Professional Documents

Culture Documents

Elme 817 Spreader Parts

Elme 817 Spreader Parts

Uploaded by

Terry Malone0 ratings0% found this document useful (0 votes)

139 views73 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

139 views73 pagesElme 817 Spreader Parts

Elme 817 Spreader Parts

Uploaded by

Terry MaloneCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 73

SWEDISH

SPREADER

SYSTEMS®

MobeEL

817-18321

SERVICE AND Parts MANUAL

MANuaL No

1-2041

SE-343 22 ALMHULT

‘SWEDEN

Phone: +46 476 55.800

(© 2010 ELME Spreader AB

SERVICE MANUAL

SectionA User instruction

Section B Service manual

Section C Diagrams

PARTS MANUAL

Section D Mechanical parts

Section E Hydraulic parts

Section F Electrical parts

Section G Special parts

Section H

Revision records

ELME:= MODEL: 817 BUILD INDEX NO. 1-2041

Service manual build index

SECTION A USER INSTRUCTION

100-008 Driver instruction

100-089 User instruction lifting eyes

SECTION B SERVICE MANUAL

B110-198 Lubrication chart

B110-017 Maintenance instruction

B110-068 Servicing pensular twistlock

110-081 Extension cylinder service inst

B110-251 Twistlock indication and end beam adjustment

B110-302 Tightening torques

B110-324 Storage

8110-391 Tighten of wear pads

B9111 Description damping block

B9-134 Description rotation block

SECTION C DIAGRAMS.

€120-001 Hydraulic symbols

788 717 Hydraulic schematic

802 136 Wiring diagram

802 135 Electric schematic

802 137 Electrical device list

WARNING!

This spreader is equipped with a CAN-BUS type of control system.

The plug connecting the spreader electrical system to the control box must

ALWAYS be disconnected before any welding is performed on the spreader

or the machine that the spreader is mounted on.

The plug is removed from the controller (the controller is mounted on the

main frame) by lifting the metal lever and removing the plug completely from

the controller.

The cables of the orange coloured IN and OUTPUT boxes mounted on the

rotator should also be disconnected. This is done by removing the plastic

retainer and pulling the 10-pole rubber plug completely apart.

After finishing the welding operation the plugs should be reconnected in the

reverse order.

© 2010 ELME SWEDEN Tt0

ELME:=: MODEL: 817 BUILD INDEX NO. 1-2041

Parts manual build index

SECTION D MECHANICAL PARTS

D10-689 Main frame

D10-1144 Rotator assy.

D10-790 Wear pads.

D50-230 Pendular twistlock assy.

SECTION E HYDRAULIC PARTS

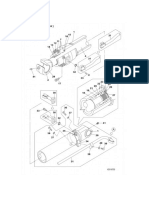

60-419 Extension cylinder assy.

60-187 Damping cylinder assy.

60-248 Damping cylinder assy. (power damping)

60-340 Sideshift cylinder assy.

70-525 Swivel assy.

E70-838 Valve assy, (sideshift)

£70-633 Valve assy. (extension)

E70-758 Valve assy. (swivel)

E70-784 Valve assy. (rotation/brake)

E70-510 Valve assy. (damp locking)

E70-511 Valve assy. (power damping)

E70-1138 Valve assy. (damping)

70-610 Parker fittings

£70-611 Hydraulic hose system

SECTION F ELECTRICAL PARTS

F80-323 ‘Sensor arr. (end beam)

F80-390 Sensor arr. (rotator)

F80-264 Electrical parts

F80-266 Indicator lights assy.

F80-348 Indicator LED-lights assy.

SECTION G SPECIAL PARTS (OPTIONAL)

690-121 Additional parts (hose clamp)

G90-152 tional parts (brackets for hoses and cables)

G90-216 tional parts (cover plate)

G90-226 ional parts (bracket for hydraulic body)

G90-285 ional parts (bracket for controller)

SECTION H REVISION RECORDS

© 2010 ELME SWEDEN Tt0

SECTION

A

USER INSTRUCTION

USER INSTRUCTIONS A tooee

ELME CONTAINER SPREADER

Model No. 817

DRIVER INSTRUCTIONS

The ELME Model 817 Container spreader is a technically advanced piece of equipment

which, if itis carefully used and maintained will serve its purpose for many years

Initial check.

Each work shift should be started by making a visual check of the unit (this must be part

of the daily routine.) Possible damage will in this way be discovered at an early stage

thus enabling repairs to be carried out at much lower cost.

NEVER USE THE UNIT UNLESS ALL SAFETY DEVICES FUNCTION

CORRECTLY!

CONTAINER HANDLING

1. Starting work with the spreader.

First of all the length of the spreader must be adjusted to the size of container that is.

required to be lifted, This is done by retracting the stops (if fitted) and then activating the

extention lever or button in order to extend or retract the spreader beams to the desired

length

NOTE! It is important to remember that loads should only be lifted at the specified

lengths for which the spreader is designed i.e. 20ft. 30ft. 35ft. 40ft and in some cases

45ft. Where stops are fitted the stops should be used to position the beams accu-

rately at one of the above mentioned positions. If the spreader is not equipped with

stops then the spreader may only be used for lifting 20 and 40ft. containers. Li

outside the specified positions can result in serious damage to the spreader.

When the required length has been reached , lift the spreader high enough to give good

visibility under it. This serves two purposes, 1 it gives good visibility for travelling and 2 it

positions the spreader ready for picking up the first container. The spreader should now

be side shifted to the center position and the reach function operated to the fully retrac-

ted position. This will be termed "THE BASIC POSITION” in the rest of the instruction,

2. Picking up a container.

If necessary raise the spreader in order to have plenty of space between it and the con-

tainer. Always attempt to position the spreader centrally over the container.

The final adjustments for lining up the twist locks with the corner castings of the contai-

ner can now be made,

(© 2002 ELME SWEDEN 05-02

Pre no

‘A.100-008-2

ELME=:

USER INSTRUCTIONS

By using the controls for shift and reach, position the spreader accurately over the

comer castings and then lower the spreader into them. If the twist locks or some of the

twist locks do not fit into the comer castings properly, CAREFULLY lift the spreader just

free of the container, readjust its position and the try again. NEVER PUSH OR SIDE

SHIFT while any of the twist locks are still engaged in the corner castings of the contai-

ner. When all the twist locks are correctly engaged in the comer castings the spreader

should be lowered until it rests unsupported on the container, this is termed as the

spreader being correctly SEATED, and this will be indicated by the SEATED LIGHT be-

ing switched on. As soon as this happens the twist locks can be activated to the locked

position and the LOCKED LIGHT will be switched on.

CHECK THAT THE "LOCKED” LIGHT HAS BEEN SWITCHED ON and then lift the

container to the required height for loading and/or travelling. Before moving the contai-

ner, return the spreader to the "BASIC POSITION". The container is now ready to be

transported to a new location. When travelling always keep the load at the lowest pos-

sible height and drive carefully

3. Detach a container.

When approaching the new location for the container (this could be a chassis or a stack

etc.) lower the container to the required height and adjust the position of the corner cas

tings so that they are accurately situated above the corner locks of the chassis. Lower

the container ensuring that its comer castings locate on the comer locks.

NEVER USE MORE TILT THAN NECESSARY AND NEVER PUSHI!!

WARNING!!! A heavy container and the weight of a spreader will do serious

damage to a trailer or chassis if not handled with care.

The twist locks may now be activated to the "UNLOCKED" position, the spreader lifted

free of the container and the truck backed away.

4, General advice.

- Always adjust the spreader back to the "BASIC POSITION” after every handling cycle.

- When parking the truck and spreader or when they are not in use for longer periods of

time, always make a habit of lowering the spreader to its lowest position.

- Read all instruction books carefully and be sure that you understand them.

- Should there be anything you do not understand, then contact your local dealer who

will ensure that all your questions are answered.

(© 2002 ELME SWEDEN 05-02

USER INSTRUCTIONS Atos

Instructions on the safe use of the various types of lifting

eyes that an ELME spreader can be equipped with.

Acontainer spreader was initially designed for lifting containers and the calculations

used for the design, take into account a certain amount of uneven distribution of the

loads inside the container. The criteria that is used is, that the center of gravity (the

load) can be offset from both the axial and transvers center-lines by a maximum of

10%. This fact is also valid when lifting loads from the lifting eyes mounted on the

spreaders end beams.

Another limitation when using the lifting eyes mounted on the end beams, is

that the loads may only be lifted at the specified lengths for which the spreader

is designed ie. 20ft. 30ft. 35ft.40ft and in some cases 45ft. Where stops are fitted

(Optional) the stops must be used to position the beams accuratly at one of the

above mentioned positions. If the spreader is not equipped with stops then the

spreader may only be used for lifting at the 20 and 40ft. positions. Lifting out-

side the specified positions can result in serious damage to the spreade!

Standard lifting eyes welded to the inside surface of the spreader end beam close to

each twist lock, Various designs of lifting eyes can be fitted see below.

Fig 4 f Fig2 Fig3

The main frame can be equipped with 2 lifting eyes centre mounted or 4 lifting eyes.

which can be spaced equally on each side of the spreader centre line at various dis-

tances. Various designs of lifting eyes can be fitted see below.

Fig 5 Fig 4

Common for all lifting eye combinations fitted during the production of the spreader is

that their collective capacity is the same as the capacity of the spreader. For example

a spreader with a total lift capacity of 40 metric tons with 4 lifting eyes fitted to the

main frame, can lift 40 metric tons with the load evenly distributed between all four

lifting eyes.

Note the max. capacity for the open hook Fig 5 is only 12.5 metric tons therefore

in the case of only 2 hooks being fitted in the center position on the man frame

then the total capacity will only be 24 metric tons,

© 2008 ELME SWEDEN '03-08(07-08)

Pre no

AM

Load evenly distributed on four Load evenly distributed on two

lifting eyes

I

fa Le

NTT

Ideally the load should be lifted with the lifting slings vertical between the lifting eyes

and the load (90° to the underside of the spreader). However the slings can be at-

tached to the load with a negative angle (less than 90°) but the smaller the angle the

lower the load that can be lifted.

The lifting eyes should never be used to lift a load with the lifting slings at a positive

angle (greater than 90° angle to the underside of the spreader) however if a damaged

container needs to be lifted with slings then this is acceptable

7 J 7

P14 Max = Spreader

P2 Max 7,500Kg

© 2008 ELME SWEDEN 103-08;07-08)

SECTION

B

SERVICE MANUAL

Pace no

B 110-198-1

ELME=:

MAINTENANCE INSTRUCTIONS

LUBRICATION CHART

for Model 817

41 SuingR Pans EXTENSION

2 Twist Loc

3 Extension cvuNoER

4 Srors|

5 SuDER PADS SIDE SHIFT

6 SLewIc RING BEARING AND GEAR

7 Sipe SHIFT evuNDERs

8 Siew GEAR 20x AND BRAKE

WHERE GREASE IS RECOMMENDED USE (See iNowoun. orscarion oF

MULTI PURPOSE GREASE (EP2) EACH LUBRICATION POINT.)

POSITION 1

WEAR PADS FOR MAIN BEAMS AND EXTENDING BEAMS

NO, OF GREASE POINTS 24,

INTERVAL - EVERY 500 HOURS OR 3 MONTHS.

6 TRACKS ON EACH EXTENDING BEAM,

6 TRACKS ON THE INSIDE OF EACH MAIN BEAM,

(SEE ARROWS "A" AND "8" )

LUBRICANT - MULTI PURPOSE GREASE

(© 2002 ELE SWEDEN (05-10(11-03,12-02,05-02)

ELME=:

POSITION 2

END BEAMS AND TWIST LOCKS.

NO. OF GREASE POINTS 8

INTERVAL - EVERY 500 HOURS OR 3 MONTHS.

1 GREASE NIPPLE IN EACH END BOX.

1 GREASE NIPPLE IN EACH SLEEVE

LUBRICANT - MULTI PURPOSE GREASE

MAINTENANCE INSTRUCTIONS

Pre no

B 110-198-2

POSITION 3

EXTENSION CYLINDER SUPPORT WEAR PADS

‘AND TRACKS.

INTERVAL - EVERY 1000 HOURS OR 6 MONTHS

NO. OF GREASE POINTS 4

2 TRACKS IN EACH EXTENSION BEAM.

LUBRICANT - MULTI PURPOSE GREASE.

OPTIONAL

POSITION 4

STOP CYLINDERS, —

NO. OF GREASE POINTS 2 ey!

INTERVAL - EVERY 500 HOURS OR 3 MONTHS.

POINTS. 1 GREASE NIPPLE ON EACH STOP CYLINDER.

LUBRICANT - MULTI PURPOSE GREASE (EP2)

LOCKING PLATE

INTERVAL - ON A REGULAR BASIS OR EVERY 3 MONTHS.

MULTI-PURPOSE GREASE WITH

2-4% MOLYBDENUM DISULPHIDE ADDITIVE (S2).

LOCKING PLATE

© 2002 FLME SWEDEN

(05-10(11-03,12-02,05-02)

Pace no

B 110-198-3

cLME=

LUBRICANT - MULTI PURPOSE GREASE.

POSITION 6

NO. OF LUBRICATION POINTS 6.

4 GREASE NIPPLES POSITION "A" MOUNTED AT A Fl

ONE CENTRAL POINT ON THE UPPER ROTATOR

FRAME PLATE FOR GREASING THE BEARING.

2 HOLES AT POSITION "B" IN THE STOP BLOCKS:

FOR SPRAYING LUBRICATION ONTO THE GEAR

RING WITH A SPRAY CAN OF SPECIAL GREASE.

LUBRICANT. - “AY MULT! PURPOSE GREASE.

XPOSED GEAR LUBRICANT

WITH ADHESIV AND EP ADDITIVE

POSITION 7

SIDE SHIFT CYLINDER BEARINGS.

INTERVAL - EVERY 500 HOURS OR 3 MONTHS

NO. OF GREASE POINTS 4.

2. GREASE NIPPELS ON EACH CYLINDER TUBE BEARING.

LUBRICANT. - MULTI PURPOSE GREASE

POSITION 8

SLEWING GEAREOX (2 off)

NO. OF POINTS - 2,

INTERVAL - CHECK OIL LEVEL EVERY 100 HOURS OR_ MONTHLY.

CHANGE OIL AFTER THE FIRST 50 HOURS OF

OPERATION AND THEN EVERY 2000 HOURS OR YEARLY.

POINTS. - PLUG "A" IN ELBOW AT TOP OF GEARBOX = FILLER -B

AND EVEL PLUG

PLUG 8 INTHE BOTTOM OF THE BOX = DRAIN PLUG.

LUBRICANT. - SAE 90 GEAR OL,

© 02 EME SWEDEN TEHO( 0812000572)

Pre no

B110-017-1

ELME=:

MAINTENANCE INSTRUCTIONS

GENERAL MAINTENANCE INSTRUCTIONS,

1, = The nylon wear pads should be inspected for wear at the same time

as their tracks are lubricated, The pads should be replaced when their

thickness is reduced to minimum 18 mm.

Replacing the wear pads can be done with ordinary hand tools and

without removing the beams.

Minimum thickness 18 mm

2. = Twist locks are wearing parts and need inspecting on a regular

basis. Lubrication of the twist locks is recommended at monthly

intervals and it is also recommended that they are inspected for

wear and damage at the same time.

| | Wear max. 6mm.

|| |

=p

Should be replaced if this

dim. is less than 25mm

The drawing above shows where the heads of the twist locks

wear. When the worn part exceeds the area indicated by cross

hatching the twist locks should be replaced.

Generally it is recommended that twist locks be replaced after a

max. use of 5000 working hours or 80 000 TWL-cycles,

© 1862 ELME SWEDEN 11-10(05-03,17-92)

ELME=:

Pre no

B110-017-2

MAINTENANCE INSTRUCTIONS

The extension cylinder support has wear pads under it. These should also

be inspected on a regular basis and replaced when their thickness is

reduced to minimum 18 mm. See item 1.

Maintenance of the stop cylinders if fitted, consists of checking all mounting

bolts for tightness and inspection for leakage from the cylinder.

The side shift wear pads should be inspected for wear at the same time as

lubrication is carried out. The wear pads should be replaced when their

thickness is reduced to minimum 18 mm. See item 1

Other recommended spreader maintenance is:

a- Inspect the main spreader components for damage, cracks and distortion.

b- Check the signal and safety systems for correct operation.

¢- Check the hydraulic pressures periodically.

d= Check all hydraulic cylinders for leakage and reseal if necessary.

e- Inspect all hydraulic hoses for damage and leakage. Replace if faulty.

© 1862 ELME SWEDEN

11-10(05-03,17-92)

| ELME = | MAINTENANCE INSTRUCTIONS

SERVICING THE PENDULAR TWISTLOCK

2

The tie-rod is a fixed unit and is not adjustable,

To remove the tie-rod proceed as follows:

1 Remove the Locked / Not locked sensor bracket (item 1).

2 Loosen one of the adjuster bolts at the twistlock cylinder, enough to give some play.

3 Loosen and remove the Mé x 80 bolts (item 2) in the top of both twistlocks in the

‘same end beam,

4 Use two of the M8 x 80 bolts (item 2) as pullers by inserting them in the two threaded

holes (item 3) in each of the cranks (item 4) and tighten them alternatly until they lft

the cranks (item 4) off the top of the twistlock shaft (item 5)

5 The tie-rod (item 6) including both cranks (item 4) can now be removed from the

end beam,

To remove the twistlock and sleeve proceed as follows:

6 The key (item 7) that locates the crank (item 4) to the twistlock (item 5) is held in

place on the twistlock by a roll pin so that it will remain in place on the twistlock after

the crank is removed.

By lightly knocking the key away from the twistlock it can be removed.

© 1087 ELME SWEDE

108-00(08-88, 05-88, 08-87)

| ELME = | MAINTENANCE INSTRUCTIONS

7 Support the twistlock (item 5) from below so that it does not drop out.

Using a screwdriver prise the collets (item 8) out of the recess in the twistlock (item

5). Itis now possible to lower the twistlock out of the end beam. The sleeve (item 9)

and lower bearing set (item 10) will in most cases accompany the twistlock as itis

removed, this is quite normal.

INSPECTION PRIOR TO REASSEMBLY

8 After removal of all twistlock parts remove all grease and dirt from the parts and also

from the corner of the end beam, Steam clean or clean with some form of solvent.

9 Check the twistlock (item 5) for wear at the head and also for wear at the bushing

surfaces. Inspect the lower (item 10) and upper (item 11) bearing sets for wear and

damage, if badly wom or damaged they should be replaced. The collets (item 8) and

and the crank (item 4) should be inspected for possible wear or damage and replaced

if necessary.

It should be noted that the state of the collets (item 8) and the recess in the

twist lock (item 5) is very important as these parts are carrying the load when a

container is lifted.

REPLACING / FITTING TWISTLOCKS

10 Replacing the twistlock is the revers order of removal, however the best way to start

assembly is to assemble the sleeve tem 9) including bushes, onto the twistlock (item

5) and then grease the lower bearing set (item 10) and place in position on top of

the sleeve, Fit the four centering springs in the sides of the sleeve.

11 Grease the upper bearing set (tem 11) and place in position on the top surface of the

comer plate (in the end beam) with the convex half uppermost (threaded holes up)

12 Lift the twistlock assy, as assembled in point 10 and position up through the comer

plate in the end beam, ensuring that the upper bearing set (item 11) is positioned

correctly around the twistlock. Support the assembly with a jack or other means and

then go to the next point,

13. Fitthe collets (jtem 8) with the pointed part upwards.

14. Fit the key (item 7) incl. roll pin to the keyway of the twistlock (item 5)

15 In order to fit the tie-rod (item 6) itis necessary to mount both cranks (item 4) to the

tie-rod before placing it in the end beam. Fit the ball joints, O rings, and plastic

washers to the tie-rod ends and then fit the fork of the crank (item 4) over the tie-rod

‘end. Ensure that the countersunk ends of the securing holes in the crank are upper

most. Secure the crank to the tie-rod end by fitting the pin (tem 12) and then the ring

pin and allen screw.

16 _ In order to simplify assembly of the crank to the twistlock it is advisable to fit two

alignment pins to the assy. The pins can be made from two M8 x 75 bolts or allen

screws with the heads removed and slightly chamfered

‘These pins should be screwed into the top plate of the upper bearing (item 11)

diagonally so that each pin guides one half of the collets (item 8)

© 1007 ELME SWE 108-00(08-88, 05-88, 08-87)

| ELME = | MAINTENANCE INSTRUCTIONS

17 Insert the tie-rod (item 6) into the end beam and the fit the cranks (item 4) onto the

alignment pins and ensure that the key and keyway line up. Fit two of the allen

securing (item 2) in the remaining two holes and screw in and tighten lightly. Remove

the alignment pins and fit the other two securing screws. The securing screws can

now be tightened to approx. 25 Nm.

18 Activate the twistlocks to the NOT LOCKED position and then adjust the twistlock

cylinder adjuster bolts so that the twistlocks are positioned accuratly in the NOT

LOCKED position, Ensure that there is Zero play between the adjuster bolts and the

twistlock cylinder rod ends.

19 Grease the complete assembly with a high-pressure grease gun.

In order to test the operation it is necessary to land the spreader on a container so that the

seated pins are activated.

© 1007 ELME SWE 108-00(08-88, 05-88, 08-87)

Pre no

B 110-081

ELME=:

MAINTENANCE INSTRUCTIONS

Removal and fitting instructions

for the spreader extension cylinders.

| ———

1 | |

B Fig 1 c

A Extension beams

B Extension cylinder

C Inspection hole

D_ Hose / Cable chain

1 Retract the spreader to the 20ft position

2 Before removing the securing pin pos.1 of the extension cylinder it must be

supported by a small hydraulic jack or likewise so that the cylinder pos. B does

no fall down,

Remove the pin from the rear of the cylinder fig1 pos 1 (opposite end to the

piston rod) and at the same time also remove the hose and electrical

connections at the rear of the extension cylinder pos. B. The securing bracket

that secures the cable chain to the track in the bottom of the extension beam

should also be disconnected

3. Byusing a crane or forklift truck pull the end beam pos. A out approx. 50cm so

that it is just possible to get into the inspection hole pos.C in the top of the beam.

4 Remove the pin from the piston rod end of the extension cylinder.

5 The extension cylinder pos. B can now be lifted out of the spreader by sliding it

horisontally with the help of suitable lifting equipment, (by "suitable lifting

equipment" is meant that the crane or truck must be capable of lifting 150kg.)

until the slider pads slide out of the rail by which the foot of the cylinder is guided.

6 Replacing the cylinder is the revers procedure of the removal.

‘© 2002 ELME SWEDEN 05-02

ELME

Pace no

|TWISTLOCK INDICATION AND ENDBEAM ADJUSTMENT] 54 10.067-1

Proximity switch / Sensor

Pa Proximity switch / Sensor

4 bracket

~ Mounting surface

ft

|

70 8mm

810mm

Distance from landing surface

to underside of seated pin

\

\

Landing surface of end beam

1, Check that the SEATED PIN can move up and down freely. The force needed to lift the pin

is approx. 10 kg (20 Ibs).

2. The SEATED signal should switch on with the pin protruding approx. 9mm below the landing

surface of the end beam

3. if adjustment of the proximity switch / sensor is necessary, remove the seated sensor

mounting bracket incl. sensor from the top of the seated tower, and adjust the proximity

switch / sensor so that the end surface is 7-8 mm above the lower mounting surface of the

bracket. This adjustment will result in the seated pin indication being switched on when the

underside of the seated pin is approx. 8 to10mm lower than the end beams landing surface.

This adjustment also ensures that the mechanical and electrical lockout is released so that

the twistlocks can be tured

© 7008 ELME SWEDEN (02-05(08-04,09-03,05-03)

Pace no

B110-251-2

ELME

HTWISTLOCK INDICATION AND ENDBEAM ADJUSTMENT]

‘TWISTLOCK ANGLE ADJUSTMENT

1. Tum the twistlocks (pos1) to the fully UNLOCKED position (as shown)

2. Ifthe twistlock heads do not line up with the twistlock sleeve, they can be adjusted by

loosening the lock nuts (pos §) for the adjuster bolts (pos 2)

3, Turn the twistlocks at each end of the end beam so that they line up with the sleeves, if it

is found difficult to line up the twistlocks and sleeves accurately distribute the

misalignment equally on both sides of the sleeve. Make sure that the twistlock heads

DO NOT protrude outside the the theoretical line between twistlocks, If the twistlocks do

protrude outside the previously mentioned line between the twistlocks it can cause

jamming in corner castings as the spreader is lifted off the container.

4. Run both adjuster bolts (pos 2) up to the piston rod (pos 4) ends of the twistlock cylinder

(Pos 3) by hand making sure that neither the twistlocks nor the cylinder are moved.

Tighten the lock nut (pos Sa) ofthe inside adjuster (pos 2a) first,

5. Unscrew / back off the outer adjuster bolt (pos 2b) no more than 2 flats of the hexagan

head (60°) so that there is only just enough play to allow the tie rod (pos 6) to slide back

and forth across the adjuster bolts when the twistlock cylinder (pos 3) is activated.

CAUTIONiifthe gap between the twistlock cylinderrod endsis toolarge the rod ends will

hammer against the adjusters and subsequent damage will occur to the piston rod ends.

6. Tighten the lock nut (pos 5b) securely while at the same time ensuring that the adjuster

bolt (pos 2b) does not move.

7. Activate the twistlocks to the LOCKED position and check that the twistlock heads are

90°. 10°to the twistlock sleeve.

© 7008 ELME SWEDEN (02-05(08-04,09-03,05-03)

ELME=:

TIGHTENING TORQUES

Recommended standard torque values in Nm, for electro plated hardware.

In order to obtain the correct torque values, a reliable torque wrench should

always be used and the threads should be dry.

Pace no

B 110-302

Metric TaReAos (COARSE) Bour Quaury Bott Quay $S-4SO 898/4

88 10.9 129

SIZE (wn) Nat Now Not

5 55 78 93

6 94 8 16

8 23 32 38

10 45 63 76

12 78 110 131

14 123 174 208

16 189 266 320

18 264 370 444

20 370 519 623,

22 497 699) 839

24 638 898 1075

30 1257 1766 2121

36 2189 3081 3696

Note! The slewing ring hardware is Dacrolite coated,

Recommended torque value is 898 Nm.

(© 2005 ELME SWEDEN

(07-06 (03-05)

ELME=:

STORAGE OF SPREADERS

Storage of ELME spreaders where it is necessary to have the spreader

standing outside for periods longer than 3 months

When storing an ELME spreader for longer periods of time, the following precautions

should be taken:

All chromed piston rods must be activated to the closed position so that the

rods are stored inside the cylinder where this is possible.

If tis not possible to retract the rod into the oylinder (for example the twistlock

cylinders) then the exposed part of the chromed rod should be sprayed with a

rust inhibitor similar to, for example "Tecty!"

CAUTION! Efficient rust inhibitors often dry with time and should therefore be

removed by a solvent before using the spreader again. Failure to do this can

cause damage to the sealsof the oylinders with subsequent leakage to follow.

All grease points must be pumped full of molybdenum saturated grease.

The hydraulic tank should be filled to 80% of its total volume with clean

hydraulic oil, in order to reduce uncovered areas inside the tank, on which

condensation can form.

Grease all sliding surfaces by brushing on a suitable layer of grease.

Where possible it would be advisable to equip the electric box with a heater

(this could be a small electric bulb for ex. 40 watt which is allowed to burn

constantly) and if the hydraulic tank is equipped with a heater it would be

advisable to have it connected during the spring and autumn months

Spray all electric connections both inside and outside of the box with a self-

drying lubricant. This will efficiently protect electric connections against

corrosion

Parse no

B 110-324

(© 2005 ELME SWEDEN

0208

ELME=:

wc

‘Toagiust the damping force:

Sorew adjuster on cartridge No.1 in to increase the dam-

ping force when piston is pressed inwards, and screw

the adjuster out to reduce the force. Screw the adjuster

‘on cartridge No. 5 in, to increase the damping force

when the piston is extended, and screw the adjusting

screw out to reduce damping force.

Item list

Flow control valve

Relief valve Setting: 80 Bar

Cylinder port

Tank port connected to tank line

Flow control valve

Relief valve Setting: 80 Bar

Cylinder port

DESCRIPTION OF DAMPING CYLINDER,

SPREADER MODEL 817, 857

Pace no

Bott

© 1902 ELME SWEDEN

04-97(05-82)

10

2

B

14

5

ELME=:

ITEM Uist

Solenoid valve

High speed

Low speed

Solenoid valve

Solenoid valve

Drain port

Brake port

Brake port 2

Relief valve

Relief valve

Motor port 4

Motor port 2

Pressure line

Relief valve

Tank port

DESCRIPTION OF DUAL SPEED ROTATION BLOCK

Aajustment of the inital low speed rotation

‘To alter the intial speed of rotation, turn the adjuster on cartridge no 3,

clockwise to decrease speed and anti-clockwise to increase speed.

Agjustment of high speed rotation

‘To alter the high speed of rotation, tum the adjuster on cartridge no 2,

clockwise to decrease speed and anti-clockwise to increase speed.

Agjustment of rotation motor pressure

‘To alter the rotation motor pressure, turn the adjusters on cartridge nos 9 and 10 clockwise to

increase the pressure and anti-clockwise to decrease the pressure.

Rotation direction

Flow control valve

Flow control valve

Rotation speed

Brake release

Setting (80 bar)

Setting (80 bar)

Setting (40 bar)

Parse no

89134

© 2002 ELME SWEDEN

05-02

SECTION

C

DIAGRAMS

10.

"

12,

ELM!

Pump

(variable displacement)

Motor

(fixed displacement)

Pressure relief valve

(normally closed)

RPEC-FAN

‘Sequence valve

4 Gohay canoe)

so LAN

PBDB-LAN

Pressure reducing valve

(normally open)

by

CBCA-LHN

Load control valve

(counterbalance)

© Checkvalve

CXDAXCN

cso0s

GVH 103 >

4. Check valve

% (plot operated)

cKCB-XCN

dea, Chock valve

(plot operated

cong (Plot operated)

Flow control valve

(fully adjustable)

NFCC-LON

NV 101S

Flow control valve

ZT (fully adjustable with

Ncce-LoN verse fee flow check)

‘9F600S

FM2DDKN.

ae

BF Flow contr vai

ZT Gully adjustable,

FDCB-LAN pressure-compensated

with reverse free flow check)

HYDRAULIC SYMBOLS

3

14

16.

16,

17,

18.

19.

20,

24

22.

23,

24

28.

26

21.

28,

29,

30,

ACCORDING TO ISO STANDARD

Lo

Pace no

© 120-001

Directional valve

(single solenoid, 2 positions)

Directional valve

(single solenoid, 2 positions)

Directional valve

(single solenoid, 2 positions)

Directional valve

(Gouble solenoid, 2 positions,

without spring)

Directional valve

(double solenoid,

spring centred)

3 positions,

Directional valve

(double solenoid,

spring centred)

3 positions,

Directional valve

(double solenoid,

spring centred)

3 positions,

Directional valve

(double solenoid,

spring centred)

3 positions,

Main tine

Pitot line

Closed connection

Connection point

Crossing point without connection}

Filter

Double acting cylinder

Pressure

Tank

Components range

(© 2003 ELME SWEDEN

0503

ig

ue eat] «(=| ABER

S| i (8 a =

if bee iol]

om

tr et

san

5 |CeD-panet

g wasmige!

17 Lanett

Dect schematic dog: see coving 602 136,

J

"802 1368

SET 208 FTO TOTEATIT

TE ERIE]

= one ww ‘auwa] aaa

e, {70)Si.0 XO%|HE

[10 XO% HE

ale KOM HAAE

96) 208 40 Bumesp 385 syeUaPS

ores

802 135

wom

er OHO

Fy pizooxoxarea

‘ SO XOR ha

rar KOR

vn VAR LO KIB [OE |g —2—gg§ eh $9] | 92 rs

¥/18| 900 xi T Sy | eo es

wrateoe need oT pe

meal} A ‘amen

soemnearatt | mines

if it nn

ii aa xe spe

ht ¥_OND

= a Sor fe

SEL 208

0h

se

* sae pase

Larosa wt prnen GG veneers 4

(on x2) om ty Ble tone ale

gee pe, a

"802 135

ay

Wwe FE

wom

Ke

SEL 208

%

iF

SOUS)

smeg) Nate

802 135

wap] ao oI

i

Instruction

A [LED-panel

09-03-03] AF [1066

For effective part ordering the order must include:

1 Part number

2 Coole

3 Serial nr. of Spreader

4 For the co

oller with program see el

ric schematl

7a 507 [var vo Je [table ass

rea 507 [ysi-v53 [2 _Itobie ass

762 098 xe 28 |terninat wou 28

764 466 [x2 1 frerrinat wou 10

762300 veaa2 |e _|tana nao

763300 |veave2 [2 [adopter wae/naa

ea 550 |yea 1 [e4-pn fenale insert

769206 [yea 1 [e4-pln cabie plug 62

762 165 lve 1 [cover 24-pin socket

760 548 |va2 1 ee-pin rote insert

763 204 luee 1 [espn socket mae

762603 [us 1 [ouryptuog S=nin

762 529 [us 1 [thassiptuag Spin

769 258 |. 1 foiana 25

762 164 | 1 |cover_16-pin socket

760 521 [ws 1 lis-pn nate insert

768288 [ut 1 h-pin socket 2x05

763.757 [wane [2 [working ght

763.757 |wa4u4 |e [working ght DeTION

01 300 |cobie 45 size 1

763 921 |cabie 41 tfiex 10 NR 85

761401 _[siese 2 [sensor S-Si6

723 586 |siasi@ [2 [table to sensor 03n

7a6 609 [s1546 2 loable to hternesiate stop 2m

rai 252 |sppaa [2 Harness

rai 496 [sppse |e _IHorness

7a 435 [sone 1 Morness

762 696 |vs-vid [4 [table to solenoid Om

762602 [cont 1 [oan controter 960 cR0020 _[Progran, see schenadie

723 358 Nove 23 [1 [1/0 nodue SpB 23

704754 Node 24 |r__[/0 nodue spb 24 option)

76417 [3 1 [Light panes ELME

el 698 [La 1 [Pox cenpiy>

02 188 1 harness with connector

Part nmber | tove | Oty Part nine Wore

Saar aay [inset ives 36

rT Bill of material ee __vi P*8-03-04

ELMHULTSKONSTRUKTIONS AB] 817 SMV CAN-bus 802 137A

SECTION

D

MECHANICAL PARTS

Pace no

D 10-689

ELME=:

Main FRAME

rvs ARE FOR A COMPLETE SPREADER

Note|tem| Partno | Qty] Partname

1 | 760337 | 12 | Bor MéS M6x25

2 | 741179 | 4 | stip

3 | 741178 | 4 | Cover

4 | 760950 | 12 | Nut Mem 6

5 | 740726 | 2 | Pin

6 | 761122 | 2 | Cotterpin

7 | 760564 | 2 | Washer

8 | 740677 | 2 | Bracket

9 | 760917 | 12 | Nut M12 Locking

10 | 761950 | 12 | Washer

+t | 760309 | 12 | Bot Mes M12x55

e) fiz 2 | Extension cylinder assy.

x) 740726 | 2 | Pin

x) 761122 | 2 | Cotter pin

x) 760564 | 2 | Washer

bd) |13 2 | Pendular twistlock assy.

pb) [14 2 | Wear pads

D) See section D

E) See section E

x) Mounted in opposite end of the ext. oyl

© 2002 ELE SWEDEN '06-08(10-07,01-04,02-03,05-02)

35

22.21

46

47

37 38 39 40

Rotaror assy.

i)

23 24 252627

41 42!

48

Pre no

D10-1144-1

28 21.22

© 2010 ELME SWEDEN

08-10

‘ea Pre no

ELME®: ane

Note|item | Partno | ty | Part name

1 | 7er626 | 4 | Bor MBS 10 x 90

2 | 760301 | 12 | Washer

3 | 771877 | 1 | Bracket

4 | 760927 | 6 | Nut M10 Locking

H» | 5 1. | Valve assy. (swivel)

6 | 760250 | 2 | O-ring

5» |7 + | Sviwel assy,

x) | 8 | zettt | 4 | Hydraulic motor

9 | 761463 | 1 | Key

10 | 760983 | 8 | Screwallen Mcés 12x30

11 | 760557 | 8 | Washer M12 Nordlock

| 12 1. | Valve assy. (rotation/brake)

13 | 763092 | 1 | Cover

y) | 14 | 763084 | 2 | Transmission

15 | 782172 | 1 | Bracket

FR /18 1. | Spiter box.

17 | 761815 | 20 | Bolt MéS 16 x60

18 | 761907 | 20 | Washer M16 Nordlock

19 | 759818 | 2 | Key

20 | 770794 | 2 | Nutring

21 | 760556 | 36 | Washer M10 Nordiock

22 | 762772 | 36 | Bot MBS 10 x 25

F) [23 X | Sensor

24 | 761807 | 2 | Bracket

25 | 7e2e4a | 2 | Top plate

26 | 760585 | 4 | Washer M6 Nordlock

27 | 762246 | 4 | Screw allen MCBS 6x 55

28 | 759718 | 2 | Coverplate

29 | 763380 | 59 | Bott MBS 24 x 190

30 | 760380 | 52 | Bot MBS 24 x 160,

31 | 761813 |222 | Washer

32 | 760910 | 111 | Nut Mas

35 | 761469 | 1 | Slewing ring

36 | 743874 | 8 | Nylonpad

749.007 | x | Shim

749.008 | X | Shim

7ago09 | Xx | Shim

749.010 | X | Shim

37 | 744793 | 8 | Plate

38 | 760511 | 16 | Rollpin

39 | 760314 | 24 | Bott MBS 20 x 100

40 | 724704 | 4 | Housing

at | 745101 | 4 | Key

42 | 760901 | 12 | Screw allen Mces 8x 16

43 | 761812 | 24 | Washer

44 | 760959 | 24 | Nut M20

45 | 754900 | 2 | Pin

48 | 771438 | 2 | Ring

47 | 760922 | 2 | Nut M36

e) [48 2 | Side shit cylinder assy.

49 | 771059 | 2 | Pin

so | 760991 | 2 | Bot MBS 10 x 80

si | 7er649 | 1 | Bracket left

52 | 7e1648 | 1 | Bracket right

53 | 7e3si1 | 4 | Bott MBS 12 x 45

54_| 760557 | 4 | Washer M12 Nordlock

E) See section E x) Use seal kt’ 790 969 for Chart Lynn type of motor

F) See section F Use seal kt 791 077 for Ross Parker type of motor

VY) __Use sealkit 791 083

© 2010 ELME SWEDEN

08-10

Pace no

D 10-790

ELME=:

Wear pans

SUPPORT RING OF

MAIN FRAME

2 oY \ <

| " =" REAR SUPPORTO}

EXTENSION BEAM

‘Multiply Qtys by 2 for a complete spreader

Note] tem | Part no | aty | Part name

1 | 760309 | 6 | Bow M6S 12x55 10.9

2 | 760557 | 6 | Washer M12 Nordlock

3 | 744928 | 1] Shim

4 | 743.983 | 10 | Wear pad

5 | 762772 | 30 | Bort MBS M10x25 10.8

6 | 760368 | 30 | washer M10 Nordlock

7 | 771507 | 6 | Retainer

8 | 743510 | 2 | Wear pad

9 | 776369 | 1 | Retainer

10 | 776368 | 1 | Retainer

1t_| 776367 |_1 | Retainer

© 2002 ELME SWEDEN (08:08(03-04,08-03,10-02,08-02)

Pace no

esa

32

‘© 2002 ELME SWEDEN '08-09(085-08 08-06, 10-04,05-04,09.05,02.08, 12-02, 10-02,09-02,06-02,05-02)

ELME=:

‘Multiply Qtys by 2 for a complete spreader.

PeNDULAR TWISTLOCk ASSY.

Pace no

D50-230-2

Note| tem | Part no

ty

Part name

1 | 752652

2) | 2 | 779280

2) | 3 | 779281

2) | 4 | 761908

FR | 5

2) | 6 | 760489

2) | 7 | 760926

2) | 8 | 760927

2) 761 903

2) | 3 | 760950

2) |10 | 760 908

s) | 11 | 752651

12 | 760379

13 | 760 969

14 | 760 556

15 | 760 907

2) | 16 | 760 5e6

z) [17 | 762849

z) | 18 | 761 897

19 | 762.864

20 | 760 556

21 | 758 134

22 | 763.377

23 | 760 927

24 | 758 133

25 | 762.848

26 | 758 132

a7 | 762 175

28 | 760.291

29 | 758131

30 | 70.368

x) [31 | 760511

32 | 752.626

33 | 754.760

x)_[34 | 760 901

Tie rod

Bracket

Sensor bracket

Bolt MBS M10x45 8.8

Proximity switc

Washer

Bolt M6S M10x40 8.8

Nut M10 Locking

Washer

Nut Mé Locking

Bolt MBS M6x60 8.8

‘Twistlock cylinder assy.

Roll pin

Bolt MBS M10x25 8.8

Washer M10 Nordlock

Bolt MBS M6x35 8.8

Washer ME Nordlock

Washer

Bracket

Bolt MBS M10x65 8.8

Washer M10 Nordlock

Bracket

‘Screw allen MCBS 12x150 12.9

Nut M10 Locking

Indicator

Spring

Bracket

Spring

Screw allen MCS M12x90 8.8

Rod

Seated tower

Roll pin

‘Seated pin

Pin

Sorew allen MLC8S M&x16 8.8

‘© 2002 ELME SWEDEN '08-09(08-08 08-06, 10-04,05-04,09.05,02.08, 12-02, 10-02,09-02,06-02,05-02)

ELME== o'bzea

Note item] Part no | aly | Part name

x) | 35 | 760555 2 | Washer M8 Nordlock

x) | 36 | 760487 2 | Ring pin

x) | 37 | 761607 8 | Bolt MBS M8x80 8.8

x) [32 | 760555 | 8 | Washer MB Nordlock

x) [32 | 752687 | 2 | crank

x) [40 | 752646 | 2 | cotet

2)0| 41 | 791 022 | 2 | Upper bearing

42 | 762172 | 4 ong washer

a3 | 762171 | 4 | Oing

44 | 762170 | 2 | Balloint

45 | 740866 | 2 | adjuster

46 | 760586 | 2 | Washer M16 Noralock

47 | 76094 | 2 | Nut mis

wy] 43. | 791 023 | 2 | Lower bearing

W}x)] 49. | 791 024 | 2 | Steeve xt (4x fora complete spreader)

v)x)| 50 | 762 169 2 | Bushing

v) | 51 | 760417 4 | Grease nipple

v)x)] 52. | 760 371 8 | Spring

x) | 53 | 752649 2 | Key

x) | sa | 752625 | 2 | twistock

y) [55 | 763971 | 1 | clamp

y) 56 | 760.403 | 1 | Snapring

¥) | sr | 763.972 | +] wasner

y) |58 | 763373 | 2 | Bushing

y) |§9 | 776406 | 1 | Housing

y) | 60 | 760970 2 | Bolt M6S M8x45 8.8

y) |61 | 761154 | 4 | Washer

y) |62 | 776403 | 1] Am

¥) 63 | 775850 | 1 | indicator

y) e+ | 760819 | 2 | nut MB Locking

65 | raases | 1 [Bracket

F) See section F or electrical device list

5) Tastlock ey Seal kino. 791 024

1) Upper bearing Use kitno. 791 022

u) Lower bearing Use kit no, 791 023

vy) Sleeve Use kit no, 791 024 (4x for a complete spreader)

x) Twistlock assy. —_ Use kit no. 791 026 (4x for a complete spreader)

y) Truck spreaders only

2) Sensor bracket kt Use kino. 791 173

© 2002 ELME SWEDEN

'08-09(05-08 08-06, 10-04,05-04,09.05,02.08, 12-02, 10-02,09-02,06-02,05-02)

SECTION

E

HYDRAULIC PARTS

© 2002 ELME SWEDEN '03-09(07-09,08-05,08-02)

Pace no

E60-419-2

ELME=:

Note[ tem] Partno | Qty | Partname

xy)| 1 | 790959] 1 | Sealkit

y) | 2 | 760929] 1 | Set screw

y) | 3 | 740956} 1 | Nut

y) | 4 | 740955] 1 | Piston

y) | 5 | 744153] 1 | Spacer

y) | 6 | 761483 | 1 | Bushing

y) | 7 | 744192] 1 | Gland

y) | 8 | 760266 | 1 | Guide ring

y) | 9 | 744193] 1 | Washer

y) |10 | 741670] 1 | Ring

y) | 11 | 760587 | 4 | Washer M12 Nordlock

y) |12 | 7eo3t1 | 4 | Bott MBS M12x85 8.8

y) [13 | 745621 | 1 | Piston rod

y) | 14 | 760401 | 2 | Ball joint

y) |15 | 760402 | 2 | Snap ring

&) | 16 1 | Valve assy,

17 | 771026) 1 | Bracket

18 | 760555 | 6 | Washer M8 Nordlock

19 | 760949 | 4 | Bott MeS MBx35 8.8

y) |20 | 758543} 1 | Sheu

21 | 762044 | 1 | Flexstrack-chain

22 | 756911 | 1 | Flex chain bracket

23 | 761253} 8 | Screw

24 | 760912 | 4 | Bolt Mes MBx20 8.8

25 | 754758 | 2 | Bracket

26 | reogta | 4 | Nut MeM 8 Locking

27 | reoot | 4 | Bolt MBS M12x25 8.8

28 | 760557 | 4 | Washer M12 Nordlock

29 | 760983 | 4 | Screw allen MC6S M12x30 8.8

30 | 755603 | 1 | Support

31 | 760917 | 4 | Nut M12 Locking

32 | 743177 | 2 | Nylon pad

33 | 761703 | 4 | Screw allen MLCSS M12x45 8.8

34 | 804105 | 1 | Cover, without flow regulator

804108 | 1 | Cover, with flow regulator

35 | 761391 | 2 | Bolt MBS MBx10

E) See section E

x) Repair kit Use kit no: 780 959

y) Hydraulic cylinder assy: 757 500

© 2002 ELME SWEDE

'95-09(07-0908-05,09-02)

ELME=:

DAMPING CYLINDER ASSY FOR SPREADER MODEL 817

Pace no

60-187

12 3 4 56 08 7 98

Hyorautie cvunoer assy 800 593

Note[item] Partno | iy] Part name

1 | 760426] 2 Snap ring

2 | 760588) 2 | Ball joint

3 | 760417| 41 Greaser

sso] 4 | 749326] 1 | Snell

5 | 760929) 1 | Set screw

6 | 744885] 1 Piston

x | 7 | 790936) 1 seaixit

t=8e9] 8 | 749.925] 1 | Piston rod

9 | 741605] 1 | Gland

10 | 762549] 1 | Guide ring

x) Repair kit available: Seal kit 790 936

© 1995 ELME SWEDEN

104-08(02-03,09-02,04-01,11-97,03-95)

ELME=:

DampiNe CYLINDER Assy. Pace No

FOR SPREADER MODEL 817 60.248

i y

34 5 6 78 9 8 1

Note] ttem| Partno | aty| Part name

756785 | 1 Hydraulic cylinder assy.

| | 4 1| Valve body

2 | 760713 | 2 Elbow Triple-lok

or | 762507 | 2| Elbow O-Iok

3 | 760426 | 2] Snap ring

4 | 760588 | 2| Ball joint

5 | 760417 | 4] Greaser

=002| 6 | 749.926 | 1] Shell

7 | 751136 | 1] Piston

y) | 8 | 790921 | 1] Seaikit

sees] 9 | 749325 | 1] Piston rod

to | 741605 | 1] clang

E) See section E

y) Repair kt available: Seal kit 790 924

‘© 2002 ELME SWEDEN

0502

ELME=:

‘SIDESHIFT CYLINDER

SIDESHIFT CYLINDER ASSY.

Pace no

60-340

7

2

Note [Item] Partno [aty | Partname

771152 | 1 | Sideshitt cylinder assy.

1 | 771155 | 1 | Piston rod

x) | 2] 790958 | 1 | Seal kit

3 | 748612 | 1 | Gland

4 | 740300 | 1 | Piston

5 | 740302 | 1 | Nut

6 | 760929 | 1 | Set screw

7 | 771153 | 1 | Shell

8 | 760584 | 2 | Snapring

9 | 760583 | 2 | Ball joint

to | 760417 | 4 | Grease nipple

x) Seal kit 790 956

(© 2002 FLME SWEDEN

05-02

ELME:=: Swiver assy, Pee

Sora . 70-525

14

6

5

4 =o

3 4

2

1

Note] ltem] Partno [Qty | Partname

771725 | 1 | Swivel assy,

1 | 761947 | 4 | Screw allen MCS Max50 8.8

2 |774321 | 1 | Base plate

3 | 760217 | 4 | Screw allen MCS M6x30 12,9

4 | 760585 | 4 | Washer ME Nordlock

5 | 771723 | 1 | Housing

6 | 771722 | 1 | Spindle

7 | 761.820 | 4 | Screw allen MC6S M10x30 8.8

8 | 760556 | 4 | washer

9 | 763123 | 1 | Bushing

x) [10 | 763122 | 2 | Sealring

11 | 763121 | 1 | Bearing

x) [12 | 761710 | 1 | o-ring

13 | 774320 | 1| Washer

x) [14 | 760250 | 2 | o-ring

x) Seal kit: 791 101

© 2002 ELME SWEDEN

05-02

ELM!

Pace no

E 70-838

4

5

7

Note] item] Partno | Qty[ Part name

783831 | 1 | Valve assy.

1 | 761911 | 4 | Screwalien MC8S Méx40 12.9

x) | 2 | 763247 | 1 [Electro valve 2aVDe

3. | 764311 | 1 | Valve body

4 | 762080] 2 | Gauge adapter

5 | 762482 | 4 | Fitting

6 | 762621 | 4 | Fitting

7 | 763099] 1 | Relief vane

8_|762505 | 2 | Fitting

x) Solenoid:763 085 (2x); Nut: 763 097 (2x); O-ring kit 760 469 (1x)

(© 2005 ELME SWEDEN 0205

EE Me= Pace no

ELME:=: 2, FOR EXTENSION eYLNDER Pro

ast ben

6

1 9 10 iF

clin \ (i 8

a !

= i semen

|

5 2

Wee] ter] Pare [ay [Par rame

+ |reaase | 2] Fitna

2 | reason | 2] Fine

3 |reasor | 2] Fine

4 | 150.20 | 1) Rotate

5 |ro0707 | 2] Pus

x | 8 [rere | 7] Eetvovane aay

x) 7 | 762693 1 | Electro valve 24v

& |Zet7m | 12] Scewaion ———Aesssia0 12.9

» [rst | “3 | Gover ae

10 [reve | + [orm

x) Solenoid: 764 668 (2x), Nut 763 096 (2x), O-ring kit 761 631 (1x)

© 7002 ELME SWEDEN ‘08-09(02-05,09-02)

ELME=:

Vauve assy. (swvet)

Pace no

70-758

Note] Item] Partno | Qty] Partname

779982 | 1 | valve assy.

1 | 763144 | 1 |Pressure reducer

2 | 774061 | 1 |Mani fold

3 | 762505 | 2 | Fitting

4 | 763098 | 1 | Check vate

5 | 762651 | 2 [Plug

6 | 762654 | 1 | Pug

7 | 762481 | 1 | Fitting

a | 762482 | 2 | Fitting

9 | 762592 | 1 [Fitting

© 2008 EME SWEDEN

ono

Sora

ELM!

VALVE ASSY. ROTATIONIBRAKE

FOR ROTATOR WITH QUAL SPF

Pace no

70-784

Note] item] Partno | Qty [Part name

731971 | 1 |Valve assy

1 | 761773} 4 |Screw allen MCBS M5x30 12,9

x) | 2 | 761109 | 1 |Etectro valve 2av

3 | 760120] 3 |Relief valve

4 | 760159 | 2 |Flow regulator

5 | 763366 | 2 |Solenoia

6 | 763804 | 2 |Cartridge valve

y) | 7 | 762550] 3 [Fitting

a | 756180 | 1 |Manifols

2 | 9 | 762482 | 2 [Fitting

10 _| 761928 | 4 [Screw allen MC6S M@x80 8.8

x) Solenoid: 764 668 (2x); Nut: 763 096 (2x); O-ring kit 761 631 (1x)

y) —Orring: 763 105 (3x)

2) Osring: 763 107 (2x)

© 2008 ELME SWEDEN

105-08 (08-04)

Vatve assy. (DAMP LOCKING)

F

Note] Item] Partno | Qty [Part name

756703 | 1 |Valve assy.

1 | 751146 | 1 |Valve body

2 |762482 | 5 |Fiting

3 |760120 | 2 |Relief vatve

4 |760170 | 2 |Flow regulator

5 |762760 | 1 [Electro valve 2av

6 |761773 | 4 [Screw allen MC6S 5x 30

7_| 763126 | 4 [Plug

Solenoid: 764 668 (2x), Nut 763 096 (2x), O-ring kit 761 631 (1x)

© 7002 ELME SWEDEN

Page no

70-510

06-09(09-02),

VALVE Assy. (POWERDAMPING)

Pace no

70511

8

7

1"

T

F

Part no Part name

756704 | 1 | Valve assy.

1 | 760738 | 2|Plug

2 |735604 | 1 | Valve body

3 | 762482 | 2 | Fitting

4 |760276 | 4 | Screw allen MCBS 6x75

5 |760468 | 1 | o-ring plate

6 |760469 | 1 | o-ring kit

7 |760120 | 2 |Relief valve

@ 744849 | 1 | Valve boay

9 |763247 | 1 | Electro valve 2ay

10 | 762507 | 2 Fitting

11_| 762509 | 2 | Fitting

Solenoid: 763 085 (2x), Nut 763 097 (2x), O-ring kit 760 469 (1x)

© 2002 ELME SWEDEN

'06-09(06-08,06-04,09-02)

ELME=:

Vatve Assy (DAMPING)

Pace no

70-1138

wt!

Ss

Note [item [Partno [Qty _[Partname

785367 | 1 [Valve assy

1 | 744065 | 1 |Vaive body

2 |760170 | 2. |Fiow regulator

3 | 760120 | 2 |Relicrvaive

4 | 762621 | 2. |Fiting

5 ]760793 | 1 [Pug

6 760738 | 1 [Plug

© 2000 ELWE SWEDEN w08

ELME=:

ce Parker FirTines O-Lox FoR ELME sPReADER

Pace no

E70-610-1

Tuneao om [Terex om | ORS

ELME nr Parken name seach

(iwones) | (wa) “THREAD

Ts16 | Ta16 T

Male connector

782 625 118 9728 |orteta

762 550 44 13,157 fort6-18

762 592 318 16862 favte-18

763 005, 412 20955 |are-t8

762 585 44 13,197 |13/16-16,

762 482 3/8 16662 |13/16-16

762 621 B-BF42 eomos | 1/2 20,955 |13/16-16

762 722 8.124; 34 26441 |13/16-16

782 838, 10F42 eomos | 1/2 poss |1-14

762 619 10-12F42 26441 (1-14

762 505, 1242 26441 |1.3/16-12

762.483, 12-8F42 42 20955 |1.3/6-12

Male connector UNF

763 080 ‘BFS omos 36-16 rs6-16

762.623, 8-6F5 mos | 916-18 1316-418

762.618 8-12F5 amos | 1.1/16-12 1316-16

763 119 10-42F5 amos | 1,1/16-12 14

782.617, 125 omos 16-12 1.3/16-12

Male connector Metric

762 566 M14F82 comos Miaas [1116-16

‘Swivel male connector BSPP

762 622 aF642e0ms | 38 16,662 /13/16-16

763 036 8-4F642 coms | 1/4 13,157 |13/16-16

762620 10642 12 20.955 [1-14

Male elbow BSPP 45°

762 639 wave amos | Te 13,167 jalte-18

762 509 Bv4omos — | 3/8 16662 |13/16-16

762 638, 10-124 omos | 3/4 24st |1-14

762637 12veomos — | 3/4 26441 |1.3i6-12

Male elbow BSPP 90°

762.632 4c4omos | 118 9.728 [ote-t8

762 508 4-404 omos | 1/4 13,157 fait6-18

762 507 acéomes — | 3/8 16662 — | 1/1616

762 673 ascsomos | 1/4 13,157 | 13/1616

763 016 ascsomos | 1/2 20,955 [13/1616

762 629 10-1264 omos | 3/4 26441 |1-14

762 627 1204 omos | 3/4 26441 |1.3/16-12

Male elbow UNF 90°

762 628 1205 omos 1.41612, 1.371612

‘Swivel nut elbow 90°

762631 406 Los 716-18 lerte-18

762 630 8C8 mos 1316-16 1316-16

762 628 1208 mos 136-12 1.311612

© 1998 ELE SWEDEN

105-02(04-98,12-98)

ELM!

rows Parker FirTines O-Lox FoR ELME sPReADER

Pace no

E70-610-2

‘Tureao pi | THREAD DIM nr

ELME we | Parner wane sree

(eens) | (amy | Semen

TareTe| Tree

Male branch tee BSPP

762.634 estou | 318 16.962 _| 1376-16

Male run toe BSPP

762 633 @Rtomos | 3/8 16.662 | t9/t6-16

162.728 1eRdomos_|_ 314 2oaat_ | 1,3/16-12

‘Swivel nut un tee

762695 BRE mos | 19/1616 19716-16

762.773 12R6 vos 4,3/16-12 3ne-12

‘Swivel nut branch tee

762696 @86mos | 1916-16 1376-16

Pressure gauge fitting

762 640 4aG4 mows | We 13.157 | 9716-18

Bulkhead union (without bulkhead locknut)

762 643 “Ws 976-18

752.641 AW nos 1316-16

763.116 10W mos 114

763.008 12W mos tamte-t2

Bulkhead union 90° elbow (without bulkhead locknut)

762 644 WE tos on6-18

762 642 AWE mos 19it6-16

Bulkhead locknut

762 646 owen 916-18

762.645 aWons 1916-16

763.117 10W ius 114

763 008 12W wus 13/t6-12

O-ring for Parker fittings ORFS male

sumer | 82 Jereccrtrmcao| Mn)

restos | 4 onete | 7esxt70

763 107 a waneae | 12aaxt76

veai08 | 10 | vie | tonne

esos | 2 | 1aneaa | ierrxire

© 1998 ELE SWEDEN

105-02(04-98,12-98)

How to Know we

HYDRAULIC HOSE wet. Firris you »

Pre no

E 70-611

ELME=:

‘See table and following example part no 632 550

the first digit specifies a hydr, steel braid hose with Parker fittings,

the second dit species hose dimension (hoss 3/5")

the third digit specifies fittings (Triple-lok JIC 37)

the fourth digit specifies the hose’s cut length in 100 cm

the fifth di

the sixth digit specifies the hose’s cut length in em

[= Hydraulic hose, 18", fiting straight90, 550cm

First digit is always 6 Third digit spec.

TRIPLE-LOK JIC 37| | 0-LOK ORE!

‘Second digit spec T| straght-staight [a | straight-straight

1 | hose 14" + 4-4 ep 2| straight-20 degr. | | straight-20 degr

2 | hose 1/4" + 5-4 cpl(only JIC) 3| straight-45 degr. —_|6 | straight-45 dear.

3 | hose ae" 7 | 90 degr-00 deg, | | special

4 | hose 1/2" 8 | special 9 [90 degr-00 dear

5 | hose 5" T= no filings, only hose

6 | hose x4"

Fourth to sixth digit spec. cut length in em

Ce] a

HYDRAULIC HOSE / METER

farker no, [ELMEno, |Description

491-04 [762 116 | hose 1/4

441-06 — {762 128 | hose 3/8

461-08 — |762 115

46-10 |r62 114

461-12 |762 120

FITTINGS ONLY

[TRIPLE-LOK JIC 37 [O-LOK ORF:

Parker no. [ELME no] Description Parker no. |ELME no, Description

Pressure fittings - straight Pressure fittings-straight

H1e846-4-4 | 762017 | straight - 1/4” hose IC464-4 | 762 608 |straight - 1/4" hose

l16846-5-4 | 762.021 | straight - 1/4" hose 1446-86 | 762603 | straight -3/8" hose

l16e46-2-6 | 762.018 | straight - 378" hose 1c46-8.8 | 762.604 | straight - 1/2" hose

l16846-8-8 | 762019 | straight - 1/2" hose }1048-12-8 | 762.725 | straight - 1/2" hose

116846-10-10 | 762 020 | straight - 5/8" hose 1048-10-10) 762 600 | straight - 5/8" hose

l10846-12.12 | 762.022 | straight - 3/4" hose 1046-12-12] 762 599 | straight - 3/4’ hose

Pressure fittings - 45 degr. Pressure fittings -45 degr.

Havae-4-4 | 762 023 | 45deqr- 1/4" hose TITAS | 762 610 [45 degr. - 14" hose

1av46-8-6 | 762024 | 45deqr - 3/8" hose 1u746-8-6 | 762 607 |45 degre. - 3/8" hose

Hava6-8-8 | 762025 | 45deqr - 1/2" hose 1746-88 | 763 100 |45 degr. - 1/2" hose

11av46-10-10| 762 026 | 45degr - 5/8 hose

l13746-12-12 | 762 027 | a5degr - 314" hose

Pressure fittings - 90 degr. Pressure fittings - 90 degr. short

Wawae-4-4 | 762028 | S0deqr- 1/4" hose TIe4eA-4 | 762 609 190 degr - 114" hose

liswa6-s-4 | 762029 | a0deqr - 1/4" hose }1y946-6-6 | 762612 | 90 degr. -3/8" hose

lisw46-8.6 | 762030 | 90deqr - 3/8" hose }1y946-8-6 | 762.606 | 90 degr. - 3/8" hose

liswa6-8-8 | 762031 | 90deqr - 1/2" hose /1ya46-8-8 | 762 602 | 90 degre. - 12" hose

l1aw48-10-10| 762 032 | 90degr - 5/8" hose 1946-10-10] 762 601 |90 degr. - 5/8" hose

l1g046-12-12 | 762 033 | s0degr - 3/4” hose 1946-12-12] 762 598 |90 dear. -3/4" hose

Pressure fittings - ext. Prossure fittings - 90 dear. long

110846-6-4 | 762.070 J ext. straight - 14 TIT466-6 | 762611 90 degr. - 3/8" hose

jnos46-8-8 | 762335 | ext. straight - 1/2" 1146-8-8 | 762605 [90 degr. - 1/2" hose

© 1098 FLME SWE "¥12-04(08-04,06-04,08-03,10-02,05-02,02-02,09-98,12-68)

SECTION

F

ELECTRICAL PARTS

TwisTLock ARR.

(see secnion D)

ELME=:

Multiply Qtys by 2 for a complete spreader.

‘SeNsoR ARR. (ENO BEAM)

FOR TRUCK SPREADERS

Pace no

F 80-323

Note | Item] Partno [ay | Partname

1 | 7er491 | 4 | sensor

2 |7e1897 | 4 | Clamp

3 | 762849 | 4 | Top plate

4 [780907 | 4 | Bolt MBS M6x35

760585 | 4 | Washer M6 Nordlock

5 | 760908 | 4 | Bot MBS M6x60)

7s0.950_| 4 | Nut M6 Locking

© 2008 ELME SWEDE

07-05(08-08)

EEL MIE 22% | 821502 ane. (Rovar0n) ror truck sereaners Pacer

Pace no

\ |

|

|

' |

|

\ | \

| \

2

3

4 5

Note | tem] Partno [ary | Partname

x 1 | 761 491 2 | Sensor

2 | 781897 | 2 | clamp

3 | 762049 | 2 | Topplate

4 | 760585 | 4 | washer M6 Noralock

5 [762246 | 4 | Scrowallen _ MCES MOxS5

X) Quantity can vary, see electrical schematic forthe right quantity

© 2006 ELME SWEDEN

05-08

ELME=:

CCanie assy, INTERFACE NOXES, PRINTED CIRCUIT BOARD,

Cunss! wousine.ete - See Wine Diagram section ©

F

Pre no

80-264-1

ELectnic foxes FoR TRUCK SPREADERS

Cover 3-roce 762 138 (veLL0")

Cover 10-pore 764 478 (aac)

(© 2002 ELME SWEDEN

Soreaver aox (curry) 777 384

Rowon oo (arn) THT 385 ll

Bracke: 774.034

Bracker 787 459

‘Snook assonsen(rox Cusus}761 600 t u

‘Shock ABSORBER 760 587 a i i a

Nur 760919 MB Lockna ee rt

‘Waser 760.555 M8 Noro.ock th e o h

Bowr 761389 Méx40

Nur 760950 MB Locxnc.

Tr

Sensors

Sensor 762446 12.0

Sensor 762680 1840

Sensor 762527 30am

Ucrra sonte proxi siren 763223 18 a0

Sensor ir wins Spm connector «794187 12.4

SENSOR WITH CABLE AND CONNECTOR «761454 18 ut

SENSOR WITH CABLE ANO CONNECTOR «76149130 4mt

Ucrra sonte Prox swren = \

= WITH CABLE AND CONNECTOR 782654 184m s .

Prioroeuecric sensor 763191

Phorosvecrric Sensor wri case 763.76

wires 761 523

Asa 761 524

Covers

108-09(08-08,08-08, 1-05 08-04 084

702-03,05-02)

ELM!

Parse no

E.ectRical parrs FoR TRUCK sPReAnens Fp02642

= Wasser M4 Noro.ock

Sockey aLocks For PCB's Pant ni.

BN 762 923,

10-P 763 573

Mounrine sock 762940

(Fo socker stocx)

Cover For ITERFACE-B0x 758 414 - co

= Sonew ALLEN MBS M4x25 763 459 (3x)

761 879 (3x)

(© 2002 ELME SWEDEN

108-09(08-08,08-08, 1-05 08-04 084

702-03,05-02)

Workine Licitt

ELM!

Won tir (202)

Wornanc uci (sauare)

771 956 (assewsty No.)

763 757 (assewaty No.)

LigHTS FOR TRUCK SPREADERS

Parse no

F 80-266

RUBBER FRAME 763 379

Suis 763 800

Green

otearon ai ASSY. FOR 1 LGN.

ASSEMBLY NO. (INKL. CABLE)

Rice

772 602

772 808

780 391

804 937

ane. 744 988

Inptearor uci ASSY. FoR 3 LIcHTS.

COLOURS FROM LEFT TO RIGHT

covours [ASSEMBLY NO, (INKL. CABLE)

772 180

776 207 (wir 5 70% Mate cosNectoR)

COREEN, WHITE, 775.433,

CACEN, YELLOW, 775 521

(GREEN, RED, wh 772.429

WHITE, YELLOW, RE 772 668

RED, YELLOW, WHITE 772.432

RED, YELLOW, GREEN 772.417

yellow, wHre, veo — 772 383

J

7

ane 743 928

Iworearor air Assy. FoR 4 LIGHTS,

AASSEMBLYNO. (INKL. CABLE)

Low 772.414

YELLOW, GREEN,RE0,veLLOW 776 177 (roR 812,813 soneaDERs)

panet 757 164

/

7

Iotearor cH ASSY. FoR 6 LIGHTS,

[ASSEMBLY NO. (INKL. CABLE)

772.430

Panel 746 269)

Panel 772 255 (oR 572 seREADERS)

775.128

Iotearor ual ASSY. FOR 11 PANELS

cotours ‘ASSEMBLY NO, (NHL. CABLE)

veu.ow (Bx) 772784

panel 737 088

Iwoteario uci covouns.

Reo 761657 Green 763-118 Bue 761707

Yewon 761659 Were 761 658,

© 2002 ELME SWEDEN

Parse no

F 80-348

ELME=:

Working ici

LigHTS FOR TRUCK SPREADERS

covours ASSEMBLY NO. (KL, CABLE)

Woreane tick (sauare) 763 757 (asscusty No.) sue 763 800

IWotearoR ui assy. FoR 1 LED wir cn

covouns ASSEMBLY HO. (WL CABLE) pyres 744 988 )

were 786 823 -

Inotenron Lio Assy. FoR 2 LED uci Foe

coours ASSEMBLY NO. (WAL. CABLE) \

Lue, YELLOW 764740 fe

InotearoR uci Assy, FoR 3 LED Lois, COLOURS FROM LEFT TO RUG foe

covours AsseMoLy NO. (mL. CABLE) }

cee, veto, ned 74717 Sree) 4

GREEN, WATE, RED 763 989 LY YY

InoJcaTon cit Assy. Fon 4 LED ui. coLouRs FROW LEFT To RIGIT Coe

covours ASSEMBLY NO. (KL CABLE) |

OREN, YELLOW, RED, YEUOW 764.756 > (-\ (OS (A J

EUOW, ONCE RED euow — 78ATES Or@ (ee

Iotearon uate assy. For 11 LED uicwrs ane. 737 088

colours ASSEMBLY NO. (WKL. CABLE)

veu.ow (8x) 792.459 ) Oe 6

I

Twotcaror LED uci

covours ASSEMBLY NO. (INKL. CABLE)

Green 764728

Reo 764727

Ware 764729

Yetwow 764726

(© 2005 ELME SWEDEN "02-00(07-08, 12:08 08-07,11-06,08-05)

SECTION

G

SPECIAL PARTS

Hose caus

Hose c.anp 11

Hose cian 31

Hose c.an 31

Hose cvanp 11

prion

Bracker

Loca PLATE

Hose ctaues - Ruse

Hose tan 31

Hose cian 1/2"

Cover Pare

Bout

Waster M8 woratock

ELME=:

ADDITIONAL PARTS (HOSE CLAMPS)

ki no. 791 140,

Kir no. 791 141 (FoR Hose wirh olaweTER 17,4 4m)

Kir No. 791 203 (oR HOSE WITH DIAMETER 15,5 um)

ki no, 794 142

Kir no. 791 143

Kir no. 791 144

Parr wo. 802.020 —

Pret wo. 761 700

Pant wo. 764.492

Pant no, 764.493

Parr no, 762 118

Part no. 760 321

Parr no. 760 555

Pre no

690-121

(© 2002 ELME SWEDEN

‘D4-T0(04-08,02-08,10-04,10-02)

ELME=:

Brackers

Backer (oN sPReanen)

Bour MS_M10x20

Wastes M10 Nornocs

Backer (oN roraror)

Bour MS M12x20

Waster M12 Noro.oce

ADDITIONAL PARTS (BRACKET FOR HOSES AND CABLES)

Part No. 771 968

Paar no. 760 967 (4x)

Psat No. 760 368 (4x)

Parr No. 771 969

Past no. 760 998 (3x)

az no. 760 557 (3x)

771 969

771 968,

Pace no

6 90-152

© 2008 ELME SWEDE

106-03(04-03)

ELME:=: ADDITIONAL PARTS (COVER PLATE)

WHEN STOPS ARE NOT FITTED, THIS COVER PLATE IS MOUNTED ON MAIN FRAME

Cover Pare Paar no. 74 133

~Sorew aun MC6SM12x25 Prat no. 760 915 (4)

= Washer, M12 Norovock Paz no. 760 557 (4x)

Pre no

690-216,

© 2003 ELME SWEDEN

7203

ELME=:

Bracker

-Bowr Mas M10x20

-Wasnier M10 Norn.ocx

Bot MBS MBx20

-Wastier MB NooLock

‘ADDITIONAL PARTS (BRACKET FOR HYDRAULIC LOCK)

Part no.

Past no,

Paar xo.

Paar xo,

Past xo,

. 787 753

760 967 (2x)

760 556 (2x)

760 912 (2x)

>. 760 555 (2x)

Pace no

690-228,

© 2004 ELME SWEDEN

or-04

ELME=:

-Bor — MBS M10x20

= Waster M10 Noro.ock

Mes M6x20

M6 Locins

‘ADDITONAL PARTS (BRACKET FOR CONTROLLER)

Parr no.

Pant no

Paar no

Par no

Par no

Par wo

Part wo

783307

760 967 (3x)

760 556 (3x)

784 391

741 179

760 936 (3x)

760 950 (3x)

Pre no

90-285

© 2008 ELME SWEDEN

(02-05(17-04)

SECTION

H

REVISION RECORDS

ELME=:

REVISION RECORDS

Revision Date Issued by Description if change

2010-11-24 M. Lindell Initial Release

© 2010 ELME SWEDE!

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Case 621C Wheel Loader: Help Improve This Specification Print SpecificationDocument2 pagesCase 621C Wheel Loader: Help Improve This Specification Print SpecificationTerry Malone100% (1)

- 20-40 Cylinder DCF80Document1 page20-40 Cylinder DCF80Terry MaloneNo ratings yet

- 130X2 Tool Box LockDocument2 pages130X2 Tool Box LockTerry MaloneNo ratings yet

- Kalmar Parts DRS4527-S5Document598 pagesKalmar Parts DRS4527-S5Terry MaloneNo ratings yet

- UntitledDocument298 pagesUntitledTerry MaloneNo ratings yet

- 235X3 Arm PartsDocument2 pages235X3 Arm PartsTerry MaloneNo ratings yet

- 225LX Spin Ace Sensors 2Document3 pages225LX Spin Ace Sensors 2Terry MaloneNo ratings yet

- 160X2 Harleigh FarmsDocument2 pages160X2 Harleigh FarmsTerry MaloneNo ratings yet

- Engine Gasket MH25-4TDocument4 pagesEngine Gasket MH25-4TTerry MaloneNo ratings yet

- 240LX Rotate Motor and Other PartsDocument4 pages240LX Rotate Motor and Other PartsTerry MaloneNo ratings yet

- Honda GXV390 PartsDocument3 pagesHonda GXV390 PartsTerry MaloneNo ratings yet

- 360 Steer Valve #HPCJ0196Document4 pages360 Steer Valve #HPCJ0196Terry MaloneNo ratings yet

- Upper Roller Assembly 2800 QuantumDocument2 pagesUpper Roller Assembly 2800 QuantumTerry MaloneNo ratings yet

- 160 LX PartsDocument3 pages160 LX PartsTerry MaloneNo ratings yet

- 130X2 Hyd PumpDocument2 pages130X2 Hyd PumpTerry MaloneNo ratings yet

- Seat Parts LX600Document10 pagesSeat Parts LX600Terry MaloneNo ratings yet

- Lower Roller Assembly 2800 QuantumDocument2 pagesLower Roller Assembly 2800 QuantumTerry MaloneNo ratings yet

- LB300X3 Temp SensorDocument2 pagesLB300X3 Temp SensorTerry MaloneNo ratings yet

- Fan Belt 240LXDocument3 pagesFan Belt 240LXTerry MaloneNo ratings yet

- BUCKET CYLINDER (STD & EMS) (Part# KSV18700) - 002Document4 pagesBUCKET CYLINDER (STD & EMS) (Part# KSV18700) - 002Terry MaloneNo ratings yet

- Back-Hoe Attachment-Short Arm - 13-001-039-00Document4 pagesBack-Hoe Attachment-Short Arm - 13-001-039-00Terry MaloneNo ratings yet

- Partspro Plus: Alpha Y CAP 0355 SUF SEQ 41 LOT 4323 Description Power Steering Cylinder POM Illu 26-059Document2 pagesPartspro Plus: Alpha Y CAP 0355 SUF SEQ 41 LOT 4323 Description Power Steering Cylinder POM Illu 26-059Terry MaloneNo ratings yet