Professional Documents

Culture Documents

Volumetric Efficiency of Refrigerating Compressor and Its Importance

Uploaded by

Punit ShindeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volumetric Efficiency of Refrigerating Compressor and Its Importance

Uploaded by

Punit ShindeCopyright:

Available Formats

1.855.262.

2487 Linkedin Contact us Careers Employee Login

Volumetric Efficiency: Why it Matters and How to Maximize It

Part 3 of our 6-part blog series, What you Need to Know About Reciprocating

Gas Compressors

by Randy Franiel, Compass Senior Accounts Manager, Canada

In the control and operation of a reciprocating gas compressor, the goal is efficiency: compressing the greatest volume of gas for

the least cost.

Volumetric efficiency (VE) plays a key role in the overall efficiency of a compressor, but it’s an area that’s not sufficiently

understood in the industry. VE may be defined as the ratio of the total cylinder volume of gas to the displacement the piston

actually delivers.

Several factors can affect VE, but the most important is re-expansion of the gas trapped in the clearance-volume space from the

previous piston stroke. In effect, there’s a volume of gas that you’re compressing, decompressing, compressing, decompressing –

over and over again.

A good cylinder design with minimal base clearance will have VE in the mid- to high-70% range. If volumetric efficiency is down in

the mid-40% range, the equipment can exhibit what we in the industry call valve flutter. This is where the compressor valve plates

inside the valves do not fully open or close on impact.

To picture the effect of valve flutter, think of swinging a baseball bat against a metal pole. When the bat strikes the pole, a high-

frequency vibration travels up the bat. This happens because the bat does not reach a dead stop when it first hits the pole, but

bounces just a little. Valve flutter is this bounce effect, and it’s one of the major contributors to poor performance of compression

equipment. It also contributes to lowering the reliability of the unit, increasing the stress applied to the valve and damaging it over

time, and causing additional wear to the plates and springs.

How can you improve a unit’s volumetric efficiency? If you are not limited by horsepower and you need to control capacity, the first

change I typically look at is varying operating speed. This can both improve VE, and reduce wear and tear of the machine as the

piston speed is slowed.

Varying operating speed can address a subpar VE in an operating unit, but appropriately sizing your equipment in the first place

works even better.

If you select a cylinder that’s too large for the available HP of the driver, you will need to add additional clearance to unload the

cylinder to suit the available horsepower. Selecting a cylinder that’s too large, and needing to unload or add clearance will reduce

the VE. This is where experience comes into play.

There are literally thousands of combinations of frames, stroke lengths, cylinder sizes and driver RPMs that can be used for any

application. Knowing how to apply all these combinations to best suit the application will result in a better design and higher VE.

The financial impact of poor VE is significant. Valve flutter can easily cost one or two days of downtime per year, bringing a huge

cost via lost revenue to the producer. Improvement from a moderate VE rating to a higher VE rating can increase gas flow by 1% –

2%, and extend the overall life of the equipment.

The lower your volumetric efficiency, the greater the volume of gas you’re compressing over and over again. Time spent at the

design stage to maximize volumetric efficiency delivers a powerful return on investment.

Privacy - Terms

You might also like

- Cylinder Head PortingDocument10 pagesCylinder Head Portingdebugevdo75% (8)

- Notes On Camshaft Selection - Gary LewisDocument4 pagesNotes On Camshaft Selection - Gary Lewisgaragepunkfan100% (2)

- Engine TuningDocument7 pagesEngine TuningJOSE100% (1)

- Choosing The Perfect Performance CamshaftDocument9 pagesChoosing The Perfect Performance CamshaftDesotoJoe100% (1)

- Connecting Rod Vs Stroke RatioDocument11 pagesConnecting Rod Vs Stroke RatioJameel Khan0% (1)

- Intake and Exhaust System TuningDocument15 pagesIntake and Exhaust System TuningAmir Izham100% (1)

- Yfm350s Yfm350s Yfm350s Yfm350s Yfm350: (5yt1) (5yt2) (5yt3) (5yt1) (5yt1)Document75 pagesYfm350s Yfm350s Yfm350s Yfm350s Yfm350: (5yt1) (5yt2) (5yt3) (5yt1) (5yt1)David Castro GasteluNo ratings yet

- Diesel Engine ImprovementDocument12 pagesDiesel Engine Improvementkumail raza100% (1)

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyFrom EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNo ratings yet

- Recruiting Hacks 2018 DigitalDocument26 pagesRecruiting Hacks 2018 DigitalAbhishek SinghNo ratings yet

- Diesel Injector FailureDocument19 pagesDiesel Injector FailureWayne Mcmeekan100% (2)

- Camshaft Design ScienceDocument7 pagesCamshaft Design Sciencencampagna8134100% (3)

- Cylinder Head Design and Modification - Getting StartedDocument4 pagesCylinder Head Design and Modification - Getting StartedBruno BambinetiNo ratings yet

- Diesel Smoke - WOF Failure?: Home Specials Products Services Events Gallery ContactDocument2 pagesDiesel Smoke - WOF Failure?: Home Specials Products Services Events Gallery Contactben razNo ratings yet

- Carburetor Tuning: Understanding CarburetionDocument11 pagesCarburetor Tuning: Understanding CarburetionMuhammad Rashid Jaidon ⎝⏠⏝⏠⎠80% (5)

- CDU Increase Distillate YieldDocument9 pagesCDU Increase Distillate Yieldrvkumar61No ratings yet

- Oil (Your Hidden Asset)Document17 pagesOil (Your Hidden Asset)jorge campos100% (1)

- Estatement - 2021 10 22Document3 pagesEstatement - 2021 10 22Joseph HudsonNo ratings yet

- COSTING Total Cost of Ownership (TCO)Document10 pagesCOSTING Total Cost of Ownership (TCO)Chemical.AliNo ratings yet

- 10 Steps To Pump Reliability Part 1Document5 pages10 Steps To Pump Reliability Part 1Anonymous ua66zYwrpNo ratings yet

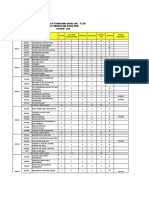

- Compressor Maint ListDocument3 pagesCompressor Maint Listsantosh kumar100% (1)

- ML July August 2012Document53 pagesML July August 2012rona41brNo ratings yet

- Practical Experience With Oil Mist LubricationDocument8 pagesPractical Experience With Oil Mist Lubricationannccknarime100% (1)

- AIChE Surge Control PaperDocument38 pagesAIChE Surge Control Paperscongiundi100% (1)

- Best Practices For Lubing API Centrifugal Pump Bearing HousingsDocument7 pagesBest Practices For Lubing API Centrifugal Pump Bearing HousingsguluuNo ratings yet

- 10 Steps To Pump ReliabilityDocument15 pages10 Steps To Pump ReliabilityaqhammamNo ratings yet

- Proactive Vs Reactive MaintenanceDocument7 pagesProactive Vs Reactive MaintenanceyoyokpurwantoNo ratings yet

- Pump Impeller Trimming AspectsDocument17 pagesPump Impeller Trimming AspectsUdhayakumar VenkataramanNo ratings yet

- Rightsizing Compressed Air SystemDocument6 pagesRightsizing Compressed Air SystemRahul ChandrawarNo ratings yet

- Solve The Five Most Common FCC ProblemsDocument21 pagesSolve The Five Most Common FCC ProblemsOMID464No ratings yet

- 10 Steps To Pump ReliabilityDocument13 pages10 Steps To Pump ReliabilityfalconesasNo ratings yet

- Centrifugal PumpDocument13 pagesCentrifugal Pumpafr5364No ratings yet

- Technical Guide Edition 1.2 - Gas Spring OverviewDocument18 pagesTechnical Guide Edition 1.2 - Gas Spring OverviewCamlocMotionNo ratings yet

- Retrofit - Propulsion ImprovementDocument4 pagesRetrofit - Propulsion ImprovementRamon Velasco StollNo ratings yet

- The Secret Life of CarburetorsDocument8 pagesThe Secret Life of CarburetorsDan MoyerNo ratings yet

- Published in The Independent Lubricant Marketers Association, June 2005Document3 pagesPublished in The Independent Lubricant Marketers Association, June 2005ahmed mohamedNo ratings yet

- Fuel Dilution in Gasoline Engines From Direct InjectionDocument2 pagesFuel Dilution in Gasoline Engines From Direct InjectionRafael Nakazato RecioNo ratings yet

- Mikuni Part 2 1Document5 pagesMikuni Part 2 1diegoNo ratings yet

- Ic-Mid Exam N SolutnDocument9 pagesIc-Mid Exam N SolutnFasilNo ratings yet

- 10 Steps To Pump ReliabilityDocument5 pages10 Steps To Pump ReliabilityallmcbeallNo ratings yet

- Cylinder Lubrication Timed InjectionDocument6 pagesCylinder Lubrication Timed Injectionapi-3701567No ratings yet

- Engine Value and PerformanceDocument5 pagesEngine Value and PerformanceM Umar ChatthaNo ratings yet

- A Step Change in Feed Nozzle DesignDocument26 pagesA Step Change in Feed Nozzle DesignNaiduJagarapuNo ratings yet

- WWW Mechanicalengineeringsite Com Centrifugal Pump Online Quiz Part 2Document10 pagesWWW Mechanicalengineeringsite Com Centrifugal Pump Online Quiz Part 2Prashant Kumar mishraNo ratings yet

- Midterm ZDocument9 pagesMidterm ZWilbert HernandezNo ratings yet

- DIY FI FlowBench (Assembly)Document11 pagesDIY FI FlowBench (Assembly)BespokeReader100% (1)

- Experimental Analysis of Air Oil Separator PerformanceDocument10 pagesExperimental Analysis of Air Oil Separator PerformanceAdrian SetyadharmaNo ratings yet

- Valvoline - Diesel Engine Oil - Let's Talk ViscosityDocument3 pagesValvoline - Diesel Engine Oil - Let's Talk Viscosityranjitv10No ratings yet

- RLE Article Final 022404Document9 pagesRLE Article Final 022404Arun KumarNo ratings yet

- GDW RO Prospekt EnglischDocument13 pagesGDW RO Prospekt EnglischRamón Ariel AstudilloNo ratings yet

- Internal Combustion Engines WorksheetDocument1 pageInternal Combustion Engines WorksheetRees Tracee WintersNo ratings yet

- Potentials For Efficiency Improvement Out of The Synchronizer - enDocument13 pagesPotentials For Efficiency Improvement Out of The Synchronizer - enR KathirasanNo ratings yet

- Hyd Oil IncreaseS Machine ProductivityDocument4 pagesHyd Oil IncreaseS Machine ProductivitymuhrezzqiNo ratings yet

- Implementation of Bharat Stage VI Norms For Small and Medium Duty CI EnginesDocument6 pagesImplementation of Bharat Stage VI Norms For Small and Medium Duty CI EnginesADITYA SHARMA 1927706No ratings yet

- The Influence of Oil Pressure in The Engine Lubrication System On Friction LossesDocument6 pagesThe Influence of Oil Pressure in The Engine Lubrication System On Friction LossesAmr ShebanNo ratings yet

- Variable Valve Timing Lab ReportDocument14 pagesVariable Valve Timing Lab ReportSyed Imtinan AhmedNo ratings yet

- Pilot-Operated PSV - Effective Plant UpgradeDocument7 pagesPilot-Operated PSV - Effective Plant UpgradeChem.EnggNo ratings yet

- Drill JigDocument36 pagesDrill JigVijay GanapathyNo ratings yet

- The Power of Wear RingsDocument18 pagesThe Power of Wear RingsVinh Do ThanhNo ratings yet

- Blow by Breather SystemsDocument19 pagesBlow by Breather SystemsekumaranNo ratings yet

- Effect of Integrating Variable Intake Runner Diameter and Variable Intake Valve Timing On An SI Engine's PerformanceDocument10 pagesEffect of Integrating Variable Intake Runner Diameter and Variable Intake Valve Timing On An SI Engine's PerformanceCyril D'souzaNo ratings yet

- The RoTechBoosterDocument3 pagesThe RoTechBoosterhtdk312No ratings yet

- Centrifugal Pump EfficiencyDocument3 pagesCentrifugal Pump EfficiencyAlfredo GallardoNo ratings yet

- Muffler CFDDocument11 pagesMuffler CFDfarhath78No ratings yet

- PSY316-Week-2-MODULE-1-Clinical PsychologyDocument12 pagesPSY316-Week-2-MODULE-1-Clinical PsychologyYza Cambosa-ReyesNo ratings yet

- The Wedding DayDocument2 pagesThe Wedding DayJomari Paulino PangilinanNo ratings yet

- Factors Affecting Job Performance of Criminology Working StudentDocument10 pagesFactors Affecting Job Performance of Criminology Working StudentJAIKO JOSE LAGANo ratings yet

- Список Сводеша Уточнение СемантикиDocument44 pagesСписок Сводеша Уточнение СемантикиalexNo ratings yet

- Brain Controlled Car For Disabled Using AiDocument21 pagesBrain Controlled Car For Disabled Using AiS.T KAUSALYAA100% (1)

- Autonomous CarsDocument7 pagesAutonomous CarssantiagoNo ratings yet

- Instrument Hydra B&GDocument176 pagesInstrument Hydra B&GPer LöfgrenNo ratings yet

- Determination of Moisture Content (ASTM D2216) : ProcedureDocument20 pagesDetermination of Moisture Content (ASTM D2216) : ProcedureJr SayreNo ratings yet

- UX User Manual - 6063308 G01 01 - EnglishDocument65 pagesUX User Manual - 6063308 G01 01 - EnglishCristian VegaNo ratings yet

- TcsDocument48 pagesTcsAsokan NiveditaNo ratings yet

- Peter Wynn Kirby - Troubled Natures - Waste, Environment, Japan-University of Hawaii Press (2010)Document265 pagesPeter Wynn Kirby - Troubled Natures - Waste, Environment, Japan-University of Hawaii Press (2010)Tereza KovalskáNo ratings yet

- Crack Prelims in 60 DaysDocument4 pagesCrack Prelims in 60 Dayssmanju291702No ratings yet

- 2017 Curriculum Structure PDFDocument2 pages2017 Curriculum Structure PDFAhmad ZubirNo ratings yet

- City News Nov '09Document1 pageCity News Nov '09Guillermo CapatiNo ratings yet

- Worldwide Hospitality and Tourism Themes: Article InformationDocument17 pagesWorldwide Hospitality and Tourism Themes: Article Informationagus wahyudiNo ratings yet

- English Top Notch 1Document12 pagesEnglish Top Notch 1MATE JOSNo ratings yet

- The Martian ChroniclesDocument23 pagesThe Martian ChroniclesIlana GuttmanNo ratings yet

- SMeyer-CA1231872A1-Hydrogen Injection System V3Document38 pagesSMeyer-CA1231872A1-Hydrogen Injection System V3Bryan RodríguezNo ratings yet

- 2908F W17 Outline KazmierskiDocument8 pages2908F W17 Outline KazmierskijoeNo ratings yet

- FS Data - NIC0020 - Anhydro Evaporator v002Document6 pagesFS Data - NIC0020 - Anhydro Evaporator v002john kenneth vasquez vasquezNo ratings yet

- Oscar Wilde, The Portrait of Dorian GrayDocument13 pagesOscar Wilde, The Portrait of Dorian GrayaaeeNo ratings yet

- Locating The CaribbeanDocument48 pagesLocating The CaribbeanNyoshi CaballeroNo ratings yet

- P4 Out 1Document74 pagesP4 Out 1josepheritu3No ratings yet

- Using Slide Master in Powerpoint 2010Document5 pagesUsing Slide Master in Powerpoint 2010AHMAD AZHARNo ratings yet

- COE LUISA-Main Class Annual-Requirements-SignedDocument6 pagesCOE LUISA-Main Class Annual-Requirements-SignedNavo MareNo ratings yet

- Service: Mașină de Spălat Cu TamburDocument44 pagesService: Mașină de Spălat Cu TamburRacoviţă Ionuţ-LucianNo ratings yet