Professional Documents

Culture Documents

Microsoft PowerPoint - BLCP Training Cource F Turbine 3

Uploaded by

Natthaphon NaosookCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microsoft PowerPoint - BLCP Training Cource F Turbine 3

Uploaded by

Natthaphon NaosookCopyright:

Available Formats

BLCP POWER PROJECT

TRAINING PROGRAM

COURCE - F

ITEM - TURBINE & AUXILIRY

CONTENTS - TURBINE

No. 3 TURBINE GLAND SEALING SYSTEM MAINTENANCE

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

OBJECTIVES

TERMINAL OBJECTIVES:

Upon completion of the lesson, the trainee will be able to describe the main

components of construction of the Turbine Gland Sealing System. In

addition, the trainee will be able to state the different categories of

maintenance applied at BLCP Power Project and some of the maintenance

procedures applicable to the Turbine Gland Sealing System.

Objectives PAGE 1

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

OBJECTIVES

ENABLING OBJECTIVES:

In order to achieve terminal objective of the lesson, the trainee will be

able to:

• Give an overview of the Turbine Gland Sealing System.

• Describe the major components of the Turbine Gland Sealing

System.

• Explain the functions of the main components of the Turbine Gland

Sealing System.

• State the differences between the different categories of Preventive

maintenance.

• Explain how to disassemble and reassemble the Turbine Gland

Sealing System components.

• State some of the common faults which occur with the Turbine

Gland Sealing System.

• State the safety requirements necessary to carry out maintenance

on the Turbine Gland Sealing System.

Objectives PAGE 2

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

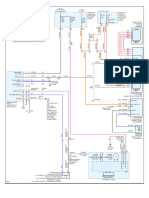

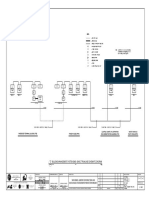

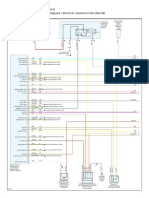

TURBINE GLAND SEALING SYSTEM

STEAM INLET STEAM INLET

( FROM IP TURBINES ) ( FROM IP TURBINES )

STEAM INLET

( FROM MAIN STEAM )

REHEAT

STEAM INLET

TE TE TE TE

GOVERNOR HP-IP TURBINE LP-1 TURBINE LP-2 TURBINE GENERATOR

SIDE (LOW PRESSURE SECTION 1) (LOW PRESSURE SECTION 2) SIDE

OPERATING FLOOR

OUTER GLAND INNER GLAND

RING RING

STEAM INLET ( FROM MAIN STEAM )

PS PS

HP-IP INNER GLAND LEAKOFF STEAM

LEAK OFF TO NO. 5

EXTRACTION

STEAM

GLAND LEAKOFF STEAM

FROM CONDENSATE ( FROM BFP TURBINE)

PUMP DISCHARGE GLAND LEAKOFF STEAM

(FROM TE OF LP TURBINE GLANDS) TO

ATMOSPHERE

PT PT PT

TE

GLAND SEALING

STEAM FROM WATER SEPERATOR FROM MAIN TURBINE

GLAND STEAM HEADER

GLAND STEAM STEAM VALVES

HEADER STEM LEAK

DESUPERHEATER

GLAND LEAK OFF

STEAM + AIR TO CONDENSER

TO GLAND STEAM TO ATMOSPHERE TO CONDENSER 01(02)MAW01AN102

CONDENSER (LP DRAIN MANIFOLD) GLAND CONDENSER

EXHAUST FAN-B

01(02)MAW01AN101

TO LP NO.1 HEATER GLAND CONDENSER

EXHAUST FAN-A

M

FROM MAIN GLAND STEAM

STEAM LINE HEADER SYMBOL

NORMALLY OPEN VALVE

PT PI

NORMALLY CLOSED VALVE

M GATE VALVE LI

FROM AUXILIARY

STEAM HEADER

GLOBE VALVE

PRESSURE CONTROL VALVE CONDENSATE FROM CONDENSATE TO

01(02)MAW01AC101

CONDENSATE PUMP LP HEATER NO. 1

GLAND STEAM CONDENSER

TEMPERATURE CONTROL VALVE

M

MOTOR VALVE

CHECK VALVE

GLAND STEAM SPILL OVER VALVE

BUTTERFLY VALVE

TO LP DRAIN MANIFOLD

RELIEF VALVE TO MISCELLANEOUS

DRAINS RECEIVER

WATER SEALED VALVE

EXPANSION JOINT

DRAIN FUNNEL

DCN-3-0283

PAGE 3

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

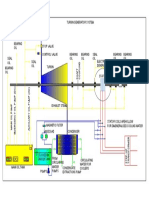

ARRANGEMENT OF HP- IP TURBINE GLAND-GOVERNOR END

0.5±0.1 0.5±0.1

0.5+0.15

-0.05

0.5±0.1

0.75+0.15

0.5+0.15

-0.05

-0.05

0.75+0.15

-0.05

0.5+0.15

-0.05

2.3

0.5+0.15

-0.05

2.3 2.3

8.1 12.7 8.1 12.7 8.1 12.7

(1.2) (1.2) (1.2)

1 OUTER GLAND CASING (UPPER)

2 OUTER GLAND CASING (LOWER)

3 INNER GLAND CASING (UPPER)

4 INNER GLAND CASING (LOWER)

42 POSITIVE PRESSURE CHAMBER

43 NEGATIVE PRESSURE CHAMBER

HP-IP TURBINE ROTOR

ATMOSPHERE INSIDE OF TURBINE

43 42

4

FROM

GLAND STEAM

HEADER

TO GLAND STEAM

CONDENSER

PAGE 4

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

ARRANGEMENT OF LP TURBINE GLANDS

1.5

0.5±0.1 0.5±0.1

0.5±0.1

0.5±0.1

5.6

1 43 42

LP TURBINE ROTOR

ATMOSPHERE INSIDE OF TURBINE

1 GLAND CASING (UPPER)

2 GLAND CASING (LOWER)

42 POSITIVE PRESSURE CHAMBER

43 NEGATIVE PRESSURE CHAMBER

2

FROM

GLAND STEAM

HEADER

TO GLAND STEAM

CONDENSER

PAGE 5

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

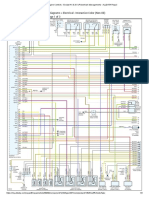

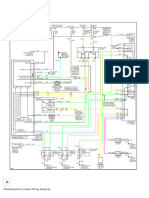

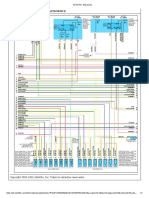

SECTIONAL ARRANGEMENT OF HP-IP TURBINE GLAND (GOVERNOR SIDE)

28 14

GLAND CASING

29 18

15 3 INNER GLAND CASING (UPPER)

4 INNER GLAND CASING (LOWER)

30 14 SET SCREW

GLAND CASE

15,16,17 PIN

27

E E 18,19,20 FLAT SPRING

c 21,22 HEXAGONAL SOCKET HEAD BOLT

HP-IP OUTER CASING 23 TAPER PIN

24 NUT

DETAIL G 25,26 PLUG

27 KEY

ROTOR 28 REAMER STUD BOLT

e

29 NUT

30,31 WASHER

CLEARANCE 32 HEXAGONAL SOCKET HEAD BOLT

CLEARANCE

33 STUD BOLT

VIEW C - C 34 REAMER STUD BOLT

35 HEXAGONAL SOCKET HEAD BOLT

36,37 SPHERICAL WASHER

HP-IP OUTER CASING F 39,40 GASKET

UPPER HALF 42 POSITIVE PRESSURE CHAMBER

VIEW E - E 43 NEGATIVE PRESSURE CHAMBER

39

HP-IP ROTOR B a OUTER GLAND ASSEMBLY

20 14 31 32 A b,c,d SEAL RING ASSEMBLY

f e INNER GLAND SUPPORT ASSEMBLY

3 80 NB GLAND STEAM 27 80 NB GLAND STEAM

43 26 25 f INSULATION STOP ASSEMBLY

LEAK OFF PIPE LEAK OFF PIPE g RADIAL PIN ASSEMBLY

27

43

C

14 a

20 14

C

19

GENERATOR GOVERNOR 22

"G"

SIDE SIDE

21

b 42 c 43

23 24

16

CL OF ROTOR VIEW D - D

37

37 36

14 19 3

42 36 35

17 15 18 14 42

35 34

33

4 27

27

d D D

g

16

B 100 NB GLAND STEAM 100 NB GLAND STEAM

SUPPLY PIPE A SUPPLY PIPE 4

F VIEW B - B VIEW F - F

HP-IP OUTER CASING

LOWER HALF

VIEW A - A 40

PAGE 6

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

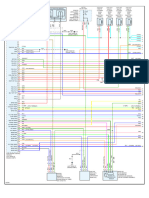

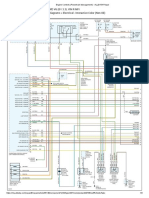

SECTIONAL ARRANGEMENT OF LP TURBINE GLANDS

1 GLAND CASING (UPPER)

2 GLAND CASING (LOWER)

5 ECCENTRIC BUSH

1 7,8 SOCKET HEAD BOLT

14 9,10 SPHERICAL WASHER

11,12 PLUG

15 14 SET SCREW

18 15 PIN

18 SPRING

13,21 SOCKET HEAD BOLT

c 22 SOCKET HEAD BOLT

23 TAPER PIN

ROTOR 25,26 PLUG

LP OUTER CASING

28 DOWEL PIN

(UPPER) 32 SOCKET HEAD BOLT

39,40 GASKET

39 32 42 POSITIVE PRESSURE CHAMBER

43 NEGATIVE PRESSURE CHAMBER

32 9 10

12 a GLAND BODY ASSEMBLY

LP-ROTOR b SEAL RING ASSEMBLY

c SEAL RING ASSEMBLY

15 26 26

25

1

13 9 10

22 21

b c 13

23

15 15

GENERATOR CL OF ROTOR GOVERNOR

END END

12

28

B

12 B 5

B

B

2

5 28

LP OUTER CASING

43

(LOWER) a

10 9 7

42

VIEW B - B

11 8 9 10

40

VIEW A - A

DCN-3-0290

PAGE 7

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

MAINTENANCE

Preventive Maintenance:

• Routine.

• Annual outage.

Prerequisites:

• Scheduling.

• Notification.

• Isolation.

• Safety.

PAGE 8

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

ROUTINE MAINTENANCE

• Enhances equipment reliability.

• Reduces costs.

• Minimizes potential downtime.

Preparation:

• Parts, tools and equipment.

• Documentation.

PAGE 9

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

ANNUAL OUTAGE MAINTENANCE

Preparation:

• Parts, tools and equipment.

• Documentation.

PAGE 10

Mitsubishi Contracting Parties

TURBINE & AUXILIARY TURBINE GLAND SEALING SYSTEM MAINTENANCE

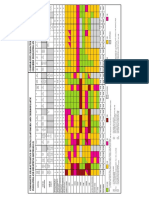

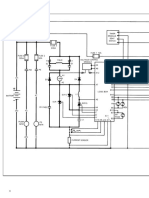

GLAND SEAL CLEARANCE MEASUREMENT PROCEDURE

WEDGE HERE TO MAINTAIN

RUNNING POSITION UPPER GLAND CASING

SEAL RING

ROTOR

CLEARANCE CLEARANCE

CL OF ROTOR

VIEW A- A

TAPERED WEDGE TAPERED WEDGE

A

PART OF GLAND SEAL RING

(SIMPLIFIED, NON SPECIFIC)

AXIAL VIEW OF GLAND CASING UPPER HALF

(SIMPLIFIED, NON SPECIFIC)

PAGE 11

Mitsubishi Contracting Parties

You might also like

- Microsoft PowerPoint - BLCP Training Cource F Turbine 2Document33 pagesMicrosoft PowerPoint - BLCP Training Cource F Turbine 2Natthaphon NaosookNo ratings yet

- ECU 1.5L 1 de 3Document2 pagesECU 1.5L 1 de 3Felix Velasquez100% (1)

- 2002 Kia Rio 1.5L ECU 1 PDFDocument1 page2002 Kia Rio 1.5L ECU 1 PDFHumberto Guerrero75% (4)

- MotoventiladoresDocument1 pageMotoventiladoresMartin SantoyoNo ratings yet

- Airbus A318/A319/A320/A321: Maintenance TrainingDocument1 pageAirbus A318/A319/A320/A321: Maintenance TrainingAnonymous QRVqOsa5100% (1)

- D10T2传动系统液压图Document1 pageD10T2传动系统液压图Chunping SongNo ratings yet

- Engine Control Mitsubishi v6 3.0Document5 pagesEngine Control Mitsubishi v6 3.0Juanck Todelar100% (1)

- Lube Oil SystemsDocument11 pagesLube Oil SystemscalcedaNo ratings yet

- Steam Injection NOx ReducDocument2 pagesSteam Injection NOx ReducEdison CheongNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pagesEngine Controls (Powertrain Management) - ALLDATA RepairRonald FerminNo ratings yet

- Microsoft PowerPoint - BLCP Training Cource F Turbine 1Document54 pagesMicrosoft PowerPoint - BLCP Training Cource F Turbine 1Natthaphon NaosookNo ratings yet

- Learjet 55: Eng Fire Pull Eng Fire PullDocument2 pagesLearjet 55: Eng Fire Pull Eng Fire PullFelipe Ponce De LeónNo ratings yet

- Shinko Turbine: Operation & MaintenanceDocument63 pagesShinko Turbine: Operation & MaintenanceYogi Pangaribuan100% (1)

- Diagrama D Honda Civid Hybrid 2009Document1 pageDiagrama D Honda Civid Hybrid 2009enio romeroNo ratings yet

- Oil Tank: Figure A Oil System Basic Schematic CFM 56 - 5A1 / 5A5Document1 pageOil Tank: Figure A Oil System Basic Schematic CFM 56 - 5A1 / 5A5mauryapiaeNo ratings yet

- Boilers FinalDocument40 pagesBoilers FinalAmeer HamzaNo ratings yet

- Ymms: Feb 25, 2021 Engine: 2.9L Eng License: Vin: Odometer: 2008 Isuzu I-290 SDocument1 pageYmms: Feb 25, 2021 Engine: 2.9L Eng License: Vin: Odometer: 2008 Isuzu I-290 SBá Đạt Đào NguyễnNo ratings yet

- Engine Controls - Except HX GX (Powertrain Management)Document3 pagesEngine Controls - Except HX GX (Powertrain Management)Muaz Ali AliNo ratings yet

- A320 Ata 79-Cfm56 CattsDocument1 pageA320 Ata 79-Cfm56 CattsabmedhussNo ratings yet

- 1153 MEP Drawings KEI 11-1102Document20 pages1153 MEP Drawings KEI 11-1102nfaa1986No ratings yet

- Bracket FilterDocument24 pagesBracket FilterjenadirNo ratings yet

- Hay AL-Hussain Sports Forum Al-Basra Hay AL-Hussain: Approved byDocument1 pageHay AL-Hussain Sports Forum Al-Basra Hay AL-Hussain: Approved byTahirJabbarNo ratings yet

- Ecm 1.5l 2 de 3Document2 pagesEcm 1.5l 2 de 3Felix VelasquezNo ratings yet

- 2019 Toyota Corolla 2.0L Eng VIN 4 SEDocument220 pages2019 Toyota Corolla 2.0L Eng VIN 4 SEalex acuña cordovaNo ratings yet

- PCM 2.7L 1 de 4Document2 pagesPCM 2.7L 1 de 4Felix VelasquezNo ratings yet

- Manual Valve List - FS-554!18!19Document1 pageManual Valve List - FS-554!18!19Ajay PrajapatiNo ratings yet

- VERSADocument1 pageVERSAsantiago dominguezNo ratings yet

- Cable Selection Guide PDFDocument1 pageCable Selection Guide PDFkapilNo ratings yet

- TP - 01 Welding For Split TeeDocument1 pageTP - 01 Welding For Split TeeLeonardo ManurungNo ratings yet

- Cessna 525 Engine SystemDocument14 pagesCessna 525 Engine SystemCesar BanchoffNo ratings yet

- Smart 2013Document6 pagesSmart 2013ecupro checoNo ratings yet

- 4 PDFDocument3 pages4 PDFjoan_padilla2000No ratings yet

- Valve List - F-5001Document3 pagesValve List - F-5001Ajay PrajapatiNo ratings yet

- Automotive Horn System CompleteDocument6 pagesAutomotive Horn System CompleteTaha Kassala100% (1)

- Bombardier Dash 8 Q400 Fire - Protection PDFDocument21 pagesBombardier Dash 8 Q400 Fire - Protection PDFSwapnil kapadiaNo ratings yet

- Run-Up Performance Data SheetDocument2 pagesRun-Up Performance Data Sheetdava gladi tataNo ratings yet

- 324DL Heavy Lift Hyd SCHDocument2 pages324DL Heavy Lift Hyd SCHEmmanuel solomonNo ratings yet

- Headlights - Headlamps & Fog Lamps Circuit (W - O DRL) (Headlamp) - ALLDATA RepairDocument2 pagesHeadlights - Headlamps & Fog Lamps Circuit (W - O DRL) (Headlamp) - ALLDATA RepairElectromecanica Integral OrtimorNo ratings yet

- Pipa Tembaga: Tandon Air Panas Tandon Air DinginDocument1 pagePipa Tembaga: Tandon Air Panas Tandon Air DinginIrvan DavinchiNo ratings yet

- Turbin N Generator SystemDocument1 pageTurbin N Generator Systemtetsu kurokoNo ratings yet

- HEADLIGHTS - Pontiac Grand Prix GTP 1997 - SYSTEM WIRING DIAGRAMSDocument1 pageHEADLIGHTS - Pontiac Grand Prix GTP 1997 - SYSTEM WIRING DIAGRAMSRicardo Alejandro Castro HernándezNo ratings yet

- Reference List ACHE PDFDocument8 pagesReference List ACHE PDFMarakanaMaheshNo ratings yet

- Caravan 98 Engine ControlsDocument3 pagesCaravan 98 Engine ControlsDavid MendezNo ratings yet

- ENGINE PERFORMANCE - Honda Civic Hybrid 2005 - SYSTEM WIRING DIAGRAMSDocument25 pagesENGINE PERFORMANCE - Honda Civic Hybrid 2005 - SYSTEM WIRING DIAGRAMSbazucaNo ratings yet

- Fire Pump Scheme & SLD NewDocument2 pagesFire Pump Scheme & SLD Newalex setiabudiNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument6 pagesEngine Controls (Powertrain Management) - ALLDATA RepairAUTOEPC LAAM (LUFACANA)No ratings yet

- 2012 GMC Truck Sierra 2500 2WD V8-6.0LDocument6 pages2012 GMC Truck Sierra 2500 2WD V8-6.0LSport CompactosNo ratings yet

- Diagrama 2 Relé de Apagado AutomáticoDocument1 pageDiagrama 2 Relé de Apagado AutomáticoRafa MackintoshNo ratings yet

- RB Model 2020Document37 pagesRB Model 2020Zikin PieurNo ratings yet

- 1999 System Wiring Diagrams. Chevrolet - SuburbanDocument1 page1999 System Wiring Diagrams. Chevrolet - SuburbanJimmy Perera BurgosNo ratings yet

- Gas Seal Support SystemDocument4 pagesGas Seal Support SystemTasawwur TahirNo ratings yet

- Pemanfaatan Fly AshDocument56 pagesPemanfaatan Fly AsharjunansyahNo ratings yet

- C300-B C300-A: SD313-9 Engine Control System (G4KJ: THETA-II 2.4L GDI) (2) Full Circuit DiagramsDocument1 pageC300-B C300-A: SD313-9 Engine Control System (G4KJ: THETA-II 2.4L GDI) (2) Full Circuit DiagramsLuis GarcíaNo ratings yet

- 2014 Nissan-Datsun Versa Sedan Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pages2014 Nissan-Datsun Versa Sedan Engine Controls (Powertrain Management) - ALLDATA RepairChino PlagaNo ratings yet

- Guide To FEDocument12 pagesGuide To FEIS InnerspaceNo ratings yet

- Kfss 1: Deyu CaiDocument1 pageKfss 1: Deyu CaiSKYLERNo ratings yet

- SERVICE MANUAL GeysersDocument11 pagesSERVICE MANUAL GeysersSajal GuptaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 4 EngineCyclesAnalysisDocument9 pages4 EngineCyclesAnalysisNatthaphon NaosookNo ratings yet

- The PID Control Algorithm: How It Works, How To Tune It, and How To Use ItDocument69 pagesThe PID Control Algorithm: How It Works, How To Tune It, and How To Use Ithamid vahedil larijaniNo ratings yet

- Image Space Lightroom Tips EbookDocument34 pagesImage Space Lightroom Tips EbookNatthaphon NaosookNo ratings yet

- Beamex MC2-Is Manual ENGDocument168 pagesBeamex MC2-Is Manual ENGNatthaphon NaosookNo ratings yet

- Calibration TablesDocument24 pagesCalibration TablesNatthaphon NaosookNo ratings yet

- Eddy Probe System On The Basis of New Technology: FT L C L I T UDocument6 pagesEddy Probe System On The Basis of New Technology: FT L C L I T UNatthaphon NaosookNo ratings yet

- Becton Dickinson Ethylene Oxide LeakDocument3 pagesBecton Dickinson Ethylene Oxide LeakJulie Wolfe100% (1)

- AD-120ES Parts PN-450160Document73 pagesAD-120ES Parts PN-450160naokito AkemiNo ratings yet

- DAF CF Gearbox Service Manual PDFDocument504 pagesDAF CF Gearbox Service Manual PDFMike QNo ratings yet

- 703 Control InstructionsDocument11 pages703 Control InstructionsJacyra Camargo AlvesNo ratings yet

- DiagramsDocument6 pagesDiagramsEriflonaNo ratings yet

- Grove Gmk5225 Cranes Material HandlersDocument28 pagesGrove Gmk5225 Cranes Material Handlersmanuelfer1985No ratings yet

- C20-32CL (Lot No 9974,8301)Document156 pagesC20-32CL (Lot No 9974,8301)Christian BedoyaNo ratings yet

- Liberty Parts ManualDocument19 pagesLiberty Parts Manualapi-3854769No ratings yet

- 500 CedarDocument8 pages500 CedarNicole WuNo ratings yet

- Porsche 911 Workshop Manual 1972-1981 enDocument1,005 pagesPorsche 911 Workshop Manual 1972-1981 engbesze100% (4)

- Ddec VDocument30 pagesDdec VeduardonemoNo ratings yet

- Technical Service Guide: 24-And 27-In. Unitized Laundry CentersDocument69 pagesTechnical Service Guide: 24-And 27-In. Unitized Laundry CentersCesar Calderon GrNo ratings yet

- Unique Small Single Seat ValveDocument14 pagesUnique Small Single Seat ValvePhrynocephalus ItaliaNo ratings yet

- 1-Testing of Automotive Frames-20-Jul-2018 - Reference Material I - Module 1 - ACDocument53 pages1-Testing of Automotive Frames-20-Jul-2018 - Reference Material I - Module 1 - ACYASH JITENDRA BHAKATNo ratings yet

- BT Tyro LHE150 - Spare Part Book 201912 TMHIDocument37 pagesBT Tyro LHE150 - Spare Part Book 201912 TMHIOficina Base Anápolis0% (2)

- Cilindro de Levante 3000 PsiDocument4 pagesCilindro de Levante 3000 PsiSergio Belmar CrisostoNo ratings yet

- Injection Pure Jet - ENGDocument38 pagesInjection Pure Jet - ENGSašo-Pregl Klaudija-MartinecNo ratings yet

- An565 Rev. 7Document4 pagesAn565 Rev. 7David WongNo ratings yet

- Copia de FORMATO INVENTARIO EWARD VALERODocument1,920 pagesCopia de FORMATO INVENTARIO EWARD VALEROJavisonNo ratings yet

- DNFT-PRX PoDocument1 pageDNFT-PRX PoSamir ELNo ratings yet

- EGB Installation Manual-03113Document16 pagesEGB Installation Manual-03113Maaz BilgramiNo ratings yet

- F - 155 - Esempio Di Calcolo IdraulicoDocument5 pagesF - 155 - Esempio Di Calcolo Idraulicokikohassan123No ratings yet

- TML 1618, 1512, 1613 CNG - JnnurmDocument6 pagesTML 1618, 1512, 1613 CNG - JnnurmkalyanammisettyNo ratings yet

- MindaDocument48 pagesMindaRohit JindalNo ratings yet

- 6 M Meister Hauptanleitung EN1006Document42 pages6 M Meister Hauptanleitung EN1006ghjtyuNo ratings yet

- Schaaf EcoRolls BrochureDocument3 pagesSchaaf EcoRolls BrochureProject Sales CorpNo ratings yet

- Battle GasDocument36 pagesBattle Gaspsn_kylmNo ratings yet

- 2KG Training Company Profile (2828)Document1 page2KG Training Company Profile (2828)BERTYNo ratings yet

- Torque Data TIX-IKS 2020Document2 pagesTorque Data TIX-IKS 2020rwinmillNo ratings yet

- WEG Synchronous Motors Pedestal Type Brushless 240E Manual EnglishDocument72 pagesWEG Synchronous Motors Pedestal Type Brushless 240E Manual EnglishBill MurrayNo ratings yet