Professional Documents

Culture Documents

8 Sludge Dewatering

8 Sludge Dewatering

Uploaded by

Essoo MetooOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8 Sludge Dewatering

8 Sludge Dewatering

Uploaded by

Essoo MetooCopyright:

Available Formats

SEWAGE TREATMENT WORKS

SLUDGE TREATMENT

3- SLUDGE DEWATERING

11/26/2018 Sanitary Engineering - D. Fergala 1

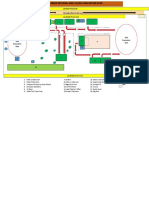

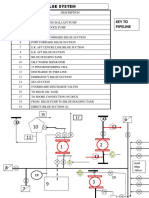

FLOW LINE OF SLUDGE TREATMENT IN ACTIVATED SLUDGE PROCESS

Sewage Treatment Components:

1. Rising Main. 5. Grit Removal Chamber. 9. Aeration Tank.

2. Deceleration Tank. 6. Distribution Chamber. 10. Final Settling Tank.

3. Approach Channel. 7. Primary Settling Tank. 11. Disinfection.

4. Screens. 8. Returned Sludge Pump Station.12. Contact Tank.

PRIMARY TREATMENT BIOLOGICAL TREATMENT

11

9 10

7

1 2 3 4 6 12

5 6 6

screening

Final Effluent

Grit

17 Primary Sludge

8

13

Secondary Excess Sludge

Final Effluent

Sludge Treatment Components :

16 15 14

13. Sludge Pump Station.

14. Thickener.

Gas

15. Digester.

SLUDGE TREATMENT 16. Drying Beds.

17. Supernatant Pump Station.

11/26/2018 Sanitary Engineering - D. Fergala 2

Drying Bed

Sludge drying beds are the oldest method of sludge dewatering.

These are still used extensively in small to medium-size plants to

dewater digested sludge.

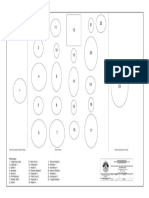

Typical sand beds consist of a layer of coarse sand 15-25 cm in

depth and supported on a graded gravel bed that incorporates

selected tiles or perforated pipe under-drains. Paved drying beds

are also used.

Each section of the bed (8m × 30 m or 10 × 20 m) contains water-

tight walls, under-drain system, and vehicle tracks for removal of

sludge cake.

Sludge is placed on the bed in 20 to 30 cm (8 to12 in) layers and

allowed to dry. The under-drained liquid (filtrate water) is returned

to the plant.

The drying period is 10-15 days and moisture content of the cake

is 60-70 percent. Poorly digested sludge may cause odor

problems.

11/26/2018 Sanitary Engineering - Dr. Fergala 3

Depending on the climatic conditions and odor control

requirements, the drying bed may be open or covered.

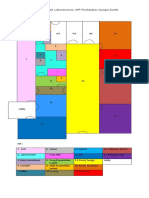

Typical design criteria for sludge drying beds receiving

digested primary and secondary sludge are given below:

1. Sludge Drying Bed Area:

0.14-0.28 m² per capita for uncovered beds.

0.10-0.20 m² per capita for covered beds.

2. Sludge Loading Rate

100-300 kg dry solids per m² per year for uncovered beds.

150-400 kg dry solids per m² per year for covered beds.

The sludge cake from drying beds contains 20-40 percent

solids and almost 90-100 percent solids capture occurs.

11/26/2018 Sanitary Engineering - Dr. Fergala 4

11/26/2018 Sanitary Engineering - Dr. Fergala 5

You might also like

- Building Code of Pakistan 2021Document614 pagesBuilding Code of Pakistan 2021Uzair Maqbool KhanNo ratings yet

- Infratest - Automatic Asphalt AnalyzerDocument22 pagesInfratest - Automatic Asphalt AnalyzerSupriyo PNo ratings yet

- ABC Guide To Dropped Object Prevention Vol 1 Worksite Hazard Management For DROPSDocument108 pagesABC Guide To Dropped Object Prevention Vol 1 Worksite Hazard Management For DROPSDara Moto100% (1)

- 7 Sludge DigestionDocument22 pages7 Sludge DigestionEssoo MetooNo ratings yet

- Modul 2 - Principles of Function of The Major Component of The PlantDocument25 pagesModul 2 - Principles of Function of The Major Component of The PlantMuhammad Yusuf Halim PutraNo ratings yet

- Hzi Ref Zistersdorf enDocument4 pagesHzi Ref Zistersdorf enPritNo ratings yet

- Incinerator PDF CatalogueDocument6 pagesIncinerator PDF CataloguePasindu PramodNo ratings yet

- Lysine Process FlowDocument1 pageLysine Process FlowlucasNo ratings yet

- Separation Plants TT Folder ENDocument8 pagesSeparation Plants TT Folder ENMohamed EmadNo ratings yet

- Reverse Osmosis Exploded DiagramDocument1 pageReverse Osmosis Exploded DiagramNazım TolaNo ratings yet

- RHS Presentation For 3rd Runway (Final)Document101 pagesRHS Presentation For 3rd Runway (Final)lui szeNo ratings yet

- SyngasPurificationbyCommonSolvers-AdvancesinSynthesisGas - MethodsTechnologiesandApplications - Volume2 (2) BorrarDocument5 pagesSyngasPurificationbyCommonSolvers-AdvancesinSynthesisGas - MethodsTechnologiesandApplications - Volume2 (2) BorrarErebus Fobos Momus ErisNo ratings yet

- Saeco Intelia Deluxe User Manual PDFDocument28 pagesSaeco Intelia Deluxe User Manual PDFMarg SmithNo ratings yet

- Esquema Huckepack Busch PDFDocument1 pageEsquema Huckepack Busch PDFEscurçó NegreNo ratings yet

- Modul 1 - General Layout of The PlantDocument5 pagesModul 1 - General Layout of The PlantMuhammad Yusuf Halim PutraNo ratings yet

- Brochure - Valves For Oil & Gas Industries (En) .Document28 pagesBrochure - Valves For Oil & Gas Industries (En) .ABULARA2K6No ratings yet

- Processes 3: Physical Processes Yhd 73.3005: Anna Mikola TKT D SC (Tech)Document34 pagesProcesses 3: Physical Processes Yhd 73.3005: Anna Mikola TKT D SC (Tech)Jim TsikasNo ratings yet

- Your Guide To: Difficulty Level: Easy Distance: 1.4km Walking Time: 1-2hr - Cycling Time: 30minDocument4 pagesYour Guide To: Difficulty Level: Easy Distance: 1.4km Walking Time: 1-2hr - Cycling Time: 30minAndre HscNo ratings yet

- MSMA Chapter 6 - Rainwater HarvestingDocument20 pagesMSMA Chapter 6 - Rainwater HarvestingFaraa BellaNo ratings yet

- Rxco2 CatalogDocument12 pagesRxco2 CatalogBadr groupNo ratings yet

- Denah Lab. Patologi Klinik Rs. Budi LestariDocument2 pagesDenah Lab. Patologi Klinik Rs. Budi LestariSintya Gilang NovitasariNo ratings yet

- In-Wash Inspira: Es / en / FR / deDocument48 pagesIn-Wash Inspira: Es / en / FR / deAlejandro García RomeroNo ratings yet

- Fabric Dust Collector Systems: Werner Flückiger Beat StockerDocument36 pagesFabric Dust Collector Systems: Werner Flückiger Beat StockerMARWAN ABDUL-HAMEEDNo ratings yet

- Water Purification: Turnkey System Design, Assembly, Install and Technical SupportDocument7 pagesWater Purification: Turnkey System Design, Assembly, Install and Technical SupportFinca La JuanitaNo ratings yet

- by Product Co2 Recovery Flow PDFDocument1 pageby Product Co2 Recovery Flow PDFOBRENo ratings yet

- Waste To EnergyDocument9 pagesWaste To EnergyIhtesham Shafiq MalikNo ratings yet

- B-DRY Omega AirDocument8 pagesB-DRY Omega AirMột Lằn QuangNo ratings yet

- Brief History of BurmaDocument6 pagesBrief History of BurmaSan Ko Ko OoNo ratings yet

- Staubsaugen Erfrischend Anders.: Der Beutellose SaugerDocument20 pagesStaubsaugen Erfrischend Anders.: Der Beutellose SaugerlubeckuNo ratings yet

- Membrane Cleaning: of The Ro-System With Isave UnitDocument4 pagesMembrane Cleaning: of The Ro-System With Isave UnitTripoli2010No ratings yet

- A Laval SaparatorDocument4 pagesA Laval Saparatoriftikharali8No ratings yet

- Barangay Road To San Luis: Landslide Prone AreaDocument2 pagesBarangay Road To San Luis: Landslide Prone Areajohn frits gerard mombayNo ratings yet

- Vnhs Evac - PlanDocument2 pagesVnhs Evac - PlanJohn Frits Gerard MombayNo ratings yet

- Post Asian Tsunami Waste Management Workshop Detail Design ImplementationDocument16 pagesPost Asian Tsunami Waste Management Workshop Detail Design ImplementationAndre SuitoNo ratings yet

- TCS37I11Document4 pagesTCS37I11ilhamakbar212.dblNo ratings yet

- Borrow Pits - Rev 4 - 8 November 2013Document27 pagesBorrow Pits - Rev 4 - 8 November 2013varity butheleziNo ratings yet

- Ew 560 F PDFDocument20 pagesEw 560 F PDFZassy ZainalNo ratings yet

- 002.scott ChesebroDocument21 pages002.scott Chesebromitch980No ratings yet

- Tropicana Metropark - Pandora EbrochureDocument8 pagesTropicana Metropark - Pandora EbrochureKentNo ratings yet

- Drilling Program Example For SemiDocument11 pagesDrilling Program Example For SemiMehrez AssidyNo ratings yet

- Casey 1990Document9 pagesCasey 1990Kevin VlogsNo ratings yet

- THE-CLAT POST-June 20235724447Document104 pagesTHE-CLAT POST-June 20235724447abhineetNo ratings yet

- FIREMIKS Recommended Setup - Fixed - Automatic Flushing PDFDocument1 pageFIREMIKS Recommended Setup - Fixed - Automatic Flushing PDFAob AprilNo ratings yet

- THE-CLAT POST-June 20235676588Document104 pagesTHE-CLAT POST-June 20235676588okayinieNo ratings yet

- GSD SERIES Belt ThickennerDocument16 pagesGSD SERIES Belt ThickennerSid Esterico SestosoNo ratings yet

- PSMS-SOP-AM XX Rev4 DM Plant RegenarationsDocument18 pagesPSMS-SOP-AM XX Rev4 DM Plant RegenarationskishorekumarvNo ratings yet

- 41-187.0 Natural Gas Processing 0Document12 pages41-187.0 Natural Gas Processing 0Thameem AnsariNo ratings yet

- Adlaw SitedevelopmentplanDocument1 pageAdlaw SitedevelopmentplanMickaela Kassandra ParanNo ratings yet

- Level Gauge Selection GuideDocument16 pagesLevel Gauge Selection GuideSrinivasan GunnerNo ratings yet

- Denah Kamar Operasi Rsud LembangDocument1 pageDenah Kamar Operasi Rsud LembangariNo ratings yet

- IHC Hydrohammer Offshore Brochure IHC03!01!11.10Document13 pagesIHC Hydrohammer Offshore Brochure IHC03!01!11.10luluNo ratings yet

- 15 Waterview DriveDocument28 pages15 Waterview DriveNiNo ratings yet

- Greensand Regen ProceduresDocument3 pagesGreensand Regen ProceduresGeancarlo GutierrezNo ratings yet

- Liquid Limit and Plastic Limit Tests - Lab ExperimentsDocument8 pagesLiquid Limit and Plastic Limit Tests - Lab ExperimentsbilalNo ratings yet

- Laundry Machine & PackingDocument4 pagesLaundry Machine & PackingbharatsarnaNo ratings yet

- Area Penyimpanan Bahan Baku Area Proses Area Penyimpanan ProdukDocument1 pageArea Penyimpanan Bahan Baku Area Proses Area Penyimpanan ProdukFebri5awalsyahNo ratings yet

- Ground FloorDocument1 pageGround FloorHrishikesh MozeNo ratings yet

- Rencana Denah Laboratorium UPT Puskesmas Sungai DarehDocument2 pagesRencana Denah Laboratorium UPT Puskesmas Sungai DarehYelvia QueenNo ratings yet

- Key To Pipeline: Bilge SystemDocument23 pagesKey To Pipeline: Bilge SystemvivekNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- RC3 Behaviour of Reinforced Concrete Beams Under ShearDocument14 pagesRC3 Behaviour of Reinforced Concrete Beams Under Shearce20b021No ratings yet

- JK Paper Launders Annexure-1 Rev.1Document1 pageJK Paper Launders Annexure-1 Rev.1kasvikrajNo ratings yet

- PDS Gyproc HabitoDocument2 pagesPDS Gyproc HabitovietNo ratings yet

- Milk Harvest CIP Sanitation SystemsDocument13 pagesMilk Harvest CIP Sanitation SystemsBouMaticNo ratings yet

- Column LayoutDocument1 pageColumn LayoutAhmed Daahir AdenNo ratings yet

- International Metal Trading NetworkDocument26 pagesInternational Metal Trading NetworkJozsef MagyariNo ratings yet

- Inergen System Operation and Maintenance InstructionDocument16 pagesInergen System Operation and Maintenance InstructionchuminhNo ratings yet

- History Q & ADocument17 pagesHistory Q & ADadajem Caseria Samson100% (2)

- Construction Materials and Testing: "Chapter 4: Concrete"Document15 pagesConstruction Materials and Testing: "Chapter 4: Concrete"DantesNo ratings yet

- Duracoil Optima, Gray, With Flat Steel Slats: R U G G E DDocument6 pagesDuracoil Optima, Gray, With Flat Steel Slats: R U G G E DdanielbustNo ratings yet

- CH 14 CarbonandAlloySteelsDocument42 pagesCH 14 CarbonandAlloySteelsdarwin_hua100% (1)

- Negative Pressure Isolation Room - Rsup. Dr. R.D. Kandou - ManadoDocument188 pagesNegative Pressure Isolation Room - Rsup. Dr. R.D. Kandou - ManadoRobert SimbolonNo ratings yet

- TMPBBC3Document152 pagesTMPBBC3Mike2322No ratings yet

- Cub Cadet Parts Manual For Model 2166 TractorDocument9 pagesCub Cadet Parts Manual For Model 2166 Tractorenid100% (54)

- Detail Boq CG - For EfsDocument3 pagesDetail Boq CG - For EfsVaibhav SawantNo ratings yet

- 14.7.6 Steel-Reinforced Elastomeric Bearings - Method A: AASHTO LRFD Bridge Design Specifications, 8th Edition (2017)Document8 pages14.7.6 Steel-Reinforced Elastomeric Bearings - Method A: AASHTO LRFD Bridge Design Specifications, 8th Edition (2017)jrjdengineersNo ratings yet

- Geberit bs12056 Drainage Design Without CompromiseDocument64 pagesGeberit bs12056 Drainage Design Without CompromiseKushalKallychurnNo ratings yet

- Overview of Commercialized R290 TechnologyDocument20 pagesOverview of Commercialized R290 TechnologySamiYousifNo ratings yet

- Case Study 1Document31 pagesCase Study 1Charlene EtlarNo ratings yet

- Module 9 Fire Safety ConceptDocument133 pagesModule 9 Fire Safety ConceptGee MacawileNo ratings yet

- Introduction To Designing Elastomeric Vibration IsolatorsDocument26 pagesIntroduction To Designing Elastomeric Vibration IsolatorsDurukan Burak DilekNo ratings yet

- Lenton Interlok - Cp7c-WwenDocument6 pagesLenton Interlok - Cp7c-WwenAndrei NeculaNo ratings yet

- Lenin Raj: Cover Letter July 30, 2018Document3 pagesLenin Raj: Cover Letter July 30, 2018Lenin RajNo ratings yet

- WD WQ 130 MLD SRSP Adilabad-1Document276 pagesWD WQ 130 MLD SRSP Adilabad-1BUKA RAMAKANTHNo ratings yet

- Traffic EngineeringDocument5 pagesTraffic EngineeringRaheelAfzaalNo ratings yet

- CE 310 - Lec 0 IntroductionDocument12 pagesCE 310 - Lec 0 IntroductionumairNo ratings yet

- Cement Mill ReportDocument13 pagesCement Mill ReportYhaneNo ratings yet

- CPWD Dar Vol I 14092023-CivilDocument992 pagesCPWD Dar Vol I 14092023-CivilNizar AhamedNo ratings yet