Professional Documents

Culture Documents

Pe4000 4500

Uploaded by

hugoamendozaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pe4000 4500

Uploaded by

hugoamendozaCopyright:

Available Formats

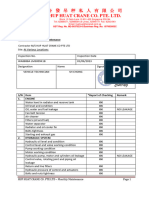

C PE 4000 &

PE 4500 Series

Planned Maintenance

Inspection Report

Customer Dealer

Date Hr. Meter Reading Make Serial No. Customer P.O. No.

I. VISUAL INSPECTION 5. Lubricate brake linkage VII. CONTACTOR PANEL

1. Oil leaks 6. Lubricate battery rollers (Opt.) 1. Line contactor tip condition

2. Control arm and handle 7. Lubricate door hinges VIII. BRAKES

3. Grab bar 8. Lubricate control handle pivots 1. Linkage

4. Forks 9. Coast selector linkage, yoke roller 2. Adjustment (a)

5. Load backrest bearing and springs 3. Shoes

6. Platform cushion 10. Lubricate steering gears 4. Drums

7. Battery retainers III. HYDRAULIC SYSTEM 5. Split bushing key

8. Tire & wheel conditions 1. Fluid level 6. Disk brake air gap

• Load wheels, left and right 2. Pump and motor mounting secure IX. STEERING

• Caster wheels and adjustment 3. Motor cable connections 1. Drive unit rollers

• Drive tire & lug bolts 4. Blow dust from motor brushes and X. FREEZER CONDITION TRUCKS

9. Bent or damaged parts armature 1. Heater operation

10. Safety labels/decals and serial plate in 5. Blow brush dust from motor 2. Wiring condition

place 6. Pump operation XI. OPERATIONAL CHECK & TEST DRIVE

11. Lift cylinder 7. Hoses and fittings 1. Horn

12. Lift linkage 8. Leaks - cylinder and hydraulic unit 2. Power disconnect

13. Skid adapter (Opt.) 9. Breather cap 3. Brake switch

14. Tape, string, etc. around drive axle IV. DRIVE UNIT 4. Verify brake operation

and load wheels 1. Lubricant level 5. Stopping distance (a)

15. Battery retainer condition 2. Leaks 6. Plugging (b)

16. Battery cable condition (truck side) 3. Motor mounting secure 7. Lift/Lower operation

17. Battery connector condition (truck side) 4. Motor cable connections 8. Travel speeds

18. Battery spacers 5. Blow dust from brush & armature 9. Lift limit switch operation

19. Battery disconnect handle condition (where applicable) 10. Directional switch operation

(Opt.) (truck side) 6. Blow brush dust from motor 11. Reversing button operation

20. Inspect the steer gears 7. Mounting to power unit secure 12. Manual coast operation

II. CLEAN & LUBRICATE 8. Motor shield secure 13. Electronic power steering operation

1. Blow off truck 9. Rollers and roller race (where applicable)

2. Blow low pressure over electrical panel V. POWER CABLES 14. Battery retainer interlock switch

3. Electric brakes - blow dust out 1. Power cable conditions operation (Opt.)

4. Lubricate all zerk fittings 2. Power cable connections 15. Load backrest operation

• Power unit pivot 3. Resistor connections 16. Travel alarm (Opt.)

• Upper lift linkage VI. CONTROL WIRING & SWITCHES 17. Verify parking brake operation

• Upper lift cylinder pivot 1. Wiring conditions 18. QuickPick™ operation

• Drive unit rollers 2. Wiring connections 19. Quick Coast™ audible & visual

• Drive unit pivot 3. Wiring harness connectors indicators

• Drive unit axle 4. Control switches in handle 20. Quick Coast operation

• Casters and mechanism 5. Reversing switch 21. Operator display/indicator lights

• Lower lift linkage 6. Lift limit switch XII. CUSTOMER CARE

• Lower lift cylinder pivot 7. Control switches in grab bar 1. Wipe off truck

• Tension bars 8. Pump solenoid 2. Clean area

• Risers 9. Battery retainer switches

• Load wheel axle and pivot 10. Brake switch

• Exit rollers

IMPORTANT: Refer to Service Manual, Service Bulletins & other pertinent technical publications for details on

inspection, lubrication & adjustment.

(a) See applicable service manual for brake adjustment procedures and recommended stopping distances.

(b) See applicable service manual for proper settings. Repair Status

Opt. = Optional Accessories/Equipment Codes

Approved

= O.K. W.O.#

Comments: A = Adjust Denied

R = Repair Quote Repairs

U = Urgent Follow-Up

Authorized Signature Service Technician

Crown 2002 PF13415 F Rev. 1/15 Printed in U.S.A.

You might also like

- CanRig Top Drive - 275T - Manual PDFDocument537 pagesCanRig Top Drive - 275T - Manual PDFNelly Beltrán Cuellar100% (2)

- Boat Condition Report1 PDFDocument2 pagesBoat Condition Report1 PDFRoss RobertsonNo ratings yet

- Konecranes Brochure SMV 4531 TBE5Document3 pagesKonecranes Brochure SMV 4531 TBE5Hadhrat Khalil100% (4)

- TA2 English - Wheel LoaderDocument22 pagesTA2 English - Wheel Loadercarlos angelNo ratings yet

- Borg Warner P38Document36 pagesBorg Warner P38Joao Miguel Bernardo Saraiva100% (1)

- Boat Condition Report PDFDocument2 pagesBoat Condition Report PDFRoss Robertson0% (2)

- GD 6. BAB IV Instrument PanelDocument16 pagesGD 6. BAB IV Instrument Panelnyoman ahmadNo ratings yet

- McCormick F Series TractorsDocument2 pagesMcCormick F Series TractorshuskerchampsNo ratings yet

- FC4500Document1 pageFC4500hugoamendozaNo ratings yet

- Pauta RMD6000Document1 pagePauta RMD6000hugoamendozaNo ratings yet

- Steering SystemDocument12 pagesSteering Systemluis tocoraNo ratings yet

- Erc Aa Motor LG263Document9 pagesErc Aa Motor LG263SANOMIONo ratings yet

- MP Misc 255 April 10 Emd CommissioningDocument6 pagesMP Misc 255 April 10 Emd CommissioningmailbkraoNo ratings yet

- WA8888A Jun23Document2 pagesWA8888A Jun23Ali md YounusNo ratings yet

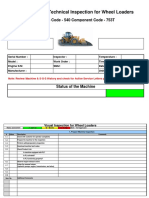

- TA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753TDocument22 pagesTA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753Tahmed el sayedNo ratings yet

- ATA App B1900D Ground Run Check ListDocument67 pagesATA App B1900D Ground Run Check ListAnton Coetzer100% (1)

- S42-3-2006 1-2t tRICICLODocument122 pagesS42-3-2006 1-2t tRICICLOFernando Gallardo UrrejolaNo ratings yet

- Maintenanace Manual For Eot CranesDocument36 pagesMaintenanace Manual For Eot CranesNikki ChauhanNo ratings yet

- TA1 English - Wheel LoaderDocument20 pagesTA1 English - Wheel Loadercarlos angel100% (2)

- 0rbitrol Marca RossDocument25 pages0rbitrol Marca RossHERNANDO A BECERRANo ratings yet

- TA1 English - Articulated TruckDocument15 pagesTA1 English - Articulated Truckcarlos angel100% (1)

- (A) Engine /cooling System (D) Centrifugals: Cbs-955/957 Stem Ii Check SheetDocument3 pages(A) Engine /cooling System (D) Centrifugals: Cbs-955/957 Stem Ii Check Sheetyao nestorNo ratings yet

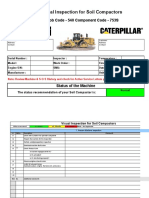

- TA1 English - Soil CompactorDocument16 pagesTA1 English - Soil CompactorAlex JuárezNo ratings yet

- Brake SystemDocument12 pagesBrake Systemluis tocoraNo ratings yet

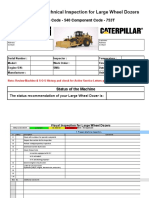

- Wheel Dozers TA2 ChecklistDocument22 pagesWheel Dozers TA2 ChecklistVictor Rodrigo Cortes YañezNo ratings yet

- Manual Misia1 End CarriageDocument44 pagesManual Misia1 End CarriageEpure GabrielNo ratings yet

- Handbook On General Maintenance Schedule For 8 Wheeler Diesel Hydraulic Tower WagonDocument66 pagesHandbook On General Maintenance Schedule For 8 Wheeler Diesel Hydraulic Tower WagonSahithya VigneshNo ratings yet

- WB-11 ManualDocument23 pagesWB-11 ManualDalokohsNo ratings yet

- Manual EF494T enDocument81 pagesManual EF494T enRafaelEdisonNo ratings yet

- Manuel de Réparation 3 Tonnes 2Document155 pagesManuel de Réparation 3 Tonnes 2Faouzi Zorgati100% (1)

- User Manual Manual de Usuario Manuel de L'UtilisateurDocument15 pagesUser Manual Manual de Usuario Manuel de L'Utilisateuro.j.dumbo0No ratings yet

- RR RD5700SDocument1 pageRR RD5700ShugoamendozaNo ratings yet

- Autogiro Ela, Maintenance Manual m07 03 Issue 2 Sep 2009.Document21 pagesAutogiro Ela, Maintenance Manual m07 03 Issue 2 Sep 2009.jotobagoNo ratings yet

- Engine ElectricalDocument4 pagesEngine ElectricalAndres Herland Balderas MirandaNo ratings yet

- Transfer CaseDocument43 pagesTransfer CasePopescu Vasile IonNo ratings yet

- Doosan Solar V Series Features Service TrainingDocument20 pagesDoosan Solar V Series Features Service Traininglinda100% (44)

- TA1 English - Compact Wheel LoadersDocument16 pagesTA1 English - Compact Wheel Loaderscarlos angelNo ratings yet

- Teq - Inspection 1Document14 pagesTeq - Inspection 1ahmed el sayedNo ratings yet

- Inmotion SCV Series User Manual: Inmotion Technologies Co., LTDDocument24 pagesInmotion SCV Series User Manual: Inmotion Technologies Co., LTDMoldoveanu LaviniaNo ratings yet

- (HSE-ForM-A.05) Form Inspection Rough Terrain CraneDocument6 pages(HSE-ForM-A.05) Form Inspection Rough Terrain CraneIvansyah SastrowardoyoNo ratings yet

- Conventional Colchester Lathe Assembly ManualDocument5 pagesConventional Colchester Lathe Assembly Manualmiguel angel reyes pinillaNo ratings yet

- TA1 English - KnuckleboomDocument30 pagesTA1 English - Knuckleboomcristian chuquicondor torresNo ratings yet

- MAINTENANCE fORKLIFT 2Document2 pagesMAINTENANCE fORKLIFT 2Ye Min HtikeNo ratings yet

- Chapter - 07 - EN - A350-A400-A450 - Edizione 09-2005Document35 pagesChapter - 07 - EN - A350-A400-A450 - Edizione 09-2005MilanNo ratings yet

- Ehs Maintenance ManualDocument30 pagesEhs Maintenance ManualSibin PiptiNo ratings yet

- Main - Industrial Lift Truck Pre Operational Inspection Checklist TemplateDocument1 pageMain - Industrial Lift Truck Pre Operational Inspection Checklist Templatewebhareggebru06No ratings yet

- Tractor Mounted - Universal Forage Harvester: Technology - You Can Depend OnDocument70 pagesTractor Mounted - Universal Forage Harvester: Technology - You Can Depend OnTesfa TsegayeNo ratings yet

- 1986-1988 SuzukiSamurai Cranking System ManualDocument12 pages1986-1988 SuzukiSamurai Cranking System ManualHatnean CristianNo ratings yet

- TA2 English - ExcavatorDocument41 pagesTA2 English - ExcavatorEfrain DYNo ratings yet

- Brake System - GDP25MXDocument25 pagesBrake System - GDP25MXvicmart3030No ratings yet

- Wag12 Handbook EnglishDocument22 pagesWag12 Handbook EnglishSATYANARAYANA BODDULANo ratings yet

- TA2 English - Wheeled ExcavatorDocument24 pagesTA2 English - Wheeled Excavatorcarlos angelNo ratings yet

- TA1 English - Wheeled ExcavatorDocument18 pagesTA1 English - Wheeled Excavatorcarlos angelNo ratings yet

- Discovery 1 300tdi Overhaul ManualDocument103 pagesDiscovery 1 300tdi Overhaul ManualEagle Brothers BynNo ratings yet

- Signal Reverser For Railway SignalingDocument23 pagesSignal Reverser For Railway SignalingVikas Srivastav100% (1)

- 3 Monthly PM - OH CraneDocument3 pages3 Monthly PM - OH CraneMuhammad RosihanNo ratings yet

- User Manual and Technical Description: E-8 Hydraulic Transport StretcherDocument11 pagesUser Manual and Technical Description: E-8 Hydraulic Transport Stretcherclaudia floresNo ratings yet

- Hiab 270Document163 pagesHiab 270hiroak06No ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Introduction to Electronic Analogue Computers: International Series of Monographs in Electronics and InstrumentationFrom EverandIntroduction to Electronic Analogue Computers: International Series of Monographs in Electronics and InstrumentationNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- General Information PanelworkDocument85 pagesGeneral Information PanelworkOXENo ratings yet

- Damper DynoDocument3 pagesDamper DynoEoin MurrayNo ratings yet

- Sym Symply50 Owner ManualDocument25 pagesSym Symply50 Owner ManualEdi IrimescuNo ratings yet

- TCMax User ManualDocument33 pagesTCMax User ManualMarcos Gomez PeresNo ratings yet

- Arctic Cat 2009 366 Service ManualDocument139 pagesArctic Cat 2009 366 Service ManualBogdan CristianNo ratings yet

- Vehicle Inspection TrainingDocument32 pagesVehicle Inspection Trainingsourabh singh tomerNo ratings yet

- 10,000 Litres Combined Vacuum & Canal Jetting TruckDocument9 pages10,000 Litres Combined Vacuum & Canal Jetting TruckDavid SabaflyNo ratings yet

- 36 Volt Ebike Owners ManualDocument49 pages36 Volt Ebike Owners ManualGautam Monipatro100% (2)

- Slash Spec Racing Setup GuideDocument9 pagesSlash Spec Racing Setup GuideTodd AlexanderNo ratings yet

- 216, 226, 232, 242, 236, 246, 252 and 262 Hydraulic System Skid Steer LoaderDocument2 pages216, 226, 232, 242, 236, 246, 252 and 262 Hydraulic System Skid Steer LoaderHector CharreNo ratings yet

- VW t5 Running Gear Axles Steering EngDocument244 pagesVW t5 Running Gear Axles Steering Engtanfred84No ratings yet

- Concrete Truck Plant Pre-Acceptance ChecklistDocument3 pagesConcrete Truck Plant Pre-Acceptance ChecklistMohamed El NasharNo ratings yet

- Information About Electric VehiclesDocument12 pagesInformation About Electric VehiclespasistNo ratings yet

- OEM Engine Oil Lubricant Specifications: White PaperDocument4 pagesOEM Engine Oil Lubricant Specifications: White Papermohamed100% (1)

- Specs TX742 PDFDocument2 pagesSpecs TX742 PDFDian SikumbangNo ratings yet

- Light Alloy WheelsDocument57 pagesLight Alloy Wheels123abc1a2b3cNo ratings yet

- TATUDocument16 pagesTATUGurdeep SahaniNo ratings yet

- Honeywell OI331 26R1Document2 pagesHoneywell OI331 26R1hotelonpicadilly100% (1)

- Toyota Model Unit PriceDocument6 pagesToyota Model Unit PriceRichardAriesDavidNo ratings yet

- Rexroth PumpDocument24 pagesRexroth Pumpvitor santosNo ratings yet

- Demontare PlafonDocument16 pagesDemontare PlafonvalyexNo ratings yet

- YOKOHAMA Motorsport Tires Catalogue 2014Document8 pagesYOKOHAMA Motorsport Tires Catalogue 2014gd007200No ratings yet

- Group 8 Conceptual Design Final ReportDocument39 pagesGroup 8 Conceptual Design Final ReportHarsh KumarNo ratings yet

- RUSH 1.5G & 1.5S (A) FMC: Kun25Kun25Mca Mxfs01P Mxfs02P MX03P MX04P MX02PDocument3 pagesRUSH 1.5G & 1.5S (A) FMC: Kun25Kun25Mca Mxfs01P Mxfs02P MX03P MX04P MX02PABDUL HALIM BIN A WAHAB MoeNo ratings yet

- Transfertaxform Apv9t Form (072010)Document2 pagesTransfertaxform Apv9t Form (072010)Karma Pema DorjeNo ratings yet

- Catalogo Lorenz 2019 PDFDocument84 pagesCatalogo Lorenz 2019 PDFAceitera Frank100% (2)

- Skyranger 2013 Price List (GB)Document1 pageSkyranger 2013 Price List (GB)bestoff82No ratings yet

- Cessna Citation Sovereign-Airplane GeneralDocument8 pagesCessna Citation Sovereign-Airplane GeneralHenryNo ratings yet