Professional Documents

Culture Documents

4 - 180 Rear Axle Brake Pin Replacement

Uploaded by

DonbassOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 - 180 Rear Axle Brake Pin Replacement

Uploaded by

DonbassCopyright:

Available Formats

TECHNICAL INFORMATION

DATE: 07/2012 ISSUE: 1 NUMBER: 4/180

SUBJECT: Rear Axle Brake Pin Replacement

PRODUCTS AFFECTED:

409 (01780500 - 01780824),

TM220 (01545000 - 01545270)

TERRITORIES AFFECTED: UK & Ireland, Spain, South-East Asia, South America, Russia, Portugal,

Poland, North America (USA and Canada), Nordic Territories and Baltic States, Middle East, Mexico,

Italy, India, Holland, Gulf States, Germany, France (and French territories), Eastern Europe, China,

Caribbean Islands, Brasil, Belgium, Australia and New Zealand, Africa

SERVICE CODE: See Warranty Instruction REPAIR TIME: See Warranty Instruction

SAFETY NOTICE: Instructions in Service Bulletins assume that the engineer has a sound knowledge of safety procedures and

has been trained in the maintenance and repair of JCB products. If you are unsure or do not understand information contained in

this or other bulletins, ask your supervisor or contact JCB Service for advice. REMEMBER SAFETY MUST COME FIRST.

Copyright © 2004 JCB SERVICE. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any other

means, electronic, mechanical, photocopying or otherwise, without prior permission from JCB SERVICE.

This communication and the information within is intended for the recipient only, for information purposes, is confidential and may not be communicated to any third party.

Whilst the information is believed to be correct, no guarantee is given by JCB as to it’s accuracy and it’s use may not be attributed to JCB. This bulletin is issued for

information only and does not constitute an instruction to carry out warranty repairs on JCB products.

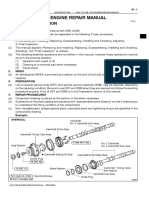

Introduction Procedure

Reports of external hydraulic oil leakage from the 1. Make the machine safe. Refer to the Operator’s

rear axle breather have been received. Manual.

Investigations show a variation in the dimensions of 2. Remove the rear axle assembly. Refer to the

the brake pins. As a result, it is possible for the O-ring related machine service manual (TM220: Section

to not seat correctly and this can cause hydraulic oil F - Transmission, Rear Axles and 409: Section F

to enter the rear axle. Refer to Figure 1. - Transmission, Axles).

JCB have introduced a new brake pin. 3. Install the new brake pins. Complete the

dismantling and assembly procedures for the

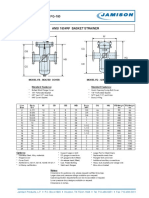

Figure 1. service and mechanical park brake. Refer to

the related machine service manual (Section G

A - Brakes, Service and Mechanical Park Brake,

Dismantling and Assembly).

B

Parts List

Table 1.

Item Part No. Description Qty.

A 333/E7592 Brake pin 3

A Brake pin

B O-ring

1/2 4/180-1 1/2

Warranty Instruction

Service Reference Number: ZX64

Service Code F500

Description Install replacement

brake pins

Repair Time 4.50h

Failed Part 333/E7592

Qty. 3

2/2 4/180-1 2/2

You might also like

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- JCB 504B TELESCOPIC HANDLER Service Repair Manual SN 277001 Onwards PDFDocument50 pagesJCB 504B TELESCOPIC HANDLER Service Repair Manual SN 277001 Onwards PDFjfksmmefm0% (2)

- Dau Keo EST - Engine ISG (English)Document2,946 pagesDau Keo EST - Engine ISG (English)Vũ Công Minh100% (2)

- Foreword: Manual Name Pub. No. DUTRO Chassis Workshop Manual Supplement S1ïYXZE10ADocument137 pagesForeword: Manual Name Pub. No. DUTRO Chassis Workshop Manual Supplement S1ïYXZE10AJerwin Jay MaderasNo ratings yet

- S5 Yw04e06aDocument130 pagesS5 Yw04e06aNelson FurtadoNo ratings yet

- S5 Ys05e06aDocument155 pagesS5 Ys05e06aNelson FurtadoNo ratings yet

- How To Use This Manual: General InformationDocument136 pagesHow To Use This Manual: General InformationAndreiNo ratings yet

- Transmission A761e OverhaulDocument356 pagesTransmission A761e OverhaulJoel R. ChanNo ratings yet

- 2az Fse Engine Repair Manual (Rm1083e)Document120 pages2az Fse Engine Repair Manual (Rm1083e)Osvaldo Chimbas100% (2)

- JS215 ManualDocument629 pagesJS215 Manualsunil dhaugoda83% (6)

- Daihatsu Feroza Engine Workshop ManualDocument440 pagesDaihatsu Feroza Engine Workshop ManualLuis Patricio Rodriguez89% (79)

- Technical Service Bulletin: ModelDocument3 pagesTechnical Service Bulletin: Modelkilofome05No ratings yet

- Fj44 Service Bulletin: 1. Planning InformationDocument5 pagesFj44 Service Bulletin: 1. Planning InformationMaral HaghaniNo ratings yet

- VOLEEX C30 Service ManualDocument580 pagesVOLEEX C30 Service Manualfabiansandez91% (34)

- GW4G15 Service Manual-E20170720Document142 pagesGW4G15 Service Manual-E20170720Santiago CosNo ratings yet

- How To Use This Engine Repair Manual: General InformationDocument3 pagesHow To Use This Engine Repair Manual: General InformationHenry SilvaNo ratings yet

- S5 Yw04e06ahinodutro PDFDocument130 pagesS5 Yw04e06ahinodutro PDFichan shodiqNo ratings yet

- SO5C Repair ManualDocument155 pagesSO5C Repair ManualAung Kham100% (6)

- Service Manual: 1 2 3 A B C E F G H K SDocument383 pagesService Manual: 1 2 3 A B C E F G H K SMakar SamarskiyNo ratings yet

- New Holland Engine J08e Uv Service ManualDocument20 pagesNew Holland Engine J08e Uv Service Manualleroy100% (36)

- General Information OverviewDocument9 pagesGeneral Information OverviewandriNo ratings yet

- Technical Information: ! Safety Notice Page 1 of 5Document5 pagesTechnical Information: ! Safety Notice Page 1 of 5Epure Gabriel100% (2)

- LA206001 Park Brake Lamp Illuminated PDFDocument4 pagesLA206001 Park Brake Lamp Illuminated PDFGino Pier100% (1)

- How To Use This Engine Repair Manual (1Az-Fe) : General InformationDocument3 pagesHow To Use This Engine Repair Manual (1Az-Fe) : General InformationNgo Binh AnNo ratings yet

- Service Manual: 1 2 3 A B C D E F G KDocument6 pagesService Manual: 1 2 3 A B C D E F G KРоман Кузів0% (1)

- Power Steering GearsDocument5 pagesPower Steering GearsDarren ANo ratings yet

- BNR32 Service Manual BookmarkedDocument804 pagesBNR32 Service Manual Bookmarkedbyrnesvictim75% (4)

- Section A: Publication NoDocument20 pagesSection A: Publication NoLuis BertaoNo ratings yet

- 4G63, 4G64 Gasoline EngineDocument110 pages4G63, 4G64 Gasoline EngineLance Thompson100% (1)

- g100 g102 Chassis ManualDocument538 pagesg100 g102 Chassis Manualtoscana1234575% (12)

- Vibration Damper and Pulley - Remove and InstallDocument3 pagesVibration Damper and Pulley - Remove and Installbejoythomas100% (1)

- Service Manual: General Information Care & SafetyDocument199 pagesService Manual: General Information Care & Safetyred100% (1)

- How to Repair a Manual TransaxleDocument3 pagesHow to Repair a Manual TransaxleMax K.No ratings yet

- 2RZ 3RZ SC PDFDocument21 pages2RZ 3RZ SC PDFUliAlejandroRodriguezCoriangaNo ratings yet

- JCB Adt: Service ManualDocument383 pagesJCB Adt: Service Manualcarlos arturo coral peñaNo ratings yet

- How To Use This Automatic Transmission Repair Manual: General InformationDocument3 pagesHow To Use This Automatic Transmission Repair Manual: General InformationNkoshiEpaphrasShoopalaNo ratings yet

- Ring(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - DodgiaDocument1 pageRing(s), Piston - Engine Block - 2.7L DOHC Engine - Engine - Dodge Journey Service & Repair Manual - DodgiaCaballitofelizNo ratings yet

- Fastrac 3170Document21 pagesFastrac 3170Patka1130% (1)

- Toyota 2AZ FSE Engine Repair Manual RM1083EDocument120 pagesToyota 2AZ FSE Engine Repair Manual RM1083EСерега Семченко100% (1)

- Service Information: U Repair GuidanceDocument2 pagesService Information: U Repair GuidanceLuís MartinsNo ratings yet

- Crankshaft Front Seal - Install: Shutdown SIS Previous ScreenDocument2 pagesCrankshaft Front Seal - Install: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- SB 10091401 2280Document14 pagesSB 10091401 2280Artur ElectroMecânicoNo ratings yet

- Free Flow Headers Reel Position, Hydraulic Ram Seals - Rp7982 MandatoryDocument7 pagesFree Flow Headers Reel Position, Hydraulic Ram Seals - Rp7982 MandatoryMessi EmetievNo ratings yet

- Technical Procedures: General Maintenance Practices (Level 1 and 2 Maintenance)Document6 pagesTechnical Procedures: General Maintenance Practices (Level 1 and 2 Maintenance)exergicNo ratings yet

- MC 10192120 9999Document4 pagesMC 10192120 9999Sam LorcaNo ratings yet

- 5l-E Engine EletricalDocument246 pages5l-E Engine EletricalMagno Dias96% (23)

- DTC Trans AltimaDocument209 pagesDTC Trans AltimaAlberto AcostaNo ratings yet

- SL 091Document10 pagesSL 091Proar Aeronaves e Revisões Ltda. OficinaNo ratings yet

- Kertas Kerja: Kod Dan Nama ProgramDocument11 pagesKertas Kerja: Kod Dan Nama ProgramLeeNo ratings yet

- Section K: Publication NoDocument8 pagesSection K: Publication NoLuis BertaoNo ratings yet

- Zx200-5g Engine Manual 6bg1 Tier 2 Edcd-En-00Document234 pagesZx200-5g Engine Manual 6bg1 Tier 2 Edcd-En-00ibnu malkan93% (14)

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (6)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- file-16473Document12 pagesfile-16473DonbassNo ratings yet

- Extracted Fromversion 145 No of Error Codes in List 978 Tracked & Wheeled ExcavatorsDocument11 pagesExtracted Fromversion 145 No of Error Codes in List 978 Tracked & Wheeled ExcavatorsMiguel Alfredo Romero Jimenez74% (31)

- 2014 - DAVINCIP-20140919-132817-Technical Information Bulletin - Right Hand Cluster and Hydraulic ECU Setup - 5 - 464 ENDocument4 pages2014 - DAVINCIP-20140919-132817-Technical Information Bulletin - Right Hand Cluster and Hydraulic ECU Setup - 5 - 464 ENDonbassNo ratings yet

- 526 SLCDocument15 pages526 SLCDonbassNo ratings yet

- Шины давлениеDocument1 pageШины давлениеDonbassNo ratings yet

- Bucyrus Cylinder Seal Kit Replacement PartsDocument2 pagesBucyrus Cylinder Seal Kit Replacement PartsMikel1020No ratings yet

- Ats 4Document231 pagesAts 4gillian marbebeNo ratings yet

- Drilling machine gravity feed magazine circuitDocument5 pagesDrilling machine gravity feed magazine circuityashveerluvNo ratings yet

- C7H 18 12 11Document464 pagesC7H 18 12 11Felipe MuñozNo ratings yet

- Cummins QSB6.7 119 KW (162 HP) at 2,200 RPM 108kW (147 HP) at 2,200 RPM 14,000 KG 2.5 M 129 KN 2,880 MMDocument2 pagesCummins QSB6.7 119 KW (162 HP) at 2,200 RPM 108kW (147 HP) at 2,200 RPM 14,000 KG 2.5 M 129 KN 2,880 MMAbo Achraf LaalawiNo ratings yet

- 24.38.502.036 enDocument7 pages24.38.502.036 entranspol2023No ratings yet

- Xtreme XR Forward Reach Forklift Service ManualDocument20 pagesXtreme XR Forward Reach Forklift Service Manualtamara100% (46)

- Ir10,20 Ir12,22 en 1025972Document9 pagesIr10,20 Ir12,22 en 1025972Steven FryeNo ratings yet

- 03-A Series 1.6-2.0tDocument3 pages03-A Series 1.6-2.0tKobusNo ratings yet

- Starex TQFLDocument1 pageStarex TQFLAero NiezNo ratings yet

- Hürner Manual Hydraulic: WhitelineDocument2 pagesHürner Manual Hydraulic: WhitelineMihai BadeaNo ratings yet

- Ge D 2100 Direct Wellhead Drive BrochureDocument2 pagesGe D 2100 Direct Wellhead Drive Brochuremariamalloney1730No ratings yet

- Zapex - ZN DentadoDocument14 pagesZapex - ZN DentadoJose Patricio Obreque RiosNo ratings yet

- Chrysler Cirrus 2000Document9 pagesChrysler Cirrus 2000Luis Angel BarajasNo ratings yet

- EPA98 Y 04 MBE 900.4000 Troubleshooting Manual DDC-SVC-MAN-0027Document248 pagesEPA98 Y 04 MBE 900.4000 Troubleshooting Manual DDC-SVC-MAN-0027Omar HernándezNo ratings yet

- Isuzu MUDocument9 pagesIsuzu MURoberto Ortega MicalizziNo ratings yet

- MX 10 PartsDocument3 pagesMX 10 PartsneelotpalnayakNo ratings yet

- Catalogo Colheitadeira Case 2388-2399aDocument2,384 pagesCatalogo Colheitadeira Case 2388-2399aThiago RomeroNo ratings yet

- Wiring DigramDocument572 pagesWiring DigramalenjazathNo ratings yet

- ANSI 150#RF BASKET STRAINER MODEL FB-150, FQ-150Document1 pageANSI 150#RF BASKET STRAINER MODEL FB-150, FQ-150klich77No ratings yet

- Repair Part List - W10336106Document6 pagesRepair Part List - W10336106YvesnounouneNo ratings yet

- Toyota Hilux 2018 Overall EWD Vehicle Exterior Turn Signal and Hazard Warning Light (RHD)Document2 pagesToyota Hilux 2018 Overall EWD Vehicle Exterior Turn Signal and Hazard Warning Light (RHD)gabrielzinho43No ratings yet

- Equipment Type Code Equipment TypeDocument24 pagesEquipment Type Code Equipment TypeFarrukh AhmedNo ratings yet

- CMC Ready ReckonerxlsxDocument3 pagesCMC Ready ReckonerxlsxShalaniNo ratings yet

- Liebherr R9200Document22 pagesLiebherr R9200andie.notoNo ratings yet

- HBBPL Catalogue Book - 2016-2017 - LOWDocument196 pagesHBBPL Catalogue Book - 2016-2017 - LOWrahul mehtaNo ratings yet

- Tamrock Spare Parts Manual 1 (1) LH410 - L810D435 Service Parts and Pressure SwitchesDocument74 pagesTamrock Spare Parts Manual 1 (1) LH410 - L810D435 Service Parts and Pressure Switchesariel avalosNo ratings yet

- Manual de Asfaltadora 1000F PDFDocument184 pagesManual de Asfaltadora 1000F PDFAlvin Smith100% (1)

- Resfri Ar Expo CatalogueDocument24 pagesResfri Ar Expo CatalogueRenan BiasibettiNo ratings yet

- 1p70en 0692Document36 pages1p70en 0692SebastianNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)