Professional Documents

Culture Documents

MS 6298 Protan AS IMO Part 2 Eng

Uploaded by

Tom HightOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS 6298 Protan AS IMO Part 2 Eng

Uploaded by

Tom HightCopyright:

Available Formats

REPORT

issued by an Accredited Testing Laboratory

Contact person Date Reference Page 1002

Johan Post 2015-06-29 5P03883-2 1 (2) ISO/IEC 17025

Fire Research

+46 10 516 58 45

Johan.Post@sp.se

Protan A/S

Postboks 420

NO-3002 DRAMMEN

EN ISO 5659-2:2012 “Plastics – Smoke generation – Part 2:

Determination of optical density by a single-chamber test” with

additional analysis of toxic gases

(2 appendices)

Introduction

SP has been commissioned by Protan A/S to perform a fire test according to EN ISO 5659-

2:2012 “Plastics – Smoke generation – Part 2: Determination of optical density by a single-

chamber test” and smoke gas analysis with FTIR.

The purpose of the test is basis for technical fire classification.

Product

According to the client:

Product called “Ventiflex 6298 FR”.

The colour is light grey.

Client

Protan A/S, Drammen, Norway.

Sampling

The sample of the product was delivered by the manufacturer. It is not known to SP Fire

Research, if the sample received is representative of the mean production characteristics.

The sample was received April 20, 2015 at SP Fire Research.

Tests results

The test results are given in appendix 1. Test parameters are explained in appendix 2.

These results relate only to the behaviour of the specimens of the product under the particular

conditions of test; they are not intended to be the sole criterion for assessing the potential

smoke obscuration hazard of the product in use.

SP Technical Research Institute of Sweden

Postal address Office location Phone / Fax / E-mail Laboratories are accredited by the Swedish Board for Accreditation and

SP Västeråsen +46 10 516 50 00 Conformity Assessment (SWEDAC) under the terms of Swedish legislation.

Box 857 Brinellgatan 4 +46 33 13 55 02 This report may not be reproduced other than in full, except with the prior

SE-501 15 BORÅS SE-504 62 BORÅS info@sp.se written approval of the issuing laboratory.

Sweden

Date Reference Page

REPORT

2015-06-29 5P03883-2 2 (2)

Test procedure

The specimen is placed horizontally within a closed chamber and exposed to a constant

irradiance level with or without a pilot flame. The smoke evolved is trapped in the chamber

and measured using photometric equipment, results are reported in terms of specific optical

density. Adjacent to the test toxic flue gases are analysed using spectroscopy with the Fourier

transform infrared technique (FTIR). The gas samples are taken from the geometrical centre of

the test chamber. Seven compounds are quantified: CO, HCl, HF, NOX, HBr, HCN, and SO2.

If any of the compounds HCl, HF, and/or HBr are detected, analysis of filtering materials used

in the gas sampling line is carried out and maximum gas concentrations (C) are corrected (C +

Cca).

The samples were tested under each of the following conditions:

1. Irradiance of 25 kW/m2 in the presence of pilot flame.

2. Irradiance of 25 kW/m2 in the absence of pilot flame.

3. Irradiance of 50 kW/m2 in the absence of pilot flame.

Note

The FTIR-analysis accreditation referred to is valid for IMO 2010 FTP Code, part 2 “Smoke

and toxicity test”.

SP Technical Research Institute of Sweden

Fire Research - Fire Dynamics

Performed by Examined by

__Signature_1 __Signature_2

Johan Post Per Thureson

Appendices

1 Test results.

2 Test parameters explanation.

SP Technical Research Institute of Sweden

Date Reference Page

REPORT

2015-06-29 5P03883-2 1 (4)

Appendix 1

Test results IMO 2010 FTP Code, part 2

Product

According to the client:

Product called “Ventiflex 6298 FR”.

The colour is light grey.

Test specifications

Sampling response period, SRP: 9.5 s

Inner volume of the gas cell: 0.2 l.

Inner volume of the gas sampling line: 0.28 l.

Capacity of the gas sampling pump: 3.5 l/min.

Backing: No other backing than the non-combustible

required by the standard.

Specimen mounting: The wire grid was not used.

Measured data

Thickness 0.61 – 0.63 mm.

Area weight 680 - 690 g/m2.

Conditioning

Temperature (23 ± 2) °C.

Relative humidity (50 ± 5) %.

Operator

Tobias Jacobson.

Date of test

May 20 and June 12 - 15, 2015.

SP Technical Research Institute of Sweden

Date Reference Page

REPORT

2015-06-29 5P03883-2 2 (4)

Appendix 1

Test results, test condition 1: Irradiance 25 kW/m2, in the presence of pilot flame

Test no 1 2 3 Mean

Ds max 309 245 288 281 = Dm

DC 45 23 19 -

Time to ignition, s 12 18 46 -

Time to self-extinguishment, s 246 255 131 -

Duration of test, s 1200 640 625 -

Light Transmission, test condition 1

Light transmission (%)

100

90 Test 1

Test 2

80 Test 3

70

60

50

40

30

20

10

0

0 120 240 360 480 600 720 840 960 1080 1200

Time (s)

Maximum gas concentration (C) for each gas, test condition 1

Maximum smoke density sampling time, DmST: 179 s.

Test 1* Test 2 Test 3 Average

Gas species

C (ppm) C (ppm) C (ppm) C (ppm)

CO - 533 191 362

HF - <5 <5 <5

HCl - 774 466 620

HBr - < 10 < 10 < 10

HCN - <3 <3 <3

NOX - < 20 < 20 < 20

SO2 - < 10 < 10 < 10

* Analysis is, according to the standard, not conducted in test 1.

SP Technical Research Institute of Sweden

Date Reference Page

REPORT

2015-06-29 5P03883-2 3 (4)

Appendix 1

Test results, test condition 2: Irradiance 25 kW/m2, in the absence of pilot flame

Test no 4 5 6 Mean

Ds max 366 375 342 361 = Dm

DC 48 45 44 -

Time to ignition, s NI NI NI -

Time to self-extinguishment, s - - - -

Duration of test, s 1200 1200 1200 -

NI = No Ignition.

Light Transmission, test condition 2

Light transmission (%)

100

90 Test 1

Test 2

80 Test 3

70

60

50

40

30

20

10

0

0 120 240 360 480 600 720 840 960 1080 1200

Time (s)

Maximum gas concentration (C) for each gas, test condition 2

Maximum smoke density sampling time, DmST: 677 s.

Test 4* Test 5 Test 6 Average

Gas species

C (ppm) C (ppm) C (ppm) C (ppm)

CO - 408 228 318

HF - <5 <5 <5

HCl - 348 568 458

HBr - < 10 < 10 < 10

HCN - <3 <3 <3

NOX - < 20 < 20 < 20

SO2 - < 10 < 10 < 10

* Analysis is, according to the standard, not conducted in test 4.

SP Technical Research Institute of Sweden

Date Reference Page

REPORT

2015-06-29 5P03883-2 4 (4)

Appendix 1

Test results, test condition 3: Irradiance 50 kW/m2, in the absence of pilot flame

Test no 7 8 9 Mean

Ds max 415 316 508 413 = Dm

DC 66 41 26 -

Time to ignition, s 7 7 NI -

Time to self-extinguishment, s 92 237 - -

Duration of test, s 1200 620 620 -

NI = No Ignition.

Light Transmission, test condition 3

Light transmission (%)

100

90 Test 1

Test 2

80 Test 3

70

60

50

40

30

20

10

0

0 120 240 360 480 600 720 840 960 1080 1200

Time (s)

Maximum gas concentration (C) for each gas, test condition 3

Maximum smoke density sampling time, DmST: 89 s.

Test 7* Test 8 Test 9 Average

Gas species

C (ppm) C (ppm) C (ppm) C (ppm)

CO - 505 110 308

HF - <5 <5 <5

HCl - 692 525 609

HBr - < 10 < 10 < 10

HCN - <3 <3 <3

NOX - < 20 < 20 < 20

SO2 - < 10 < 10 < 10

* Analysis is, according to the standard, not conducted in test 7.

SP Technical Research Institute of Sweden

Date Reference Page

REPORT

2015-06-29 5P03883-2 1 (1)

Appendix 2

Test parameter explanation – IMO 2010 FTP Code, annex 1, part 2

Sign Explanation

DS Specific optical density, calculated as follows:

100

DS 132 log where T = per cent light transmittance.

T

DSmax Maximum specific optical density.

DC Specific optical density correction factor for the smoke absorbed

on the glass windows of the optical system.

DmST Maximum smoke density sampling time.

SRP Sampling response period.

SP Technical Research Institute of Sweden

You might also like

- Traullit Akustik Fire Test En13823 Eniso11925 2 2016Document21 pagesTraullit Akustik Fire Test En13823 Eniso11925 2 2016RND SPFNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Report 4P03406-1 AFFF 3 ICAO Level B FomtecDocument3 pagesReport 4P03406-1 AFFF 3 ICAO Level B FomtecForum PompieriiNo ratings yet

- Emission Measurements After 28 Days: Test ObjectDocument7 pagesEmission Measurements After 28 Days: Test ObjectMarcelo OsorioNo ratings yet

- E-Cigarette Aerosol Analysis ReportDocument6 pagesE-Cigarette Aerosol Analysis ReportUman KinapNo ratings yet

- DIGIFLAVOR Pharaoh Mini RTA - Nicotine and EmissionsDocument6 pagesDIGIFLAVOR Pharaoh Mini RTA - Nicotine and EmissionsConcordia VaporNo ratings yet

- E-Cigarette Aerosol Analysis ReportDocument6 pagesE-Cigarette Aerosol Analysis ReportEdwinBerianzahNo ratings yet

- Direktoratets Testrapport - Furu Malm UbehandletDocument16 pagesDirektoratets Testrapport - Furu Malm UbehandletUlrich HübnerNo ratings yet

- GEEKVAPE-AEGIS BOOST PLUS KIT-Nicotine and EmissionsDocument6 pagesGEEKVAPE-AEGIS BOOST PLUS KIT-Nicotine and EmissionsEdvaNo ratings yet

- TEST REPORT: 7191034331-CHM12-04-TSL: SubjectDocument4 pagesTEST REPORT: 7191034331-CHM12-04-TSL: SubjectTibu ChackoNo ratings yet

- Corrosion CertificateDocument2 pagesCorrosion CertificateCruseenvirotechNo ratings yet

- The IMO Resolution A.800 (19) Luxury Cabin Fi Re Test ProcedureDocument22 pagesThe IMO Resolution A.800 (19) Luxury Cabin Fi Re Test ProcedurevytoNo ratings yet

- Uwell Aeglos Pod System TPD 20201114114434Document6 pagesUwell Aeglos Pod System TPD 20201114114434Arya YansyahNo ratings yet

- CE Test ReportDocument14 pagesCE Test ReportCamilo WispNo ratings yet

- E-Cigarette Aerosol Analysis ReportDocument6 pagesE-Cigarette Aerosol Analysis ReportKarim MohsenNo ratings yet

- E-Cigarette Aerosol Analysis ReportDocument6 pagesE-Cigarette Aerosol Analysis ReportJayson VicencioNo ratings yet

- Energy Dispersive X-Ray Fluorescence Spectrometer EDX-2: Leader in Lighting & Electrical Test InstrumentsDocument8 pagesEnergy Dispersive X-Ray Fluorescence Spectrometer EDX-2: Leader in Lighting & Electrical Test Instrumentslisun008No ratings yet

- Operational Qualification - Wavelength Accuracy of The UV Detector (Single Mode)Document2 pagesOperational Qualification - Wavelength Accuracy of The UV Detector (Single Mode)carlos germanNo ratings yet

- Test Report: 6/F East, Heping Building, Heping Road, Luohu, Shenzhen, ChinaDocument17 pagesTest Report: 6/F East, Heping Building, Heping Road, Luohu, Shenzhen, ChinaJosé FerreiraNo ratings yet

- Polution Test On Rodurflex 400kVDocument5 pagesPolution Test On Rodurflex 400kVKambiz TaherkhaniNo ratings yet

- 2003 SBI Calcium SilicateDocument10 pages2003 SBI Calcium SilicatevytoNo ratings yet

- pdf.J385400-BD170810zBS EN 45545-2 2013+A1 2015 50kW PDF 1Document14 pagespdf.J385400-BD170810zBS EN 45545-2 2013+A1 2015 50kW PDF 1Arockia FenilNo ratings yet

- Total Sulfur Analyzer CG ConditionsDocument8 pagesTotal Sulfur Analyzer CG ConditionsCristian ValenzuelaNo ratings yet

- GL-SPL - Series IP66Document10 pagesGL-SPL - Series IP66praween worachumpaNo ratings yet

- Gasmet DX4015 Technical Data ID 7090 2Document3 pagesGasmet DX4015 Technical Data ID 7090 2Bimalesh MishraNo ratings yet

- Aaqm Feb 2022Document8 pagesAaqm Feb 2022Shannu AdityaNo ratings yet

- Radio Measurements On Radio 4415 B2 B25 Equipment With FCC ID TA8AKRC161636 and IC: 287AB-AS161636Document62 pagesRadio Measurements On Radio 4415 B2 B25 Equipment With FCC ID TA8AKRC161636 and IC: 287AB-AS161636Cleyton Archbold BarkerNo ratings yet

- Test Procedures of The Behaviour of Cables in Case of FireDocument12 pagesTest Procedures of The Behaviour of Cables in Case of FireWalterNo ratings yet

- 1 s2.0 016523709085014E Main PDFDocument10 pages1 s2.0 016523709085014E Main PDFDuong TuNo ratings yet

- Mystic-AC-FR-SF UPH240062-3 Interfabrics BS5852 CertificateDocument4 pagesMystic-AC-FR-SF UPH240062-3 Interfabrics BS5852 Certificateandy.maldiniNo ratings yet

- Toptech GWI LEED IEQ CR 4.3 EurofinsDocument5 pagesToptech GWI LEED IEQ CR 4.3 EurofinsSuki LiuNo ratings yet

- IEC 60332 - IEC 60331 - IEC 60754 - IEC 61034 Test Procedures of The Behaviour of Cables in Case of FireDocument12 pagesIEC 60332 - IEC 60331 - IEC 60754 - IEC 61034 Test Procedures of The Behaviour of Cables in Case of FireEnzo Ochoa100% (1)

- Test Report: Client InformationDocument19 pagesTest Report: Client Informationho muzNo ratings yet

- Test Report: Client InformationDocument19 pagesTest Report: Client Informationho muz0% (1)

- GM901产品介绍Document22 pagesGM901产品介绍loli2323No ratings yet

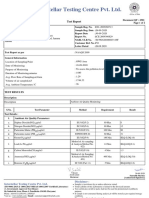

- Interstellar Testing Centre Pvt. LTD.: Test ReportDocument2 pagesInterstellar Testing Centre Pvt. LTD.: Test ReportDemon barberNo ratings yet

- Determination of Hydrocarbon Impurities in Ethylene by Gas ChromatographyDocument5 pagesDetermination of Hydrocarbon Impurities in Ethylene by Gas ChromatographyAlabbas Fadhel100% (1)

- PE-Lite Roof Insulation Technical Document - Chemical ContentDocument6 pagesPE-Lite Roof Insulation Technical Document - Chemical ContentkingsleyNo ratings yet

- STS Directory: MailtoDocument12 pagesSTS Directory: MailtoyhongleeNo ratings yet

- SF-43 Standard DieselDocument2 pagesSF-43 Standard DieselClaudiu PanaNo ratings yet

- Ni 2019Document5 pagesNi 2019Tri Indah Lestari AnnasNo ratings yet

- Test ReportDocument9 pagesTest ReportAlberto Aleman AquinoNo ratings yet

- Ki LSHF 3401 IsDocument2 pagesKi LSHF 3401 IsjamilNo ratings yet

- Fire Test - Thomas Bell Wright 12mmDocument9 pagesFire Test - Thomas Bell Wright 12mmblackcapperNo ratings yet

- DIN67510-1 Smart - Signs - Vinyl - Strip - 50 - MM - DIN PDFDocument3 pagesDIN67510-1 Smart - Signs - Vinyl - Strip - 50 - MM - DIN PDFCandice LeitãoNo ratings yet

- Detect High Building SP - Report - 2003 - 33Document120 pagesDetect High Building SP - Report - 2003 - 33Böðvar TómassonNo ratings yet

- SKL SP2Document2 pagesSKL SP2Mangalraj MadasamyNo ratings yet

- Nose Bar CertificateDocument5 pagesNose Bar CertificateMamdouhNo ratings yet

- MARISEAL 300 Potable Water Certification From SingaporeDocument6 pagesMARISEAL 300 Potable Water Certification From SingaporeVirender KumarNo ratings yet

- D 2360 - 03 - RdiznjatukveDocument7 pagesD 2360 - 03 - RdiznjatukveRaphael CordovaNo ratings yet

- General Specifications: Model FU20-FTS and FU20-MTS Differential pH/ORP-sensorDocument19 pagesGeneral Specifications: Model FU20-FTS and FU20-MTS Differential pH/ORP-sensorMadel D.No ratings yet

- General Specifications: Model FU24 Widebody Type pH/ORP SensorDocument17 pagesGeneral Specifications: Model FU24 Widebody Type pH/ORP SensorOsamaNo ratings yet

- M4D359-A1 LANXESS Corporation POCAN® B 1505 000000 Polybutylene TerephthalateDocument4 pagesM4D359-A1 LANXESS Corporation POCAN® B 1505 000000 Polybutylene TerephthalatendsramNo ratings yet

- Method 7c 1Document14 pagesMethod 7c 1operaciones2.labsolutionNo ratings yet

- Ab0001t729 - IzmirDocument18 pagesAb0001t729 - IzmirMetehan ÇalışNo ratings yet

- Dissolved Gas Analysis-1Document31 pagesDissolved Gas Analysis-1Karan Tripathi100% (2)

- Elmech Labs PVT LTDDocument7 pagesElmech Labs PVT LTDdesignNo ratings yet

- Test Report: Client InformationDocument12 pagesTest Report: Client InformationJim SmithNo ratings yet

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Document13 pagesT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Thắng NguyễnNo ratings yet

- Síntesis de Procesos: Una Propuesta Holistica Process Synthesis: A Holistic ApproachDocument10 pagesSíntesis de Procesos: Una Propuesta Holistica Process Synthesis: A Holistic ApproachGarcía Nuñez SergioNo ratings yet

- Eclipse Phase 2E v1.1 (Under CC BY-NC-SA 4.0 License)Document59 pagesEclipse Phase 2E v1.1 (Under CC BY-NC-SA 4.0 License)humanzyxNo ratings yet

- Hacking, Ian - Estilos de RazonamientoDocument18 pagesHacking, Ian - Estilos de RazonamientoBadtz MaruNo ratings yet

- Math InterventionDocument2 pagesMath InterventionEmerita TrasesNo ratings yet

- Lecture 01 ADVANCED ANIMATION AS3Document11 pagesLecture 01 ADVANCED ANIMATION AS3Febb RoseNo ratings yet

- Grade Filipino 7 Week 1-2Document10 pagesGrade Filipino 7 Week 1-2SALEM DE LA CONCEPCIONNo ratings yet

- The Norwegian Oil Experience:: Helge RyggvikDocument58 pagesThe Norwegian Oil Experience:: Helge RyggvikhiyeonNo ratings yet

- E702.3M-18 - Acceptance of Concrete Compressive Strength Test Results According To ACI 318M-14Document6 pagesE702.3M-18 - Acceptance of Concrete Compressive Strength Test Results According To ACI 318M-14Christos Leptokaridis100% (1)

- Spatial Association Effect of Regional Pollution Control2019journal of Cleaner ProductionDocument13 pagesSpatial Association Effect of Regional Pollution Control2019journal of Cleaner ProductionArthur PimentelNo ratings yet

- AP Geography Study Material-AP Geography Quiz Questions With AnswersDocument3 pagesAP Geography Study Material-AP Geography Quiz Questions With AnswersRaja Sekhar BatchuNo ratings yet

- Physical Science NOV. 20-22, 2019 DLPDocument2 pagesPhysical Science NOV. 20-22, 2019 DLPJedidiah Jara QuidetNo ratings yet

- List of Academic Design ProjectsDocument4 pagesList of Academic Design ProjectsAnurag SinghNo ratings yet

- Mark Scheme (Results) : Summer 2017Document22 pagesMark Scheme (Results) : Summer 2017Khalid AhmedNo ratings yet

- ROBOTICS (MEB-465) : Quiz QuestionsDocument21 pagesROBOTICS (MEB-465) : Quiz QuestionsVishal Dhiman100% (2)

- Independent University, BangladeshDocument8 pagesIndependent University, BangladeshMD. Akif RahmanNo ratings yet

- Combinatorics Worksheet 3 - Recurrence RelationsDocument2 pagesCombinatorics Worksheet 3 - Recurrence RelationsJane ChangNo ratings yet

- Abraham Tilahun GSE 6950 15Document13 pagesAbraham Tilahun GSE 6950 15Abraham tilahun100% (1)

- Spectral and Amplification Characteristics in San Salvador City (El Salvador) For Upper-Crustal and Subduction EarthquakesDocument9 pagesSpectral and Amplification Characteristics in San Salvador City (El Salvador) For Upper-Crustal and Subduction EarthquakesSergio Ito SunleyNo ratings yet

- Fractional DistillationDocument7 pagesFractional DistillationInspector Chulbul PandayNo ratings yet

- Pathways 4 Listening & Speaking Unit 4 TestDocument8 pagesPathways 4 Listening & Speaking Unit 4 TestaLeKs GaRcíA100% (1)

- Introducing Python Programming For Engineering Scholars: Zahid Hussain, Muhammad Siyab KhanDocument8 pagesIntroducing Python Programming For Engineering Scholars: Zahid Hussain, Muhammad Siyab KhanDavid C HouserNo ratings yet

- Time Schedule of Subjects International Class Program (Icp) Fmipa Unm Biology Department, Odd Semester, Academic Year 2010/2011Document2 pagesTime Schedule of Subjects International Class Program (Icp) Fmipa Unm Biology Department, Odd Semester, Academic Year 2010/2011El MuertoNo ratings yet

- 7 Ways To Better Your LetteringDocument5 pages7 Ways To Better Your LetteringLuciana Freire0% (2)

- Quantitative Techniques NcatDocument191 pagesQuantitative Techniques NcatJeremiah AkonyeNo ratings yet

- Sonic Drive inDocument1 pageSonic Drive inWXYZ-TV Channel 7 DetroitNo ratings yet

- Development and Assessment of A Hand Assist DeviceDocument15 pagesDevelopment and Assessment of A Hand Assist DeviceAugusto Rodas VelezNo ratings yet

- Experiment 03: Measurement of Absolute Viscosity of Fluid by A Saybolt ViscometerDocument4 pagesExperiment 03: Measurement of Absolute Viscosity of Fluid by A Saybolt Viscometer17044 AZMAIN IKTIDER AKASHNo ratings yet

- Statistics 1Document149 pagesStatistics 1Zaid AhmedNo ratings yet

- Graded Assignment: Unit Test, Part 2: Radicals and Complex NumbersDocument3 pagesGraded Assignment: Unit Test, Part 2: Radicals and Complex NumbersManuk SogomonyanNo ratings yet

- 28-11-21 - JR - Iit - Star Co-Sc (Model-A) - Jee Adv - 2015 (P-I) - Wat-29 - Key & SolDocument8 pages28-11-21 - JR - Iit - Star Co-Sc (Model-A) - Jee Adv - 2015 (P-I) - Wat-29 - Key & SolasdfNo ratings yet