Professional Documents

Culture Documents

ISO 14644 Explained

Uploaded by

riotstarbabyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 14644 Explained

Uploaded by

riotstarbabyCopyright:

Available Formats

Technical Bulletin Brief Explanation of ISO 14644 - Parts 1 & 2

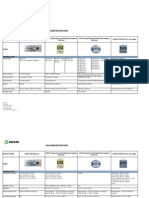

Abstract The new ISO Documents, viz, 14644 Parts 1 and 2 have already been officially released by the Technical Committee ISO/TC 209 : Cleanrooms and Associated Controlled Environments . Recently with the official cancellation of the Federal Standard 209E, more and more companies and associations will be adopting these standards for the classification of airborne cleanliness classes (ISO 14644-1) and using the second part ISO 14644-2 to specify monitoring protocol (or re-certification of cleanrooms) based on the cleanliness classes . This paper outlines the main differences between the ISO 14644-1 and the Federal Standard 209E and also explains briefly on the relevant tables and the recommended monitoring or recertification protocol of ISO 14644-2 . Scope of ISO Documents 14644 Parts 1 and 2 A. ISO 14644-1 : Classification of Air Cleanliness ISO 14644-1 covers the classification of air cleanliness in cleanrooms and associated controlled environments exclusively in terms of concentration of airborne particles . Only particle populations having cumulative distributions based on threshold (lower limit) sizes ranging from 0. lm to 5m. are considered for classification purposes . See Table 1 below for the cleanliness classification . Maximum concentration limits (particles/m3 of air ) for particles equal to and larger than the considered sizes shown below (concentration limits are calculated in accordance with equation (1) in 3.2) 0.1m 0.2m 0.3m 0.5m 1.0m 5.0m 10 2 ISO Class 1 100 24 10 4 ISO Class 2 1 000 237 102 35 8 ISO Class 3 10 000 2 370 1 020 352 83 ISO Class 4 100 000 23 700 10 200 3 520 832 29 ISO Class 5 1 000 000 237 000 102 000 35 200 8 320 293 ISO Class 6 352 000 83 200 2 930 ISO Class 7 3 520 000 832 000 29 300 ISO Class 8 35 200 000 8 320 000 293 000 ISO Class 9 NOTE : Uncertainties related to the measurement process require that concentration data with no more than three significant figures be used in determining the classification level ISO Classification Number (N) Table 1 : Selected Airborne Particulate Cleanliness Classes for Cleanrooms and Clean zones (Extracted from Table 1 : ISO 14644-1)

Cesstech (S) Pte Ltd 28 Aug 2002

Page 1

Technical Bulletin Brief Explanation of ISO 14644 - Parts 1 & 2

B. ISO 14644-2 : Specification for Testing and Monitoring to prove continued compliance with ISO 14644-1 This part of International Standard ISO 14644 specifies requirements for periodic testing of a cleanroom or clean zone to prove its continued compliance with ISO 14644-1 for the designated classification of airborne particulate cleanliness. These requirements invoke the test described in ISO 14644-1 for the classification of the cleanroom or clean zone. Additional tests are also specified, to be carried out based on the requirements of this International Standard. Optional tests, to be applied at the user's discretion, are also identified. This part of ISO 14644 also specifies requirements for the monitoring of a cleanroom or clean zone (installation) to provide evidence of its continued compliance with ISO14644-1 for the designated classification of airborne particulate cleanliness ISO 14644:1 vs FS 209E This document was prepared to address the same scope and tasks as Federal Standrad 209E, ie, Classification of Air Cleanliness . Most users are very familiar with FS 209E having used it day in and day out . The best way therefore to understand this new ISO 14644-1 is to point out the major differences in this standard as opposed to FS 209E . The matrix on the next page highlights the essential differences between the two standards . Sub Sections Units Particle range ISO 14644-1 All units are in metric 0.1m, 0.2m, 0.3m, 0.5m, 1.0m, 5.0m Class ISO 1 to ISO 9 Particles / m3 0.1m see Table 2 FS 209E Units are in English (US customary) and Metric 0.1m, 0.2m, 0.3m, 0.5m, 5.0m (No 0.1m classification) Class M1 to M7 Particles/ft3 or Particles/m3 0.5m see Table 2

Classification Units of concentration Reference particle size for classification Classification Number / Formula

C = 10N x (0.1/D)2.08

C = concentration in particles/m N = cleanliness class, D = particle diameter in m

C = 10N x (0.5/D)2.2

Classification designation

1 or more where diameter of one is 1.5 times diameter of next smaller size (D2 D1 x 1.5)

1 or more and No restriction on particle diameter

Cesstech (S) Pte Ltd 28 Aug 2002

Page 2

Technical Bulletin Brief Explanation of ISO 14644 - Parts 1 & 2

Sub Sections Sampling Location NL= A

ISO 14644-1

FS 209E Unidirectional Airflow Lesser of (a) or (b) (a) A/2.32 or (b) A x 64/10N Non-Unidirectional Airflow A x 64/10N DPC (=OPC, CNC) + optical microscopy

Where A = area of room in m2 NL = no of sampling locations N = cleanliness class

Measurement Method

DPC for 0.1 to 5 m CNC for ultrafine particles Optical Microscope for macroparticles 1 location is possible but need to sample at least 3 times

Restrictions on sample locations

Minimum of 2 sampling locations need to be taken and a minimum of 5 samples in total Particles 0.02m Not considered Required No such requirement

Ultrafine particles Macroparticles Isokinetic sampling Pretest conditions

Particles 0.1m Information on particles 5m Not required Prior to airborne cleanliness class measurement, the following tests need to be performed : Airflow volume or velocity tests Air pressure difference test Containment leakage test Installed filter leakage test If the 95% UCL calculation fails to meet the specified cleanliness class, due to a single non-random outlier value, this outlier value may be excluded from the calculation

Single Non random value

No such provision

Cesstech (S) Pte Ltd 28 Aug 2002

Page 3

Technical Bulletin Brief Explanation of ISO 14644 - Parts 1 & 2

Cleanliness Classification ISO Class 1 ISO Class 2 ISO Class 3 1 ISO Class 4 10 ISO Class 5 100 ISO Class 6 1 000 ISO Class 7 10 000 ISO Class 8 100 000 ISO Class 9 0.1m 10 100 1 000 1 240 10 000 12 400 100 000 1 000 000 0.2m 2 24 237 265 2 370 2 650 23 700 26 500 237 000 -

No of Particles per m3 0.3m 10 102 106 1 020 1 060 10 200 10 600 102 000 0.5m 4 35 35.3 352 353 3 520 3 530 35 200 35 300 352 000 353 000 3 520 000 3 530 000 35 200 000 1.0m 5.0m

8 83 832 8 320 83 200 832 000 -

29 293 247 2 930 2 470 29 300 24 700

8 320 000 293 000 -

Table 2 : Comparison of Cleanliness Classification between FS 209E and ISO 14644-1 (Top and in black : ISO 14644-1, Bottom and in Blue : FS 209E) ISO 14644-2 General This standard was formulated to specify requirements for the periodic testing of a cleanroom and/or a clean zone as there were several questions raised over the years which addressed the need for a re-certification protocol after initial commissioning of a cleanroom or clean zone . Normative tests and Time Interval This standard establishes the schedule for testing of the airborne particle count, the airflow volume or velocity test and the air pressure difference tests all these tests being normative in the standard . The maximum time interval for the airborne particle count to demonstrate compliance can range from between 6 mths to 12 mths, depending on the cleanliness classification see table 3 below . As for the airflow volume or velocity and the air pressure difference tests, these are based on a standard 12 mths interval see table 4.

Cesstech (S) Pte Ltd 28 Aug 2002

Page 4

Technical Bulletin Brief Explanation of ISO 14644 - Parts 1 & 2

Classification ISO Class 5 > ISO Class 5

Maximum Time Interval 6 months 12 months

Test Method Annex B in ISO 146441:1999 Annex B in ISO 146441:1999

NOTE : Particle count tests will normally be performed in the operational state, but may also be performed in the at-rest state in accordance with the designated ISO classification Table 3 : Schedule of testing to demonstrate compliance with particle concentration limits (Extracted from Table 1 in ISO 14644:2) Test Parameter Airflow Volume a or velocity test Air pressure difference b Maximum Time Interval 12 months 12 months Test Procedure ISO 14644-3:-, clause B.4 ISO 14644-3:-, clause B.5

NOTE : These tests may normally be performed in either the operational or at-rest state in accordance with the designated ISO classification

a b

Airflow volume may be determined by either velocity or volume measurement This test will not apply to clean zones which are not totally enclosed Table 4 : Schedule of additional tests for all classes (Extracted from Table 2 in ISO 14644:2)

Other Optional Tests The standard also states that the user can specify other optional tests to be performed at a suggested maximum interval of 24 mths, to ensure compliance . The recommended optional tests include : Installed filter leakage test Airflow visualization test Recovery test Containment leakage test The test procedures and protocol will be found in the relevant sections of ISO 14644:3 Metrology and Test methods which is not available yet even in the draft stage .

Cesstech (S) Pte Ltd 28 Aug 2002

Page 5

Technical Bulletin Brief Explanation of ISO 14644 - Parts 1 & 2

Exception to Monitoring Interval and Re-qualification If the cleanroom or clean zone is equipped with instrumentation for continuous or frequent monitoring of the airborne concentration and air pressure differential, the maximum time interval as stated in tables 3 and 4 can be extended, provided that the results of the continuous or frequent monitoring remain within the specified limit(s) . If any of the parameters fail, then remedial action will have to be immediately taken and requalification undertaken . As stated in the srabdard, re-qualification will have to be undertaken after any of the following : Completion of remedial action implemented to rectify an out-of-compliance condition A significant change from the current performance specification, such as a change in the operational use . The significance of a change should be determined by agreement between the customer and the supplier . Any significant interruption of air movement which affects the operation of the installation . The significance of an interruption should be determined by agreement between the customer and the supplier . Examples where re-qualification will be required (but not limited to) include : When there is a change in the layout of the process and equipment in the cleanroom When cleanroom walls are taken apart and the cleanroom extended When there is a change in the layout of the cleanroom filters (perhaps filters are relocated or additional filters are installed) Documentation Besides this the standard also covers the need for a written monitoring plan for the various parameters and specifies the documentation required . The documentation includes the need for a submission of a comprehensive report along with a statement of compliance or noncompliance with the specified tests CONCLUSION The ISO 14644 Parts 1 and 2 documents will no doubt catch on in due course and have attempted to globalise the protocol for airborne particle measurements . The ISO 14644:2 standard has especially addressed, inexplicably, the requirements for monitoring to demonstrate continued compliance, though only in a brief document . However the full impact of the these two ISO standards (ISO 14644:1 and ISO 14644:2) will only be realized with the release of the ISO 14644 Part 3 which establishes the test methods involved in the testing of cleanroom and clean zones . REFERENCES 1. Whyte, W "Cleanroom Design, Wiley, Second Edition, October 1999. 2. ISO 14644:1 - Classification of Air Cleanliness, 1999 3. ISO 14644:2 - Specification for Testing and Monitoring to prove continued compliance with ISO 14644-1, 2000 4. Federal Standard 209E : Airborne Particulate Cleanliness Classes in Cleanrooms and Clean Zones, 1992

Cesstech (S) Pte Ltd 28 Aug 2002 Page 6

You might also like

- Conducting The ISO 146443 Cleanroom Recovery Test With The 3400101420Document3 pagesConducting The ISO 146443 Cleanroom Recovery Test With The 3400101420Oscar Zambrano Martinez100% (1)

- Cleanroom StandardsDocument10 pagesCleanroom Standardslminhv100% (1)

- Clean Room SpecsDocument7 pagesClean Room SpecsLaxminarayan Jha100% (1)

- Cleanroom Guide Iso 14644Document8 pagesCleanroom Guide Iso 14644hitham shehataNo ratings yet

- Clean Rooms ADocument7 pagesClean Rooms ACharly Ferre100% (1)

- A Presentation by S.Syed Noor MohamedDocument39 pagesA Presentation by S.Syed Noor Mohamedrambabukomati472No ratings yet

- Summary of ISO 14644Document2 pagesSummary of ISO 14644Dharmesh PatelNo ratings yet

- Compilado de Ion para Cuartos LimpiosDocument49 pagesCompilado de Ion para Cuartos LimpiosEnrique Romero SanchezNo ratings yet

- Supplementary Training Modules On GMP: Air Handling SystemsDocument20 pagesSupplementary Training Modules On GMP: Air Handling SystemsRambabu komati - QANo ratings yet

- EU GMP Annex 1 Update 2008 Particle CountingDocument8 pagesEU GMP Annex 1 Update 2008 Particle CountingpokermarmotaNo ratings yet

- F 311 - 08 (2013)Document3 pagesF 311 - 08 (2013)juan fNo ratings yet

- Usp 797GCDocument61 pagesUsp 797GCAwni1989No ratings yet

- Testing Method of PP CAPDocument7 pagesTesting Method of PP CAPTaurusVõNo ratings yet

- Basic Guide To Particle & Particle CountingDocument40 pagesBasic Guide To Particle & Particle Countingmarindia2010100% (1)

- Injections and Implanted Drug Products (Parenterals) - Product Quality TestsDocument7 pagesInjections and Implanted Drug Products (Parenterals) - Product Quality TestsPutri PajarianaNo ratings yet

- TR 28-01Document25 pagesTR 28-01Nilay ÇelikNo ratings yet

- Faq Iso-14644-2 2015-Cleanroom-MonitoringDocument15 pagesFaq Iso-14644-2 2015-Cleanroom-MonitoringWanjhinoNo ratings yet

- Particle Monitoring in Pharmaceutical CleanroomsDocument8 pagesParticle Monitoring in Pharmaceutical CleanroomsAbd Al-Rahmman Al-qatananiNo ratings yet

- Karl Fischer ApparatusDocument54 pagesKarl Fischer ApparatusREDDYGAARI ABBAYINo ratings yet

- Calibration Requirements For Determining Particle Size Distribution Using Light Interaction MethodsDocument6 pagesCalibration Requirements For Determining Particle Size Distribution Using Light Interaction Methodstuhintahmid1093No ratings yet

- Integrity Testing of HEPA Filters - A Practical ApproachDocument11 pagesIntegrity Testing of HEPA Filters - A Practical ApproachFajar NurrohmanNo ratings yet

- CharnDocument28 pagesCharnsksingh82No ratings yet

- GMP Training Requirements for Manufacturing StaffDocument14 pagesGMP Training Requirements for Manufacturing StaffPrince MoniNo ratings yet

- Hazard and Risk Management - Sarika MamDocument24 pagesHazard and Risk Management - Sarika MamSharon DsouzaNo ratings yet

- Uncertainty of Measurements Part I Compliance Testing PDFDocument8 pagesUncertainty of Measurements Part I Compliance Testing PDFParkhomyukNo ratings yet

- Cleaning Reverse Phase ColumnDocument2 pagesCleaning Reverse Phase ColumnhbordasmNo ratings yet

- ASTM E1064 - Jtvo9242Document3 pagesASTM E1064 - Jtvo9242Nayth Andres GalazNo ratings yet

- Autonics RoHS Compliance CertificateDocument2 pagesAutonics RoHS Compliance CertificateDarwinPowChonLongNo ratings yet

- Seta Verification Materials: STVM MTVMDocument2 pagesSeta Verification Materials: STVM MTVMdchyNo ratings yet

- F 302 - 78 R00 RJMWMGDocument3 pagesF 302 - 78 R00 RJMWMGJuanNo ratings yet

- Is 13726 2002Document19 pagesIs 13726 2002john23141No ratings yet

- Lma The Ritish Laboratory Managers AssociationDocument4 pagesLma The Ritish Laboratory Managers Associationchatxxnoir4263No ratings yet

- Aseptic Area ClassificationDocument9 pagesAseptic Area ClassificationNaresh BabuNo ratings yet

- Climet ParticleMonitoring SOP GenericDocument8 pagesClimet ParticleMonitoring SOP GenericMohammad IsmailNo ratings yet

- Sop For Recovery TestDocument2 pagesSop For Recovery TestFrendz Forevr Ati100% (1)

- HPLC TroubleshootingDocument49 pagesHPLC Troubleshootingspsp alumniNo ratings yet

- Lab Testing Report - REACHDocument4 pagesLab Testing Report - REACHajayNo ratings yet

- CLEANROOM PramoteDocument28 pagesCLEANROOM Pramotedavincicode888100% (2)

- ISO 14644-1v2015 ProcedureDocument1 pageISO 14644-1v2015 ProcedurekhlowNo ratings yet

- Ethanol 96 Per Cent 1317eDocument3 pagesEthanol 96 Per Cent 1317edrs_mdu48No ratings yet

- Apparel Considerations For Clean ManufacturingDocument2 pagesApparel Considerations For Clean ManufacturingGaurav ShakyaNo ratings yet

- Particle Count - STANDARDSDocument15 pagesParticle Count - STANDARDSpraveen kumar vengadasamy100% (1)

- Basic Cleanroom ProtocolDocument3 pagesBasic Cleanroom ProtocolkarengisellNo ratings yet

- Environment Validation SopDocument8 pagesEnvironment Validation SopNguyen ChienNo ratings yet

- Data Logger Selection Chart Vacker Dubai UAEDocument10 pagesData Logger Selection Chart Vacker Dubai UAEVacker Group UAENo ratings yet

- GMP 11 Calibration Intervals For Laboratory Standards PDFDocument6 pagesGMP 11 Calibration Intervals For Laboratory Standards PDFleoNo ratings yet

- ISO14644 GUIDE - KEY CHANGES TO CLEANROOM STANDARDDocument7 pagesISO14644 GUIDE - KEY CHANGES TO CLEANROOM STANDARDRick WylieNo ratings yet

- FS-209E and SIO-14644 Cleanroom Classification StandardsDocument8 pagesFS-209E and SIO-14644 Cleanroom Classification Standardsmaqsoodch1100% (1)

- Cleanroom Requirements, Certification and Monitoring Per Common Accepted Standards by Sean Birch, Lighthouse Worldwide SolutionsDocument3 pagesCleanroom Requirements, Certification and Monitoring Per Common Accepted Standards by Sean Birch, Lighthouse Worldwide SolutionsApoloTrevino100% (1)

- 7 Iso14644Document84 pages7 Iso14644mgvtertv100% (2)

- Classification Vs MonitoringDocument4 pagesClassification Vs MonitoringrohitdeolNo ratings yet

- ISO 14644 Cleanroom StandardsDocument84 pagesISO 14644 Cleanroom StandardsDenny Simeon100% (8)

- Sampling Plan For Cleanroom ClassificationDocument15 pagesSampling Plan For Cleanroom Classificationjpabloqf100% (2)

- White Paper New Changes To Cleanroom and Clean Air Device Classifications 01Document7 pagesWhite Paper New Changes To Cleanroom and Clean Air Device Classifications 01Reza JafariNo ratings yet

- PharmaDocument21 pagesPharmaThế KiệtNo ratings yet

- Standards For Classification of Cleanrooms (February 2005) : 1 Federal Standard 209Document8 pagesStandards For Classification of Cleanrooms (February 2005) : 1 Federal Standard 209RamboNo ratings yet

- Standards For Classification of Clean RoomsDocument8 pagesStandards For Classification of Clean Roomszvieizikovics50% (2)

- Airborne Particle Monitoring Update for Pharmaceutical FacilitiesDocument7 pagesAirborne Particle Monitoring Update for Pharmaceutical FacilitiesKye Hwan KimNo ratings yet

- Classifications of Clean RoomsDocument4 pagesClassifications of Clean RoomsDenny DiergantaraNo ratings yet

- Calibration Requirements For Determining Particle Size Distribution Using Light Interaction MethodsDocument6 pagesCalibration Requirements For Determining Particle Size Distribution Using Light Interaction Methodstuhintahmid1093No ratings yet

- ISO 14644-3 Cleanroom Recovery Test MET Particle CounterDocument6 pagesISO 14644-3 Cleanroom Recovery Test MET Particle CounterJesusNo ratings yet

- Validation Part2Document48 pagesValidation Part2gvasNo ratings yet

- Iso 14644-1Document20 pagesIso 14644-1annisa nur ainiNo ratings yet

- Semiconductor Fabircation FacilitiesDocument38 pagesSemiconductor Fabircation Facilitiesdg ds100% (2)

- Environmental Monitoring Overview GOOD TABLESDocument13 pagesEnvironmental Monitoring Overview GOOD TABLESPsilosNo ratings yet

- Iso 14644 3 2005Document15 pagesIso 14644 3 2005AnaNo ratings yet

- Airflow Visualization (Smoke Studies) - The Most Misunderstood and Underappreciated Cleanroom Test 2021sDocument8 pagesAirflow Visualization (Smoke Studies) - The Most Misunderstood and Underappreciated Cleanroom Test 2021sGaston Loo100% (1)

- PE 009-16 GMP Guide (XAnnexes)Document235 pagesPE 009-16 GMP Guide (XAnnexes)Micheli Mayumi UnnoNo ratings yet

- Usp - 1116 - Usp 36Document11 pagesUsp - 1116 - Usp 36Jusuf Hasan100% (1)

- EU GMP Annex 1 Draft Proposes Expanded Guidance for Sterile Product ManufacturingDocument12 pagesEU GMP Annex 1 Draft Proposes Expanded Guidance for Sterile Product ManufacturingAntónio Ferreira100% (1)

- 2 Understanding Cleanroom Classification PDFDocument22 pages2 Understanding Cleanroom Classification PDFTECHNO DATENo ratings yet

- Ahu & Chiller OkDocument40 pagesAhu & Chiller OkAndy DwiNo ratings yet

- For Clean Room Technology: CablesDocument12 pagesFor Clean Room Technology: CablesalphiteNo ratings yet

- S209E and ISO Cleanroom StandardsDocument8 pagesS209E and ISO Cleanroom StandardsJawad HussainNo ratings yet

- STD-02-0860 Rev 5.0 Part Cleanliness StandardDocument8 pagesSTD-02-0860 Rev 5.0 Part Cleanliness StandardCARLOS A.N. LANZILLOTTONo ratings yet

- Conducting The ISO 14644-3 Cleanroom Recovery Test With The MET ONE 3400Document9 pagesConducting The ISO 14644-3 Cleanroom Recovery Test With The MET ONE 3400Mohammed S.GoudaNo ratings yet

- Gravimetric Determination of Nonvolatile Residue From Cleanroom GlovesDocument5 pagesGravimetric Determination of Nonvolatile Residue From Cleanroom Glovesjun floresNo ratings yet

- 17-08-24 AppliedBiosafetyMeeting PRAES Schmidlin GmuenderDocument32 pages17-08-24 AppliedBiosafetyMeeting PRAES Schmidlin GmuenderPulkitNo ratings yet

- AG-TCF-2-04. Manufacturing of Products 10.11 ClauseDocument26 pagesAG-TCF-2-04. Manufacturing of Products 10.11 ClauseKarina GorisNo ratings yet

- Technical and Qualification Issues: Alain KupfermanDocument65 pagesTechnical and Qualification Issues: Alain KupfermanHassan HoudoudNo ratings yet

- Particle Counting - Theory - Guidelines - Monitoring (05!09!16)Document214 pagesParticle Counting - Theory - Guidelines - Monitoring (05!09!16)mangthuy100% (2)

- 3HAC052982 PS IRB 14000-EnDocument126 pages3HAC052982 PS IRB 14000-EnJosé Manuel MoaNo ratings yet

- Particle Monitoring Requirements in Pharmaceutical CleanroomsDocument7 pagesParticle Monitoring Requirements in Pharmaceutical CleanroomsananthNo ratings yet

- Cleanroom CablesDocument12 pagesCleanroom CablesluisRuben medinaNo ratings yet

- Mann+Hummel: Air Filtration For CleanroomsDocument12 pagesMann+Hummel: Air Filtration For Cleanroomssani gozaliNo ratings yet

- BioburdenDocument95 pagesBioburdenTumma RamaraoNo ratings yet

- COMPLYING WITH CLEANROOM STANDARDS WITHOUT CONFUSIONDocument86 pagesCOMPLYING WITH CLEANROOM STANDARDS WITHOUT CONFUSIONursabu100% (6)

- Validation Master Plan Example - LongDocument31 pagesValidation Master Plan Example - LongJayesh kolheNo ratings yet