100% found this document useful (2 votes)

651 views39 pagesInterlock and Logic

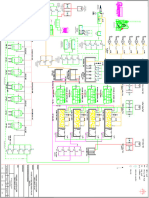

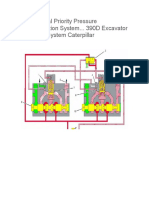

The document discusses guidelines for defining which safety-critical actions should be performed by an interlock safety (IS) system versus a distributed control system (DCS) due to the higher cost of IS hardware. It states that trips in the IS are generally based on 2-out-of-3 voting and the IS must protect personnel, critical equipment, and processes that could result in significant production losses if tripped. The DCS handles less critical actions like starting/stopping motors and switching operating modes. It then provides examples of specific interlock logics for various plant equipment.

Uploaded by

Harish KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

651 views39 pagesInterlock and Logic

The document discusses guidelines for defining which safety-critical actions should be performed by an interlock safety (IS) system versus a distributed control system (DCS) due to the higher cost of IS hardware. It states that trips in the IS are generally based on 2-out-of-3 voting and the IS must protect personnel, critical equipment, and processes that could result in significant production losses if tripped. The DCS handles less critical actions like starting/stopping motors and switching operating modes. It then provides examples of specific interlock logics for various plant equipment.

Uploaded by

Harish KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Interlock & Logic Diagram Introduction

- Pump Diagrams

- Trip Procedures

- Steam Condensate Pump

- Lube Oil System

- Polishing Pump

- Compressor Systems

- Interlock Diagrams