Professional Documents

Culture Documents

National Bulding Regulations Sans10400 N

Uploaded by

Lindelwe MoyoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

National Bulding Regulations Sans10400 N

Uploaded by

Lindelwe MoyoCopyright:

Available Formats

E:Mail: sagga@aaamsa.co.

za

www.sagga.co.za

Tel: (011) 805-5002 Fax: (011) 805-5033

E:Mail: aaamsa@iafrica.com www.aaamsa.co.za

SANS 10400-N:2012 Edition 3.1 requires glazing (framing and glazing materials) to comply with all the requirements of

SANS 613 in respect of wind and impact loads, water penetration and air leakage. Upon completion of project provide

appropriate Performance Test Certificates confirming compliance with all the requirements of SANS 613.

Installations of glass panes will be inspected in accordance with SANS 10400-Part N:2012 Edition 3.1.

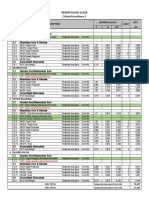

1. EXTERNAL VERTICAL GLAZING – Structures not exceeding 10m in height (3 storeys) Single Glazing

Vertical Glazing supported all round

Maximum Pane sizes in sq. m

Nominal Glass Thickness (mm) 3 4 5 6 8 10 12

Monolithic Annealed Glass 0.75 1.5 2.1 3.2 4.6 6.0 6.0

Patterned Annealed & Wired Glass - 0.75 1.2 1.9 2.6 3.4 -

Laminated Annealed Safety Glass - - - 2.9 4.3 5.7 5.7

Toughened Safety Glass - 1.9 3.0 4.5 8.0 8.0 8.0

Vertical Glazing - two opposite sides supported

Maximum Span between support in m

Nominal Glass Thickness (mm) 3 4 5 6 8 10 12

Monolithic Annealed Glass - 0.4 0.5 0.6 0.85 1.0 1.3

Patterned Annealed & Wired Glass - 0.25 0.3 0.35 0.5 0.6 -

Laminated Annealed Safety Glass - - - 0.55 0.8 0.95 1.2

Toughened Safety Glass - 0.55 0.7 0.85 1.15 1.3 1.8

2. INTERNAL VERTICAL GLAZING – Single Glazing

Vertical Glazing all round supported

Maximum Pane sizes in sq. m

Nominal Glass Thickness (mm) 3 4 5 6 8 10 12

Monolithic Annealed Glass 0.75 1.5 2.1 3.2 4.6 6.0 6.0

Patterned Annealed & Wired Glass - 0.75 1.2 1.9 2.6 3.4 -

Laminated Annealed Safety Glass - - - 4.1 6.0 7.2 7.2

Toughened Safety Glass - 3.0 4.2 6.4 9.2 9.2 9.2

Vertical Glazing – Two opposite sides supported

Maximum Span between support in m

Nominal Glass Thickness (mm) 3 4 5 6 8 10 12

Monolithic Annealed Glass - 0.65 0.8 0.95 1.3 1.55 2.0

Patterned Annealed & Wired Glass - 0.4 0.48 0.57 0.78 0.9 -

Laminated Annealed Safety Glass - - - 0.9 1.25 1.5 1.95

Toughened Safety Glass - 0.9 1.1 1.3 1.75 2.0 2.7

3. VERTICAL DOUBLE GLAZING (SIGU) – External (up to 3 storey) and Internal applications

Double Glazing (SIGU) all round supported only

Maximum pane area in sq. m

Type of glass Nominal glass thickness weakest light

3 4 5 6 8 10 12

Monolithic annealed glass 1.00 2.00 2.80 4.27 6.13 8.00 8.00

Patterned annealed & wired glass - 1.00 1.60 2.53 3.47 4.53 -

Laminated annealed safety glass - - - 3.87 5.73 7.60 7.60

Toughened safety glass - 2.53 4.00 6.00 10.67 10.67 10.67

Deviations from the above must be approved by Competent Person (Glazing) including applications in excess of three storeys.

Two-edge supported SIGU (double glazing) must be done in consultation with the manufacturer of the SIGU and approved by Competent

Person (Glazing).

4. GLASS FIN DIMENSIONS

Minimum Glass Fin Dimensions

Fin Height

Internal External

in m

1.5 150 x 12 150 x 15 Note: A butt joint is assumed to have no structural strength. Accordingly panels, which

2 150 x 12 150 x 19 incorporate a butt joint, are not considered to be supported on four sides. A glass fin is

necessary to provide the support at the joint so that the pane can be considered to be

2.5 150 x 12 175 x 19 supported along four sides. Should no fin be in place selection of glass must be in

3 175 x 15 200 x 25 accordance with Tables 1 or 2 above. Butt joints are not recommended for SIGU.

3.5 225 x 15 275 x 25

4 275 x 15 300 x 25

4.4 SAFETY GLAZING (Obtain SAGGA Certificate of Conformance confirming compliance).

4.4.1 The performance of safety glazing material shall be in accordance with the requirements of SANS 1263-1 and the individual panes

of safety glazing material shall be permanently marked by the installer in such a manner that the markings are visible after

installation.

4.4.2 Safety glazing materials that comply with SANS 1263-1 shall be used where:

a) doors and sidelights form part of any entrance up to 2100mm from finished floor level;

b) a window has a sill height of less than 500mm from the floor or external ground level;

c) a window has a sill height of less than 800mm from the floor or external ground level without any permanent barrier that prevents

persons from coming into contact with the glass panel, and is so placed that persons are likely, on normal traffic routes, to move

directly towards such window.

NOTE: A barrier could be any feature, i.e. a heavy bar across a window or a flower box placed in front of the window, that will provide

a physical or visual barrier between the glass and a person.

d) a bath enclosure or shower cubicle is glazed, or where glazing occurs immediately above and within a distance of 1800mm

horizontally or vertically from a bath or shower;

e) glazing is used in any shop front or display window within 2100mm from the finished floor level;

f) glazing is used in any wall or balustrade to (or immediately adjacent to) a stairway, ramp, landing, pathway, patio, veranda or

balcony;

g) glazing is used within 1800mm of the pitch line of a stairway or the surface of a ramp, landing, pathway, patio, veranda

or balcony;

h) glazing applications are sloped or horizontal;

i) a mirror is installed as a facing to a cupboard door less than 800mm above floor level and there is no solid backing;

j) glazing is used around areas such as swimming pools and ice rinks; and

k) glazing is used in internal partitions, within 2100mm of floor level.

4.4.3 All glazing for occupancy or building classification is A3 (places of instruction), E1 (place of detention), E2 (hospital), E3 (other

institutional (residential buildings) and H2 (dormitory), where such is associated with a building of occupancy classification A3, E1, E2

or E3 (see SANS 10400-A) shall be safety glazing material that complies with the requirements of SANS 1263-1.

4.4.4 Glass in balustrades shall be toughened safety glass unless rigidly supported on all sides. Glazing material in balustrades is subject

to impact and line loads determined in accordance within the requirements of SANS 10160-2.

4.4.5 Glass in horizontal or sloping applications shall be laminated safety glass or toughened safety glass. Toughened safety glass shall only

be used where individual panes are framed on all sides.

4.4.6 Wired glass having two-edge support may be used in vertical glazing in sawtooth roofs.

4.4.7 The thicknesses and maximum panel dimensions of frameless bath and shower enclosures shall be as given in table below.

Dimensions for flat frameless glass shower enclosures

Toughened safety glass Maximum panel size in sq. m

thickness

mm Doors and panels supporting doors Fixed panels

6 1.6 2.1

8 2.0 3.3

10 2.2 4. 0

Note: This table does not apply to curved glass

White areas do NOT require Safety Glass

GENERAL

Glazing installations not covered by or deviating from the items above such as, but not limited to, external glazing in

structures in excess of 10m in height, overhead or sloped glazing, glass flooring, three and one edge supported glass,

toughened glass assemblies and entrances, glass for balustrading etc. must be signed off and approved in writing by

Competent Person (Glazing) or Structures. The SAGGA Certificate of Conformance does NOT cover water penetration, air

leakage and wind load capacity of framing.

HANS A SCHEFFERLIE FSAGI (EXECUTIVE DIRECTOR) OCTOBER 2015

You might also like

- Glazing RegulationsDocument3 pagesGlazing RegulationsDaniel ReynoldsNo ratings yet

- Standards and Regulations With Regards To Safety Glass For Use in BuildingsDocument5 pagesStandards and Regulations With Regards To Safety Glass For Use in BuildingszoranmiskovicNo ratings yet

- M C D 8 - D W: 1. GlassDocument7 pagesM C D 8 - D W: 1. GlassEm PeeNo ratings yet

- Drosibas Stiklu Klasifikacija PDFDocument2 pagesDrosibas Stiklu Klasifikacija PDFMārcis LukšēvicsNo ratings yet

- 1 HTDocument12 pages1 HTHarrison Daka LukwesaNo ratings yet

- Jpaul QuoteDocument4 pagesJpaul QuoteKeyvin dela CruzNo ratings yet

- Saint Gobain Glass Protection PDFDocument20 pagesSaint Gobain Glass Protection PDFAnonymous t83HjAvXNo ratings yet

- G. James Glass Handbook Part CDocument28 pagesG. James Glass Handbook Part CPulbere NeagraNo ratings yet

- GB18045 2000 (E)Document15 pagesGB18045 2000 (E)Mehdi MosayebiNo ratings yet

- Safety Glazing in BuildingDocument8 pagesSafety Glazing in Buildingfakhrul anwarNo ratings yet

- Bs Untuk Glass LiftDocument3 pagesBs Untuk Glass LiftsaifulNo ratings yet

- Determination of Safe Thickness GlassDocument12 pagesDetermination of Safe Thickness GlassArun Mohan100% (1)

- A SECURE LIFE BEHIND THE GLASSDocument2 pagesA SECURE LIFE BEHIND THE GLASSGeorge-Gabriel MarinNo ratings yet

- Building Code Requirements for Glass in Single Family DwellingsDocument8 pagesBuilding Code Requirements for Glass in Single Family DwellingsHamza TikkaNo ratings yet

- GLASSDocument8 pagesGLASSNowella MendozaNo ratings yet

- Vitro-Td-138 Het GlassDocument8 pagesVitro-Td-138 Het GlassEdgar ValverdeNo ratings yet

- NTN PRO 006 Glass Types Used in BuildingsDocument2 pagesNTN PRO 006 Glass Types Used in BuildingsMoren AlfonsoNo ratings yet

- Professional Gabion Manufacturer NovaDocument8 pagesProfessional Gabion Manufacturer NovamabNo ratings yet

- (Brand Asahimas) : Rekapitulasi GlassDocument1 page(Brand Asahimas) : Rekapitulasi GlassRidwanRmdnNo ratings yet

- Annexure To Tender No Dps/Mrpu/1/5/3820 Technical Specification of Laminated Safety Glass PanelDocument1 pageAnnexure To Tender No Dps/Mrpu/1/5/3820 Technical Specification of Laminated Safety Glass Panelaman3327No ratings yet

- Safety ProtectionDocument23 pagesSafety ProtectionKhurshed Alam IndiaNo ratings yet

- Tempered Glass Test Report SummaryDocument4 pagesTempered Glass Test Report Summarytest testtNo ratings yet

- Glass Thickness Calc PDFDocument3 pagesGlass Thickness Calc PDFAnonymous cGM3hWNo ratings yet

- Mex MT Gamma Isoparete Rev.03 180531 EngDocument53 pagesMex MT Gamma Isoparete Rev.03 180531 Engscibduser001No ratings yet

- Window DetailsDocument5 pagesWindow Detailspsn_kylmNo ratings yet

- Gorilla Glass 3Document2 pagesGorilla Glass 3Riuk ShinigamiNo ratings yet

- Doors & WindowsDocument21 pagesDoors & Windows200211555No ratings yet

- General Specifications Section O: Glazing: Page 1/4Document5 pagesGeneral Specifications Section O: Glazing: Page 1/4shidik hossenNo ratings yet

- Toughened Glass Data SheetsDocument2 pagesToughened Glass Data SheetsAr Aayush GoelNo ratings yet

- Kurarayl4 3 Post-GlassDocument11 pagesKurarayl4 3 Post-GlassLuis ArciaNo ratings yet

- MMMMMMMM PDFDocument61 pagesMMMMMMMM PDFsirjorgehidalgo7741No ratings yet

- Public Funded Buildings Glazing SpecificationDocument8 pagesPublic Funded Buildings Glazing SpecificationShamim Ahsan ZuberyNo ratings yet

- Main Types of Glass: Flat Glass Float ProcessDocument3 pagesMain Types of Glass: Flat Glass Float ProcessDarcyTyrionNo ratings yet

- 2553 1Document17 pages2553 1praj2408No ratings yet

- The Best Fire Resistance Rated Glazing MaterialDocument3 pagesThe Best Fire Resistance Rated Glazing MaterialchuckNo ratings yet

- Switch AbleDocument36 pagesSwitch AbleSameer InamdarNo ratings yet

- Body (Interior and Exterior)Document56 pagesBody (Interior and Exterior)Phan DungNo ratings yet

- Structural Glass Barrier GuidelinesDocument4 pagesStructural Glass Barrier GuidelinesSiYing LaiNo ratings yet

- Distillation of Cut-Back Asphaltic Products PDFDocument8 pagesDistillation of Cut-Back Asphaltic Products PDFKevin TangNo ratings yet

- Types of Glass Using in Building ConstructionDocument14 pagesTypes of Glass Using in Building ConstructionTaniya Sara PhilipNo ratings yet

- Part 2 GlassDocument13 pagesPart 2 GlassLenard UsonNo ratings yet

- MULTIVER-Verre Low Iron ENDocument9 pagesMULTIVER-Verre Low Iron ENPeter BourasNo ratings yet

- Products, Glazing Techniques and Maintenance SECTION4 GGF Datasheet For The Quality of Thermally Toughened Soda Lime Silicate Safety Glass For Building PDFDocument12 pagesProducts, Glazing Techniques and Maintenance SECTION4 GGF Datasheet For The Quality of Thermally Toughened Soda Lime Silicate Safety Glass For Building PDFgulilero_yoNo ratings yet

- DuPont BRG Technical BulletinDocument4 pagesDuPont BRG Technical Bulletincrbr.corpNo ratings yet

- Facial Mirror With Plywood BackingDocument65 pagesFacial Mirror With Plywood BackingVinod Mohan100% (1)

- Sight GlassDocument2 pagesSight GlassLorenzoNo ratings yet

- Structural Facade Glass DesignDocument5 pagesStructural Facade Glass DesignPrantik Adhar SamantaNo ratings yet

- PVB Laminated Glass & Tempered GlassDocument14 pagesPVB Laminated Glass & Tempered GlassSamantha Lim Ai PeiNo ratings yet

- Toughened Glass - WikipediaDocument5 pagesToughened Glass - Wikipediaramthecharm_46098467No ratings yet

- Comparison of Kajaria Tiles Parameters To International Standards Bib Iso-13006:2012Document1 pageComparison of Kajaria Tiles Parameters To International Standards Bib Iso-13006:2012jagmohan.nanawareNo ratings yet

- Lecture 09-10 - Division 08 - Division 09Document126 pagesLecture 09-10 - Division 08 - Division 09Via AnapiNo ratings yet

- NGP Section 04Document4 pagesNGP Section 04poonam_ranee3934No ratings yet

- Information Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Document2 pagesInformation Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Khurshed Alam IndiaNo ratings yet

- FasaraGlassFinishes DS BulletinDocument4 pagesFasaraGlassFinishes DS Bulletinreflections1272No ratings yet

- FASARA Tech Data SheetDocument12 pagesFASARA Tech Data Sheetvlade naumovskiNo ratings yet

- Nova Gabion CatalogDocument20 pagesNova Gabion CatalogPearl ZhaoNo ratings yet

- INCREASED SAFETY JUNCTION BOX SPECSDocument2 pagesINCREASED SAFETY JUNCTION BOX SPECSdip461No ratings yet

- AGC Safety Glass Technical Information 2008 enDocument10 pagesAGC Safety Glass Technical Information 2008 enzoranmiskovicNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- TCW2101200809 Engineering Survey I - 2Document7 pagesTCW2101200809 Engineering Survey I - 2Lindelwe MoyoNo ratings yet

- 2020a.20-Site Inspection Report & Instruction 2Document1 page2020a.20-Site Inspection Report & Instruction 2Lindelwe MoyoNo ratings yet

- TCW2101200809 Engineering Survey I - 2Document7 pagesTCW2101200809 Engineering Survey I - 2Lindelwe MoyoNo ratings yet

- Structural Survey ReportDocument8 pagesStructural Survey ReportLindelwe MoyoNo ratings yet

- TCW2102200905 Engineering Survey IDocument10 pagesTCW2102200905 Engineering Survey ILindelwe MoyoNo ratings yet

- 2142a BS04Document1 page2142a BS04Lindelwe MoyoNo ratings yet

- AQS1208201108 Engineering SurveyingDocument2 pagesAQS1208201108 Engineering SurveyingLindelwe MoyoNo ratings yet

- TCW2204200808 Engineering Survey IIDocument5 pagesTCW2204200808 Engineering Survey IILindelwe MoyoNo ratings yet

- AQS1208201106 Engineering SurveyingDocument3 pagesAQS1208201106 Engineering SurveyingLindelwe MoyoNo ratings yet

- N Sibanda Back Building Eaves LayoutDocument1 pageN Sibanda Back Building Eaves LayoutLindelwe MoyoNo ratings yet

- 2142a BS03Document1 page2142a BS03Lindelwe MoyoNo ratings yet

- 2142a BS01Document1 page2142a BS01Lindelwe MoyoNo ratings yet

- N Sibanda Classroom Foundation LayoutDocument1 pageN Sibanda Classroom Foundation LayoutLindelwe MoyoNo ratings yet

- N Sibanda Back Building Foundation LayoutDocument1 pageN Sibanda Back Building Foundation LayoutLindelwe MoyoNo ratings yet

- N Sibanda Classroom Eaves LayoutDocument1 pageN Sibanda Classroom Eaves LayoutLindelwe MoyoNo ratings yet

- N Sibanda Hall Eaves Beam LayoutDocument1 pageN Sibanda Hall Eaves Beam LayoutLindelwe MoyoNo ratings yet

- Design of Mining Explosive VaultsDocument2 pagesDesign of Mining Explosive VaultsLindelwe MoyoNo ratings yet

- Assignment 1 PART 1Document9 pagesAssignment 1 PART 1Lindelwe MoyoNo ratings yet

- A C B E/R D: Mark Location No. Off Code No. Each Total Size No. IN Length ShapeDocument1 pageA C B E/R D: Mark Location No. Off Code No. Each Total Size No. IN Length ShapeLindelwe MoyoNo ratings yet

- A C B E/R D: Mark Location No. Off Code No. Each Total Size No. IN Length ShapeDocument1 pageA C B E/R D: Mark Location No. Off Code No. Each Total Size No. IN Length ShapeLindelwe MoyoNo ratings yet

- A C B E/R D: Mark Location No. Off Code No. Each Total Size No. IN Length ShapeDocument1 pageA C B E/R D: Mark Location No. Off Code No. Each Total Size No. IN Length ShapeLindelwe MoyoNo ratings yet

- Nokuthaba Moyo AssignmentDocument5 pagesNokuthaba Moyo AssignmentLindelwe MoyoNo ratings yet

- Assignment 1 PART 1Document9 pagesAssignment 1 PART 1Lindelwe MoyoNo ratings yet

- A C B E/R D: Mark Location No. Off Code No. Each Total Size No. IN Length ShapeDocument1 pageA C B E/R D: Mark Location No. Off Code No. Each Total Size No. IN Length ShapeLindelwe MoyoNo ratings yet

- Assignment 2 PART 1Document6 pagesAssignment 2 PART 1Lindelwe MoyoNo ratings yet

- CBLM Rogh-In PDFDocument64 pagesCBLM Rogh-In PDFmyco saura80% (5)

- GE Zoneline - 3000 - SeriesDocument8 pagesGE Zoneline - 3000 - SeriesDavidNo ratings yet

- Roof Terracing: Construction and Materials-Iii (Rar - 302)Document24 pagesRoof Terracing: Construction and Materials-Iii (Rar - 302)jashndeep100% (1)

- 4 3 3 1-Materials-Testing-LabDocument7 pages4 3 3 1-Materials-Testing-LabUday ChanNo ratings yet

- Mspr6 - Baseline Rev02: Key Access DateDocument1 pageMspr6 - Baseline Rev02: Key Access DateWan AzriNo ratings yet

- Two Way SlabDocument47 pagesTwo Way SlabSuson DhitalNo ratings yet

- Sethi Haveli, An Indigenous Model For 21st Century 'Green Architecture' PDFDocument16 pagesSethi Haveli, An Indigenous Model For 21st Century 'Green Architecture' PDFardalan baizNo ratings yet

- Sunguard PerformanceDocument5 pagesSunguard PerformanceRachman SyamsudinNo ratings yet

- A Review of The Effect of Corner LoadsDocument4 pagesA Review of The Effect of Corner LoadsATSNo ratings yet

- Mto Civil ArsitekturDocument1 pageMto Civil Arsitekturkoko srihandokoNo ratings yet

- View 203Document36 pagesView 203Maureen GarridoNo ratings yet

- SECTION 15081: Duct Insulation 15081Document5 pagesSECTION 15081: Duct Insulation 15081fatREVITNo ratings yet

- Dazzle LED LightingDocument8 pagesDazzle LED LightingmrharshadppatelNo ratings yet

- Water Supply Pressure TestDocument3 pagesWater Supply Pressure TestarlanNo ratings yet

- DFF180E2SSDB-Product SpecificationsDocument2 pagesDFF180E2SSDB-Product SpecificationsCesar Alfredo TrejoNo ratings yet

- ANTI-STATIC RAISED FLOORING INSTALLATION METHODDocument4 pagesANTI-STATIC RAISED FLOORING INSTALLATION METHODPunk GowthamanNo ratings yet

- Types of PlasterDocument25 pagesTypes of PlasterKhael Angelo Zheus Jacla100% (3)

- MAHONEY TABLE NagpurDocument2 pagesMAHONEY TABLE NagpurUrvashi Bagde100% (1)

- 131-13025-00 - Issued For Permit - Struct PDFDocument8 pages131-13025-00 - Issued For Permit - Struct PDFJust HendraNo ratings yet

- Types of WallsDocument12 pagesTypes of Wallsdreamboy8792% (13)

- Masonry 2103.3 - TABLE 2103.7 (1) : A C D BDocument2 pagesMasonry 2103.3 - TABLE 2103.7 (1) : A C D BRafeeq Ur RahmanNo ratings yet

- 2012 Performance Evaluation of Hybrid Fiber Reinforced Concrete PDFDocument8 pages2012 Performance Evaluation of Hybrid Fiber Reinforced Concrete PDFSrikanth KonikiNo ratings yet

- Composite Panel SpecificationsDocument4 pagesComposite Panel SpecificationsMØhãmmed ØwięsNo ratings yet

- Approved List of Manufacturers: Pipe FittingsDocument8 pagesApproved List of Manufacturers: Pipe FittingsSourav Kumar GuptaNo ratings yet

- KPCC Daily Activities ReportDocument7 pagesKPCC Daily Activities ReportNhoek RenNo ratings yet

- PH Coagulation Tank Structural PDFDocument2 pagesPH Coagulation Tank Structural PDFBenderlip CortezNo ratings yet

- Precast Wall PanelsDocument9 pagesPrecast Wall Panelschandanes100% (1)

- Bill of Quantities (Boq)Document22 pagesBill of Quantities (Boq)DADADADGGGNo ratings yet

- DuctworkDocument5 pagesDuctworkducatti996chNo ratings yet

- Kauffman Center For The Preforming ArtsDocument10 pagesKauffman Center For The Preforming ArtsRishika SoniNo ratings yet