Professional Documents

Culture Documents

RR RD5700S

Uploaded by

hugoamendozaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RR RD5700S

Uploaded by

hugoamendozaCopyright:

Available Formats

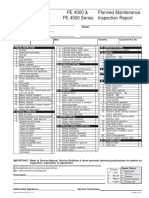

RR/RD 5700/5700S Series Planned Maintenance Inspection Report

Customer Dealer

Date Hr. Meter Reading Make Serial No. Customer P.O. No.

I. Visual and Fastener Inspection III. Hydraulic Pumps and Motors IX. Hydraulic System

Oil leaks Mounting secure Hoses and fittings

Overhead guard Cable connections torqued Filter

Mast assembly Hoses and fittings X. Mast Assembly

Forks Leaks Roller and tracking

Sideshifter Brushes and armatures (DC lift only) Height sensors

Tilt and reach mechanism Blow brush dust from lift pump motors (DC lift only) Height switches

Load backrest Lift pumps operation Lift chain condition

Operator compartment pads IV. Drive Unit Lift chain adjustment

Floorboard Lubricant level Cylinders mounting and condition

Brake pedal Leaks Installation screws to power unit secure

Tiller knob Motor mounting secure Control cables

Safety shield Motor cable connections Bumpers

Battery retainers Blow dust from motor Sideshifter

Tire and wheel mounting and condition Mounting to undercarriage secure Tilt and reach mechanism

Lift chain Articulation stop screws inspect and adjust XI. Freezer Condition Lift Trucks

Hoses Pump operation Heater operation

Control cables Articulating spring adjustment Wire condition

Monitoring switches Axle assembly XII. Operational Check and Test Drive

Multi-task control handle installation screws V. Power Cables and Control Wires Horn

Access 4 mount Power cable conditions and connections Access 1

Cracked, deformed, or damaged parts Wire conditions and connections Power disconnect

Safety labels and decals in place VI. Contactor Panel and Power Contactors Steering operation

Capacity and data plates in place ED1 contact tip condition Verify brake operation

Battery retainer condition P2 Contact tip condition (DC lift only) Stopping distance

Battery cable condition (lift truck side) Control wire connections Plugging

Battery connector condition (lift truck side) Power cable connections torqued Lift, tilt, and reach operation

Battery spacer and roller condition VII. Brakes Sideshift operation

Static strap Pedal operation Mast height switch operation

II. Clean and Lubricate Brake switches condition Direction switch operation

Blow dust and dirt off lift truck Brake adjustment, drive, and caster Multi-task control handle

Blow off electrical panels and fans Brake linings rotor Rated capacity

Lubricate fittings VIII. Steering Dome light and worklights

Lubricate steering gears Power steering operation Fan (overhead guard)

Mast channel and roller assemblies Electronic power steering snubber resistance Battery retainer switches

Brake pedal Steer control unit Entry bar switch operation

Floorboard pivot Steer motors (hydraulic or electric) Travel alarm operation

Battery rollers (clean) Lubricate steer input linkage (DC lift only) XIII. Customer Care

Lubricate lift chains Steer control unit and motor installation screws Wipe off lift truck

Lubricate sideshifter IX. Hydraulic System Clean area

Lubricate tilt and reach mechanism Oil level and condition

Lubricate door hinges Leaks

Floating floorboard Breather cap

Lubricate multi-task control handle

Comments:_______________________________________________________________________________________ Repair Status

Codes

oApproved

__________________________________________________________________________________________________ ü= O.K.

W.O.#:_________

A = Adjust

oDenied

__________________________________________________________________________________________________ R = Repair

oQuote Repairs

U = Urgent

_________________________________________________________________________________________________ oFollow-Up

Authorized Signature Service Technician

IMPORTANT: Refer to the Service Manual for details on inspection, lubrication, and adjustments.

Crown 2020 PF17421 F

You might also like

- Robot Mechanisms and Mechanical Devices IllustratedFrom EverandRobot Mechanisms and Mechanical Devices IllustratedRating: 4 out of 5 stars4/5 (1)

- Scheduled MaintenanceDocument1 pageScheduled MaintenanceTan Minh Tam TruongNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- FC4500Document1 pageFC4500hugoamendozaNo ratings yet

- Geoprobe 32 Series Inspection Form - 0Document2 pagesGeoprobe 32 Series Inspection Form - 0فاقد السيطرهNo ratings yet

- Direct Push Inspection Form 6-15-2023Document2 pagesDirect Push Inspection Form 6-15-2023Mohd Firdaus OthmanNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Pe4000 4500Document1 pagePe4000 4500hugoamendozaNo ratings yet

- Microsoft Word - Tire Handler Owners Manual PDFDocument195 pagesMicrosoft Word - Tire Handler Owners Manual PDFPlanificador MantencionNo ratings yet

- LP Forklift AbsoluteDocument2 pagesLP Forklift AbsoluteJose CamposNo ratings yet

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- EV PDI PDS Sheet - v2Document2 pagesEV PDI PDS Sheet - v2yonatan solomon100% (1)

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume I: the Twin CamNo ratings yet

- Liftking Forklift PDIDocument1 pageLiftking Forklift PDIManual ForkliftNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionFrom EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionRating: 4 out of 5 stars4/5 (1)

- Xvac Hydro Excavator x15 SeriesDocument87 pagesXvac Hydro Excavator x15 SeriesАлександр ПанкратовNo ratings yet

- Golf Course Irrigation: Environmental Design and Management PracticesFrom EverandGolf Course Irrigation: Environmental Design and Management PracticesNo ratings yet

- QAF 2001 Rev. 1 Batch Mixer PM1 ChecklistDocument1 pageQAF 2001 Rev. 1 Batch Mixer PM1 ChecklistMohamed El-SawahNo ratings yet

- Inspection CraneDocument2 pagesInspection CranedroidsNo ratings yet

- Pri Hse FRM 014 Mewp ChecklistDocument1 pagePri Hse FRM 014 Mewp ChecklistTopeNo ratings yet

- Vertical Elevator InspectionhydroDocument3 pagesVertical Elevator InspectionhydroTek tek hapNo ratings yet

- Safety & Maintenance Inspection Checklist - Cold PlanersDocument1 pageSafety & Maintenance Inspection Checklist - Cold PlanersPedro BarriosNo ratings yet

- Needs Attention CompletedDocument2 pagesNeeds Attention CompletedahmedNo ratings yet

- Hoist ForkliftDocument12 pagesHoist ForkliftMamta RaybageNo ratings yet

- Pre-Delivery Inspection Checklist: Under Hood - Engine Off On InsideDocument1 pagePre-Delivery Inspection Checklist: Under Hood - Engine Off On InsideAshok AmmaiyappanNo ratings yet

- STC250Document8 pagesSTC250fajarNo ratings yet

- SSL Comparison PPT - CASE SR130 JCB135JCB 155Document10 pagesSSL Comparison PPT - CASE SR130 JCB135JCB 155josephNo ratings yet

- AME Basic Training Program M Rating-EnDocument6 pagesAME Basic Training Program M Rating-EnJulio OLiveiraNo ratings yet

- Mma 152 MotorDocument101 pagesMma 152 Motoraviacion gnaNo ratings yet

- Service Report: GraderDocument3 pagesService Report: Graderainul arifNo ratings yet

- Maintenance ESC & TRV FujiDocument4 pagesMaintenance ESC & TRV Fujikhadavi kulonNo ratings yet

- Inspection Sheet Excavator: Unit No: Type:: Date:: HM:: Company OK Not OK OK Not OK Engine Safety Kondisi KondisiDocument1 pageInspection Sheet Excavator: Unit No: Type:: Date:: HM:: Company OK Not OK OK Not OK Engine Safety Kondisi KondisigenjiNo ratings yet

- Marine Genset-CCFJ30J-W : Gen-Set SpecificationsDocument2 pagesMarine Genset-CCFJ30J-W : Gen-Set SpecificationsFerby AnjasNo ratings yet

- Pauta RMD6000Document1 pagePauta RMD6000hugoamendozaNo ratings yet

- Doosan BR15-18J-5 BrochureDocument4 pagesDoosan BR15-18J-5 BrochureMuhammad SohailNo ratings yet

- CCFJ20J WDocument2 pagesCCFJ20J WBaudouin ItaliaNo ratings yet

- Norma CMAA 70Document90 pagesNorma CMAA 70Marcelo Navarro100% (7)

- TA2 950G Wheel Loader AYLDocument21 pagesTA2 950G Wheel Loader AYLMekanik Alat Berat100% (2)

- B877F Product Prensentaiton 11758Document43 pagesB877F Product Prensentaiton 11758ivaho707No ratings yet

- UntitledDocument213 pagesUntitledMatias MantovaniNo ratings yet

- Tata Hitachi Zw370 1 Wheel LoaderDocument7 pagesTata Hitachi Zw370 1 Wheel LoaderPranav lavateNo ratings yet

- Form Inspeksi Alat Berat (Compactor)Document1 pageForm Inspeksi Alat Berat (Compactor)HELMY RUSANDYNo ratings yet

- Sample: Excavator Safety TrainingDocument61 pagesSample: Excavator Safety Trainingvega f ankaNo ratings yet

- قائمة اعمال وفحوصات صيانةDocument6 pagesقائمة اعمال وفحوصات صيانةAliNo ratings yet

- 962H Wheel Loader SSADocument22 pages962H Wheel Loader SSAPercy Herrera Zeballos100% (1)

- MS DD 3000 HSE FRM 0029 - MEWP - Inspection - ChecklistDocument1 pageMS DD 3000 HSE FRM 0029 - MEWP - Inspection - ChecklistcrystinNo ratings yet

- 3.160dozer Driven Componet PDFDocument53 pages3.160dozer Driven Componet PDFDedi rahmat100% (1)

- Defender 2.4D Maintenance Check Sheet - MilesDocument2 pagesDefender 2.4D Maintenance Check Sheet - MilesJose SilvaNo ratings yet

- (FORD) Manual de Taller Ford Ranger 1983 1987Document515 pages(FORD) Manual de Taller Ford Ranger 1983 1987Francisco0% (2)

- Prestart Checklist & Defect Report - Grader: For Hot Seat Change All Category "A" Must Be InspectedDocument1 pagePrestart Checklist & Defect Report - Grader: For Hot Seat Change All Category "A" Must Be InspectedindraNo ratings yet

- 140H Motor Grader XZHDocument18 pages140H Motor Grader XZHHebert Trujillo100% (2)

- Equipment/Vehicle Checklist: Name of Company: Date/Time: Machine Make & Model: Unit #: Mileage: Km/milesDocument2 pagesEquipment/Vehicle Checklist: Name of Company: Date/Time: Machine Make & Model: Unit #: Mileage: Km/milesJack PNo ratings yet

- Scan0218 PDFDocument1 pageScan0218 PDFJayson Jonson AraojoNo ratings yet

- Safety & Maintenance Checklist - D7E Track-Type Tractors V0611.2 PDFDocument1 pageSafety & Maintenance Checklist - D7E Track-Type Tractors V0611.2 PDFcherifNo ratings yet

- Check Sheet PM Mobil Crane Sany ST 500Document4 pagesCheck Sheet PM Mobil Crane Sany ST 500Desta Andri Muryono100% (1)

- Elevator Maintenance Check ListDocument6 pagesElevator Maintenance Check ListSohailNo ratings yet

- Pre T&C Checklist (3 Language) - Updated - 2022 DavidDocument1 pagePre T&C Checklist (3 Language) - Updated - 2022 Davidmuhammad farisNo ratings yet

- PEG Catalog Siemens PDFDocument419 pagesPEG Catalog Siemens PDFrukmagoudNo ratings yet

- Personal Training Program Design Using FITT PrincipleDocument1 pagePersonal Training Program Design Using FITT PrincipleDan DanNo ratings yet

- Psychology and Your Life With Power Learning 3Rd Edition Feldman Test Bank Full Chapter PDFDocument56 pagesPsychology and Your Life With Power Learning 3Rd Edition Feldman Test Bank Full Chapter PDFdiemdac39kgkw100% (9)

- Security Questions in UPSC Mains GS 3 2013 2020Document3 pagesSecurity Questions in UPSC Mains GS 3 2013 2020gangadhar ruttalaNo ratings yet

- Buddhism & Tantra YogaDocument2 pagesBuddhism & Tantra Yoganelubogatu9364No ratings yet

- Chapin Columbus DayDocument15 pagesChapin Columbus Dayaspj13No ratings yet

- 2019 09 20 New Balance Harvard Business CaseDocument7 pages2019 09 20 New Balance Harvard Business CaseFrans AdamNo ratings yet

- Hydraulics Experiment No 1 Specific Gravity of LiquidsDocument3 pagesHydraulics Experiment No 1 Specific Gravity of LiquidsIpan DibaynNo ratings yet

- Applied Thermodynamics - DraughtDocument22 pagesApplied Thermodynamics - Draughtpiyush palNo ratings yet

- Conceptual Diagram of Ways To Increase SalesDocument1 pageConceptual Diagram of Ways To Increase SalesO6U Pharmacy RecordingsNo ratings yet

- Formal Letter Format Sample To Whom It May ConcernDocument6 pagesFormal Letter Format Sample To Whom It May Concernoyutlormd100% (1)

- 1 Introduction To PPSTDocument52 pages1 Introduction To PPSTpanabo central elem sch.No ratings yet

- Concept of HalalDocument3 pagesConcept of HalalakNo ratings yet

- MSC in Healthcare Management (Top-Up) Degree From ARU - Delivered Online by LSBR, UKDocument19 pagesMSC in Healthcare Management (Top-Up) Degree From ARU - Delivered Online by LSBR, UKLSBRNo ratings yet

- Alcatraz Analysis (With Explanations)Document16 pagesAlcatraz Analysis (With Explanations)Raul Dolo Quinones100% (1)

- Nursing Education and Nursing Service ProgramsDocument10 pagesNursing Education and Nursing Service ProgramsLevy DuranNo ratings yet

- Industrial Visit Report Part 2Document41 pagesIndustrial Visit Report Part 2Navratan JagnadeNo ratings yet

- Speaking Test FeedbackDocument12 pagesSpeaking Test FeedbackKhong TrangNo ratings yet

- Introduction To Control SystemDocument9 pagesIntroduction To Control SystemAbdulhakam Abubakar YusufNo ratings yet

- Sample Financial PlanDocument38 pagesSample Financial PlanPatrick IlaoNo ratings yet

- CAPE Env. Science 2012 U1 P2Document9 pagesCAPE Env. Science 2012 U1 P2Christina FrancisNo ratings yet

- Political and Institutional Challenges of ReforminDocument28 pagesPolitical and Institutional Challenges of ReforminferreiraccarolinaNo ratings yet

- Veritas CloudPoint Administrator's GuideDocument294 pagesVeritas CloudPoint Administrator's Guidebalamurali_aNo ratings yet

- Roberts, Donaldson. Ante-Nicene Christian Library: Translations of The Writings of The Fathers Down To A. D. 325. 1867. Volume 15.Document564 pagesRoberts, Donaldson. Ante-Nicene Christian Library: Translations of The Writings of The Fathers Down To A. D. 325. 1867. Volume 15.Patrologia Latina, Graeca et OrientalisNo ratings yet

- Final Module in Human BehaviorDocument60 pagesFinal Module in Human BehaviorNarag Krizza50% (2)

- LIM Gr7 Q4W3Document9 pagesLIM Gr7 Q4W3Eto YoshimuraNo ratings yet

- Meike SchalkDocument212 pagesMeike SchalkPetra BoulescuNo ratings yet

- SHS PE MODULE 1 - RemovedDocument21 pagesSHS PE MODULE 1 - RemovedXypher NNo ratings yet

- EMI - Module 1 Downloadable Packet - Fall 2021Document34 pagesEMI - Module 1 Downloadable Packet - Fall 2021Eucarlos MartinsNo ratings yet