Professional Documents

Culture Documents

Hydraulic Fan Drive System

Uploaded by

Samson MwenyaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Fan Drive System

Uploaded by

Samson MwenyaCopyright:

Available Formats

Directory Previous

Previous Next Search Exit

Hydraulic Fan Drive System

Table of Contents

Sub-Headings Figure 2—Oil Reservoir 6

Safety 2 Figure 3—Hydraulic Pump 7

Warnings 2 Figure 4—Oil Flow Divider Valve 7

Caution 2 Figure 5—Hydraulic Fan Motor 7

Introduction 2 Figure 6—Fan Motor Control Valve 7

Hydraulic Fan Drive Components 2 Figure 7—Pilot Control System

Description of Operation 2 Ports 8

Reservoir 3 Figure 8—Hydraulic Oil Cooler 8

Hydraulic Pump 3 Figure 9—Engine Coolant Thermo-

Priority Flow Divider 3 Valve 8

Fan Motor Bypass 4 Figure 10—Charge Air Override

Pilot Control Circuit 4 Solenoid/Relief Valve 8

Charge Air Override Control Valve 5 Figure 11—Charge Air Temperature

Thermo-Valve 5 Sensor 9

Port T 6 Figure 12—Cooling Fan

Description of Major Module 6 Temperature Switch 9

Hydraulic Reservoir 6 Figure 13—Oil Reservoir

Hydraulic Pump 7 Temperature Warning Light 9

Priority Oil Flow Divider 7

Hydraulic Fan Motor 7 List of Tables

Fan Motor Control Valve 7 Table 1—Fan Speed vs Engine

Pilot Control System (RPT) 8 Speed 16

Hydraulic Oil Cooler 8 Table 2—Hydraulic Cooling System

Engine Coolant Thermo-Valve 8 Performance, Rear Engine 17

Charge Air Override Control Valve 8

Charge Air Temperature Sensor 9

Cooling Fan Temperature Switch 9 List of Charts

Oil Reservoir Temperature Warning Chart 1—Troubleshooting 10

Light 9 Chart 2—Troubleshooting (2) 11

Hydraulic Fan Drive Trouble-

Shooting 9

Hydraulic Flushing Procedures 17 List of Schematics

Schematic 1—Hayden Hydraulic

Oil Cooler Circuit 12

List of Figures

Figure 1—System Oil Flow Diagram 3

Figure 1.1—Fan Motor Control

Valves 5

Figure 1.2—Pilot Operated Circuit 5

All American Hydraulic Fan Drive System 1

Directory Previous

Previous Next Search Exit

Hydraulic Fan Description of Operation

The fan drive system responds to cooling

Drive System requirements by monitoring engine coolant

temperature and charge air temperature.

The system then provides a modulated fan

speed to meet cooling requirements for each

Safety system. Figure 1—System Oil Flow

Diagram.

The purpose of this safety summary is

twofold. First, it is to help ensure the safety

A hydraulic fan motor directly drives the

and health of personnel performing work on

engine Modulated fan speed will depend on

this Blue Bird product. Second, it is to help

the amount of oil flowing through the fan

ensure the protection of equipment.

motor. The oil flow is measured in gallons

Individuals performing service on this Blue

per (GPM) minute.

Bird product should adhere to applicable

warnings, cautions and notes contained

Low oil flow results in low fan speed. As

herein.

oil flow increases, fan speed increases.

Oil flow through the fan motor will depend

Warnings on three main areas of the hydraulic fan

Warnings refer to a procedure or practice, drive system.

that, if not correctly adhered to, could result

in injury or death. 1. Pump speed

2. The amount of oil allowed to bypass the

fan motor

3. Fan Circuit Relief Valve

Caution

Cautions refer to a procedure or practice A pump creates oil flow necessary to

that, if not correctly adhered to, could result operate the hydraulic fan drive system. The

in damage to, or destruction of, equipment. pump is a positive displacement gear type

pump.

Introduction As engine Revolution Per Minute (RPM)

increases proportionately, oil flow increases.

The All American rear engine bus uses a

As engine RPM decreases, oil flow

hydraulic fan drive. The hydraulic fan drive

decreases proportionately.

creates airflow through the engine-cooling

radiator and the charge air cooler.

The amount of oil allowed to bypass the fan

motor is controlled by the fan motor bypass

valve. The valve is located in the fan motor

Hydraulic Fan Drive control valve, which is integrated into the

fan motor housing.

Components

1. Hydraulic Reservoir The fan motor bypass valve is controlled by

2. Hydraulic Pump the hydraulic pilot operated circuit. The

3. Priority Oil Flow Divider Valve hydraulic pilot circuit is, in turn, controlled

4. Fan Motor by a charge air override valve and a thermo-

5. Fan Motor Control Valve valve.

6. Pilot Control System

7. Hydraulic Oil Cooler

2 All American Hydraulic Fan Drive System

Directory Previous

Previous Next Search Exit

The charge air override sensor and the

thermo-valve monitor charge air temperature

Reservoir

and engine coolant temperature. As charge A 12-quart reservoir provides a supply of

air and engine coolant temperature increase, clean, air free oil to the pump. The reservoir

the charge air override solenoid valve and is vented and uses a dipstick and sight glass

thermo-valve respond, to control oil flow for monitoring the oil level. The reservoir

through the pilot circuit. has an internal filter that filters return oil

flow from the fan and the steering column.

With the engine at full speed and at

maximum operating temperature, the

following conditions exist. Hydraulic Pump

The single stage hydraulic pump provides

1. The pump would deliver maximum oil oil flow for the fan drive circuit and the

flow to the fan motor control valve. power steering circuit. This is done by a

2. The fan motor bypass valve would allow priority flow divider valve integrated into

minimum oil to bypass the fan motor. the back of the pump housing.

This would result in maximum pressure

developing in the fan drive circuit.

3. The fan circuit relief valve would open, Priority Flow Divider

limiting the system pressure. The flow divider valve prioritizes the

4. This would allow oil to bypass the fan steering circuit by providing 4.3 GPM flow

motor. Pressure relief at the fan motor to the steering circuit regardless of oil flow

allows the pressure relief valve to available for the fan drive circuit.

control maximum fan speed under those With proper operation of the flow divider

conditions. valve, both systems function as if they have

dedicated pumps.

Figure 1—System Oil Flow Diagram

All American Hydraulic Fan Drive System 3

Directory Previous

Previous Next Search Exit

A steering circuit pressure relief valve is 2240 RPM at maximum operating

integrated into the flow divider housing. temperatures.

The valve limits pressure in the steering

circuit only, and has no effect on the fan The RPM will vary, depending on the

circuit. specific engine and engine specifications.

The RPM referenced is for a typical 190-

Oil flow required for the fan drive circuit is horse power (HP) Cummins Electronically

approximately 4.3 GPM, depending on Controlled "B" Series Engine. Chart 1.

engine speed. Oil will flow to the fan motor

control valve.

Pilot Control Circuit

Fan Motor Bypass A hydraulic pilot circuit controls the fan

The fan motor control valve has a fan motor motor bypass valve. A pilot-operated circuit

bypass valve to modulate fan speed and a is one hydraulic circuit controlling another

pressure relief valve to limit fan circuit hydraulic circuit. Usually, it is a smaller

pressure. circuit controlling a large circuit.

When the fan motor bypass valve is in the This circuit consists of the following:

full bypass position, most of the oil will

bypass the fan motor. Oil flow bypassing 1. Hydraulic circuits that start at port P and

the fan motor flows through an integral stops at port R on the fan motor control

passage in the fan motor control valve valve. Figure 1.1—Fan Motor

housing. Control Valves.

2. Charge Air Override Solenoid

The fan will be in an "off" mode, with the 3. Thermo-valve

engine operating below 185° Fahrenheit. In 4. Bypass Valve

the "off" mode, the fan will rotate at a very

low RPM, regardless of engine speed. As The pilot-operated circuit controls the

the engine RPM increases, there should not position of the bypass valve by regulating

be a noticeable increase in fan RPM. the pressure in the pilot circuit. The

pressure reacts against the bypass valve,

When the fan motor bypass valve is in full spring tension and an opposing oil pressure

closed position, all fan circuit oil flow will to determine the bypass valve position.

be directed through the fan motor. The fan

will be in a full run mode with the engine at Unrestricted oil flow in the pilot circuit will

maximum operating temperature and full position the bypass valve in the full open

engine speed. position, allowing maximum oil flow to

bypass the fan motor. This will result in a

As vehicle operating conditions change, the low fan speed. Any restriction in oil flow in

load on the engine changes. This will affect the pilot circuit will result in a pressure

the engine operating temperature. To increase, applying force to the bypass valve.

compensate for varying cooling needs, the This will make the valve move toward the

bypass valve is designed and controlled to closed position, limiting the amount of oil

allow varying amounts of oil to bypass the allowed to bypass the fan motor, resulting in

fan motor. an increasing fan speed.

This will result in a modulated (variable) fan

speed of approximately 320 RPM at low

operating temperatures to approximately

4 All American Hydraulic Fan Drive System

Directory Previous

Previous Next Search Exit

operated circuit. The pressure increase will

force the bypass valve toward the closed

position, increasing the fan speed.

Pressure will continue to increase in the

pilot circuit, until the relief valve setting is

reached. The valve will open, maintaining a

moderate pressure against the bypass valve,

while maintaining a moderate fan speed.

The integrated relief valve allows oil flow to

bypass the solenoid valve when the solenoid

valve is in the closed position. The relief

valve is adjustable and preset at the factory.

Figure 1.1—Fan Motor Control The valve allows a moderate fan speed

Valves during charge air fan operation.

A charge air override sensor monitoring

charge air temperature in the engine air

Charge Air Override intake, controls the solenoid. It is normally

a closed sensor set to open at approximately

Control Valve 150° Fahrenheit.

There are two (2) control valves running in

series in the pilot-operated circuit. Oil will

flow from port P on the fan motor control

valve to port P on the charge air override

control valve. The oil will then flow to the

port labeled "in" on the thermo-valve and

return to the R port on the fan motor control

valve, completing the circuit.

The charge air override solenoid consists of

two (2) parts. The two parts are integrated

into one valve body. These two parts are the Figure 1.2—Pilot Operated Circuit

charge air override solenoid (see Figure

1.2—Pilot-Operated Circuit) and the relief

valve.

Thermo-Valve

The charge air override solenoid is normally Oil flow from the charge air override

a closed, electromagnetic, on/off hydraulic solenoid valve flows through the thermo-

solenoid valve. The solenoid is fully closed, valve and returns to port T on the fan motor

maximum restriction (when de-energized) or control valve.

fully open minimum restriction (when

energized). The thermo-valve is a thermostatically

sensitive hydraulic valve that monitors

When the charge air temperature reaches engine coolant temperature. This is the

150° Fahrenheit, the charge air override second valve in the pilot operated circuit.

sensor will open, de-energizing the solenoid

valve. The closed valve will make a The thermo-valve is designed to provide

restriction, increasing pressure in the pilot- minimum restriction when engine coolant

All American Hydraulic Fan Drive System 5

Directory Previous

Previous Next Search Exit

temperature is below 185° Fahrenheit and at

maximum restriction when the engine

Description of Major

coolant temperature increases to Module

approximately 200° Fahrenheit. This section is used for the description and

configuration of the major modules in the

The valve action is progressive, varying oil Hydraulic Fan Drive System.

flow restriction for minimum to maximum,

according to engine coolant temperature.

This action varies oil flow restriction in the

pilot-control circuit and varies fan speed

Caution

When routing hydraulic hoses, make sure

from minimum to maximum, resulting in a

the hoses are away from sharp edges.

modulated fan drive.

This configuration of the thermo-valve and Caution

the charge air override solenoid valve can Do not operate the bus will a coolant leak,

independently, or in conjunction, control the engine oil leak or hydraulic oil leak. Major

fan speed. engine damage will occur.

Port T

Port T of the fan motor control valve is Hydraulic Reservoir

connected to the bottom of the reservoir. The 12-quart reservoir (39) supplies clean,

Figure 1.1—Control Valves. air free oil to the hydraulic pump and is

vented to the outside.

Port T provides a vent line, preventing

excessive pressure build up in low-pressure The reservoir has a sight glass to monitor oil

areas of the pump, including the area behind level. The oil filter cleans return oil flow

the shaft seal. This configuration extends from the fan circuit and the steering circuit.

the service life of the pump shaft seal. Figure 2—Oil Reservoir.

Hydraulic Oil Cooler

Oil flowing from the fan motor flows

through the hydraulic oil cooler, before

returning to the reservoir. A liquid to air

heat exchanger (Hayden oil cooler), separate

from the engine cooling system, is used for

cooling the hydraulic oil.

Air flow through the heat exchanger is

created by an electric fan, controlled by a

sensor, monitoring hydraulic oil temperature

in the bottom of the hydraulic oil reservoir.

The sensor energizes the fan motor through

a Bosch™ relay when the oil is

approximately 160° Fahrenheit. The sensor Figure 2—Oil Reservoir

will energize hydraulic oil over heat light on

the instrument panel, if the oil reaches 200°

Fahrenheit.

6 All American Hydraulic Fan Drive System

Directory Previous

Previous Next Search Exit

Hydraulic Pump Hydraulic Fan Motor

The hydraulic pump (16) supplies oil flow The fan motor drives a fan to cool the

for the fan drive circuit and the power charge air and engine coolant. The more oil

steering circuit. The flow divider valve is that passes through the motor, the faster the

responsible for the supply of oil flow to each fan speed.

circuit.

Figure 3—Hydraulic Pump Figure 5—Hydraulic Fan Motor

Priority Oil Flow Divider Fan Motor Control Valve

The fan motor control valve uses the bypass

Valve valve and the pilot control system to module

The oil flow divider valve (16) prioritizes the fan. The fan motor control valve also

the steering circuit and supplies 4.3 GPM serves as a pressure-limiting valve to protect

flow to the steering circuit. The valve has a the circuit.

pressure relief valve to limit steering circuit

pressure.

The flow divider valve, the steering system

and the hydraulic fan drive system function

as if each system receives oil flow from a

dedicated pump.

Figure 6—Fan Motor Control Valve

Figure 4—Oil Flow Divider Valve

All American Hydraulic Fan Drive System 7

Directory Previous

Previous Next Search Exit

Pilot Control System Engine Coolant Thermo-

Port (R P T) Valve

The pilot control systems govern fan speed The thermo-valve (29) is the second valve in

by using pilot oil flow restrictions. the pilot control circuit to receive oil and

return the oil to port R.

Flow Restrictions convert to pressure and

position the piston in the bypass control

valve. The piston position determines the

amount of oil flow that is delivered to the

fan motor or reservoir.

Figure 7—Pilot Control System Ports

Figure 9—Engine Coolant Thermo-

valve

Hydraulic Oil Cooler

The oil cooler (26) is an air to oil heat

exchanger, located forward of the radiator Charge Air Override

(skirt-mounted). Control Valve

The solenoid (30) is an electromagnetic,

on/off hydraulic relief valve, which is the

first valve that receives pilot flow from port

P in the fan control valve.

Figure 8—Hydraulic Oil Cooler Figure 10—Charge Air Override

Solenoid/Relief Valve

8 All American Hydraulic Fan Drive System

Directory Previous

Previous Next Search Exit

Charge Air Temperature Oil Reservoir

Sensor (Kysor) Temperature Warning

A Kysor™ sensor monitors the charge air

temperature in the intake manifold and

Light

controls the charge air override solenoid. The warning light turns on at 200°

Fahrenheit. The light is located on the

driver's instrument panel.

Figure 13—Oil Reservoir

Temperature Warning Light

Figure 11—Charge Air Temperature

Sensor

Hydraulic Fan Drive

Cooling Fan Troubleshooting

Temperature Switch

The cooler fan temperature switch monitors Tools Required

the oil temperature controls the oil cooler

electric fan and the hydraulic oil over 1. High pressure hydraulic test cut off

headlight. valve

2. 0 to 4000 psi pressure gauge

3. Phototach

4. Power Steering Analyzer

5. Zero to 30 gallon per minute flow meter

Abbreviations

! Hydraulic fan drive circuit (HFDC)

! Hydraulic fan drive system (HFDS)

! Charge air override solenoid (CAOS)

! Gallon per minute (GPM)

! Revolution per minute (RPM)

Figure 12—Cooling Fan Temperature

Switch

All American Hydraulic Fan Drive System 9

Directory Previous

Previous Next Search Exit

Symptom Problem Remedy

Hydraulic Warning circuit or temperature sensor has 1. Disconnect hydraulic oil

oil is not failed. temperature sensor connector.

overheating. If light goes off, temperature

Hydraulic sensor has failed.

oil overheat 2. Replace sensor. If light stays

indicator on, the warning circuit is

light is on. grounded.

3. Check and repair circuit.

Hydraulic Hydraulic oil overheating (Hydraulic System Refer to Hydraulic Fan Drive

oil overheat Failure) Troubleshooting

light on. Caution: Do not problem temperature

sensor. Electronic circuitry can be damaged.

Hayden hydraulic oil cooler contaminated

externally.

Clean the cooler thoroughly.

Hayden oil 1. Check Hayden fan fuse for continuity. 1. Replace fuse if no continuity.

cooler 2. Check for 12 volt on number 30 pin of 2. If 12 volt is not present, check

electric fan the Hayden fan cooler. circuit between fuse and

will not run. 3. Jumper between terminal 30 and 87 of the relay.

fan relay. 3. If the motor does not run, the

4. If the fan does not run, jumper 12 volt to motor has failed. Replace

terminal A and a ground to terminal B of motor.

the Hayden fan connector. 4. If the motor does not run, the

5. If the fan motor does not run, the fan motor has failed. Replace

motor and fan circuits are okay. The motor.

relay or the hydraulic oil sensor has 5. Check relay and/or

failed. With ignition on, check for 12 temperature sensor.

volt on terminal 86 of the fan relay.

! Disconnect the hydraulic oil temperature If the fan runs, the hydraulic oil

sensor on connector P2 sensor or the circuit is at fault.

! Jumper a ground to terminal 85 of the

Hayden fan relay. If the fan runs, the hydraulic oil

sensor or the circuit is at fault.

Chart 1—Troubleshooting (1 of 2)

Symptom Problem Remedy

Hayden oil 6. Jumper a ground to terminal C on If fan runs, circuit is OK. If the fan

cooler electric the temperature sensor connector does not run, check circuits between

fan will not P2 sensor and relay.

run 7. With ignition on, check for 12 volt

on pin B of the temperature sensor If 12 volt is not present, check circuit.

connector P2

8. Check for ground on pin A of the If a ground is not present, check

temperature sensor connector P2 circuit.

9. It tests on pins A, B and C check

OK, the temperature sensor is Replace sensor.

faulty

10 All American Hydraulic Fan Drive System

Directory Previous

Previous Next Search Exit

Noisy Fan 1. Low oil supply Check oil level and refill.

Drive 2. Restricted oil supply Check for restriction to oil supply

hose inside of reservoir.

Check for restriction in supply line.

Check for kinked supply line.

Look for obstruction inside of supply

hose.

Check for a collapsed supply hose.

Air in the oil Note Check oil level in reservoir.

supply Remove the dipstick, shine a light into Check for loose fitting on supply

the reservoir, and look for bubbles. lines.

Oil should be air-free. Check for restriction in supply hose.

Check the hydraulic pump shaft seal.

Mechanical Note Check for excessive metal in filter, as

Failure Rotation of fan is done in the normal this will indicate a mechanical failure.

rotation direction With the engine off, spin the fan by

hand and check for free rotation.

Fan should rotate freely with no

excessive noise.

Fan not Remove and replace motor.

rotating and

hearing

excessive

noise

Normal oil Note Reservoir may be overfilled

color with air Oil overflowing will have air mixed Check for loose connection on the

in the supply with it or will be foamy supply hose.

line Check for restriction in supply hose.

Check hydraulic pump shaft seal.

Discolored oil Check pump shaft seal. Seal has

is black like failed, allowing engine oil to transfer

engine oil into the hydraulic system.

Chart 1—Troubleshooting (2 of 2)

All American Hydraulic Fan Drive System 11

Directory Previous

Previous Next Search Exit

Schematic 1—Hayden Hydraulic Oil Cooler Circuit

Caution 3. If air bubbles are in the oil or the oil is

Do not operate bus with a coolant leak, foamy:

engine oil leak, or hydraulic oil leak. Major a. Check oil level in reservoir.

engine damage will occur. b. Check connections on the pump

supply line.

c. Check for restriction in supply

Engine is Over-heating hose, internal and external.

d. Check the hydraulic pump shaft

A—Check Engine Coolant Level seal.

1. Check all hoses for leaks. D—Check De-Energize the Charge

2. Check all valves for leaks. Air Override Solenoid (CAOS)

3. Check for radiator blockage.

Caution

Do not operate bus or run test if engine

B—Check Hydraulic Oil Level temperature is above 212° Fahrenheit.

Major engine damage will occur.

1. Check reservoir level.

2. Check all hoses for leaks.

3. Check all valves for leaks. Note

De-energizing the CAOS will cause the fan

to operate in a charge air override mode all

the time rather than cycling on and off to

C—Check for Air in the Hydraulic Oil

meet charge air-cooling needs. In this mode

of operation, the hydraulic fan drive system

1. Remove the dipstick.

will operate at approximately 50% to 60%

2. Shine a light in the reservoir and look

of maximum efficiency.

for air bubbles.

12 All American Hydraulic Fan Drive System

Directory Previous

Previous Next Search Exit

1. With the engine temperature above Caution

250°, accelerate the engine from idle to Operating the hydraulic fan system in a

full RPM and visually observe the fan charge air override mode may provide

speed. adequate cooling under light operating

a. If the fan speed does not loads and cooler weather. Bus may

increase as engine speed overheat under heavier loads and hotter

increases, disconnect the climate.

electrical circuit at the CAOS or

the electrical circuit at the E—Check the Condition of the Fan

charge air override sensor.

Blade

2. Accelerate the engine to full RPM and

observe the fan speed.

a. If there is a large increase in fan Warning

speed with the CAOS de- Rotating fan blade can cause serious bodily

energized, the thermovalve is at injury.

fault.

3. Replace the thermovalve ! Check for cracked, chipped or broken

a. If there is no large increase in fan blades.

fan speed, go to Step I—Check ! Replace the fan if needed.

Hydraulic Fan Circuit Pressure

b. If the engine temperature is F—Check the Fan Motor for Free

below 200° Fahrenheit. Rotation

4. Disconnect the electrical circuit at the

CAOS, disconnect the electrical circuit Note

at the charge air override sensor. The hydraulic fan drive system should be

5. Test-drive the bus to determine if this thoroughly flushed when the system has

resolves the over-heating. been opened for mechanical repair.

a. If this resolves the problem, the

thermovalve is at fault. Replace

the valve. Note

b. If this does not fix the problem, The fan should rotate smoothly with some

refer to Step I—Check resistance from oil in the fan motor.

Hydraulic Fan Circuit Pressure.

! With the engine off, manually rotate the

fan.

Caution ! A rough rotation indicates a mechanical

Do not operate a bus with the CAOS de- failure in the fan motor.

energized. This is a test procedure only. ! Repair or replace the fan motor.

Operating the bus with CAOS de-energized

can result in the following conditions.

G—Check Radiator for External

! Shorten the life of the hydraulic fan

Contamination

1. Inspect the entire area of the radiator

drive system

and the charge air cooler for obstructed

! Increase service requirements for the

airflow using a light source.

HFD

! Decrease fuel mileage

! Over cool the engine Note

! Shorten the life of the engine thermostat The charge air cooler may have to be

! Decrease efficiency of the engine removed to properly clean the radiator.

! Adversely affect the engine's emissions

system 2. Clean the radiator and charge air cooler,

as necessary.

All American Hydraulic Fan Drive System 13

Directory Previous

Previous Next Search Exit

H—Check Radiator and Charge Air overheating is in the cooling system.

Baffles Refer to Section 040—Cooling

System.

Note

Missing or damaged baffles can cause

heated engine compartment air to re-

Method 2

circulate through the radiator, causing an

overheating condition. Note

This procedure bypasses the thermovalve

1. Check the condition of the baffles and should cause fan to run at full speed

between the radiator and the charge air and full system pressure.

cooler.

2. Check the condition of the baffles 1. Disconnect hydraulic line G from fan

between the charge air cooler and the motor control valve.

bus body. 2. Install a pressure gauge that will

3. Replace or repair baffles, as necessary. function from 0 to 4000 PSI in port P on

the fan motor control valve.

3. Start the engine and accelerate to full

I—Check Hydraulic Fan Circuit RPM while observing the pressure

Pressure gauge.

Check hydraulic fan circuit pressure with 4. Compare the pressure with the

engine temperature between 205 and 210° specifications. See Table 2—Hydraulic

Fahrenheit. Cooling System Performance HDRE.

!If the pressure is low, the HFDS is at

There are two methods for checking the fault. Go to Step J—Check Fan

pressure. Speed.

!If the pressure reading is correct and

fan speed appears to be correct, it is

an indication the overheating is in

Method 1

the cooling system. Refer to

Section 040—Cooling System and

Warning specific manufacturer's

Do not exceed maximum pressure ratings troubleshooting guide.

for the system. Bodily injury can occur.

1. Install a test fitting in hydraulic line H J—Check Fan Speed

and pressure gauge that will function

from 0 to 4000 PSI.

2. Start the engine and accelerate to full Note

RPM while observing the pressure Fan should run at full TPM with engine

gauge. temperature above 205°, provided the

3. Compare the pressure with the engine is at full RPM.

specifications. See Table 2—Hydraulic

Cooling System Performance Rear Check fan speed with engine temperature

Engine. between 205° and 210° Fahrenheit.

!If the pressure reading is low, the

HFDS is at fault. Go to Step J— 1. Start engine and accelerate to full RPM.

Check Fan Speed. 2. Check the fan RPM with a Phototach.

!If the pressure reading is correct and Compare with specification. See Table

the fan speed appears to be correct, 2—Hydraulic Cooling System

this is an indication that the Performance Rear Engine.

14 All American Hydraulic Fan Drive System

Directory Previous

Previous Next Search Exit

If the fan speed is within specification, the completely off, the fault is in one of

HFDS is not at fault. the following areas.

!Hydraulic Pump

3. Check the engine cooling system to !Priority Flow Divider Valve

determine overheating. Refer to Section !Fan Motor Control Valve

040—Cooling System and specific !Fan Circuit Relief Valve

engine manufacturer's troubleshooting !Fan Motor

guide.

If the fan does not run at full TPM, one K—Test the Hydraulic System

of the following is at fault:

Caution

! Thermovalve Clean and lubricate all parts before

! Hydraulic Pump assembly.

! Priority Flow Divider Valve

! Fan Motor Control Valve Note

! Fan Circuit Relief Valve

Careful disassembly, cleaning and

! Fan Motor

reassembly of the flow divider valve may

resolve the problems. Fine emery cloth

Check fan speed with engine temperature

dipped in a cleaning solvent may be used to

below 200° Fahrenheit.

polish spool valves. All spool valves should

move freely through the bore inside the

valve body.

Warning

The test valve must be capable of 1. Install 0 to 30 GPM flow meter in H

withstanding 5000 PSI and designed for line.

hydraulic test purposes. The use of 2. Start engine and accelerate slowly to full

improper test equipment can cause serious RPM and observe GPM. See Table 2—

injury. Hydraulic Cooling System Performance

Rear Engine.

!If GMP is within specifications, go to

1. Disconnect hydraulic lines E and F. See Step FF.

Figure BB—Hydraulic Fan Drive !If the GPM is low, stop engine and

Circuit from the thermovalve. install a power steering analyzer in

H line (the steering circuit supply

Note line). Refer to Section 120—

Make sure the valve is in the full open Steering.

position. 3. Start engine and accelerate to full RPM,

and observe the GPM in the power

2. Connect hydraulic lines E and F to A steering circuit.

hydraulic cut off test valve. !If GPM is within specification, the

3. Start engine and accelerate to full RPM. pump is at fault. See Table 2—

4. Observe the fan speed using a Phototach Hydraulic Cooling System

while slowly closing the cut off valve. Performance Rear Engine.

!If fan speed reaches full RPM, the !Replace or repair pump.

thermovalve is defective. See Table !If GMP is higher than specified, the

1—Troubleshooting. priority flow divider valve is at

!If the fan does not run at full TPM fault.

with the test valve closed 4. After replacing or repairing the flow

divider, recheck steering system and

All American Hydraulic Fan Drive System 15

Directory Previous

Previous Next Search Exit

hydraulic fan drive system flow rates 1. Fan Motor Control Valve (FMCV).

and fan speed. Compare data with Repair or replace the FMCV.

specifications. See Table 2—Hydraulic 2. Fan Circuit Relief Valve (FCRV).

Cooling System Performance Rear Repair or replace the FCRV.

Engine. 3. Fan Motor. Disassemble and inspect the

fan motor for internal damage. Replace

!If systems are not within specification, or repair.

proceed with troubleshooting.

!If the GPM is within specification,

one of the following is at fault.

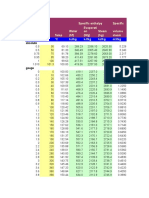

Cummins 8.3, Rear Engine Bus, Pump (31.5 cc), Motor + S53 (16.8), Trim RPM (2200)

Engine Speed RPM Pump Flow GPM Motor/Fan Speed System Pressure PSI

RPM

700 0.90 178 13

850 1.99 395 64

1000 3.09 613 155

1150 4.19 831 285

1300 5.29 1049 453

1450 6.39 1267 661

1600 7.49 1484 908

1750 8.59 1702 1194

1900 9.68 1920 1519

2050 10.78 2138 1883

2200 11.88 2200 1994

2225 12.06 2200 1994

2250 12.25 2200 1994

2275 12.43 2200 1994

2300 12.61 2200 1994

2325 12.80 2200 1994

2350 12.98 2200 1994

2375 13.16 2200 1994

2400 13.34 2200 1994

User Input

1818 9.08 1801 1336

Table 1—Fan Speed vs Engine Speed Cummins ISB—Rear Engine

Data Reflects 885 Pump and Motor Performance

Kysor Fan BBC #1855634

Engine Pump Motor Idle Drive Gov'd No Relief Max P/S Max Fan Eng

Disp Disp RPM Ratio RMP Load PSI Fan GPM GPM RPM RPM

C.I. C.I. RPM RPM Idle Trim

ISB 1885854 1964923

190 1.92 1.03 800 1:1 2600 2800 2030 2240 4.3 20.5 320 2130

195- 1.92 1.03 800 1:1 2500 2700 2030 2240 4.3 19.7 320 2130

275

ISC 1885854 1964931

215- 1.92 1.03 800 1:1 2400 2600 2175 2400 4.3 19 320 2240

250LT

250- 1.92 1.03 800 1:1 2200 2400 2175 2400 4.3 17.6 320 2240

16 All American Hydraulic Fan Drive System

Directory Previous

Previous Next Search Exit

275HT

ISC 0001051 1964931

300 216 103 800 1:1 2200 2400 2175 2400 4.3 22.4 451 1991

3126b 1964980 1964931

190- 1.57 1.03 700 1:1 2500 2640 2175 2400 N/A 15.8 824 2030

210

250- 1.57 1.03 700 1:1 2400 2640 2175 2400 N/A 15.8 824 2030

300

JD 8.1 1855543 1964923

250 1.57 1.03 700 .96:1 2200 2424 2030 2240 N/A 14 797 1968

Table 2—Hydraulic Cooling System Performance, Rear Engine

Hydraulic Flushing Note

Oil level must be maintained in the sight

Procedures glass while the engine is running.

The hydraulic flushing procedures should be

used whenever component failures have 15. Start and run the engine for 30 seconds.

accrued in the system. 16. Stop the engine and refill the reservoir.

17. Repeat Steps 14 and 15 until oil level is

Caution maintained in sight glass.

Failure to thoroughly flush and clean all 18. Restart the engine.

areas of the hydraulic system after a failure 19. Disconnect the electrical circuit at the

may cause repeat failure of the same charge air override solenoid valve. This

component. will cause the fan to run at a moderate

speed.

1. Remove the hydraulic pump, fan motor 20. Run the engine at approximately 1500

and all hoses. RPM.

2. Disassemble, inspect and clean any 21. Reconnect and disconnect the electrical

component that is to be used again. charge air override circuit 3 times.

3. Flush all hydraulic hoses. 22. Place chocks at the rear wheels.

4. Flush the thermovalve. 23. Jack the front axle off the ground.

5. Remove the filter inside the reservoir. 24. Turn the steering wheel to full turn left

6. Flush the reservoir and install a new and right four times.

filter. 25. Run the engine for 10 minutes and

7. Remove the stop bolt in the bottom of repeat steps 21 and 24.

the steering gear and the steering circuit 26. Stop the engine.

pressure relief valve. Refer to Section 27. Drain the oil from the reservoir.

120—Steering. 28. Remove the filter from the reservoir.

8. Place chocks at the rear wheels. 29. Install a new filter.

9. Lift the front axle off the ground. 30. Fill the reservoir with 10W/30W oil.

10. Turn the steering wheel to full turn left 31. Inspect the total hydraulic system for

and right four times. leaks.

11. Clean the stop bolt and pressure relief 32. Test drive the bus.

valve.

12. Install the stop bolt and relief valve. Back to Top

13. Install all removed components and

hoses.

14. Fill the hydraulic reservoir with

10W/30W Haveoline oil.

All American Hydraulic Fan Drive System 17

You might also like

- Marine Diesel Engines: Maintenance, Troubleshooting, and RepairFrom EverandMarine Diesel Engines: Maintenance, Troubleshooting, and RepairRating: 4.5 out of 5 stars4.5/5 (15)

- Caterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BFA) Service Repair Manual (BFA00001 and Up) PDFDocument22 pagesCaterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BFA) Service Repair Manual (BFA00001 and Up) PDFfkdmma0% (1)

- Curso Cat Fan System STMGDocument79 pagesCurso Cat Fan System STMGSilas F Pimenta100% (14)

- DG Operator InterviewDocument24 pagesDG Operator InterviewZez Samuel100% (1)

- Manual of 06naDocument35 pagesManual of 06naKannan Krishnamoorthy100% (8)

- Brake Cooling Oil System, DescriptionDocument5 pagesBrake Cooling Oil System, DescriptionMrAlbert200950% (2)

- GT Various Systems (G)Document62 pagesGT Various Systems (G)shtiwari2002100% (2)

- DEUTZ Diesel Engine BF4/6M2012 Operation ManualDocument62 pagesDEUTZ Diesel Engine BF4/6M2012 Operation Manualnicoss69No ratings yet

- DG Operator InterviewDocument41 pagesDG Operator InterviewZez SamuelNo ratings yet

- 5-1 Steering SystemDocument7 pages5-1 Steering SystemSumitomo Laos Sumitomo LaosNo ratings yet

- Edoc - Pub - st7 01 Motor PDFDocument26 pagesEdoc - Pub - st7 01 Motor PDFEric CNo ratings yet

- Section 2 EngineDocument7 pagesSection 2 EngineЕвгений СолдатовNo ratings yet

- Section 2 EngineDocument6 pagesSection 2 EngineDomingo BravoNo ratings yet

- HL740-9 2-1Document7 pagesHL740-9 2-1REMZONANo ratings yet

- Pump UnitDocument5 pagesPump UnitAli ZerifiNo ratings yet

- Module 5 - Fuel Cell SystemsDocument32 pagesModule 5 - Fuel Cell Systemsjim chimaicoNo ratings yet

- Apoio FreioDocument57 pagesApoio Freiogerallazo29No ratings yet

- Cummins QSX15 Engine TrainingDocument65 pagesCummins QSX15 Engine TrainingJhonatan BayonaNo ratings yet

- HYD0044 DL Cooling SystemDocument21 pagesHYD0044 DL Cooling SystemTomas TsegayeNo ratings yet

- Section 2 Engine: Group 1 Structure and Function 2-1 Group 2 Fan Drive Circuit For Cooling System 2-5Document5 pagesSection 2 Engine: Group 1 Structure and Function 2-1 Group 2 Fan Drive Circuit For Cooling System 2-5Jeymi AlemanNo ratings yet

- Brake Oil OverheatingDocument3 pagesBrake Oil OverheatingevanNo ratings yet

- 2-1. EngineDocument14 pages2-1. EngineSumitomo ExcavatorNo ratings yet

- Section 2 EngineDocument5 pagesSection 2 EngineJuan Felipe Garza GNo ratings yet

- Section 2 Engine: Group 1 Structure and Function 2-1Document5 pagesSection 2 Engine: Group 1 Structure and Function 2-1REMZONANo ratings yet

- Manual de Sistema Hidraulico D9R 2 PDFDocument96 pagesManual de Sistema Hidraulico D9R 2 PDFgodavicho100% (2)

- Lubrikasi OliDocument18 pagesLubrikasi OliDeni SetiawanNo ratings yet

- 2 1 4 PDFDocument7 pages2 1 4 PDFAndre STANo ratings yet

- 966H Fan SystemDocument3 pages966H Fan SystemSaidou COULIBALYNo ratings yet

- Aoa 737ngx Groundwork Engines HandoutDocument25 pagesAoa 737ngx Groundwork Engines HandoutDonald MokNo ratings yet

- Heating and Ventilation-Heating and Ventilation-1Document12 pagesHeating and Ventilation-Heating and Ventilation-1bibif93794No ratings yet

- Chapter 1. Introduction To Hydraulic & Pneumatic SystemsDocument25 pagesChapter 1. Introduction To Hydraulic & Pneumatic SystemsHiphop OpNo ratings yet

- Engine Diag - CumminsDocument19 pagesEngine Diag - CumminsthaiNo ratings yet

- Unit 2: Intermediate Hydraulics - 950G Wheel LoaderDocument45 pagesUnit 2: Intermediate Hydraulics - 950G Wheel LoaderAlha DNo ratings yet

- Section 2 Engine: Group 1 Structure and Function 2-1Document5 pagesSection 2 Engine: Group 1 Structure and Function 2-1Manuel PomahualiNo ratings yet

- CompressorsDocument11 pagesCompressorsNishaNo ratings yet

- Section 2 EngineDocument14 pagesSection 2 EngineCarlosNo ratings yet

- Standard Training Materials - R1Document65 pagesStandard Training Materials - R1Marco MacaNo ratings yet

- Group 12 LubricationDocument32 pagesGroup 12 LubricationLuisTocoraNo ratings yet

- Hyundai Airconditioning - TextbookDocument121 pagesHyundai Airconditioning - TextbookMichael IanNo ratings yet

- Section 2 EngineDocument14 pagesSection 2 EngineMarco OlivettoNo ratings yet

- Troubleshooting Guide For The HydraulicDocument5 pagesTroubleshooting Guide For The Hydraulicweldsaidi100% (1)

- Manual de Operación & Mantenimiento EEG 345Document47 pagesManual de Operación & Mantenimiento EEG 345juan0377No ratings yet

- دورة وقود فولفو 180Document3 pagesدورة وقود فولفو 180ali100% (2)

- 13.11 - Air ConditioningDocument40 pages13.11 - Air ConditioningTheo kl100% (2)

- "Engine Cooling System": Seminar Presentation OnDocument15 pages"Engine Cooling System": Seminar Presentation OnMastering Solidworks0% (1)

- Engine CoolingDocument7 pagesEngine CoolingpradipNo ratings yet

- Brake Cooling Oil System, Diagram A40E (De La 12558 A La 69999)Document2 pagesBrake Cooling Oil System, Diagram A40E (De La 12558 A La 69999)CEVegaONo ratings yet

- Airflow FormulasDocument11 pagesAirflow FormulasVicky GilangNo ratings yet

- Engine Systems: Intake Throttle Valve (ITV)Document26 pagesEngine Systems: Intake Throttle Valve (ITV)carmelo galotaNo ratings yet

- Sistema de DireccionDocument18 pagesSistema de DireccionFredy ReyesNo ratings yet

- Hyundai Technical Training Step 2 Air Conditioning System 2009Document10 pagesHyundai Technical Training Step 2 Air Conditioning System 2009doris100% (25)

- 30 HydraulicDocument61 pages30 HydraulicPaola GonzalezNo ratings yet

- Chap 1. Fundamental PrinciplesDocument37 pagesChap 1. Fundamental Principlesbucyeye shema mireilleNo ratings yet

- Hydraulic Fan SystemDocument4 pagesHydraulic Fan SystemEVER DAVID SAAVEDRA HUAYHUA100% (1)

- Service and Parts Manual: Series 14 Hydraulic BackhoesDocument89 pagesService and Parts Manual: Series 14 Hydraulic BackhoesJoe ZhaoNo ratings yet

- Engine Control UnitDocument1 pageEngine Control Unituser1No ratings yet

- Engine Cooling - INGENIUM I4 2.0L PetrolDocument736 pagesEngine Cooling - INGENIUM I4 2.0L Petrolkhaledserag23No ratings yet

- Hydraulic Fan Student Booklet EngDocument16 pagesHydraulic Fan Student Booklet Engali100% (2)

- 2 Week1 Day2Document10 pages2 Week1 Day2Alvin joe ramosNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Info RequiredDocument284 pagesInfo Requiredjukeboss0% (1)

- Department of Defense Design Criteria StandardDocument30 pagesDepartment of Defense Design Criteria StandardAlvaro Rojas AnzolaNo ratings yet

- Steam Tables - MetricDocument4 pagesSteam Tables - MetricUdhayakumar VenkataramanNo ratings yet

- Low Voltage 3-Phase Induction Motors 0.55kW To 500kW: RangeDocument12 pagesLow Voltage 3-Phase Induction Motors 0.55kW To 500kW: Rangealimoya13No ratings yet

- Polycab LDC HDC Composite CatalogueDocument7 pagesPolycab LDC HDC Composite CatalogueIon VairamuthuNo ratings yet

- Catalogue Easypact Ezc100!1!1507626617Document58 pagesCatalogue Easypact Ezc100!1!1507626617Pharmacist ShimaaNo ratings yet

- 174B-MCC Boiler - As BuiltDocument33 pages174B-MCC Boiler - As BuiltDharun KumarNo ratings yet

- Ventilation On DemandDocument3 pagesVentilation On DemandAngelo Ramirez RojasNo ratings yet

- EX. FAN CAL-01-3rdDocument1 pageEX. FAN CAL-01-3rdAlroukn MechanicalNo ratings yet

- RBM Expenses - Truck 1411 (Additional) & JCDocument9 pagesRBM Expenses - Truck 1411 (Additional) & JCMark DerracoNo ratings yet

- Controladores Dixell Xm678d GBDocument14 pagesControladores Dixell Xm678d GBReinaldo MarquesNo ratings yet

- Marine Diesel EnginesDocument44 pagesMarine Diesel EnginesArmando Alvarado Araujo100% (2)

- FlowThroughPipes NumericalProblems SolvedDocument39 pagesFlowThroughPipes NumericalProblems SolvedONYANGO IFULAIMNo ratings yet

- Standard Connection Provisions ResearchDocument3 pagesStandard Connection Provisions ResearchAlen RodrigoNo ratings yet

- SUMMATIVE ASSESSMENT-II - (2014-2015) Subject: SCIENCE Class: VIII Time 2: 30 Hrs. + 30 Mins For OTBA M.M. 60 General InstructionsDocument3 pagesSUMMATIVE ASSESSMENT-II - (2014-2015) Subject: SCIENCE Class: VIII Time 2: 30 Hrs. + 30 Mins For OTBA M.M. 60 General InstructionsMd ImranNo ratings yet

- 420 KV Shunt ReactorDocument59 pages420 KV Shunt Reactordeepak2628No ratings yet

- 03.5 - FPFF - Fire Preventing and FightingDocument78 pages03.5 - FPFF - Fire Preventing and FightingkunaalNo ratings yet

- Alex Kaivarainen - New Hierarchic Theory of Water and Its Role in Biosystems: The Quantum Psi ProblemDocument54 pagesAlex Kaivarainen - New Hierarchic Theory of Water and Its Role in Biosystems: The Quantum Psi ProblemJoaokaaNo ratings yet

- Exam - Inhinyero - Student Portal - Hydro GeoDocument16 pagesExam - Inhinyero - Student Portal - Hydro GeoaphroditeNo ratings yet

- Modern Technology in Ship Building IndustryDocument17 pagesModern Technology in Ship Building IndustrySwapnil Rupaye100% (2)

- 4500 Series: Bellows Sealed Valves (0.156"/3.962 MM Orifice)Document2 pages4500 Series: Bellows Sealed Valves (0.156"/3.962 MM Orifice)dhaktodesatyajitNo ratings yet

- BE State of The Transition 2023Document131 pagesBE State of The Transition 2023Chetan GaonkarNo ratings yet

- Davis Lynch PDFDocument32 pagesDavis Lynch PDFDonna GrayNo ratings yet

- Light and Color: Radiant EnergyDocument5 pagesLight and Color: Radiant Energyskywalker_handsomeNo ratings yet

- (PPMS Evercool Brochure) PPMS EvercoolDocument2 pages(PPMS Evercool Brochure) PPMS EvercoolMylena Pinto NascimentoNo ratings yet

- Flowmeter Selection Guide-Technical InformationDocument1 pageFlowmeter Selection Guide-Technical InformationMelina SbhNo ratings yet

- VKBSDocument40 pagesVKBSharish_sekarNo ratings yet

- Technical Seminar On VFDDocument17 pagesTechnical Seminar On VFDRadhika Priyadarshini100% (7)

- Vibration SeverityDocument19 pagesVibration Severityanon_900141394No ratings yet