Professional Documents

Culture Documents

NPSH and Cavitation 1677471948

Uploaded by

Srinivas Bobby0 ratings0% found this document useful (0 votes)

19 views1 pageOriginal Title

NPSH_and_Cavitation__1677471948

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pageNPSH and Cavitation 1677471948

Uploaded by

Srinivas BobbyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

NPSH and Cavitation – Common lapses

NPSH available is not a constant value given in the datasheet

Suction head or NPSH available consists of static head and dynamic

head.

Dynamic head or head loss across the suction systems (piping, valves,

∝ elbows, expander / reducer etc) is vary in square of the flow.

Head loss across the system at 10% and 20% higher flow would increase

by 21% and 44% respectively.

± − If nature of product (viscosity or density) changed, it affects affect the

friction factor and resultant head loss. That could be negligible.

Actual NPSH available value vary with operating temperature

= ± − − Vapor pressure being considered in the data sheet is at certain

operating temperature.

If actual operating temperature is higher, vapor pressure would also

increase and that would lead to low NPSH available than anticipated.

It is very important point, while handling light HC or product at sub-zero

temperature. Suction temperature at source could be normal but while

it reaches to pump casing sometimes it may increase by few degree C if

suction system is not properly insulated.

Suction strainer is friend of pump, but not the always.

Suction strainer is a good friend of pump, protect from solid, lump and

foreign material. However, if not handled properly and maintained its

condition, it may prove worst enemy.

In the above NPSHa formula, suction strainer loss is either not

considered or assumed to be very low whereas while fine mesh get

chocked Diff. pressure across the strainer goes very high.

Sometimes pressure gauge is not installed in between the strainer and

pump so not possible to know the strainer condition without opening it.

Datasheet NPSHr is not only an absolute value

NPSHr value given in the data sheet is at rated condition.

It increases with increase in operating flow.

NPSH also increase on extreme left side to BEP, close the Minimum

continuous flow region. Internal recirculation at impeller suction would

generate excessive heat and may cavitate the pump.

Pump Start up venting matters

Proper venting of centrifugal pump is essential while handling HC at

cryonic temperature.

It is not all about the open casing or seal vent line for some time and

close it. It is to ensure no vapor or gas hold up inside the casing or

mechanical seal cavity.

While pump is on standby with suction valve open, there is a possibility

of huge amount of HC hold up in suction piping, casing and seal cavity.

Venting may be required for extended time than normal practice.

If piping and pumps are not insulated and ambient temperature is

high, situation may get worse while change over. Continues venting,

Plan 13M may help to improve the situation.

You might also like

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- Cold and .N2Document24 pagesCold and .N2IVAN ARNULFO BUITRAGO LOZANO100% (3)

- CMP800 Maintenance and TroubleshootingDocument57 pagesCMP800 Maintenance and TroubleshootingSofiane Halimi100% (1)

- Dead Head HeatingDocument6 pagesDead Head HeatingSimon TudorNo ratings yet

- Selection of PumpsDocument8 pagesSelection of Pumpssmohsinshah9492100% (9)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Turboexpander CompressorsDocument5 pagesTurboexpander CompressorsNuri LealNo ratings yet

- T II P Training Program On Basic Process Engineering PracticesDocument26 pagesT II P Training Program On Basic Process Engineering PracticesAsmita AndaniNo ratings yet

- Whitepaper Reciprocating MachineryDocument19 pagesWhitepaper Reciprocating MachinerySofiane HalimiNo ratings yet

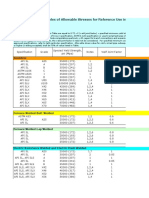

- Allowable Stress in PipingDocument6 pagesAllowable Stress in PipingpelotoNo ratings yet

- 05 - Sonatrach Srga2 Ms 5002 Startup & ControlDocument17 pages05 - Sonatrach Srga2 Ms 5002 Startup & ControlSofiane Halimi100% (1)

- Elements of Compressor ThermodynamicsDocument44 pagesElements of Compressor ThermodynamicsSofiane Halimi100% (1)

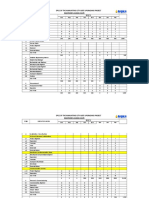

- Manpower HistogramDocument15 pagesManpower HistogramZaem Afifi100% (3)

- Whitepaper Reciprocating Machinery PDFDocument19 pagesWhitepaper Reciprocating Machinery PDFSofiane HalimiNo ratings yet

- PSC I-Girder Bridge Design in BSDocument82 pagesPSC I-Girder Bridge Design in BSSANDIPNo ratings yet

- Mobile Crane or Boom Truck Checklist Rev4Document2 pagesMobile Crane or Boom Truck Checklist Rev4maomontes100% (2)

- ASCE - 'Astoria Tunnel Profile Under The East River'Document109 pagesASCE - 'Astoria Tunnel Profile Under The East River'Colin PearceNo ratings yet

- 20 - IWCF Practice Exam Booklet - 05mar13 PDFDocument127 pages20 - IWCF Practice Exam Booklet - 05mar13 PDFAdolfo AnguloNo ratings yet

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- Eco 100 Wind Turbine PlatformDocument4 pagesEco 100 Wind Turbine PlatformSofiane HalimiNo ratings yet

- Net Positive Suction HeadDocument7 pagesNet Positive Suction HeadNenad MutavdzicNo ratings yet

- Calculate NPSH With Confidence (CE)Document6 pagesCalculate NPSH With Confidence (CE)jdgh1986No ratings yet

- TurboExpander PDFDocument6 pagesTurboExpander PDFDevran Al FaruqNo ratings yet

- ETI Part BooksDocument63 pagesETI Part Booksyugopuspoyo100% (1)

- NPSHDocument1 pageNPSHMustafa MehdiNo ratings yet

- Centrifugal Pump NPSH and Cavitation 1652342154Document1 pageCentrifugal Pump NPSH and Cavitation 1652342154mohammadNo ratings yet

- File 906Document12 pagesFile 906ak_adamNo ratings yet

- Ad 19 NPSHDocument14 pagesAd 19 NPSHkevinNo ratings yet

- NPSHDocument4 pagesNPSHrex tanongNo ratings yet

- Cavitation: What Damage Does Cavitation Cause?Document2 pagesCavitation: What Damage Does Cavitation Cause?Sulist N WahyudieNo ratings yet

- Considering NPSH When Making A Pump SelectionDocument8 pagesConsidering NPSH When Making A Pump SelectionMuhammad ImranNo ratings yet

- Pump NomenclatureDocument3 pagesPump NomenclatureRashami VasavaNo ratings yet

- Tanques Condensado AtmosfericosDocument4 pagesTanques Condensado AtmosfericosmarcmanichNo ratings yet

- Centrifugal Pumps Knowledge HandbookDocument260 pagesCentrifugal Pumps Knowledge HandbookSurya AdiNo ratings yet

- Net Positive Suction Head Analysis For Testing The Condition of A Centrifugal Pump PDFDocument6 pagesNet Positive Suction Head Analysis For Testing The Condition of A Centrifugal Pump PDFJaime Andrés HuertasNo ratings yet

- 10 Things You Need To Know About NPSHDocument4 pages10 Things You Need To Know About NPSHB rgNo ratings yet

- Melab Act2Document2 pagesMelab Act2Theo AlapanNo ratings yet

- NPSH Note Piping Easy23764Document6 pagesNPSH Note Piping Easy23764Samuel OlonadeNo ratings yet

- NPSH For PumpDocument2 pagesNPSH For PumpkapsarcNo ratings yet

- Captura de Tela 2022-08-03 À(s) 15.59.58Document141 pagesCaptura de Tela 2022-08-03 À(s) 15.59.58Max MarquesNo ratings yet

- YAMADA Engineering Handbook 2014Document141 pagesYAMADA Engineering Handbook 2014ToyinNo ratings yet

- Stauff Accumulators - Maintenance InstructionsDocument6 pagesStauff Accumulators - Maintenance InstructionsBill MurrayNo ratings yet

- Calibration Column Milton RoyDocument4 pagesCalibration Column Milton Royrubens072No ratings yet

- Case 52 Problems With A Blocked-In Centrifugal PumpDocument2 pagesCase 52 Problems With A Blocked-In Centrifugal Pumphwang2No ratings yet

- N2 Triplex Pump - 1Document6 pagesN2 Triplex Pump - 1Ibrahim AhmedNo ratings yet

- Avoid Cavitation ProblemsDocument1 pageAvoid Cavitation Problemssushant_jhawerNo ratings yet

- Standfast Surplus ValveDocument2 pagesStandfast Surplus ValveAlexandre MartinsNo ratings yet

- Sizing Steam TrapsDocument4 pagesSizing Steam Trapsjesus_manrique2753No ratings yet

- MechChem Africa Sept 2017 Pump Systems 101Document1 pageMechChem Africa Sept 2017 Pump Systems 101Parvez ShahedNo ratings yet

- Unit Processes in Pharmacy: Pharmaceutical MonographsFrom EverandUnit Processes in Pharmacy: Pharmaceutical MonographsRating: 4.5 out of 5 stars4.5/5 (4)

- 10b Dodge SleevoilDocument32 pages10b Dodge SleevoilSofiane HalimiNo ratings yet

- Brush Seals FlyerDocument2 pagesBrush Seals FlyerSofiane HalimiNo ratings yet

- Halimi Sofiane: Dear RecruiterDocument1 pageHalimi Sofiane: Dear RecruiterSofiane HalimiNo ratings yet

- Installation and Operation Guide Cartridge Change InstructionsDocument8 pagesInstallation and Operation Guide Cartridge Change InstructionsSofiane HalimiNo ratings yet

- SVS.4105.0618 Elliott Rotor and Diaphragm Storage CanistersDocument2 pagesSVS.4105.0618 Elliott Rotor and Diaphragm Storage CanistersSofiane HalimiNo ratings yet

- 7th 3Document53 pages7th 3Sofiane HalimiNo ratings yet

- TCDocument2 pagesTCSofiane HalimiNo ratings yet

- Woodward Governor'S Troubleshooting and Rectification: A Case On Jamuna Fertilizer Company PerspectiveDocument0 pagesWoodward Governor'S Troubleshooting and Rectification: A Case On Jamuna Fertilizer Company PerspectiveSofiane HalimiNo ratings yet

- Api 52Document3 pagesApi 52Sofiane HalimiNo ratings yet

- Presdiagrams 24970Document1 pagePresdiagrams 24970Sofiane HalimiNo ratings yet

- E Yanmar 2v78caDocument42 pagesE Yanmar 2v78caDannyNo ratings yet

- Infrastructure Design Report - G1!1!41Document41 pagesInfrastructure Design Report - G1!1!41Hafizul ZaidanNo ratings yet

- IB-80000B Nonsegregated-Phase Bus: 600V To 38kV, 1200A To 4000ADocument17 pagesIB-80000B Nonsegregated-Phase Bus: 600V To 38kV, 1200A To 4000Adestro57No ratings yet

- Construction and Building Materials: Abhishek Jain, Rajesh Gupta, Sandeep ChaudharyDocument13 pagesConstruction and Building Materials: Abhishek Jain, Rajesh Gupta, Sandeep ChaudharySchool of EngineersNo ratings yet

- 6 Sizing Example #3Document26 pages6 Sizing Example #3BryanHarold BrooNo ratings yet

- Building Materials Module 1 PPT NotesDocument20 pagesBuilding Materials Module 1 PPT NotesmanojNo ratings yet

- FRA MV Cable TerminationsDocument1 pageFRA MV Cable Terminationsmohamed1303No ratings yet

- SFSDFDocument1 pageSFSDFbillNo ratings yet

- Case Study - ChecklistDocument4 pagesCase Study - Checklistsafiulla syedNo ratings yet

- Marina Square II BrochureDocument11 pagesMarina Square II BrochureAbdul Rasyid Abdullah SebliNo ratings yet

- Unit Method of EstimatingDocument8 pagesUnit Method of EstimatingAmulie JarjuseyNo ratings yet

- p355n NH Nl1 Nl2 TubesDocument4 pagesp355n NH Nl1 Nl2 Tubesado31No ratings yet

- Projection WeldDocument20 pagesProjection WeldCebrac ItatibaNo ratings yet

- Ladder Stiles Retractable Data SheetDocument1 pageLadder Stiles Retractable Data SheetnandanaNo ratings yet

- 20 THDocument2 pages20 THdohamateNo ratings yet

- C50X100Document3 pagesC50X100Gabriel RojasNo ratings yet

- Coorporate Office BuildingDocument35 pagesCoorporate Office BuildingSivaiNo ratings yet

- 3-Typical Upgrade Trash RackDocument1 page3-Typical Upgrade Trash RackRodelio Aboda Jr.No ratings yet

- Air Vee BendingDocument4 pagesAir Vee Bendinganil chejaraNo ratings yet

- 9 BOQ Street Lights FINALDocument3 pages9 BOQ Street Lights FINALmooorthuNo ratings yet

- Appendix - I (See Paragraph - 6) Form - 1Document11 pagesAppendix - I (See Paragraph - 6) Form - 1Vishnu PatidarNo ratings yet

- The Fire Resistant Solution For Steel Conduit: Cable DescriptionDocument10 pagesThe Fire Resistant Solution For Steel Conduit: Cable DescriptionBhagoo HatheyNo ratings yet