Professional Documents

Culture Documents

Cranes Inspection Check List UPDATE

Uploaded by

Iskandar Azri0 ratings0% found this document useful (0 votes)

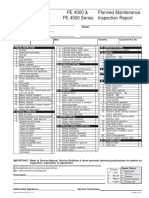

7 views2 pagesThis document is a checklist for inspecting cranes. It lists 9 items to check including the log book, identification and capacity, operator compartment, carrier, boom and turret, hydraulic system, outriggers, sheaves, hook block, and crane block. For each item, inspectors check for issues like wear, damage, cracks, leaks, and proper operation and documentation. The inspection is witnessed and verified by additional parties before being documented.

Original Description:

4. Cranes inspection check list UPDATE

Original Title

4. Cranes inspection check list UPDATE

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a checklist for inspecting cranes. It lists 9 items to check including the log book, identification and capacity, operator compartment, carrier, boom and turret, hydraulic system, outriggers, sheaves, hook block, and crane block. For each item, inspectors check for issues like wear, damage, cracks, leaks, and proper operation and documentation. The inspection is witnessed and verified by additional parties before being documented.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views2 pagesCranes Inspection Check List UPDATE

Uploaded by

Iskandar AzriThis document is a checklist for inspecting cranes. It lists 9 items to check including the log book, identification and capacity, operator compartment, carrier, boom and turret, hydraulic system, outriggers, sheaves, hook block, and crane block. For each item, inspectors check for issues like wear, damage, cracks, leaks, and proper operation and documentation. The inspection is witnessed and verified by additional parties before being documented.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

CRANES INSPECTION

COMPANY : ____________________________________________

LOCATION : ____________________________________________

S/NO ITEM TO BE CHECKED YES NO REMARKS

1. Log book and crane manual operation

i. Maintenance schedule

ii. Operating hour

iii. Oil Change

2 Identification and Capacity

i. PMA no & Cert

ii. Safe working load

iii. Registration no

iv. Chassis no

v. Operator cert

3 Operator compartment

i. Cabin

ii. Load chart

iii. Load rating chart

iv. Fire Extinguisher

4 Carrier

i. Tire damage & proper inflation

ii. Engine fluids,leaks&loose component

iii. Proper working light

iv. Frame cracked welds,loose bolts

v. Drive train

Cap and Turret

i. Winch & component,wire rope spooling

ii. Cracks & loose bolts on winch mounting

iii. Wear in boom hinge pin & bosses

iv. Cracks & loose bolts in turret frame

v. Condition of rotation bearing & drive gear

vi. Cracked or broken glass

vii. Working windshield wiper

5 Boom & Turret

i. Winch

ii. Weld

iii. Pins & Bosses

iv. Pads

v. Head

vi. Boom - wear in hoist cylinder pins&bosses

vii. Condition of jib extension

viii. Wear in block&hook

ix. Wear sheaves,pins & head

x. Deformation in boom extension

xi. Slide pad wear

xii. Deformation in main boom

xiii. Inspect boom for dents or other deformed part

xiv. Jib ears must be straight

xv. Test the A2B switch for operation

xvi. Inspect condition of electrical cable

xvii. A2B cable reel must operate smoothly

Hydraulic system

i. Hydraulic hoses and fitting

ii. Hydraulic functions

6 Outrigger

i. Cracked or broken knuckle

ii. Bent or damaged beam

iii. Excessive play in beams

iv. Cracked welds

v. Deformed pad

vi. Leaks in hydraulic hoses and fittings

7 Sheaves

i. Flanges for chip cracks, wear

ii. Groove wear

iii. Bearings for wobble, crease, ease of rotation

8 Hook Block

i. Slide plate blots tight

ii. Shave pin & bearing tight

iii. Sheave pin keeper in place and tight

iv. Safety latch functioning

v. Side plates straight

vi. Hook rotation &swivel smooth and tight

vii. Shave groove not worn, sheaves turn freely

9 Crane Block

i. Wear & Deformation

ii. Cracks & sharp nicks & twisting

iii. neck

iv. Safety latch

v. Swivel wear & lubrication

vi. Hook shackle mousing

vii. Cranes hook terminal

INSPECTED BY: WITNESS BY: VERIFIED BY:

NAME: Iskandar Azri NAME: NAME:

Bin Abdullah Sani

DESIGNATION: DESIGNATION: DESIGNATION:

Lifting Supervisor

DATE: DATE: DATE:

You might also like

- TRI 1008 Quality CardingDocument17 pagesTRI 1008 Quality Cardingalcon1No ratings yet

- Diesel MechanicDocument23 pagesDiesel MechanicAtif MahmoodNo ratings yet

- KOLee Tool Grinder Owners ManualDocument139 pagesKOLee Tool Grinder Owners ManualJason Bowman100% (4)

- Lift Plan TrainingDocument73 pagesLift Plan TrainingMohammad AbdullahNo ratings yet

- Tower Crane Inspection ChecklistDocument1 pageTower Crane Inspection Checklistshakti123456789No ratings yet

- KO Lee Owners Manual 1979 OCR& - 39 D Low Resolution - JpegDocument139 pagesKO Lee Owners Manual 1979 OCR& - 39 D Low Resolution - JpegRusty_Iron_WorksNo ratings yet

- Tank Method Statement - r0Document11 pagesTank Method Statement - r0AravindanNo ratings yet

- Service Manual Elna 745Document61 pagesService Manual Elna 745alexa bNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionRating: 5 out of 5 stars5/5 (2)

- Pedestal Crane Student ManualDocument25 pagesPedestal Crane Student ManualDangtrinh Nguyen100% (1)

- Boom Truck Instructors NotesDocument76 pagesBoom Truck Instructors NotesWill RodriguezNo ratings yet

- Condition Monitoring For Steam Turbines Part IIDocument31 pagesCondition Monitoring For Steam Turbines Part IIidigiti100% (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- G.V. Manual (FC Type)Document20 pagesG.V. Manual (FC Type)sambhajiNo ratings yet

- Rigging: GuideDocument244 pagesRigging: Guideyusry72100% (11)

- Reconditioning of ValvesDocument6 pagesReconditioning of ValvesPaul PhiliphsNo ratings yet

- Bico MotorsDocument132 pagesBico Motorsamir_hayfa50% (2)

- Alatas ComDocument6 pagesAlatas ComsamNo ratings yet

- Airframe Control and RiggingDocument17 pagesAirframe Control and RiggingIdrisNo ratings yet

- Operator Cabin Mounting Bolts Replacement and Platform Repair - Rev0Document2 pagesOperator Cabin Mounting Bolts Replacement and Platform Repair - Rev0shakhowiNo ratings yet

- SyllabusDocument12 pagesSyllabusPrasad MolletiNo ratings yet

- Catalogo Embragues 20-21 010620 SMALLDocument48 pagesCatalogo Embragues 20-21 010620 SMALLSol TdiNo ratings yet

- IM-09-A9 Tower Crane Inspection Check ListDocument2 pagesIM-09-A9 Tower Crane Inspection Check ListVishnu SNo ratings yet

- K017 - OHSE Tower Crane ChecklistDocument2 pagesK017 - OHSE Tower Crane ChecklistRajib MondalNo ratings yet

- FC4500Document1 pageFC4500hugoamendozaNo ratings yet

- Tower Crane ChecklistDocument1 pageTower Crane ChecklistkardinyenduNo ratings yet

- ME2029 DJF 2 Marks +16 Mark QuestionsDocument15 pagesME2029 DJF 2 Marks +16 Mark QuestionssureshkumarNo ratings yet

- Manual Stacker Do's & DontsDocument3 pagesManual Stacker Do's & DontsJin DelaCruzNo ratings yet

- Straatman Dredging EquipmentDocument24 pagesStraatman Dredging EquipmentMNo ratings yet

- Pe4000 4500Document1 pagePe4000 4500hugoamendozaNo ratings yet

- Rigging GuideDocument142 pagesRigging GuideJB MadeleineNo ratings yet

- (B) Viewing Procedure of Crank Shaft AimDocument3 pages(B) Viewing Procedure of Crank Shaft Aimesakkimuthu100% (1)

- Failure of Rotary Flow Divider PDFDocument8 pagesFailure of Rotary Flow Divider PDFsanjeevchhabraNo ratings yet

- Grade 12 KeeplerDocument2 pagesGrade 12 Keeplerjulie ann marie gregorioNo ratings yet

- Iom-Ball ValveDocument10 pagesIom-Ball ValveMohamadIbnuHassanNo ratings yet

- Roatary Actuators - Micromatic Repair Manual - SS-001 Thru SS-130Document12 pagesRoatary Actuators - Micromatic Repair Manual - SS-001 Thru SS-130tungNo ratings yet

- Brewers ChecklistDocument2 pagesBrewers ChecklistMax CrawfordNo ratings yet

- XL650 InstructionsDocument59 pagesXL650 InstructionsLeonardo SilveiraNo ratings yet

- Bambi Bucket Operations Manual REV2020ADocument32 pagesBambi Bucket Operations Manual REV2020AReinaldo SouzaNo ratings yet

- Dynaco Telescopic CylinderDocument41 pagesDynaco Telescopic CylinderDark Cenobite0% (1)

- Field Services Inspection ChecklistDocument5 pagesField Services Inspection ChecklisttyoNo ratings yet

- Pipe Spinner OWI 35C-7Document20 pagesPipe Spinner OWI 35C-7Shag ShaggyNo ratings yet

- Answers - Questionnaire-Bonder06-TT+LaminationDocument6 pagesAnswers - Questionnaire-Bonder06-TT+Laminationchandana kumarNo ratings yet

- Bavaria 44 - 3-Cabin 2001Document36 pagesBavaria 44 - 3-Cabin 2001RODRIGONo ratings yet

- P Check List Responsiblity ChartDocument1 pageP Check List Responsiblity ChartShakul NainNo ratings yet

- F - QCD - 06 Check List For Suspn TWRDocument3 pagesF - QCD - 06 Check List For Suspn TWRsumit kumarNo ratings yet

- Folk LiftDocument1 pageFolk LiftAlamindris DrisNo ratings yet

- Roatary Actuators - Micromatic Repair Manual - 26R-2 Thru 26R-124Document14 pagesRoatary Actuators - Micromatic Repair Manual - 26R-2 Thru 26R-124tungNo ratings yet

- Section4-Chapter1 OIL WELL DERRICK STABILITY GUYWIREDocument10 pagesSection4-Chapter1 OIL WELL DERRICK STABILITY GUYWIREfarajNo ratings yet

- Ex - No 1 Dismantling of Piston EngineDocument9 pagesEx - No 1 Dismantling of Piston EngineesakkimuthuNo ratings yet

- Mechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7Document58 pagesMechanical Overhaul Procedures For Hydroelectric Units: Facilities Instructions, Standards, and Techniques Volume 2-7patar marpaungNo ratings yet

- Jigsfixtures 2marks FinalDocument11 pagesJigsfixtures 2marks FinalalhaggagiNo ratings yet

- Ring Pocket RRS Rev008bDocument22 pagesRing Pocket RRS Rev008bPaul BarriosNo ratings yet

- 2010 MMEP Res BearingsDocument4 pages2010 MMEP Res BearingsMasood AlamNo ratings yet

- Monthly Technical Meeting Testing Department MARCH 6, 2023 People360 Consulting CorporationDocument10 pagesMonthly Technical Meeting Testing Department MARCH 6, 2023 People360 Consulting Corporationrome reyesNo ratings yet

- Work Scope - Francis Turbine Refurbishment WorkDocument6 pagesWork Scope - Francis Turbine Refurbishment WorkmanikanthNo ratings yet

- Scope of WorkDocument2 pagesScope of WorkAngelo PuraNo ratings yet

- Level III Inspection Vfinal Form Enabled PDFDocument3 pagesLevel III Inspection Vfinal Form Enabled PDFagusNo ratings yet

- Grove B4B B4C B5 IOM ManualDocument28 pagesGrove B4B B4C B5 IOM Manuala.solvev100% (1)

- Form Descrition of Lifting PlanDocument1 pageForm Descrition of Lifting PlanIskandar AzriNo ratings yet

- Checlist Lifting PermitDocument1 pageCheclist Lifting PermitIskandar AzriNo ratings yet

- Monthly Inspection Record For Lifting GearDocument2 pagesMonthly Inspection Record For Lifting GearIskandar AzriNo ratings yet

- Daily Inspection Checklist For Mobile Crane (Crawler Crane)Document1 pageDaily Inspection Checklist For Mobile Crane (Crawler Crane)Iskandar AzriNo ratings yet