or replaced, If load voltage increase is fll ess thon

0.5 volt, alternator must be removed from vehicle for bench

testing

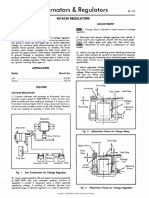

Jumper Wire Connected to

Jalternotor "BAT" ond "FLD"

Terminels

oQ

Regulator with

Connector Plug Removed

Fig. 1 Alternator with Jumper for Testing

‘ipo 200 Rapa ema Campa

Alternators & Regulators 3

19

MOTORCRAFT ALTERNATORS (Cont.

OVERHAUL

DISASSEMBLY

1) Scribe mark across front and rear housings and stator for

clignment during reassembly. Remove through bolls and

‘separate front housing ond rotor from rear housing and stator.

2) Remove terminal nuts and insulators from rear housing ond

separate stotor/rectitier assembly from havsing, Remove

brushes and brush holder.

3) To remove stacked type rectifier, remove stator terminal

‘crew ond grounded screw by turning them "4 turn to unlock

from rectiier. Unsolder leads fram rectifier using caution not 10

overheat rectifier aseembly. To remove flat type rectifier,

remove stator terminal screw by pressing straight out of rec

fife. Do NOT turn screw or remove grounded screws. Un

solder leads from rectifier.

4) Remove front pulley and fon, then separate rotor from

housing and bearing, Bearing may be reploced by removing

retainer screws ond retainer

TESTING

1) Using 12 volt test lamp, check rotor continuity ot slip rings

cond absence of ground between slip ring and rotor shaft. With

ohmmeter, check for resistance of 4.0 10 4.4 ohms between slip,

rings

2) Check resistance of 14 to .16 ohms between stator wires

‘ath chmmeter. Check that windings ore not grounded ond

have winding continuity with 12 volt test lamp.

3) Check diodes for continuity (approximately 60 ohms) in one

direction only, It na continuity is observed in either direction,

diode is open. I continuity is observed in both directions, diode

is shorted. Rectifier assembly must be replaced if open or shor

ted diodes are found,

REASSEMBLY

1) Install bearing and retainer in front housing. Install rotor in

housing to stop-ring, then install spacer, fan, pulley and nut

with Tock washer.

2) Assemble brush holder with brushes and springs, holding

brushes in retracted position by inserting length af wire (paper

clip} in holder. Solder leads from stator to rectifier pack and

everse disossembly procedure noting thot scribe marks ore

cligned.

3) Remove brush retracting wire (paper clip) and seal hole

‘with waterproof cement, Install and test alternator.

Rear

Bearing Rear Housing

Rectitior

Assembly

Springs

Bearing

ue Spacer

Terminal fea

Insulators Radio

Suppression

Copacitor

Stotor

Assembly

Front Housing

Rotor

Assembly

Front

Bearing

ah?

Front Bearing

Fan Spacer

Retainer .

Fig. 2 Exploded View of Motorcraft Alternator

‘ipo 200 Rapa ema Campa

-PO-240Mmem

You might also like

- V2I803028Document1 pageV2I803028Salvador ReyesNo ratings yet

- V2I783004Document3 pagesV2I783004Salvador ReyesNo ratings yet

- V2I783002Document1 pageV2I783002Salvador ReyesNo ratings yet

- V2I803020Document1 pageV2I803020Salvador ReyesNo ratings yet

- V2I803029Document3 pagesV2I803029Salvador ReyesNo ratings yet

- V2I803032Document1 pageV2I803032Salvador ReyesNo ratings yet

- V2I803010Document2 pagesV2I803010Salvador ReyesNo ratings yet

- V2I803017Document1 pageV2I803017Salvador ReyesNo ratings yet

- V2I803021Document2 pagesV2I803021Salvador ReyesNo ratings yet

- V2I803023Document2 pagesV2I803023Salvador ReyesNo ratings yet

- V2I803025Document1 pageV2I803025Salvador ReyesNo ratings yet

- V2I783011Document2 pagesV2I783011Salvador ReyesNo ratings yet

- V2I803003Document1 pageV2I803003Salvador ReyesNo ratings yet

- V2I803012Document2 pagesV2I803012Salvador ReyesNo ratings yet

- V2I803007Document3 pagesV2I803007Salvador ReyesNo ratings yet

- V2I803004Document2 pagesV2I803004Salvador ReyesNo ratings yet

- V2I783015Document2 pagesV2I783015Salvador ReyesNo ratings yet

- V2I803002Document1 pageV2I803002Salvador ReyesNo ratings yet

- V2I803006Document1 pageV2I803006Salvador ReyesNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)