Professional Documents

Culture Documents

Quotation For 800-1000 KG Sunward

Uploaded by

Farzan Pune0 ratings0% found this document useful (0 votes)

2 views7 pagesfortified rice Machine

Original Title

Quotation For 800-1000 kg Sunward

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfortified rice Machine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views7 pagesQuotation For 800-1000 KG Sunward

Uploaded by

Farzan Punefortified rice Machine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

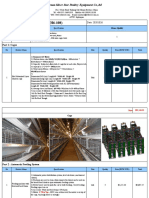

Quotation for 800-1000kg/h Fortified rice Machinery

(Sunward)

390 KW

1, The flow chart of this processing line:

Milling machine-----Mixer----Screw conveyor----Extruder(95)---Sifter --Air conveyor---Dryer ---Cooling machine

Price – 1,19,48,500

One Crore Ninteen Lac Forty Eight Thousand Five Hundred Only /-

Address:. 184, D.D.A. Office Complex, Jhandewalan Extn., New Delhi-110055.

Tel: 011 43584157 Mob: +91 9811014184 E-mail: delhi@emtex.in

2, Technical parameters of the equipment’s for reference:

Quantity

No. Name Describe Function /set

Photo

Main motor: 22kw

Function: milling the products to be powder type. Then get the

Grinding Baiting motor: 0.75kw

baby food.

1 machine Feeder motor: 1.1kw 1

(FSJ-60) Cleaner motor: 5.5kw

Material: all is stainless steel

Size: 1500*900*1000mm

Size:

1310x800x1200(mm) Mixing the raw materials (In powder form) with water

Real power: 10kw 1,The part where can be touched is stainless steel;

Mixer

2 Motor power:15kw 2,Mixed materials can be discharged automatically 1

(BFJ-IIII)

Installed power: 15kw 3,With wheels and handle, suitable for moving

200kg/one Outlet is with dam-board design

time(2-3minutes)

Size:2500x800x2300(mm) Convey the raw materials to the extruder

Screw Real power: 1kw 1,Height adjustable;

3 conveyor Motor power:1.5kw 2,With wheels for convenient moving; 1

(SL-II) Installed power: 1.5kw 3,Enclosed pipe, suitable for food conveying

Output:suit for extruder Stainless steel

Address:. 184, D.D.A. Office Complex, Jhandewalan Extn., New Delhi-110055.

Tel: 011 43584157 Mob: +91 9811014184 E-mail: delhi@emtex.in

1, Gear box:

1) Gearbox weight roughly: 4ton

2, Square barrel:

1) Beautiful appearance, higher processing accuracy

2) Water cooling is more scientific, the cylinder and water

cooling are one, safe and durable

3) Generally, wear-resistant sleeve is embedded in the barrel,

which has a longer life

4) Uniform heating

Size:6550x920x2890(mm) 5) 45# Alloy Steel and Alloy sleeve

Real power:90kw 3, Screws:

Extruder Motor power:110kw 1) Screw material Cr12Mov , the material hardness and

(TSE95-R Installed power: 175kw strength performance is excellent, can withstand high

4 1

) Output:800-1000kg/h temperature and pressure, long service life

2) The length of the screw is 2520mm, and the diameter is

8pcs barrel, 7pcs heater. 95mm, aspect ratio is 32.3:1, which makes the rice pre-cooking

8.5KW *7= 60KW better

3) Double screw with automatic cleaning function, without

manual disassembly for screw cleaning

4) Screw is a full combination of screw, so that when replacing

only need to replace the worn parts can be (generally the front

section of the barrel, near the end of the grinding head, high

pressure wear is the most serious), the barrel is a half combined

barrel

4, Heating system:

1) There are a total of seven heating areas, heating method for

Address:. 184, D.D.A. Office Complex, Jhandewalan Extn., New Delhi-110055.

Tel: 011 43584157 Mob: +91 9811014184 E-mail: delhi@emtex.in

heating sheet heating, heating sheet to the material in the barrel

heating speed faster, better heating effect

2) Each heating sheet is 3.5KW, and there are seven heating

zones in total, 8.5KW *8= 68KW

5, Water cooling system:

The six zones are all equipped with water cooling. The function

of water cooling is to help the machine cool down during long-

term working, avoid the materials puffing, so as to produce

products of better shape and prolong the life of the machine

6, Cutter parts:

With sliding table, easy to adjust the cutter. With universal

joint, rotary cutting operation is more stable.

7, PLC Control system:

1) Computer operation, more convenient, with memory

function, so that you do not need to reset the temperature when

using the machine again

2) Automatic temperature control system, more convenient

and accurate operation

8, Mullti-function extruder:

1) Changing different spiral can produce different products,

such as fish feed dog food, puffed snacks, nutritional powder,

protein (Resistance ring and kneading block)and other products

Address:. 184, D.D.A. Office Complex, Jhandewalan Extn., New Delhi-110055.

Tel: 011 43584157 Mob: +91 9811014184 E-mail: delhi@emtex.in

Size:4000x750x740(mm) Function: sieve residue off products

Real power: 0.5kw

Sifter

5 Motor power:0.55kw Material: just the frame is carbon steel, other is ss201 1

(ZDS-I)

Installed power: 0.55kw

Output: suit for extruder

2pcs fans

Size:2860x750x2300(mm)

Function: Send the products to the oven

Air Real power:2kw

6 conveyor Motor power:3kw 1

(FSJ-II) Installed power: 3kw

Material: all is ss201

Output:suit for extruder

1. The heating way is electricity heating.

Size:11000x1600x2200(m 2. The net belt running speed can be controlled by the frequency

m) inverter;

Real power: 120kw 3. Full stainless steel where touching materials(except for the

Motor power:2.2kw structure);

Oven

Installed power: 160kw 4. With drawer at the bottom for convenient cleaning of the

7 (w-KX-7- 1

Output: 800-1000kg/h crumbs after long term production;

11)

4pcs circle 5. With warm keeping cover board to avoid heat loose;

2pcs remove moisture 6. 7 layers, totally 77 meters inside to make sure the drying

Swing feeder effect;

Belt width 1.4m, 7. Compact size advantage than common dryers;

8. Visual and automatic temperature control

Address:. 184, D.D.A. Office Complex, Jhandewalan Extn., New Delhi-110055.

Tel: 011 43584157 Mob: +91 9811014184 E-mail: delhi@emtex.in

Size:5300x1200x1500(m

m) 1,The goods are transfered by the belt while they are cooling

Cooling Real power: 1kw by the fan

8 1

conveyor Motor power:0.75kw Material touching the food and the guard all is stainless steel,

Installed power: 1.23kw just the frame under is iron.

Output:800-1500kg/h

3, The spare for free, delivery with processing line:

For Extruder (one set extruder spare part)

Tool 1 pcs Mould 4 pcs

Temperature control meter 1 pcs Shunt plate 3 pcs

Green and Red Button 2 pcs Cutter 6 pcs

Emergency stop button 1 pcs Thermocouple 1 pcs

Reset button 1 pcs Belt for cutter 1 pcs

Current Breaker 1 pcs Stud bolt 4 pcs

Relay 1 pcs Tubing 5m

A C contactor 1 pcs Common remove tool for mould 1 set

Barrel heater 2 pcs Specification of transducer 1 set

Specification of extruder 1 set

Address:. 184, D.D.A. Office Complex, Jhandewalan Extn., New Delhi-110055.

Tel: 011 43584157 Mob: +91 9811014184 E-mail: delhi@emtex.in

For oven

Conveyor mesh-belt 5 pcs Oven handle 1 pcs

Temperature control meter 1 pcs Heater tube 3pcs

Push button on temperature

Thermocouple 1 pcs 2 pcs

control table

Specification of transducer 1 set

Terms & Condition:

GST: 18% GST is applicable on all the prices.

Delivery Time: 80-90 days after receipt of your purchase order with advance

Payment Terms: 30% advance along with the Purchase Order, 40% within 1-2 days after receiving of the

BL, Balance 30% to be paid against Performa invoice before dispatch.

Installation & Commissioning: Rs.2, 00,000 extra to be paid for installation & commissioning.

Warranty: 1 year warranty from the date of supply.

If customer cancelled the order, advance amount won’t be refund.

Thanks & Regards

M. R k Gupta (Director)

+91 9811014184

Address:. 184, D.D.A. Office Complex, Jhandewalan Extn., New Delhi-110055.

Tel: 011 43584157 Mob: +91 9811014184 E-mail: delhi@emtex.in

You might also like

- Quotation For 500 KG Line SunwardDocument10 pagesQuotation For 500 KG Line SunwardFarzan PuneNo ratings yet

- Single - Station - Presswood - Pallets - Machines For RiadhDocument12 pagesSingle - Station - Presswood - Pallets - Machines For RiadhRiadh JomaaNo ratings yet

- Plant Based Meat MaterialsDocument7 pagesPlant Based Meat MaterialsKhampa Ngawang PhuntshoNo ratings yet

- Quotation For Nutritional Powder Production Line DSE70 200-250 KG Per Hour-Dingrun20200401 PDFDocument18 pagesQuotation For Nutritional Powder Production Line DSE70 200-250 KG Per Hour-Dingrun20200401 PDFTheodros HaileNo ratings yet

- Quotation For 1 Ton Per Hour Poultry Feed Pellet Production Line - Strongwin-20210204-1Document17 pagesQuotation For 1 Ton Per Hour Poultry Feed Pellet Production Line - Strongwin-20210204-1samall food companyNo ratings yet

- Quotation of 1.5TH Cow Feed Pellet Production Line-Rita (LEABON) 2022.12.12Document5 pagesQuotation of 1.5TH Cow Feed Pellet Production Line-Rita (LEABON) 2022.12.12Erde ErdeneNo ratings yet

- NCC Nangsing HaisiDocument10 pagesNCC Nangsing HaisiLam NgoNo ratings yet

- Parameter MachineDocument10 pagesParameter MachinePhuong Thuc Duong LeNo ratings yet

- Manual 120726 Blow Moulding PDFDocument31 pagesManual 120726 Blow Moulding PDFrize1159No ratings yet

- Four Cavities PVC Wall Edges Extrusion LineDocument7 pagesFour Cavities PVC Wall Edges Extrusion LineguldavistNo ratings yet

- SGII-3L1500 报价统一格式Document5 pagesSGII-3L1500 报价统一格式Mahmoud FathiNo ratings yet

- Ollital Quotation ZG-160YRD Manual Type (Lab Open Mill)Document3 pagesOllital Quotation ZG-160YRD Manual Type (Lab Open Mill)Choon Zhe ShyiNo ratings yet

- Quotation: Five Layers Fully Automatic Stretch Film Making Machine Model:WT65-100-100-65-1850MMDocument10 pagesQuotation: Five Layers Fully Automatic Stretch Film Making Machine Model:WT65-100-100-65-1850MMDaniel DanirNo ratings yet

- 2022.11.8 Complete HKJ-250 Poultry Feed Pellet Production Line 1tph PDFDocument25 pages2022.11.8 Complete HKJ-250 Poultry Feed Pellet Production Line 1tph PDFdinero dahustleNo ratings yet

- 2 - (7.7 HUILI SJ120 200-300kg Single-Stage PE Film Granulator MachineDocument9 pages2 - (7.7 HUILI SJ120 200-300kg Single-Stage PE Film Granulator MachineMohamed El-HarrasNo ratings yet

- 110mm HDPE Double Wall Corrugated Pipe Extrusion Line-BEIER210701JDocument9 pages110mm HDPE Double Wall Corrugated Pipe Extrusion Line-BEIER210701JAdoniyas Abayneh Negash100% (1)

- 800-1000kg Per Hour Pellet Feed Production LineDocument2 pages800-1000kg Per Hour Pellet Feed Production Linemanoj prajapatiNo ratings yet

- 5 - Double Layer Roll Forming MachineDocument6 pages5 - Double Layer Roll Forming MachineJHON SEGURA GONZALEZNo ratings yet

- 22.02.25.HG-Chocopie Cake Line 5T-LucasDocument23 pages22.02.25.HG-Chocopie Cake Line 5T-LucasmaenNo ratings yet

- Data Sheet Pit Carburizing Furnace - 1656052217Document4 pagesData Sheet Pit Carburizing Furnace - 1656052217Kestrel MgNo ratings yet

- Offer of Hexagonal ShapeCharcoal Briquette Production Line 20191024Document4 pagesOffer of Hexagonal ShapeCharcoal Briquette Production Line 20191024Nipan DekaNo ratings yet

- 1-Tiffany, (B) Quotation 5TPH Animal Feed Line, ZONSTAR RICHI PDFDocument14 pages1-Tiffany, (B) Quotation 5TPH Animal Feed Line, ZONSTAR RICHI PDFAnonymous oRXzylDPNNo ratings yet

- QY Peeling Machine and Tape Edge Machine To MahmoudFamily Foam Egypt 2016.03.08Document4 pagesQY Peeling Machine and Tape Edge Machine To MahmoudFamily Foam Egypt 2016.03.08saver mendleevNo ratings yet

- Charcoal Briquette Production Line 2-3tonDocument32 pagesCharcoal Briquette Production Line 2-3tonБат-Эрдэнэ ЭрдэнэчулуунNo ratings yet

- Quotation 409Q CXE 65 E BPAB Takalar Kop GKDocument3 pagesQuotation 409Q CXE 65 E BPAB Takalar Kop GKAhmad Risal IcalNo ratings yet

- Quotation For Layer Equipment With Capacity 55000 Hens - Janey PDFDocument16 pagesQuotation For Layer Equipment With Capacity 55000 Hens - Janey PDFNasim KurdistanNo ratings yet

- Quotation: H - Type Price List (H6-108) : Henan Silver Star Poultry Equipment Co.,ltdDocument11 pagesQuotation: H - Type Price List (H6-108) : Henan Silver Star Poultry Equipment Co.,ltdNasim KurdistanNo ratings yet

- Coplate Plant For Pellet 1000kgDocument4 pagesCoplate Plant For Pellet 1000kgAgim ZilkicNo ratings yet

- 10-21 JXSC Quote For Gold Wash PlantDocument2 pages10-21 JXSC Quote For Gold Wash PlantErnest First GroupNo ratings yet

- Technical Project For Wire Drawing MachineDocument3 pagesTechnical Project For Wire Drawing MachineZakhamaNo ratings yet

- DCI BrochureDocument34 pagesDCI BrochureALI NASSERNo ratings yet

- Design and Development of Turmeric Polishing MachineDocument4 pagesDesign and Development of Turmeric Polishing MachineIJMERNo ratings yet

- CSCPOWER Cube Ice MachineDocument2 pagesCSCPOWER Cube Ice MachineBetty CuperNo ratings yet

- TF Feed Pellet Machinery 2019.4Document3 pagesTF Feed Pellet Machinery 2019.4Jadamba DashNo ratings yet

- Model EL9512A Four Spindle Wood Copy Lathe Torno Copiador 1Document5 pagesModel EL9512A Four Spindle Wood Copy Lathe Torno Copiador 1Juan Martín Montes NeriNo ratings yet

- 2m EPS Block Production LineDocument10 pages2m EPS Block Production LineBoulos NassarNo ratings yet

- New QTJ4-40B2 Production Line PDFDocument7 pagesNew QTJ4-40B2 Production Line PDFTwokir A. TomalNo ratings yet

- Quotation For Quail Egg Breaking Machine and Peeling MachinesDocument4 pagesQuotation For Quail Egg Breaking Machine and Peeling MachinesRichard ReyesNo ratings yet

- Extruded 3D Pellet Machinery Model LT100Document3 pagesExtruded 3D Pellet Machinery Model LT100senthilleeNo ratings yet

- COMACO LB1000-Asphalt Mixing PlantDocument12 pagesCOMACO LB1000-Asphalt Mixing PlantHermawan Septian Adittya100% (1)

- Waste Tire Recycling Machine Price List For Rubber BlocksDocument8 pagesWaste Tire Recycling Machine Price List For Rubber BlocksDavid AlorNo ratings yet

- Mesin WP CKDDocument4 pagesMesin WP CKDHerry YsNo ratings yet

- Nanjing YJ SJSL51 Air-Strand Twin Screw Extruder Pelletizing LineDocument9 pagesNanjing YJ SJSL51 Air-Strand Twin Screw Extruder Pelletizing LineOSCAR CORREANo ratings yet

- PVC Tube Extrusion Line1Document6 pagesPVC Tube Extrusion Line1zakariaNo ratings yet

- Design and Development of Beans (Phaseolus Vulgaris) Shelling MachineDocument11 pagesDesign and Development of Beans (Phaseolus Vulgaris) Shelling MachineAngeli Cascaño JoseNo ratings yet

- Quotation of ADP40 Stationary Drum Mix Asphalt PlantDocument7 pagesQuotation of ADP40 Stationary Drum Mix Asphalt PlantChandra Prakash Karki100% (1)

- Roll CrusherDocument7 pagesRoll CrusherSudarshan Devarapalli100% (1)

- SC135 High Equipped ConfigurationDocument3 pagesSC135 High Equipped ConfigurationJedidiah SupportNo ratings yet

- SJ75 High Strength PET Strap Production Line From Barry 20200716Document12 pagesSJ75 High Strength PET Strap Production Line From Barry 20200716voronwe5No ratings yet

- Project: SJ325+SJ125 EPS Cold-Strand Pelletizing Machine: (Double Stages)Document5 pagesProject: SJ325+SJ125 EPS Cold-Strand Pelletizing Machine: (Double Stages)Helmy AYEDINo ratings yet

- Quotation of 100-150 DSE65 Fish Feed Production Line 7.5Document7 pagesQuotation of 100-150 DSE65 Fish Feed Production Line 7.5Lucien AtcholadiNo ratings yet

- Quote For 1.83x3m Ball Mill - FTM JerryDocument13 pagesQuote For 1.83x3m Ball Mill - FTM JerryChristian HuamanNo ratings yet

- 120tph Mobile Asphalt Mixing Plant FinalDocument9 pages120tph Mobile Asphalt Mixing Plant FinalCesar AlvaradoNo ratings yet

- Frozen French Fries Processing Line For 300KGHDocument9 pagesFrozen French Fries Processing Line For 300KGHAnkit PatelNo ratings yet

- The Silk Ax48120 Flange Facing MachineDocument2 pagesThe Silk Ax48120 Flange Facing Machinemij021986No ratings yet

- HG HWB Full Set Chocolate Wafer Roll Production Line QuotationDocument16 pagesHG HWB Full Set Chocolate Wafer Roll Production Line QuotationNikita SariogloNo ratings yet

- Intertec Maquinas para Su Empresa33Document2 pagesIntertec Maquinas para Su Empresa33Alberto VELOSA ROANo ratings yet

- 4 - PPR63 Pipe Extrusion Line-160kgDocument15 pages4 - PPR63 Pipe Extrusion Line-160kgDennis machariaNo ratings yet

- Máy Khoan HXY-5ADocument6 pagesMáy Khoan HXY-5AThem Bui XuanNo ratings yet

- Soal PHTDocument46 pagesSoal PHTJIHAN MAGHFIROH ALRINANo ratings yet

- Cause and EffectDocument16 pagesCause and EffectMJ CORPUZNo ratings yet

- Karakteristik Ekstrak Pewarna Alami Bunga Kenop (Gomphrena Globosa L.) Pada Perlakuan Jenis Pelarut Dan Suhu Ekstraksi Serta Korelasi Antar VariabelDocument12 pagesKarakteristik Ekstrak Pewarna Alami Bunga Kenop (Gomphrena Globosa L.) Pada Perlakuan Jenis Pelarut Dan Suhu Ekstraksi Serta Korelasi Antar Variabelrizky tsintaNo ratings yet

- ESSAY WRITING FOR EXAMS - E-Atsakymai - 2015.02.20 - Su CopyraituDocument55 pagesESSAY WRITING FOR EXAMS - E-Atsakymai - 2015.02.20 - Su CopyraitudaibitNo ratings yet

- Mighty Meaty Pasta SauceDocument1 pageMighty Meaty Pasta SauceOttawa CitizenNo ratings yet

- English KaranganDocument1 pageEnglish KaranganSweetSoundSystemNo ratings yet

- Personal Wellness Nutrition Guided NotesDocument7 pagesPersonal Wellness Nutrition Guided NotesINESSA IUSCEACNo ratings yet

- Seward Stomacher 400Document2 pagesSeward Stomacher 400ugomiesterNo ratings yet

- Jokes For Kids Author GrandparentsDocument17 pagesJokes For Kids Author Grandparentslagoj82597No ratings yet

- Seed Bank ListingsDocument168 pagesSeed Bank ListingsVinceNo ratings yet

- Clases de InglesDocument13 pagesClases de InglesJuan AlejandroNo ratings yet

- Peanut Research PaperDocument9 pagesPeanut Research PaperrosoproductsNo ratings yet

- Business PlanDocument4 pagesBusiness PlanAprinfel TimaanNo ratings yet

- Full Blast - British - Level - B1+ - Tests - Midterm - Mod - 1-6Document9 pagesFull Blast - British - Level - B1+ - Tests - Midterm - Mod - 1-6Marco AntonioNo ratings yet

- BrochureDocument3 pagesBrochureLadyNareth MierdoNo ratings yet

- Please Follow Me!: Lees El Menú?)Document2 pagesPlease Follow Me!: Lees El Menú?)Erick AlvarezNo ratings yet

- IELTS ADDITIONAL BOOK With Oxana AdditionsDocument212 pagesIELTS ADDITIONAL BOOK With Oxana AdditionsCopy World - Work Al NasarNo ratings yet

- Lesson01 PDFDocument9 pagesLesson01 PDFJuan Tercero TabladaNo ratings yet

- English 6 W10 DAYS 1-2Document13 pagesEnglish 6 W10 DAYS 1-2Mary Jane CuevasNo ratings yet

- Quantifiers CuantificadoresDocument2 pagesQuantifiers CuantificadoresBrayan Manuel Diaz ZevallosNo ratings yet

- Food Safety and SanitationDocument5 pagesFood Safety and SanitationKong KrcNo ratings yet

- SD VegetablesDocument4 pagesSD VegetablesNeolen RevalynaNo ratings yet

- Training Activity Trainee Facilities/Tool S Equipment Venue (Workstation / Area) Date and Time RemarksDocument6 pagesTraining Activity Trainee Facilities/Tool S Equipment Venue (Workstation / Area) Date and Time RemarksMary MairaNo ratings yet

- HackJournal 4 05Document20 pagesHackJournal 4 05Chorch GimenezNo ratings yet

- Indent SheetDocument11 pagesIndent SheetNeelesh KadamNo ratings yet

- DPR On Ginger Powder NA-2017-103.Document25 pagesDPR On Ginger Powder NA-2017-103.Salman ShaikNo ratings yet

- Herbal TeasDocument8 pagesHerbal Teasapi-507527047No ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument6 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsHadrien FaryalaNo ratings yet

- NoneDocument8 pagesNoneIrfan Maulanna PNo ratings yet

- Adjectives Worksheet-5 2021-22 - ANSWER KEYDocument3 pagesAdjectives Worksheet-5 2021-22 - ANSWER KEYnehajtNo ratings yet