Professional Documents

Culture Documents

123 - Recommended Guidelines For Classification of Process Control Safety and Support

123 - Recommended Guidelines For Classification of Process Control Safety and Support

Uploaded by

Popovici AlexandruOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

123 - Recommended Guidelines For Classification of Process Control Safety and Support

123 - Recommended Guidelines For Classification of Process Control Safety and Support

Uploaded by

Popovici AlexandruCopyright:

Available Formats

123 - Norwegian Oil and Gas Association

Guideline

for

Classification of process control, safety and support

ICT systems based on criticality

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 1

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Guideline title: Classification of process control, safety and support ICT systems

based on criticality

Norwegian Oil and Gas Guideline 123 approved by:

Operations Committee Approval date: 05.01.2009

Entry into force: 15.01.2009

Revision no: 01 Revision date: 01.02.2009

Norwegian Oil and Gas Guideline 104 approved by:

Steering Group Integrated Operations Approval date: 08.12.2006

Objective of the guideline:

To contribute to the improvement of the overall information security of the offshore industry

on the Norwegian Continental Shelf, specifically safety, regularity and integrity of operations.

To ensure that information security is adequately addressed in all ICT systems installed in

production control, safety and support networks.

Status with the authorities:

This guideline is a supplement to the Norwegian Oil and Gas Guideline 104. Similar to the

Guideline 104 this document has no formal relations to the authorities. However, the

Petroleum Safety Authority Norway (PSA) and the Norwegian Petroleum Directorate (NPD)

have had one observer each in the Work Group Information Security (WG IS) who produced

the Norwegian Oil and Gas Guideline 104 document.

Web site location:

This guideline and the Norwegian Oil and Gas Guideline 104 Information Security Baseline

Requirements for Process control, safety and support ICT Systems can be downloaded for

free from Norwegian Oil and Gas’s web site:

http://www.norskoljeoggass.no/retningslinjer/category180.html

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 2

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

TABLE OF CONTENTS

Foreword ................................................................................................................................... 4

Scope......................................................................................................................................... 4

Terms and definitions.............................................................................................................. 5

Introduction ............................................................................................................................... 5

The classification scheme ...................................................................................................... 9

The classification process .................................................................................................... 10

Appendix A

Examples of criticality classification.................................................................................... 11

Appendix B

Examples of criticality classification questionnaire .......................................................... 15

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 3

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Foreword

A prerequisite to implement effective and efficient information security controls and measures

is to have a clear understanding of the business needs of each system and importance of the

system in the production environment. To simplify the process of ensuring that all necessary

safeguarding measures have been implemented and prevent systems having uneven

security levels within the same domain a classification system is useful – and in larger

installations considered a necessity.

The document “Information Security Baseline Requirements for Process Control, Safety and

support ICT Systems” (ISBR) was first issued in June 2006 as Norwegian Oil and Gas

Guideline no. 104. The guideline consists of 16 requirements to operators and suppliers

within the oil and gas industry on the Norwegian Continental Shelf. The IBSR #2 requires

that “Risk assessment shall be performed for process control, safety and support ICT

systems and networks”. To help focus the risk assessment on essential systems, a

classification of the ICT systems in the process control environment may be needed. This

document is a guideline on how to perform classification of Process Control, Safety and

support ICT Systems based on the systems criticality.

Scope

This guideline applies to all ICT systems for Process Control, Safety and Support (PCSS)

which are part of any type of production or drilling facility.

The guideline does not apply to ICT systems installed in the corporate office domain.

However, if systems needed to sustain production are placed on the corporate office domain,

they should be included in the classification system to evaluate any information security

controls and measures needed. Typical systems in this category might be weather systems,

telecommunication systems, simulators, engineering systems, integrated operations work

places, plant production optimizers, information management systems and remote services.

The target audience for this document include personnel responsible for carrying out the

criticality assessment:

Plant/installation manager

System Owners

Data Owners

Information Security Responsible for the PCSS domain

Furthermore the following groups should be acquainted with the document:

Design Engineers

Technical Managers

Vendors and suppliers of PCSS/ICT systems and services

Operation Support Managers

Discipline Advisors

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 4

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Terms and definitions

Within the scope of this document:

Criticality is an indicator of the importance of an ICT system given its purpose in the

production environment.

Criticality Level is a ranking that signifies the importance of the equipment or ICT system for

maintaining defined aspects of HSSE (Health, Safety, Security & Environment) as well as the

production operations.

Classification is the assignment to a particular Criticality Level.

HSSE is an abbreviation for Health, Safety, Security & Environment.

ICT system is defined as the combination of computer hardware, firmware and software, i.e.

computers, operating systems, networks, communication equipment and applications (Ref.

ISO/IEC 27005). In the PCSS domain this will typically entail ICT systems such as systems

for monitoring process variables in the production environment, controlling motors and

actuators, remotely programmable devices, smart sensors, flow computers, and condition

monitoring.

PCSS is an abbreviation for Process Control, Safety and Support.

For other terms and definitions refer to Appendix B in Norwegian Oil and Gas Guideline no.

104 - Information Security Baseline Requirements for Process Control, Safety and Support

ICT Systems.

(http://www.norskoljeoggass.no/retningslinjer/category180.html)

Introduction

Criticality Assessment is not equal to Risk Assessment, but the output of the Criticality

Assessment will be an input to the Risk Assessment. When performing a Risk Assessment,

both the probability of an information security incident can happen and the consequence

should the incident occur, are considered. When performing a Criticality Assessment only the

consequence is considered. The probability of loss, interrupts or irregularities in the function

or service is not an element that needs to be considered – only the consequence of an event

or an incident is relevant for a criticality assessment.

In Figure 1 a simplified Risk Management Process is shown. During the Criticality

Assessment the organisation should consider the importance of the ICT assets in the

production environment. The consequences related to HSE, production regularity and

information security should be assessed and evaluated, related to possible relevant ICT

incidents. The results should be documented and used as an input to the Risk Assessment,

where the most critical ICT systems should be assessed first. The output of the Risk

Assessment should be a Risk Treatment Plan, to ensure that necessary and adequate

information security controls and measures are implemented. The concept of the barriers to

improve safety and security (as defined in the Norwegian Facilities Regulations – The

Management Regulations § 2) shall always be paramount when producing the plan.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 5

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Figure 1: Risk management process

When evaluating the criticality of a function, the two following aspects should be considered:

o The consequences of interrupt or loss of the PCSS function

o The consequences of irregular functionality, malfunction or unexpected behaviour in the

PCSS function

The criticality of a PCSS/ICT system depends on the context where it is used and may vary

from installation to installation. It will also differ depending on where the system is used; is

the system deployed in a production environment or in a drilling operation; is it on a platform

or a floater; is it offshore or onshore? Furthermore, the criticality may change over time,

depending on the character of the process’ and the reservoir’s nature, character and state,

as well as other factors such as new or changed business objectives, new or updated

regulations, major process modifications and tie-ins of other fields. The occurrence of such

factors should trigger a repeat of the classification process. Furthermore, it is recommend-

able to re-evaluate to classification scheme periodically.

In the table below systems typically found in a production environment are listed, along with

the typical possible consequences, should an incident occur.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 6

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

System type Possible consequences of an information security incident

Safety Systems HSSE impact.

Process control systems HSSE and economical impact or impact on reputation.

Electrical control systems

Fiscal metering systems Data integrity. Economical impact or impact on reputation.

Support systems (e.g. Economical impact.

condition monitoring)

Telecommunication Economical impact. Incidents may escalate to HSSE impact.

infrastructure

Telecom systems (e.g. PA, HSSE impact.

CCTV, UHF, VHF)

Table 1: System type and possible consequence of an information security incident

This guideline only focuses on the PCSS/ICT systems in the production environment, with

the system’s corresponding engineering tools. It is obvious that the criticality of the whole

function has to be considered. In many instances the criticality level of the ICT system will be

equal to the criticality level of the PCSS function. However, in some instances the ICT

system will not be as critical as the PCSS function itself; hence it is important to evaluate the

criticality of the ICT system after, or as a part of, the criticality assessment for the whole

PCSS function, service or system.

Example:

The PCSS function depicted in Figure 2 is a vibration protection and monitoring function for a

rotating machinery unit. The machinery is equipped with a number of transducers to monitor

vibrations in all directions. In case of excessive vibrations during normal operation, the

compressor will immediately be tripped by the protection system.

The embedded ICT system will monitor the vibrations of the rotating machinery for trending

purposes, to enable the recognition of evolving failures. The criticality of the complete

vibration monitoring function will be assessed and evaluated as part the organisation’s

maintenance strategy. However, in this guideline only the ICT system part of the function is

covered.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 7

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Figure 2: Focal point for Criticality Assessment

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 8

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

The classification scheme

ICT systems supporting, monitoring and controlling equipment for process control, safety and

support are typically real-time systems where the requirements for availability and integrity

are high. With today’s level of connectivity, “all” systems are connected to networks running

TCP/IP and hence the need for information security measures and controls are essential. As

the companies have to invest in the security measures and controls and there are costs

associated with the maintenance of the safeguards to have them perform efficiently and

effective, the need of protection should be assessed for all the PCSS/ICT systems in the

production domain. The ICT systems should be classified based on their criticality in the

production chain. To prevent the assessment from being subjective and imprecise a

methodology is needed. Furthermore, to ensure consistent information security levels

through-out the production environment a classification scheme with defined criticality levels

is required.

The classification scheme should be based on HSSE – where Security in this context is

Information Security and primarily focuses on Availability and Integrity of the PCSS/ICT

systems, but also to some extent on Confidentiality – and on production regularity.

More detailed, the classification scheme for the ICT systems in the PCSS domain should

consist of four categories:

I. Health and Safety, including SIL rating (IEC 61511 & Norwegian Oil and Gas 070)

II. Environment

III. Production regularity and the Availability and Integrity aspects of Information Security

IV. Confidentiality aspects of Information Security

The number of criticality levels should be defined and documented. The number of levels

should be aligned with the company’s existing assessment system, and preferably be 4 or 5.

It may be recommended to label each level to prevent any confusion whether a 1 is the

highest or lowest level. Good practice for naming four levels is Low, Medium, High and Very

High. If five levels are used, then Very Low may also be used. Colour coding each level is

also useful, to make it easier to quickly find the critical ICT systems in a list of systems. In the

office domain the colours of the traffic light is used. As the colour green often is associated

with “no risk” and “no need to implement any security measures”, the use of this colour

should be avoided in the production environment, where there “always” will be a need for

safeguards, controls and security measures. The colour pallet used may instead be blue,

orange, light red and dark red.

The criteria for selecting a particular criticality level, i.e. the attributes of each criticality level,

should be documented for each of the four categories above (I–IV). Furthermore, for each

criticality level the company or operating unit should specify which information security

controls and measures should be implemented as a minimum. These minimum information

security measures constitute the Information Security Baseline for that particular criticality

level.

For the third category; Production regularity and the Availability and Integrity aspects of

Information Security, it may be useful to evaluate the time frame for each criticality level.

Should an ICT system go offline, the process may still continue to work unobstructed for a

period of time. Some processes or systems will then gradually become more and more

vulnerable and hence, compensating measures may be needed, or the whole or parts of the

production may have to be shut down. As an example; An ICT system may be considered

having a Medium Level of Criticality for the first fifteen minutes it is not available. From then

on the Criticality Level is rated as High for the next two hours and finally, if the system is still

unavailable, the level rises to Very High.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 9

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

The classification process

A premise for implementing and maintaining the required information security level with

effective and efficient controls is a complete register of all ICT systems and communication

devices installed in the production network, as well as all operational applications. This asset

register may be a paper based list, but preferably it is a database used to register and

manage all the information about the systems and applications – CMDB – Configuration

Management DataBase,

All types of PCSS/ICT systems and equipment including the installed applications should be

evaluated and rated against each of the four categories (I–IV). The criticality level may be

given by the system’s function within the production environment, as well as the criticality

level of the other dependant systems, before or after the assessed PCSS/ICT system, in the

production chain.

The classification of each PCSS/ICT system should be performed against the organisation’s

defined criteria (see Appendix B for an example of classification questionnaire). The

justification for the evaluation and rating of each PCSS/ICT systems should be documented.

The rationale and possible additional comments should be specific and precise.

A pragmatic approach to define the criticality level for each particular system is suggested. It

is not recommended to differentiate between and weight each of the categories. In stead,

aggregate the highest criticality level from the four categories and make this applicable for

the system.

The information security measures and controls required for all ICT systems within each

criticality level should be documented. Examples of information security measures are anti-

virus software, local firewall, intrusion detection/prevention system, system monitoring

software, single sign-on (SSO) and use of virtual private networks (VPN).

For each system the required or acceptable access method should also be documented, e.g.

local access (i.e. physical presence is required), remote login is accepted, VPN connection is

required, remote login via terminal server.

The types of system activities should also be documented. Examples of such are; if access is

limited to read-only, if changes to system configurations are prohibited, if remote installation

of applications is restricted and if back-up and restore may be executed remotely.

If these baseline security measures and controls are not sufficient for particular ICT systems,

then additional necessary safeguards should be evaluated. The concluding solutions should

be implemented, tested and documented.

Should the baseline security controls and measures be impossible to implement or

unfeasible due to technical or system restraints, then compensating security measures

should be evaluated and documented.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 10

Appendix A

Examples of criticality classification

This appendix gives examples of classification of PCSS/ICT systems. The examples do not

reflect a complete evaluation and are not necessarily set answers to the criticality for the

systems described.

In these examples, four criticality levels have been chosen. Each organisation should choose

the number of levels it finds suitable.

System Aggregated result

PCS System Very high

Category Criticality level Rationale and comments

The system does not perform functions directly related

Health and Safety Low

to health and safety.

The system affects the quality of products and waste in

Environment Medium

normal operations.

Regularity, Availability

Very high The system has direct impact on the production.

and Integrity

Production data and parameters handled by the system

Confidentiality Medium

may be sensitive.

Other systems that typically may be classified similarly:

o PIMS (Production Information Management Systems). The systems may have lower

rating on Regularity, Availability and Integrity.

o Subsea Control Systems (PCS functions).

o Power management and electrical distribution control systems.

NOTE: The criticality level of the Health and Safety category in this example is considered to b e Low. However,

the b arrier concept given in the Norwegian Facilities Regulations may in other installations necessitate a higher

criticality level.

System Aggregated result

ESD/F&G System Very high

Category Criticality level Rationale and comments

Health and Safety Very high The system handles health and safety related situations.

The system has impact on reducing spillages and

Environment High

emissions.

Regularity, Availability The fail safe nature of the system (e.g. automatic

Medium

and Integrity shutdown) can cause reduced production regularity.

Confidentiality Low The system does not handle production sensitive data.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 11

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Other systems that typically may be classified similarly:

o HIPPS (High Integrity Pipeline Protection System).

o Subsea Control Systems (PSD functions).

o PSD (Production Shutdown System). The rating on H&S and Environment may be lower

and higher on Regularity, Availability and Integrity.

o Positioning and ballast system. The rating on Environment may be lower and higher on

Regularity, Availability and Integrity.

System Aggregated result

PA System Very high

Category Criticality level Rationale and comments

The PA System is a critical part of the incident

Health and Safety Very high

management system.

The functionality of the system does not affect the

Environment Low

environment.

Regularity, Availability

Low The system has no direct impact on the production.

and Integrity

Confidentiality Low The system does not handle production sensitive data.

The PA System has traditionally been an analogue system and hence not been considered

being a part of the PCSS domain. The state-of-the-art PA Systems are digital and integrated

into the PCSS domain, where the system configuration is done through TCP/IP communication.

Other systems that typically may be classified similarly:

o Personal Tracking System. The rating on Confidentiality will typically be higher and lower on

the H&S. (The system is generally not considered being a part of the PCN.)

o Phone Exchange System. (The system is generally not considered being a part of the

PCN.)

System Aggregated result

Fiscal Metering System Very high

Category Criticality level Rationale and comments

The system does not perform functions related to health

Health and Safety Low

and safety.

The functionality of the system does not affect the

Environment Low

environment.

Regularity, Availability

Very high The system is the basis for the income and taxation.

and Integrity

Production data and parameters handled by the system

Confidentiality Medium

may be sensitive.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 12

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Other systems that typically may be classified similarly:

o Gas Chromatograph.

o Environment Monitoring System. The rating on Regularity, Availability and Integrity may

be lower. (The system is generally not considered being a part of the PCN.)

o Marine Surveillance System. (The system is generally not considered being a part of the

PCN.)

System Aggregated result

Conditioning Monitoring System High

Category Criticality level Rationale and comments

The system does not perform functions related to health

Health and Safety Low

and safety.

The functionality of the system does not affect the

Environment Low

environment.

Regularity, Availability The system warns of evolving failures which enables

High

and Integrity preventive maintenance.

Confidentiality Low The system does not handle production sensitive data.

Other systems that typically may be classified similarly:

o Systems installed to monitor equipment performance. The rating on Regularity,

Availability and Integrity may be lower, based on the criticality of the monitored

equipment as well as the repair cost and time.

o Valve Monitoring System.

System Aggregated result

Corrosion Monitoring System Medium

Category Criticality level Rationale and comments

The system does not perform functions related to health

Health and Safety Low

and safety.

Good control of corrosion rates may reduce the use of

Environment Medium

chemicals that not are environmentally friendly.

The system does not directly affect platform

Regularity, Availability

Medium performance, unless the system is out of service for a

and Integrity

longer period.

Confidentiality Low The system does not handle production sensitive data.

Other systems that typically may be classified similarly:

o Structure Monitoring System.

o Sand Monitoring System. The rating on Regularity, Availability and Integrity may be

higher.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 13

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

System Aggregated result

Oil in Water Analyser Low

Category Criticality level Rationale and comments

The system does not perform functions related to health

Health and Safety Low

and safety.

The functionality of the system does not directly affect

Environment Low the environment. (Lack of timely analyzer results may

influence the quality of produced water to sea.)

The functionality of the system does not directly affect

Regularity, Availability

Low the regularity of the production. (Lack of timely analyzer

and Integrity

results may influence the production performance.)

Confidentiality Low The system does not handle production sensitive data.

Other systems that typically may be classified similarly:

o Lubricants Monitoring System.

o Stock Inventory System. (The system is generally not considered being a part of the

PCN.)

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 14

Appendix B

Example of criticality classification questionnaire

This appendix gives examples of valuable questions for use during the criticality assessment

process for the PCSS/ICT systems.

All of the four areas should be covered, i.e. Health and Safety, Environment, Production

Regularity and the Availability and Integrity aspects of Information Security, as well as

Confidentiality.

In the example, four criticality levels have been chosen. Each organisation should choose the

number of levels it finds suitable.

When a Yes is given to a question, the corresponding Classification Level should be noted

and the next category of questions should be reviewed. There is no need to answer the

remaining questions within the same category.

The examples given on the next pages are typical questions that may be asked. The

organisation should develop its own portfolio of relevant questions. Questions related to

financial loss and reputation may also be considered.

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 15

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Health and Safety

Example

Question Classification

Level

Is the system a part of a SIL rated functions? Very high

Is the system part of barriers defined in the Norwegian Facilities Regulations Very high

(Innretningsforskriften)?

Can a system stop or a degradation in performance cause death? Very high

Company specific questions inserted here Very high

Does the system support barriers defined in the Norwegian Facilities High

Regulations (Innretningsforskriften)?

Can a system stop or performance degradation cause permanent High

disabilities?

Company specific questions inserted here High

Can a system stop or performance degradation cause minor injuries? Medium

Does the system have a direct impact on the company’s HSSE performance Medium

goals?

Company specific questions inserted here Medium

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 16

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Environment

Example

Question Classification

Level

Is the system part of barriers defined in the Norwegian Facilities Regulations Very high

(Innretningsforskriften)?

Is the system part of barriers defined by the company? Very high

Can an unintentional system halt result in a major hydrocarbon leakage? Very high

Company specific questions inserted here Very high

Does the system support barriers defined in the Norwegian Facilities High

Regulations (Innretningsforskriften)?

Does the system support barriers defined by the company? High

Can an unintentional system halt result in a moderate hydrocarbon High

leakage?

Company specific questions inserted here High

Can the system indirectly influence other systems part of the environmental Medium

barriers?

Can an unintentional system halt result in a minor hydrocarbon leakage? Medium

Company specific questions inserted here Medium

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 17

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Production Regularity and the Availability and Integrity aspects of Information Security

Example

Question Classification

Level

Will the production process halt if the system is unavailable for ten Very high

minuttes?

Will the production process halt if the system produces erroneous data? Very high

Can a system stop or a degradation in performance cause physical damage Very high

to equipment in the production process within ten minutes?

Company specific questions inserted here Very high

Will the production process halt if the system is unavailable for one day? High

Will the production process (volume/quality) immediately be affected if the High

system is unavailable or the system’s performance is degraded?

Will the production process (volume/quality) be severely affected if the High

system produces incorrect data?

Can a system stop or a degradation in performance cause physical damage High

to equipment in the production process within one hour?

Company specific questions inserted here High

Will the production process (volume/quality) be affected over time if the Medium

system is unavailable or the system’s performance is degraded?

Will the production process (volume/quality) be affected if the system Medium

produces incorrect data?

Will a delay in the mandatory reporting to authorities of statistics from the Medium

system result in penalties or additional activities?

Can a system stop or a degradation in performance cause physical damage Medium

to equipment in the production process within one day?

Company specific questions inserted here Medium

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 18

Norwegian Oil and Gas Association Guideline No.123:

Classification of process control, safety and support ICT systems based on criticality

Confidentiality

Example

Question Classification

Level

Does the system produce/handle data that is considered sensitive as Very high

defined by the Norwegian Privacy Laws (Personopplysningsloven)?

Company specific questions inserted here Very high

Does the system produce/handle data that may affect the company’s High

reputation or competitiveness should the data be disclosed?

Does the system store data that may reduce the information security level High

should they be disclosed?

Company specific questions inserted here High

Does the system produce/handle data that may affect the company’s Medium

reputation or competitiveness locally should the data be disclosed?

Company specific questions inserted here Medium

No: 123 Revision No: 01 Date revised: 05.01.2009 Page: 19

You might also like

- 365 Journal Self DiscoveryDocument55 pages365 Journal Self DiscoveryAndromeda Sun100% (1)

- Wave 50 Series PDFDocument268 pagesWave 50 Series PDFSantiago UrreaNo ratings yet

- 456 Process Safety - Recommended Practice On KPIs PDFDocument36 pages456 Process Safety - Recommended Practice On KPIs PDFRestoration2010100% (2)

- Security Cyber AttackDocument78 pagesSecurity Cyber AttackAiman Maran100% (1)

- Instruction Manual For Portable CompressorsDocument84 pagesInstruction Manual For Portable CompressorsPopovici Alexandru100% (1)

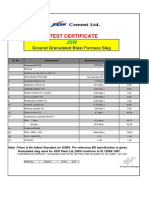

- TC of GGBS For Week No 1 28 Days - 2015Document1 pageTC of GGBS For Week No 1 28 Days - 2015Ramkumar KNo ratings yet

- Installation, Operation and Maintenance ManualDocument17 pagesInstallation, Operation and Maintenance ManualPopovici AlexandruNo ratings yet

- Safety Alarm RationalisationDocument21 pagesSafety Alarm Rationalisationsasa1900sas100% (1)

- Principles Approaches For Security-By-Design-Default 508cDocument15 pagesPrinciples Approaches For Security-By-Design-Default 508chma ydaNo ratings yet

- Norsok Standard M-101Document62 pagesNorsok Standard M-101Popovici Alexandru100% (2)

- Parts Catalogue-54624887.2004.PDF M90Document66 pagesParts Catalogue-54624887.2004.PDF M90Popovici Alexandru100% (2)

- OSCE Checklist Respiratory ExaminationDocument2 pagesOSCE Checklist Respiratory ExaminationputriNo ratings yet

- Pro Safe PLCDocument44 pagesPro Safe PLClimresNo ratings yet

- Quetzalcoatl PapercrafDocument26 pagesQuetzalcoatl PapercrafElplotter ImpresiónNo ratings yet

- Sabp Z 047Document10 pagesSabp Z 047Hassan Mokhtar0% (1)

- QP Guideline For Safety Integrity Level ReviewDocument32 pagesQP Guideline For Safety Integrity Level Reviewjeeva438475% (4)

- Introduction To Safety SystemsDocument24 pagesIntroduction To Safety SystemsThiyagarajan SankaranNo ratings yet

- Chapter 1 - Nutrition and Diet TherapyDocument59 pagesChapter 1 - Nutrition and Diet TherapySami Ingles100% (1)

- Norsok P&ID I-005Document135 pagesNorsok P&ID I-005raoul06100% (1)

- Free French BrigadeDocument12 pagesFree French BrigadeCorwen Broch75% (4)

- QP GDL S 030 1 PDFDocument32 pagesQP GDL S 030 1 PDFAnonymous U0LPhn6EjA100% (1)

- 10 Technical Guide Functional SafetyDocument44 pages10 Technical Guide Functional SafetyAlejandro MárquezNo ratings yet

- Identification of Safety Critical Equipment (SCE) : GuideDocument28 pagesIdentification of Safety Critical Equipment (SCE) : Guidemoustafa100% (1)

- Sms Small Operator 107 002 eDocument54 pagesSms Small Operator 107 002 eford460No ratings yet

- MaintenanceDocument67 pagesMaintenanceBala M100% (1)

- Well OpsDocument27 pagesWell Opsdosetiadi67% (3)

- SCADA Generic Risk Management FrameworkDocument49 pagesSCADA Generic Risk Management FrameworkAnak PohonNo ratings yet

- COMAH and Safety Case RegulationsDocument16 pagesCOMAH and Safety Case RegulationsAdeel RazaNo ratings yet

- 1 Module 1 Supply Chain FundamentalsDocument204 pages1 Module 1 Supply Chain FundamentalsAlex Villanueva60% (5)

- SIS - Safety Instrumented Systems - A Practical View - Part 1Document58 pagesSIS - Safety Instrumented Systems - A Practical View - Part 1mgkvprNo ratings yet

- Safety System - Emergency Shutdown System P2Document15 pagesSafety System - Emergency Shutdown System P2عزت عبد المنعم100% (3)

- Burner Management SystemDocument11 pagesBurner Management SystemMaurthi UppalapatiNo ratings yet

- Scada Security MGMT GuideDocument30 pagesScada Security MGMT GuideOren YulevitchNo ratings yet

- SCADA Generic Risk Management FrameworkDocument48 pagesSCADA Generic Risk Management FrameworkMustafa Cuneyt GezenNo ratings yet

- SIS Techcincal PaperDocument58 pagesSIS Techcincal PapermgkvprNo ratings yet

- Pipe Handler Machine - 10909071-PIBDocument2 pagesPipe Handler Machine - 10909071-PIBPopovici AlexandruNo ratings yet

- Process Safety - Recommended Practice On Key Performance IndicatorsDocument36 pagesProcess Safety - Recommended Practice On Key Performance IndicatorsmarianalourenNo ratings yet

- Commissioning of A PLCDocument10 pagesCommissioning of A PLCTahir DonNo ratings yet

- HSEQ-HQ-08-03-00 Guidelines For PSPI PDFDocument14 pagesHSEQ-HQ-08-03-00 Guidelines For PSPI PDFAHMED AMIRANo ratings yet

- HMC-PHC 42-02-1P00 Rev H4Document132 pagesHMC-PHC 42-02-1P00 Rev H4ElputoAmo XDNo ratings yet

- Sintef Report: Reliability Quantification of Computer-Based Safety Systems. An Introduction To PDSDocument24 pagesSintef Report: Reliability Quantification of Computer-Based Safety Systems. An Introduction To PDSJimmyJarufeNo ratings yet

- NVMSTG011 HardeningGuide v1.0.0Document67 pagesNVMSTG011 HardeningGuide v1.0.0Abhishek BahiratNo ratings yet

- 117-4417597-D01 IT SecurityDocument22 pages117-4417597-D01 IT Securitychaiya jamsawangNo ratings yet

- Pds-Report-Sis Follow Up Guideline Final v01Document38 pagesPds-Report-Sis Follow Up Guideline Final v01nnchokshiNo ratings yet

- Good Practice Guide Process Control and SCADA SecurityDocument21 pagesGood Practice Guide Process Control and SCADA SecurityJorge Daniel MonteiroNo ratings yet

- Guide 6 Engage ProjectsDocument18 pagesGuide 6 Engage ProjectsUmair IftikharNo ratings yet

- SIS - Safety Instrumented Systems - A Practical View - Part 1Document10 pagesSIS - Safety Instrumented Systems - A Practical View - Part 1al_amin1982No ratings yet

- MM-IsAC Secure Deployment of Autonomous HaulageDocument11 pagesMM-IsAC Secure Deployment of Autonomous Haulageachint GoelNo ratings yet

- TORQUE CT2109-Festo-ProcessSafety-SR-3Document27 pagesTORQUE CT2109-Festo-ProcessSafety-SR-3Zubair AamirNo ratings yet

- Deltav Alarm Management (2011) PDFDocument22 pagesDeltav Alarm Management (2011) PDFAnas AzzedineNo ratings yet

- Ecma Tr/64: Secure Information Processing Versus The Concept of Product EvaluationDocument26 pagesEcma Tr/64: Secure Information Processing Versus The Concept of Product Evaluationnetelsrt1298No ratings yet

- SC Processengineering Assessment TemplateDocument36 pagesSC Processengineering Assessment TemplateasdasdNo ratings yet

- ENCS Security Requirements For Procuring Smart Meters and DCs v2!3!28uJCyGDocument32 pagesENCS Security Requirements For Procuring Smart Meters and DCs v2!3!28uJCyGKostas MenagiasNo ratings yet

- 11.7.4 1. WinCC v7.0 - Virusscanner AdministrationDocument13 pages11.7.4 1. WinCC v7.0 - Virusscanner AdministrationMohamedNo ratings yet

- Supply Chain - Incident - ResponseDocument16 pagesSupply Chain - Incident - Responsesalvador.casellaNo ratings yet

- Shifting The Balance of Cybersecurity Risk: Principles and Approaches For Security-By - Design and - DefaultDocument18 pagesShifting The Balance of Cybersecurity Risk: Principles and Approaches For Security-By - Design and - DefaultyanezmrNo ratings yet

- ESREL 2019 RAMSS Lifecycle For The Future Vdelivered2Document6 pagesESREL 2019 RAMSS Lifecycle For The Future Vdelivered2Thor MyklebustNo ratings yet

- Siemens' Safety Integrated Adds Value To Automation ApplicationsDocument16 pagesSiemens' Safety Integrated Adds Value To Automation ApplicationsSelva KumarNo ratings yet

- A6V11763673 - C400 Climatix Controllers Basic Documentation - enDocument44 pagesA6V11763673 - C400 Climatix Controllers Basic Documentation - enHuy Dao QuangNo ratings yet

- Functional Safety For Mine Hoist-From Lilly To SIL3 Hoist ProtectorDocument20 pagesFunctional Safety For Mine Hoist-From Lilly To SIL3 Hoist ProtectorAndrew PeterNo ratings yet

- Cybersecurity Standards For The Electric Power Industry - A "Survival Kit"Document9 pagesCybersecurity Standards For The Electric Power Industry - A "Survival Kit"edsonpaveli-1No ratings yet

- NCSC TG 003Document32 pagesNCSC TG 003bromlantNo ratings yet

- Qualitative Analysis (Cut Sets) : Conversion To Other UnitsDocument6 pagesQualitative Analysis (Cut Sets) : Conversion To Other UnitsRishi NairNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Frequentieregelaars Unidrive m600 m701 Regen Design Guide en Iss6 0478 0366 06Document354 pagesFrequentieregelaars Unidrive m600 m701 Regen Design Guide en Iss6 0478 0366 06Dave CárdenasNo ratings yet

- CFD For Containment A Question MarkDocument18 pagesCFD For Containment A Question Marksanjeeviaq6873No ratings yet

- Alarm ManagementDocument5 pagesAlarm Managementchem_taNo ratings yet

- ANSSI - Cybersecurity For ICS - Classification Method and Key MeasuresDocument61 pagesANSSI - Cybersecurity For ICS - Classification Method and Key MeasuresrafahuesoNo ratings yet

- Instructions - Supply Chain Attack: Traficom Research ReportsDocument18 pagesInstructions - Supply Chain Attack: Traficom Research Reportsroneycruz.govticNo ratings yet

- SIL Project In: Slovnaft Bratislava RefineryDocument4 pagesSIL Project In: Slovnaft Bratislava RefineryLuis SantosNo ratings yet

- TN 015 Overrides 15Document8 pagesTN 015 Overrides 15Luis SantosNo ratings yet

- Bawne Vrushang (23615864)Document21 pagesBawne Vrushang (23615864)vbit1617No ratings yet

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- RL 091 Security Agreement For SuppliersDocument3 pagesRL 091 Security Agreement For SuppliersPopovici AlexandruNo ratings yet

- 064 - ENGLISH OIL AND GAS RECOMMENDED GUIDELINES FOR Establishing AREA PREPARATIONSDocument30 pages064 - ENGLISH OIL AND GAS RECOMMENDED GUIDELINES FOR Establishing AREA PREPARATIONSPopovici AlexandruNo ratings yet

- Regulations of 17 January 1978 No. 4 Concerning Cargo-Handling Appliances in ShipsDocument14 pagesRegulations of 17 January 1978 No. 4 Concerning Cargo-Handling Appliances in ShipsPopovici AlexandruNo ratings yet

- Norsok D-001 Drilling FacilitiesDocument70 pagesNorsok D-001 Drilling FacilitiesPopovici AlexandruNo ratings yet

- Api 16R-1997 (R2010)Document29 pagesApi 16R-1997 (R2010)Popovici AlexandruNo ratings yet

- Curs Drept Civil - Prescriptia ExtinctivaDocument8 pagesCurs Drept Civil - Prescriptia ExtinctivaPopovici AlexandruNo ratings yet

- Information Bulletin No. 148: Medical Care Onboard, Shipowner Liability and Social SecurityDocument6 pagesInformation Bulletin No. 148: Medical Care Onboard, Shipowner Liability and Social SecurityPopovici AlexandruNo ratings yet

- IRITS0815141 0717 MR150 Man Rider WinchscreenDocument8 pagesIRITS0815141 0717 MR150 Man Rider WinchscreenPopovici AlexandruNo ratings yet

- Cazuri de Conversiune A Actului Juridic CivilDocument7 pagesCazuri de Conversiune A Actului Juridic CivilPopovici AlexandruNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarPopovici AlexandruNo ratings yet

- NOrsock Standard R-002Document186 pagesNOrsock Standard R-002Popovici AlexandruNo ratings yet

- ThesisDocument84 pagesThesisJoshua PalubonNo ratings yet

- Thermodynamics: TopicDocument14 pagesThermodynamics: TopicMarco PlaysNo ratings yet

- Lecture1 1Document3 pagesLecture1 1Aaron JomyNo ratings yet

- UJI ANTIBAKTERI EKSTRAK DAUN SALAM (Syzygium Polyanthum) - Kitosan Nanopartikel 1% Terhadap BakteriDocument7 pagesUJI ANTIBAKTERI EKSTRAK DAUN SALAM (Syzygium Polyanthum) - Kitosan Nanopartikel 1% Terhadap BakterifitrafauziahNo ratings yet

- "The Fall of The House of Usher": Edgar Allan Poe - 1839Document13 pages"The Fall of The House of Usher": Edgar Allan Poe - 1839Ponso PelaezNo ratings yet

- WorldCement May 2018 PreviewDocument30 pagesWorldCement May 2018 PreviewRetal Mohamed100% (1)

- 21-184 45KW Sub and 150KVADocument1 page21-184 45KW Sub and 150KVAAhmedNo ratings yet

- Grand Teton: Bird Finding GuideDocument2 pagesGrand Teton: Bird Finding Guideblue wolfNo ratings yet

- Fitwel Glossary: JANUARY 2020 V2.1 StandardDocument9 pagesFitwel Glossary: JANUARY 2020 V2.1 StandardDelight KalbeNo ratings yet

- A Ten Disk Procedure For The Detection of Antibiotic Resistance in EnterobacteriacaeDocument7 pagesA Ten Disk Procedure For The Detection of Antibiotic Resistance in EnterobacteriacaeNguyen Huu HienNo ratings yet

- Eil Spec For Pmi PDFDocument8 pagesEil Spec For Pmi PDFsonnu151No ratings yet

- MAPV212 Chap 2 Worksheet 1-2-3Document3 pagesMAPV212 Chap 2 Worksheet 1-2-3Michael JohnNo ratings yet

- Bhaktapur Case StudyDocument20 pagesBhaktapur Case StudyRaj K Pandey, MBS, MA, MPA75% (4)

- Panasonic TX-21JT2P, TX-21JT2P-B (Chassis Z-M3L) (Service Manual) PDFDocument17 pagesPanasonic TX-21JT2P, TX-21JT2P-B (Chassis Z-M3L) (Service Manual) PDFpisy74No ratings yet

- Honors Chem Organic Chemistry NotesDocument3 pagesHonors Chem Organic Chemistry NotesWyatt KesterNo ratings yet

- PDF en CPF 1H23 Results 1692768555Document50 pagesPDF en CPF 1H23 Results 1692768555Tanapat ChatsatienNo ratings yet

- Db-066e Revf Radeyeprd-ErDocument124 pagesDb-066e Revf Radeyeprd-Erzrohim bapetenkfk2023No ratings yet

- Hp200rg SsDocument2 pagesHp200rg SsJad IssaNo ratings yet

- Chapter - 4: - .Chemical Kinetics (1 Mark Questions)Document7 pagesChapter - 4: - .Chemical Kinetics (1 Mark Questions)sakshiNo ratings yet

- AMPD1 c.133C T (p.Gln45Ter) - Amra - Tea EditDocument2 pagesAMPD1 c.133C T (p.Gln45Ter) - Amra - Tea EditamraovcinaNo ratings yet

- Down SyndromeDocument5 pagesDown SyndromeSheena CabrilesNo ratings yet