Professional Documents

Culture Documents

ACASESTUDYFORRETROFITTIN

Uploaded by

muhd sjdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACASESTUDYFORRETROFITTIN

Uploaded by

muhd sjdCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/347357911

A CASE STUDY FOR RETROFITTING SCHEME OF A FIRE DAMAGED RCC

STRUCTURE

Article in International Journal of Engineering Science and Technology · November 2017

CITATIONS READS

0 319

1 author:

Dipesh Majumdar

Jadavpur University

32 PUBLICATIONS 3 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

ME thesis of Construction Engineering View project

Ultra High Performance Concrete with High Compressive Strength: A Subcontinental Approach View project

All content following this page was uploaded by Dipesh Majumdar on 16 December 2020.

The user has requested enhancement of the downloaded file.

Dipesh Majumdar et al. / International Journal of Engineering Science and Technology (IJEST)

A CASE STUDY FOR RETROFITTING

SCHEME OF A FIRE DAMAGED RCC

STRUCTURE

DIPESH MAJUMDAR,

Department of Construction Engineering, Jadavpur University, Kolkata, India

dipeshce@gmail.com

Abstract : One godwon structure of Kolkata was severely damaged due to fire. This structure had two

parts one part was constructed with steel members and another was a RCC structure. Steel structure was

completely damaged fire wherear RCC structure was partially damaged. Cover concrete of beams and

columns is badly damaged in many places. Overall thorough visual survey with conducting NDT was

done to assess the damages of the structure. Proper rehabilitation technique was applied to restore the

structure.

Keywords : Repair, Concrete Column-Beam Jacketing

(1) Introduction

The godown structure of Ravi Bhansali & Mahesh Kr. Khemka consists of two parts. One part was constructed

steel truss and steel column. Steel truss portion was three storied. Other portion is RCC framed structure, which

is three storied. RCC framed structure is constructed with RCC columns placed in two rows. Columns are

connected by RCC beams at every floor level. External wall is constructed with brick masonry wall. Severe fire

broke out on the month of February, 2016. Steel truss portion of three storied godown is completely damaged,

that portion is to be reconstructed completely. Three storied RCC portion is thoroughly inspected and tested to

assess the existing condition of the building observations are described below.

(2) Nature of Distress of the structure

Damage on the superstructure due to fire is not so severe in ground floor. Some portion of plaster is partially

damaged. Some cracks are noticed on the plaster at soffit level of ground floor roof slab.

Major damage is noticed at 1st floor level. Plasters are delaminated from soffit level of 1st floor roof slab (Plate

No. 2). Alligator type cracks are noticed at soffit level of slab. Major parts of wall plaster have delaminated

from existing wall due to fire. Some moderate level cracks are noticed at exposed concrete surface also. Colours

of concrete is changed due to high temperature exposure. Doors and windows are completely damaged due to

fire. No permanent geometric deformation is noticed on the RCC structural members. Exposed surface of

concrete has shown “Dusty” feeling during touching with fingers. 2nd floor is equally damaged as 1st floor.

Condition of roof is poor. Moderate cracks are noticed on the soffit level of roof. Seepage is also noticed wall

plaster is cracked and delaminated from existing surface.

Plate No. 1 : View of RCC structure.

ISSN : 0975-5462 Vol. 9 No.11 Nov 2017 1014

Dipesh Majumdar et al. / International Journal of Engineering Science and Technology (IJEST)

Plate No. 2 : Internal view showing delamination of plaster.

Plate No. 3 : Condition of brick masonry wall.

(3) Problems to be solved with this structure

Based on the investigations carried out, the following can be concluded.

• Detailed photographs of the structure, depicting the present condition of the structure, are documented

for future reference.

• From thorough visual inspection and Non-destructive testing, it is clear that the structure is damaged by

fire exposure.

• Ultrasonic Pulse Velocity results are noticeably low, may be due to generation of micro-cracks inside

concrete members due high temperature exposure of concrete members. No permanent geometric

deformation is noticed at any structural members.

• Plasters are delaminated at various places at 1st and 2nd floor.

• Core test results of slab concrete are showing strength above M-20 grade concrete.

• Cracks are noticed on concrete surface in some places.

• Steel structure is to be reconstructed with proper drawing and design.

(4) Repair and rehabilitation strategy of the structure

Although the structure is damaged due to fire exposure, it is to be retrofitted. Detailed engineering methodology

for column and beam jacketing, slab strengthening etc. to retrofit the structure is described below.

4.1 Jacketing methodology for RCC columns and beams

First of all, minimum 10 nos. MS pipe (50NB) prop with all proper attachment are to be used to support

adjacent area of particular column to be repaired. During propping full contact between existing beam bottom

and prop top is to be ensured.

Before starting any repair works, the existing structure is to be cleaned thoroughly. All dumped materials are to

be cleaned. After complete cleaning of debris/ ashes from existing structure. After propping and cleaning of all

ISSN : 0975-5462 Vol. 9 No.11 Nov 2017 1015

Dipesh Majumdar et al. / International Journal of Engineering Science and Technology (IJEST)

loose delaminated concrete particles and plasters are to be eliminated from column surface in very sensible way.

Minimum impact due to elimination of delaminated concrete from existing column member is to be ensured.

Following process for elimination may be adopted

4.2 Repair Methodology for removing and cleaning of dust / loose particle / spalled concrete from

existing column surface.

• Staging with necessary platform to facilitate work adjacent to distressed portion shall be done.

• The Damaged /loose concrete should be removed carefully by chisel and hammer or by breaker (Direct

hammering should be avoided).

• Cleaning the surfaces by use of high pressure water blower & removal of loose adhering materials.

• The existing surface should be cleaned by gentle hammering, if flakes are observed and by wire brushing

only.

4.3 Some cracks are noticed on beams and columns, those are to be sealed with epoxy grout. Repair

Methodology for Stitching of Cracks and Sealing of Cracks.

• Groove cutting all along the line of cracks, cleaning the same by use of high pressure water blower and

removal of loose adhering materials.

• Drilling the holes by use of drill machine, fixing the 12.5 mm dia G.I nozzles/ PVC nozzle with epoxy

patching mortar along the crack area.

• Sealing the groove with 2 comp. epoxy patching mortar.

• Providing and grouting “Epoxy based, flowable, High early Strength, two stage expanding Grout”

through prefixed PVC nozzle/GI nozzle with proper consistency. The minimum pressure for grouting

shall be 2.0kg/cm².

• After grouting work, removal off the nozzles, sealing the same with 2 comp. epoxy patching mortar.

4.4 Repair Methodology for application of Polymer Modified Mortar on some portion of beam column

and slab, where distress is minor.

• Removal of loose concrete and cleaning of surfaces as per procedure outlined in earlier clause

• Providing & applying one coat of polymer bonding coat in proportion 1:0.5 (i.e. polymer : Cement by

wt.) over cleaned concrete surface etc. complete.

• Providing & applying single component, fibre reinforced high performance polymer modified mortar on

cleaned concrete surface of wall, bottom slab and other surfaces. The mortar shall develop compressive

strength up to 20 MPa in 3 days.

4.5 Repair Methodology for cleaning and removing corrosion from corroded rebar.

• The existing exposed reinforcements should be cleaned by gentle hammering, if flakes are observed and

by wire brushing only.

• Exposed reinforcements are to be cleaned and rust to be removed by use of “Corrosion Removing Gel ”.

4.6 All columns and beams are to be jacketed with free flowing micro-concrete system.

• Dismantling of existing floor and excavation around existing columns is to be done with proper care as

per following Fig. No. 1.

ISSN : 0975-5462 Vol. 9 No.11 Nov 2017 1016

Dipesh Majumdar et al. / International Journal of Engineering Science and Technology (IJEST)

Outer part of

External Brick External Brick

Existing Column

Excavation Line

Inner part of

Floor finish near to existing column is to be dismantled to access existing

foundation.

Fig. No. 1 : Excavation Plan is shown at initial stage.

• During Jacketing of existing RCC columns extra reinforcement is to be provided externally. Anchoring

of vertical reinforcement (16 mm dia) is to be done on existing top of RCC foundations.

16mm dia extra

reinforcement

P.L. Level

Temporary

wooden

support to

Excavated Side

Earth Side

Anchoring of extra rebars is to

be done on existing foundation

top with HILTI Anchoring

Fig. No. 2 : After completion of excavation near existing column. 08 (eight) nos. 16mm dia rebar is to be are honed in existing top of

foundation.

ISSN : 0975-5462 Vol. 9 No.11 Nov 2017 1017

Dipesh Majumdar et al. / International Journal of Engineering Science and Technology (IJEST)

• Stirrups of jacketed columns are to be fixed as per following Fig. No. 3. There will be two nos. of stirrup

per set as shown in Fig. No. 3.

Dismantled part of

existing brick work

Existing Brick Work

Longitudinal reinforcement Anchored rebars on

Total 7 nos. 16 mm dia existing foundation

top with epoxy

anchoring agent

Stirrup details

Fig. No. 3 : Plan drawing showing anchoring arrangement of 16mm dia rebars and fixing details of stirrup reinforcement.

• Existing RCC slab of 1st floor and 2nd floor is to be punctured to accommodate vertical extension of

vertical reinforcement into next floor level as per following Fig. no. 4.

Slab is to be puncher in five places to extend longitudinal rebars.

Fig. No. 4 : Top of first floor slab showing arrangement for extension arrangement of longitudinal reinforcement through minor dismantling

of first floor slab only.

4.7 Repair Methodology for Jacketing with Free-flowing Low-shrinkage Micro-concrete.

• Providing and fixing in position ply postbox type formwork as per the site requirement.

• Application of Acrylic Polymer based bonding agents to ensure proper bond between old and new

concrete.

• “A Dual Shrinkage-compensating, high flow, high strength ready to use micro concrete” should be

poured in the formwork to patch the damaged concrete surface

• The same should be finished in line and level with the existing finish of the RCC member.

• It should be cured for 3 days with water.

ISSN : 0975-5462 Vol. 9 No.11 Nov 2017 1018

Dipesh Majumdar et al. / International Journal of Engineering Science and Technology (IJEST)

• Existing beams are moderately damaged due to fire exposure. Existing RCC beams are to be

strengthened by jacketing methods. During jacketing of RCC columns three nos. of dowel reinforcement

are to be left for beam jacketing as per Fig. no. 5

16mm dia extra

reinforcement as

longitudinal bars.

‘L’ shaped beam

reinforcement to be anchored

with column and beam

bottom reinforcement.

Longitudinal

reinforcement

‘L’ shaped connecting

reinforcement between

column and beam

reinforcement.

Detail ‘A’

Fig. No. 5 : Sketch showing reinforcement arrangement of vertical column reinforcement. Connection between beam and column

reinforcement is also shown.

Beams are to be jacketed with micro-concrete. At first shear reinforcements are to be anchored in existing roof

slab with HILTI chemical anchor system as per Fig. No. 6. Then main longitudinal reinforcements are to be

fixed as per Fig. No. 7. Finally micro concreting is to be done with Pre Packed Micro- Concrete system.

ISSN : 0975-5462 Vol. 9 No.11 Nov 2017 1019

Dipesh Majumdar et al. / International Journal of Engineering Science and Technology (IJEST)

80mm anchor is to be

done

Existing Beam

12mm dia “U” bar is to be fixed 175mm

c/c with HILTI chemical anchoring agent

Sectional view showing fixing plan of extra shear reinforcement with existing slab.

Fig. No. 6 : Sketch showing fixing arrangement of new stirrup to strengthen existing RCC beams.

Concreting is to be done through

this zone

Micro-concrete

Shuttering plate

16mm dia is to be placed as longitudinal

reinforcement.

Sectional view showing jacketing plan for beam

Fig. No. 7 : Sketch showing fixing arrangement of new longitudinal reinforcement and shuttering arrangement for concreting.

• Existing slab is to be strengthened with overlaying concrete jacketing on top of the slab as per Fig. No. 8.

Shear connector with 10mm dia rebars is to be provided on top of the RCC slab @ 4 nos. per sqm. Area.

Thickness of overlaying concrete will be 65mm. Reinforcement bar details is to be followed as per Fig.

no. 8.

65mm concrete with 10mm

Shear connector with

down coarse aggregate

10mm dia rebars and

HILTI anchor fasteners

8mm dia @ 200 C/C

Fig. No. 8 : Sketch showing strengthening arrangement of new stirrup to strengthen existing RCC beams.

ISSN : 0975-5462 Vol. 9 No.11 Nov 2017 1020

Dipesh Majumdar et al. / International Journal of Engineering Science and Technology (IJEST)

Reference

[1] Jirsa, J.O., “Behavior Of Epoxy-Grouted Dowels And Bolts Used For Repair Or Strengthening Of R.C. Structures, “Proceedings,

9wcee.

[2] Aci Committee 318, “Building Code Requirements For Reinforced Concrete,” Aci 318-83, American Concrete Institute, 1983.

[3] Luke, Philip C.C., Chon, Carlos, Jirsa, J.O., “Use Of Epoxies For Grouting Reinforcing Bar Dowels In Concrete, “Pmfsel Report 85-2,

Ferguson Structural Engineering Laboratory, University Of Texas At Austin, September 1985.

[4] H. J. Degenkolb Associates, “Connections To Existing Concrete For Seismic Rehabilitation,” To Be Published In 1988.

[5] Bass, Robert A, Corrasquillo, Ramon L, Jirsa, J.O., “Interface Shear Capacity Of Concrete Surfaces Used In Strengthening Structures,

“Pmfsel Report 85-4, December 1985.

[6] Winer, David F, “Behavior Of Steel To Concrete Connections Used To Strengthen Existing Structures, M.S. Thesis, University Of

Texas At Austin, August 1985.

[7] S.M. Alcocer, Head Of The Seismic Testing Area, National Center For Disaster Prevention; Associate Professor, Institute Of

Engineering, Unam, Mexico ‘Design Of Earthquake-Resistant R/C Beam-Column Joints Rehabilitated Using Jacketing’

ISSN : 0975-5462 Vol. 9 No.11 Nov 2017 1021

View publication stats

You might also like

- Research PaperDocument15 pagesResearch PapershrirangNo ratings yet

- DRCS Assignment 2020Document12 pagesDRCS Assignment 2020Morya RonakNo ratings yet

- RajatDocument23 pagesRajatShah PriyamNo ratings yet

- Structural Assessment Report-STS 2020Document15 pagesStructural Assessment Report-STS 2020charlesjanguinNo ratings yet

- POV Alok Sarkar June 2008 PDFDocument4 pagesPOV Alok Sarkar June 2008 PDFindranigogoiNo ratings yet

- Question & Answer - 20marks ADocument62 pagesQuestion & Answer - 20marks AIswaryaNo ratings yet

- Shrinkage Strip Method Statment and Ther PDFDocument4 pagesShrinkage Strip Method Statment and Ther PDFhakim2020No ratings yet

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankDocument5 pagesDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsNo ratings yet

- Retrofitting Techniques For SlabDocument4 pagesRetrofitting Techniques For SlabStephanie Lois CatapatNo ratings yet

- DSR MicroprojectDocument15 pagesDSR Microprojectshobhitsahu7208No ratings yet

- Case Study - Structural RetrofittingDocument9 pagesCase Study - Structural RetrofittingKrishna KumarNo ratings yet

- Unit 1 PPT AK 7th Sem PDFDocument31 pagesUnit 1 PPT AK 7th Sem PDFNikhil PhulNo ratings yet

- Evangelista-Final Report Structural Investigation PDFDocument16 pagesEvangelista-Final Report Structural Investigation PDFthe conqueror100% (2)

- Modern Technique of Retrofitting 1Document15 pagesModern Technique of Retrofitting 1Kishore YenugudhatiNo ratings yet

- Service Life of StructuresDocument44 pagesService Life of StructuresPablo Benitez100% (1)

- Annex eDocument23 pagesAnnex eဒုကၡ သစၥာNo ratings yet

- Presented By:-Gautam SwalaDocument30 pagesPresented By:-Gautam SwalaChandrabhan Singh YadavNo ratings yet

- Design of Composite BridgeDocument10 pagesDesign of Composite BridgeHarold Jackson MtyanaNo ratings yet

- Cathodic Protection of A Multi-Storey Building, Method of Project Delivery and Long-Term MaintenanceDocument10 pagesCathodic Protection of A Multi-Storey Building, Method of Project Delivery and Long-Term MaintenanceCoevicNo ratings yet

- Repairs and Maintenance of RCC Framed StructuresDocument36 pagesRepairs and Maintenance of RCC Framed StructuresSagarKanadeNo ratings yet

- SodapdfDocument10 pagesSodapdfv adamNo ratings yet

- Code Tiltup PrecastDocument47 pagesCode Tiltup Precastkorosh75No ratings yet

- Repair Research Amr ShrifDocument18 pagesRepair Research Amr Shrifcicz 156465No ratings yet

- 3Rcs-Case Study of Vignan Bhavan (CPWD Building) : Dr.P.Rathish Kumar Department of Civil Engineering NIT WarangalDocument22 pages3Rcs-Case Study of Vignan Bhavan (CPWD Building) : Dr.P.Rathish Kumar Department of Civil Engineering NIT WarangalnamrataNo ratings yet

- Specification Guidelines For Surface Preparation of Concrete Prior To RepairDocument9 pagesSpecification Guidelines For Surface Preparation of Concrete Prior To RepairRafafuenmaNo ratings yet

- DSRS Micro ProjetDocument12 pagesDSRS Micro ProjetIsha Awhale PatilNo ratings yet

- Concrete Formwork Removal TimeDocument9 pagesConcrete Formwork Removal TimedrfkamalodeenNo ratings yet

- Assignment-10 Case StudyDocument4 pagesAssignment-10 Case StudySuman RegmiNo ratings yet

- Repair and Rehabilitation of StructuresDocument11 pagesRepair and Rehabilitation of StructuresSaravana Chandhran100% (1)

- Repair of Corrosion AffectedDocument12 pagesRepair of Corrosion AffectedKalmesh U PeerannavarNo ratings yet

- Share Gs RRRDocument9 pagesShare Gs RRRGanga gangaNo ratings yet

- Development of Repair Apparatus For Coking Chamber Walls of Coke OvensDocument6 pagesDevelopment of Repair Apparatus For Coking Chamber Walls of Coke OvensRakesh KumarNo ratings yet

- 1 GZ0929-02Document12 pages1 GZ0929-02Brian AdiemaNo ratings yet

- Retrofitting Design of Kathmandu Univers PDFDocument18 pagesRetrofitting Design of Kathmandu Univers PDFVivekCivilNo ratings yet

- Hoi - Thao T11-03 LuuDocument22 pagesHoi - Thao T11-03 LuuvuhachauNo ratings yet

- Rrs PresentationDocument69 pagesRrs PresentationPriyamvada Biju100% (1)

- Design of RC Srtuctural Elements (18CV53)Document71 pagesDesign of RC Srtuctural Elements (18CV53)savinaybharadwaj23122000No ratings yet

- Irjet V3i523Document4 pagesIrjet V3i523anon_294850851No ratings yet

- Managing The Technology of Modern and Traditional Construction WorksDocument24 pagesManaging The Technology of Modern and Traditional Construction WorksZlatin Kirov100% (1)

- Study On Causes & Control of Cracks in A Structure: Mulla FayazDocument4 pagesStudy On Causes & Control of Cracks in A Structure: Mulla FayazShubham ThakurNo ratings yet

- Causes of Deterioration of StructuresDocument5 pagesCauses of Deterioration of StructuresDhruv PatelNo ratings yet

- Retrofitting of BridgesDocument30 pagesRetrofitting of Bridgesmanu_696No ratings yet

- General:: (I) FoundationDocument67 pagesGeneral:: (I) FoundationNIRMALA100% (1)

- Comparative Study of Bubble Deck Slab With Conventional R.C.C SlabDocument7 pagesComparative Study of Bubble Deck Slab With Conventional R.C.C SlabIJRASETPublicationsNo ratings yet

- 18-0022 Elliot JA22Document33 pages18-0022 Elliot JA22basemNo ratings yet

- Method of Construction of Segmental Concrete BridgeDocument72 pagesMethod of Construction of Segmental Concrete BridgemarioestructuraNo ratings yet

- .Precast Concrete ConnectionsDocument3 pages.Precast Concrete Connectionsparamarthasom1974No ratings yet

- Paper 39 Strength Evaluation of Existing Reinforced Concrete StructureDocument5 pagesPaper 39 Strength Evaluation of Existing Reinforced Concrete StructuregemotorresNo ratings yet

- Load Carrying Capacity of Hollow Concrete Block Masonry WallDocument4 pagesLoad Carrying Capacity of Hollow Concrete Block Masonry WallGalal El-DarratNo ratings yet

- Masonry DesignDocument49 pagesMasonry DesignJohn MachariaNo ratings yet

- Repair and Rehabilitation of Structures: (Case Study) State Bank of India (Gandhidham)Document47 pagesRepair and Rehabilitation of Structures: (Case Study) State Bank of India (Gandhidham)Balan-Nogi Dan100% (1)

- Indian Standard For Industrial FlooringDocument10 pagesIndian Standard For Industrial FlooringRamprasad JeyaramNo ratings yet

- Repair and Rehabilitation After EarthquakeDocument10 pagesRepair and Rehabilitation After EarthquakeMohan NaikNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Concrete Formwork Removal Time, Specifications and CalculationsDocument6 pagesConcrete Formwork Removal Time, Specifications and CalculationsAravindanNo ratings yet

- Lec2 Materials 2Document9 pagesLec2 Materials 2Fadi Al-QasemNo ratings yet

- Methods of Retrofiting For RCC StructureDocument2 pagesMethods of Retrofiting For RCC StructureInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- (LECT 17,18) Prestressed Concrete Pipes and TanksDocument40 pages(LECT 17,18) Prestressed Concrete Pipes and TanksSushil Mundel50% (4)

- Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition): Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)From EverandComposite Steel and Concrete Structures: Fundamental Behaviour (Second Edition): Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Rating: 4 out of 5 stars4/5 (10)

- Corrosion and its Consequences for Reinforced Concrete StructuresFrom EverandCorrosion and its Consequences for Reinforced Concrete StructuresNo ratings yet

- Muscat Municipality Building Regs 2015 11 11 CH 2Document14 pagesMuscat Municipality Building Regs 2015 11 11 CH 2Raajeev NeelaNo ratings yet

- 5-Stance DrawingsDocument12 pages5-Stance DrawingsRichard mugashoNo ratings yet

- 2020 Dec. CE401-EDocument3 pages2020 Dec. CE401-EAKHIL.S1822 CE A 18-22No ratings yet

- Principal Components Controlling Building Form - Auckland Design Manual PDFDocument1 pagePrincipal Components Controlling Building Form - Auckland Design Manual PDFeyobNo ratings yet

- Technical Guidance Document M - 2010 (Access and Use)Document129 pagesTechnical Guidance Document M - 2010 (Access and Use)Niall100% (1)

- BOQ of Screen House For Saplings For KathmanduDocument1 pageBOQ of Screen House For Saplings For Kathmanduavs kfleNo ratings yet

- Advanced Glazing SystemsDocument45 pagesAdvanced Glazing SystemsSwati Singh100% (1)

- ClinicDocument11 pagesClinicPrince Adegoroye Adeniyi DicksonNo ratings yet

- Thermal Bridge Analysis For The PHPP v5Document37 pagesThermal Bridge Analysis For The PHPP v5USERNAMEMATRIX100% (1)

- (Paper) Method To Calculate The Fire Resistance of Reinforced Concrete Columns With Rectangular Cross Section (NRCC 33114)Document12 pages(Paper) Method To Calculate The Fire Resistance of Reinforced Concrete Columns With Rectangular Cross Section (NRCC 33114)Gregory SimmonNo ratings yet

- Climaveneta OverviewDocument4 pagesClimaveneta OverviewNgo Nguyen Van TheNo ratings yet

- Timber or Wooden FormworkDocument11 pagesTimber or Wooden FormworkThabaswini SNo ratings yet

- What Is Formwork?Document33 pagesWhat Is Formwork?Mukthesh ErukullaNo ratings yet

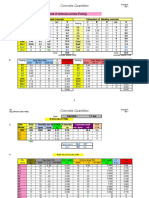

- CONCRETE QuantitiesDocument9 pagesCONCRETE QuantitiesdoxoNo ratings yet

- Report of CTBMMSMT 1Document15 pagesReport of CTBMMSMT 1api-291031287No ratings yet

- Aspire Tower: Sheetal Aryan 18BAR0123Document2 pagesAspire Tower: Sheetal Aryan 18BAR0123Sheetal AryanNo ratings yet

- Prefabricated ConstructionDocument10 pagesPrefabricated ConstructionNisha PawarNo ratings yet

- Building Technology I ReviewerDocument20 pagesBuilding Technology I ReviewerBabylyn MordenNo ratings yet

- Design Specification For Concrete ConstructionDocument18 pagesDesign Specification For Concrete ConstructionkunalmtechNo ratings yet

- Isolasi Pipa Insulflex FMDocument4 pagesIsolasi Pipa Insulflex FMsasongkoediNo ratings yet

- Yzh Affinity Heat Pump Install Manual PDFDocument16 pagesYzh Affinity Heat Pump Install Manual PDFSaid Marino CarrascoNo ratings yet

- The Soil Pipe: Chapter 6 of Plumbing Design and EstimateDocument22 pagesThe Soil Pipe: Chapter 6 of Plumbing Design and EstimateJohnRowenPerjeDianaNo ratings yet

- CH 2 - Estimate I & DDocument23 pagesCH 2 - Estimate I & DHarish Kumar MahavarNo ratings yet

- Chiller MideaDocument263 pagesChiller MideaMoraru MariusNo ratings yet

- (Pasig) Certificate of OccupancyDocument12 pages(Pasig) Certificate of OccupancyAndrew MarasiganNo ratings yet

- 50Hz R22 Air-Cooled Modular Chiller Technical Manual20120210Document117 pages50Hz R22 Air-Cooled Modular Chiller Technical Manual20120210avouzikisNo ratings yet

- Calculation of Loads For Column and Foundation DesignDocument2 pagesCalculation of Loads For Column and Foundation DesignMandar Nadgaundi100% (1)

- Lateral Force Resisting SystemsDocument75 pagesLateral Force Resisting Systemsabdalrhman AlattarNo ratings yet

- HVAC Training PresentationDocument55 pagesHVAC Training PresentationSridhar Chary KammariNo ratings yet

- 11.concrete Works ExecutionDocument16 pages11.concrete Works ExecutionVlad SpataruNo ratings yet